Damping and denoising air hammer

An air hammer and noise reduction technology, applied in the direction of power hammer, hammer driving device, etc., can solve the problems of high noise, equipment wall damage, large vibration, etc., and achieve the effect of low noise, low investment and high impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

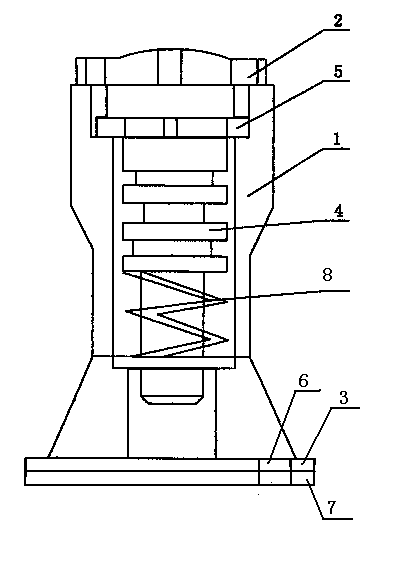

[0015] as attached figure 1 As shown: the shock-absorbing and noise-reducing air hammer of the present invention includes a housing 1, the upper end of the housing is connected to the air intake cover 2, and the lower end is connected to the rear substrate 3, and an impact piston 4 is arranged inside the housing. The upper end of the impact piston absorbs the magnetic substrate 5 by electromagnetic force, the rear substrate has an exhaust hole 6 , and the outer end of the rear substrate has a rubber pad 7 . The setting of the rubber pad protects the wall of the equipment well, and at the same time effectively reduces the noise.

Embodiment 2

[0017] For the shock-absorbing and noise-reducing air hammer, a compression spring 8 is provided at the lower end of the impact piston.

[0018] work process:

[0019] When the air hammer is not fed with compressed air (3-7kg / cm2), the magnetic piston is tightly attached to the base plate at the rear end of the hammer body by strong magnetic force. When the solenoid valve is energized, compressed air flows into the air hammer body to increase the pressure in its body. When the pressure is greater than the magnetic force, the magnetic piston breaks away from the base plate at high speed, driving the hammer head on the piston to hit the front base plate of the hammer body at high speed, and the impact force is transmitted to the silo, knocking down the dust attached to the silo; when the solenoid valve stops energizing, the compressed air Exhaust, with the help of the return spring, the magnetic piston slowly rises close to the rear end substrate, and returns to the original s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com