Method for increasing torque of magnetic sealing device

A magnetic sealing and torque technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of inability to meet the demand of high torque and small torque, to improve the transmission efficiency, improve the magnetic torque, overcome the Low torque effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

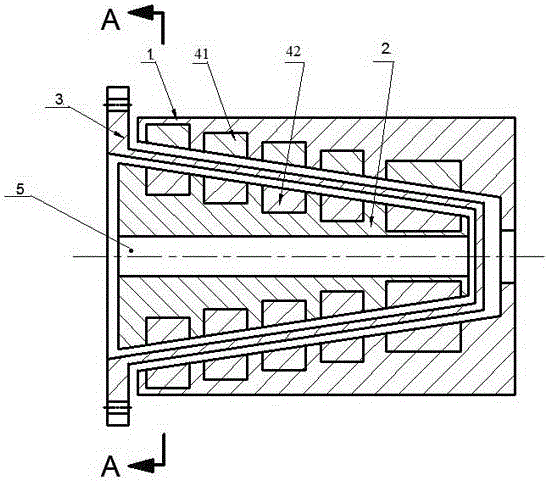

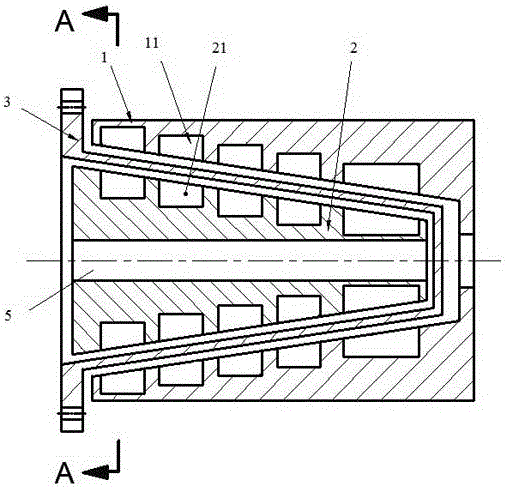

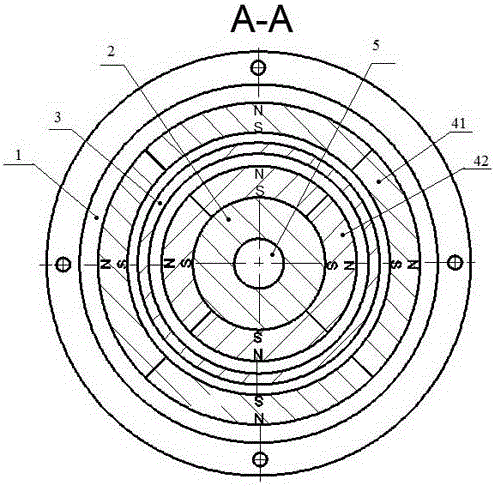

[0027] The method for increasing the torque of the magnetic sealing device of the present invention includes a driving rotor 1, a driven rotor 2, a spacer 3, and a permanent magnet 4, and the middle parts of the driving rotor 1 and the driven rotor 2 are respectively provided with shaft holes 5; The inner wall of the active rotor 1 is a conical surface, the outer wall of the driven rotor 2 is a conical surface, the active rotor 1 covers the driven rotor 2, the inner wall of the active rotor 1 is parallel to the outer wall of the driven rotor 2 The spacer 3 is located between the driving rotor 1 and the driven rotor 2, and is also conical, and its inner and outer walls are all parallel to the inner wall of the driving rotor 1, and the driving rotor 1, the driven rotor 3 and the spacer 3 There is a gap between them; the inner wall of the driving rotor 1 is provided with a plurality of annular grooves I11 at intervals, and the outer wall of the driven rotor 2 is provided with a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com