Clam concentrated liquid or clam powder, and production method thereof

A production method and concentrate technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of environmental pollution, waste of resources, etc., and achieve the effects of reducing emission pollution, no moisture content, and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

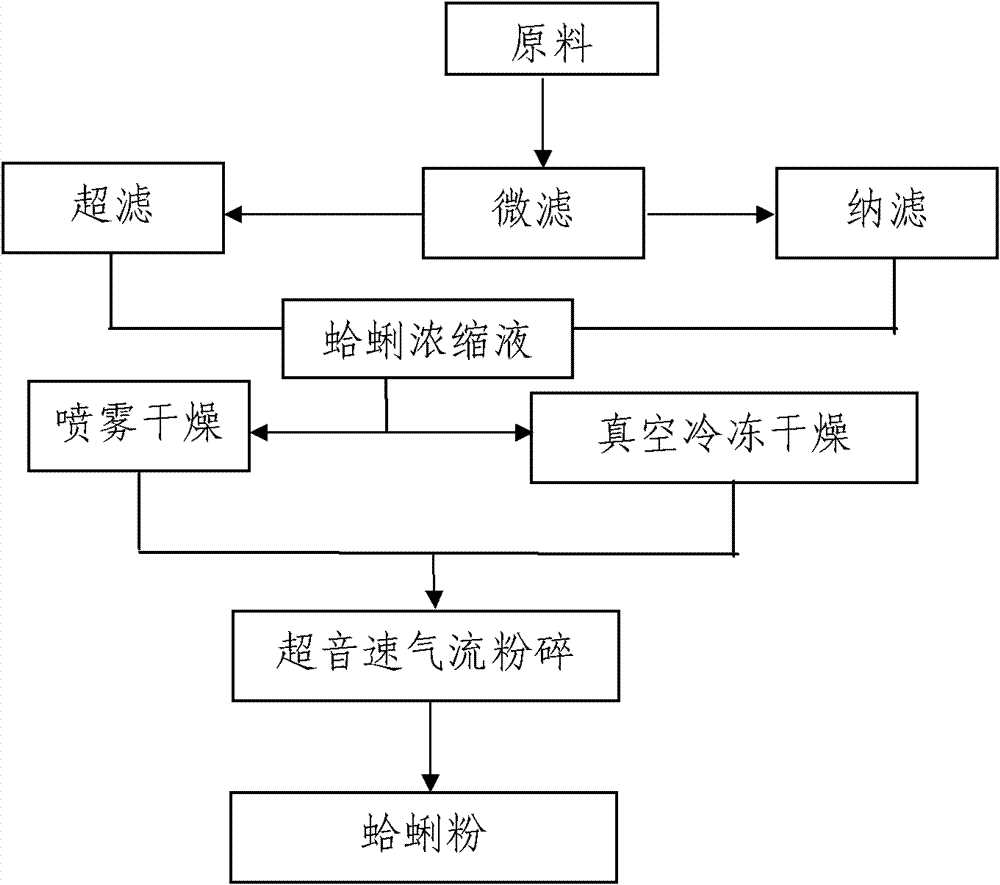

Method used

Image

Examples

Embodiment 1

[0037] Collect the cooking liquid produced during clam processing, its concentration is Brix3.2%, salt 30%, through a pressure pump, the clam cooking liquid is first microfiltered through a 0.5μm filter element, and the microfiltration pressure is 0.1MPa to remove impurities and collect the liquid. Then the liquid through microfiltration is carried out nanofiltration through the molecular weight cut-off of 800 Dalton filter element, the nanofiltration pressure is 1.0MPa, removes salt and part of water, when the liquid concentration Brix reaches 36%, and when the salt content is 5%, collect the intercepted The liquid yields clam concentrate.

[0038] Pour the clam concentrate into a tray, put it into a freezer at -20°C to freeze, and freeze all of it into a solid, then vacuum freeze-dry the frozen clam concentrate to obtain coarse clam powder. Wherein the freeze dryer condenser temperature is -30°C, the vacuum degree is 50Pa, and the heating plate temperature is 70°C. Then the...

Embodiment 2

[0042] Collect the cooking liquid produced during clam processing, and firstly pass the clam cooking liquid through a 0.8μm filter element for microfiltration through a pressure pump. The microfiltration pressure is 0.15MPa to remove impurities and collect the liquid. Then, the microfiltered liquid is ultrafiltered through a filter element with a molecular weight cut-off of 20,000 Daltons, and the ultrafiltration pressure is 0.15 MPa to remove salt and part of the water, and the intercepted liquid is collected to obtain a clam concentrate.

[0043] Pour the clam concentrate into a tray, put it into a freezer at -25°C to freeze, and freeze all of it into a solid, then vacuum freeze-dry the frozen clam concentrate to obtain coarse clam powder. Wherein the freeze dryer condenser temperature is -50°C, the vacuum degree is 100Pa, and the heating plate temperature is 60°C. The above-mentioned coarse clam powder is pulverized by a supersonic airflow pulverizer. During the pulverizati...

Embodiment 3

[0045]Collect the cooking liquid produced during clam processing, and firstly pass the clam cooking liquid through a 1μm filter element for microfiltration through a pressure pump. The microfiltration pressure is 0.3MPa to remove impurities and collect the liquid. Then the microfiltered liquid is ultrafiltered through a filter element with a molecular weight cut-off of 1000 Daltons, and the ultrafiltration pressure is 0.1 MPa to remove salt and part of the water, and the intercepted liquid is collected to obtain a clam concentrate.

[0046] Pour the clam concentrate into a tray, put it into a -30°C freezer to freeze, and freeze all of it into a solid, then vacuum freeze-dry the frozen clam concentrate to obtain coarse clam powder. Wherein the freeze dryer condenser temperature is -60°C, the vacuum degree is 80Pa, and the heating plate temperature is 100°C. The above-mentioned coarse clam powder is pulverized by a supersonic airflow pulverizer. During the pulverization, the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com