Double-physical-field-assisted single-face laminated metal composite plate manufacturing method

A metal layer and physical field technology, applied in metal rolling and other directions, can solve the problems of difficult to withstand large deformation machining, unstable oxide removal effect, poor thermal stability, etc., to refine weld grains and reduce toxicity. Side effects, the effect of avoiding the use of flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a double-physics-field-assisted single-sided metal layered composite panel, the steps are as follows:

[0034] 1) Clean the surface of pure aluminum plate and pure iron plate with pickling method to remove grease, stains and oxide film, and dry them for later use;

[0035] 2) Preheat the pure aluminum plate and pure iron plate after the above treatment to a temperature of 350°C under atmospheric conditions;

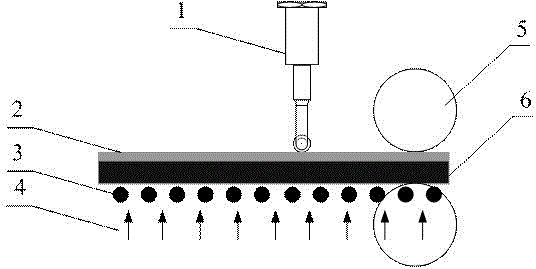

[0036] 3) The above-mentioned preheated pure aluminum plate and pure iron plate are rolled with internal cooling water-cooled rolls, and ultrasonic waves and magnetic fields are continuously applied at the same time, such as figure 1 Shown: Turn on the ultrasonic equipment to continuously apply ultrasonic action. The ultrasonic application device is composed of a transducer, a horn, and a tool head. It can apply transverse and longitudinal ultrasonic waves. The ultrasonic frequency is 3×10 4 Hz, the output amplitude of the tool head is 10μm,...

Embodiment 2

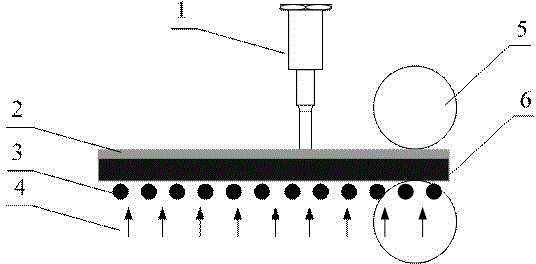

[0038] A method for preparing a double-physics-field-assisted single-sided metal layered composite plate, the steps of which are basically the same as in Example 1, the difference is that the shape of the ultrasonic head of the ultrasonic application device used is different, including roller type, column type, Inverted trumpet type, such as figure 2 shown.

Embodiment 3

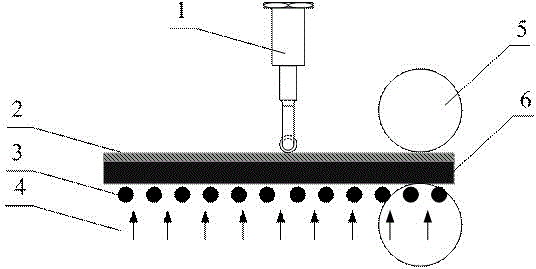

[0040] A method for preparing a double-physics-field-assisted single-sided metal layered composite panel, the steps of which are basically the same as in Example 1, except that the aluminum plate is heated and melted, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com