Pneumatic wrench

A pneumatic wrench and transmission shaft technology, applied in the field of wrenches, can solve the problems of complex structure of pneumatic torque wrench, difficult to disassemble bolts, low efficiency, etc., and achieve the effects of simple structure, improved use feeling, and convenient and quick use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

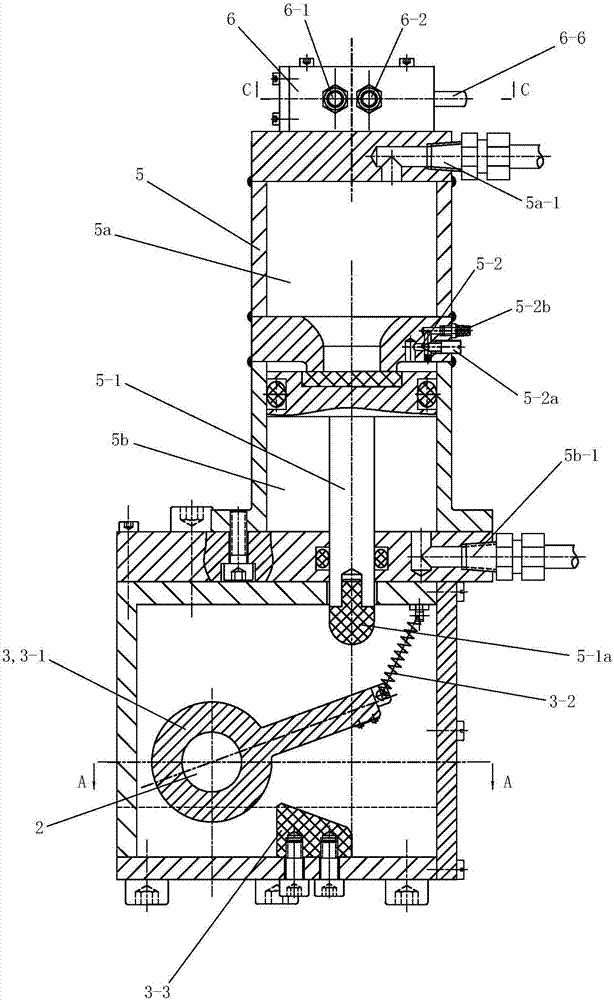

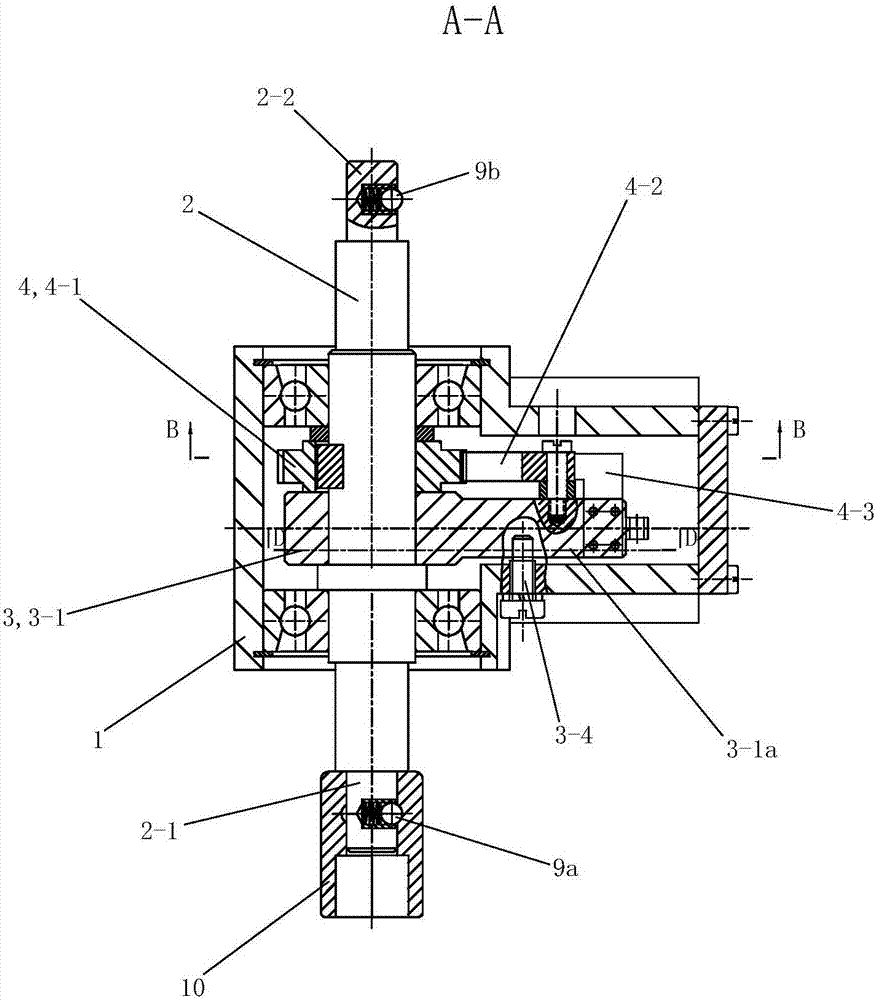

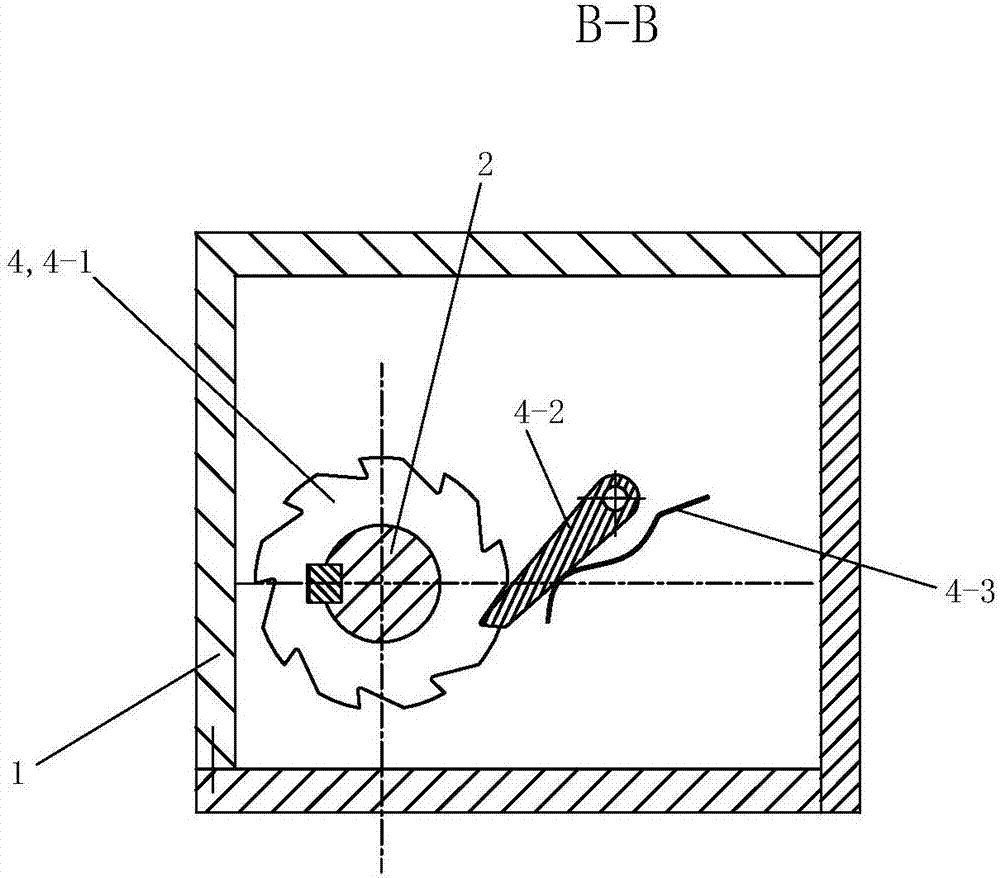

[0035] See Figure 1 to Figure 8 , The pneumatic wrench of the present invention includes a housing 1, a transmission shaft 2, a driving mechanism 3, a ratchet mechanism 4, an impact cylinder 5 and a control device 6. The control device 6 adopts a two-position five-way manual reversing valve. The front side of the valve body of the two-position five-way manual reversing valve is provided with a first interface 6-1 and a second interface 6-2 from left to right, and the rear side of the valve body of the two-position five-way manual reversing valve is arranged from left to right. The right is provided with the third interface 6-3, the fourth interface 6-4 and the fifth interface 6-5 in turn, and the middle part of the valve body of the two-position five-way manual reversing valve is equipped with a manual push rod 6-6, and the manual push rod 6- 6 slides are arranged in the valve body, and the right part of manual push rod 6-6 stretches out of the valve body. A compression spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com