Artificial vibrator

A vibrator and sliding hole technology, which is applied in the direction of electric components, mechanical energy control, electrical components, etc., can solve the problems that the permanent magnet cannot move, the simulation accuracy is not high, and the vibration device cannot simulate vibration, so as to overcome the directionality and strength of vibration no clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

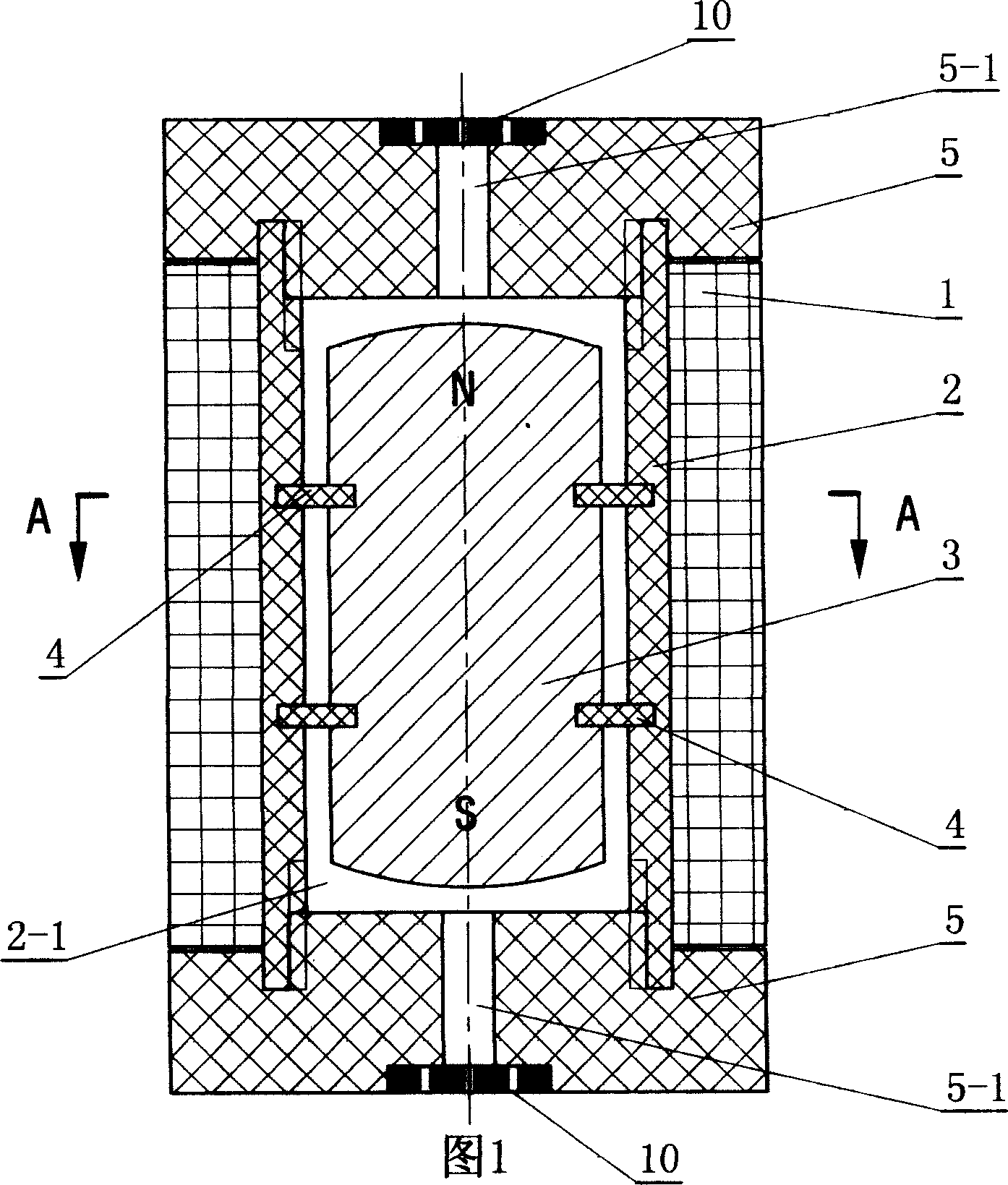

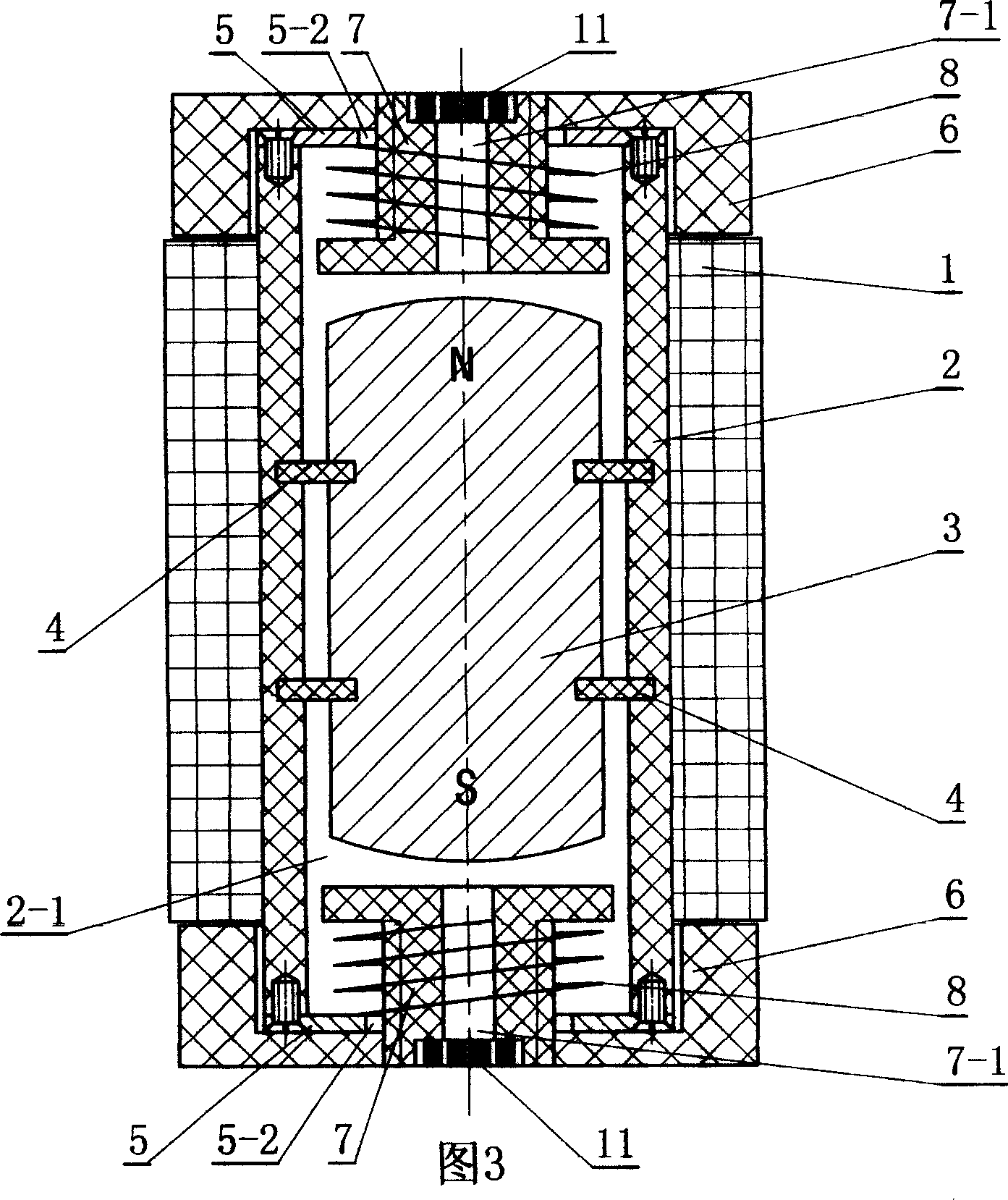

[0012] Embodiments are given below in conjunction with the accompanying drawings, and the present invention is further described in detail.

