Clean production method for high-purity cobaltosic oxide powder

A technology of tricobalt tetroxide powder and tricobalt tetroxide, which is applied in electrolysis process, electrolysis components, etc., to achieve the effects of low production cost and energy consumption, simple equipment and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

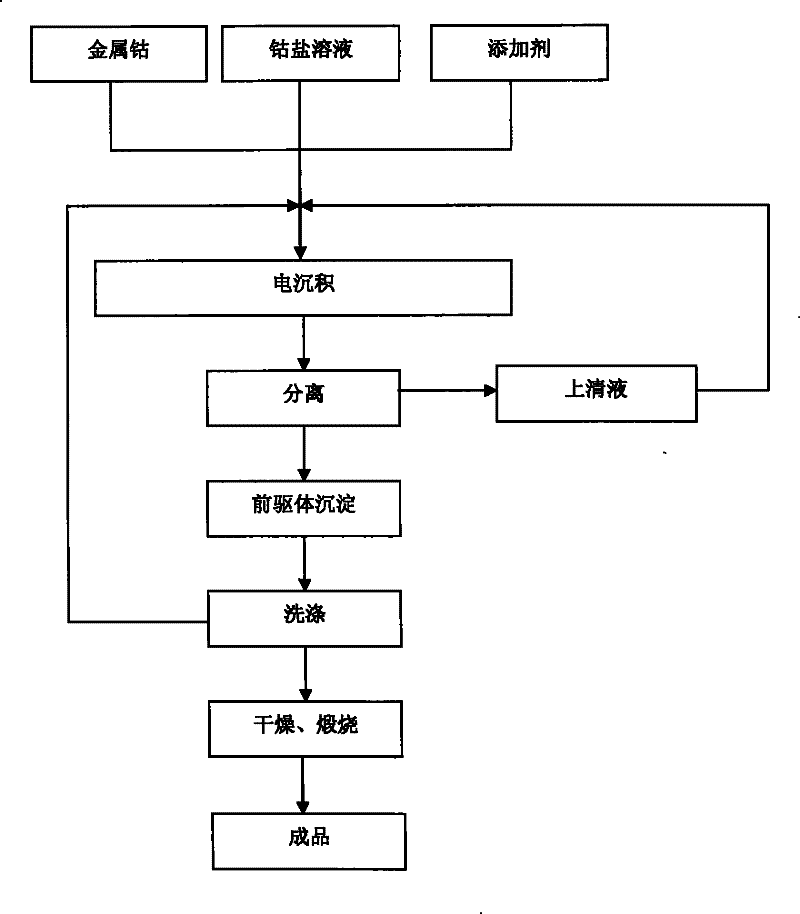

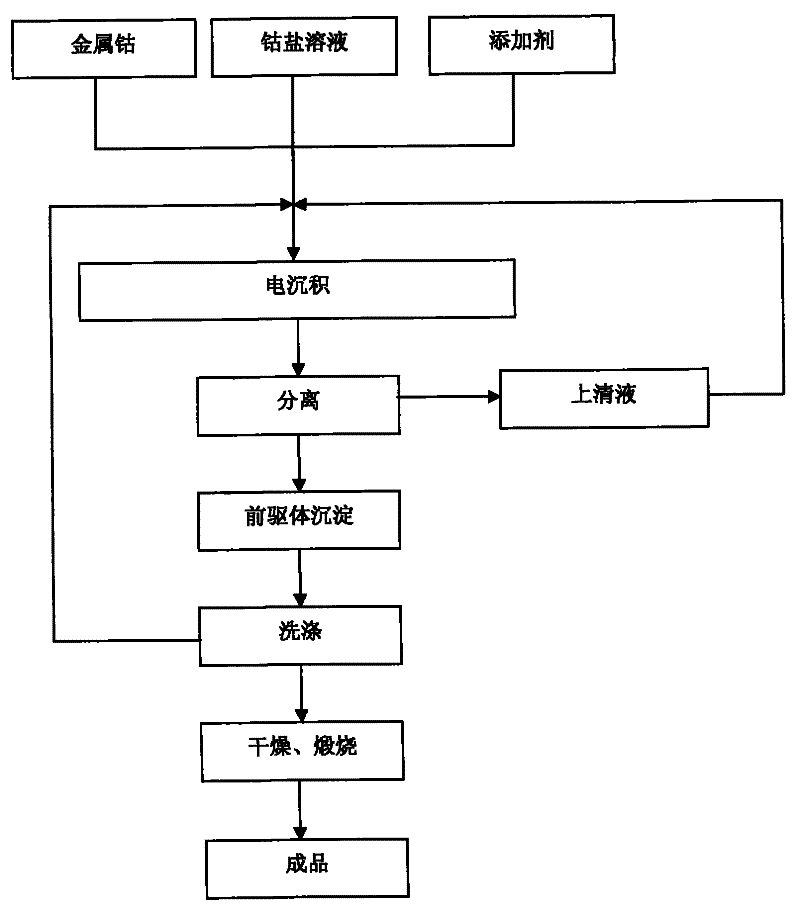

Method used

Image

Examples

Embodiment 1

[0028] Prepare an electrolyte containing 0.2 mol / L of cobalt chloride, 0.25 mol / L of potassium dihydrogen phosphate, and 0.03 mol / L of ammonium chloride, and adjust the pH value to 5 with 0.01 mol / L of potassium hydroxide; put the electrolyte into In the electrolytic cell, connect the metal cobalt sheet anode and cathode into the circuit; control the cathode current density to 500A / m 2 , Electrodeposition for 2 hours; filter the electrolyte, the supernatant does not need to be treated, it can be directly returned to the electrolytic cell for repeated use, while the precipitate is fully washed with deionized water, dried at 100°C and placed in a high-temperature furnace at 600°C Calcined at lower temperature for 5 hours to obtain superfine black cobalt tetroxide powder with an average particle size of 1.24 μm.

Embodiment 2

[0030] Prepare an electrolyte containing 0.3 mol / L of cobalt sulfate, 0.08 mol / L of citric acid, and 0.15 mol / L of boric acid, adjust the pH value to 4.5 with ammonia water; put the electrolyte into the electrolytic cell, connect the metal cobalt sheet anode and cathode into the circuit; control the cathode current density to 1000A / m 2 , Electrodeposition for 3 hours; filter the electrolyte, the supernatant does not need to be treated, it can be directly returned to the electrolytic cell for repeated use, while the precipitate is fully washed with deionized water, dried at 150°C and placed in a high-temperature furnace at 300°C Calcined at lower temperature for 2 hours to obtain superfine black cobalt tetroxide powder with an average particle size of 7.49 μm.

Embodiment 3

[0032] Prepare a mixed solution containing cobalt nitrate and cobalt chloride, the total concentration of cobalt salt is 0.45mol / L, the molar ratio of cobalt nitrate and cobalt chloride is 2:3, then add tartaric acid, its concentration is 0.25mol / L, use ammonia water Adjust the pH value to 5; put the electrolyte into the electrolytic cell, connect the metal cobalt sheet anode and cathode into the circuit; control the cathode current density to 1000A / m 2 , electrodeposited for 5 hours; the electrolyte was filtered, the supernatant was directly returned to the electrolytic cell without treatment, and reused, while the precipitate was fully washed with deionized water, dried at 130°C and placed in a high-temperature furnace at 800°C Calcined at lower temperature for 2 hours to obtain superfine black cobalt tetroxide powder with an average particle size of 20.56 μm.

[0033] In a word, the additives added when configuring the electrolytic solution containing cobalt ions in the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com