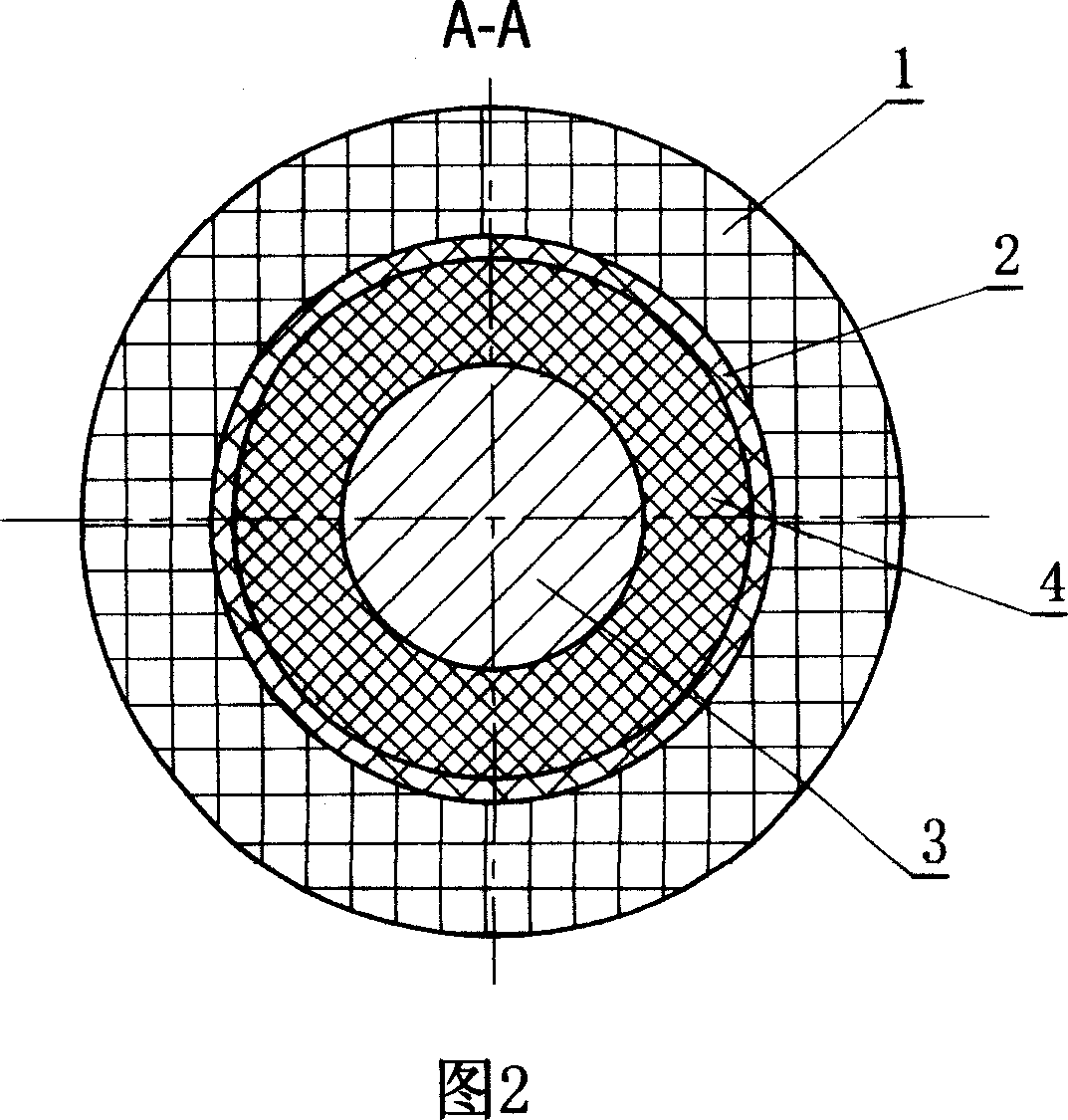

[0013] As shown in Figures 1 and 2, it is the first embodiment of the simulated vibrator of the present invention. A simulated vibrator includes a housing 2, a coil 1 and a magnetic hammer 3. The coil 1 rests on the housing 2, and the magnetic The hammer 3 is installed in the inner cavity 2-1 of the housing 2, the magnetic hammer 3 is flexibly connected with the housing 2 through the elastic member 4, and the two ends of the housing 2 are equipped with end caps 5, when the magnetic hammer 3 reciprocates, it can The end cap 5 contacts.

[0014] As shown in FIGS. 1 and 2 , the coil 1 surrounds the outer wall of the housing 2 around the central axis of the cylindrical portion of the housing 2 . The coil 1 can also conform to the inner wall of the cylindrical part of the housing 2 .

[0015] As shown in Figures 1 and 2, the magnetic hammer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com