Special tire tread pattern structure of motorcycle for race in rainy day

A motorcycle tire and tread pattern technology, which is applied to tire tread/tread pattern, tire parts, vehicle parts, etc., can solve the problems affecting the driver's personal safety, affecting the driver's competition performance, and insufficient tire grip. To achieve the effect of improving traction performance, improving traction performance and wet grip performance, and ensuring the rigidity of the tread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

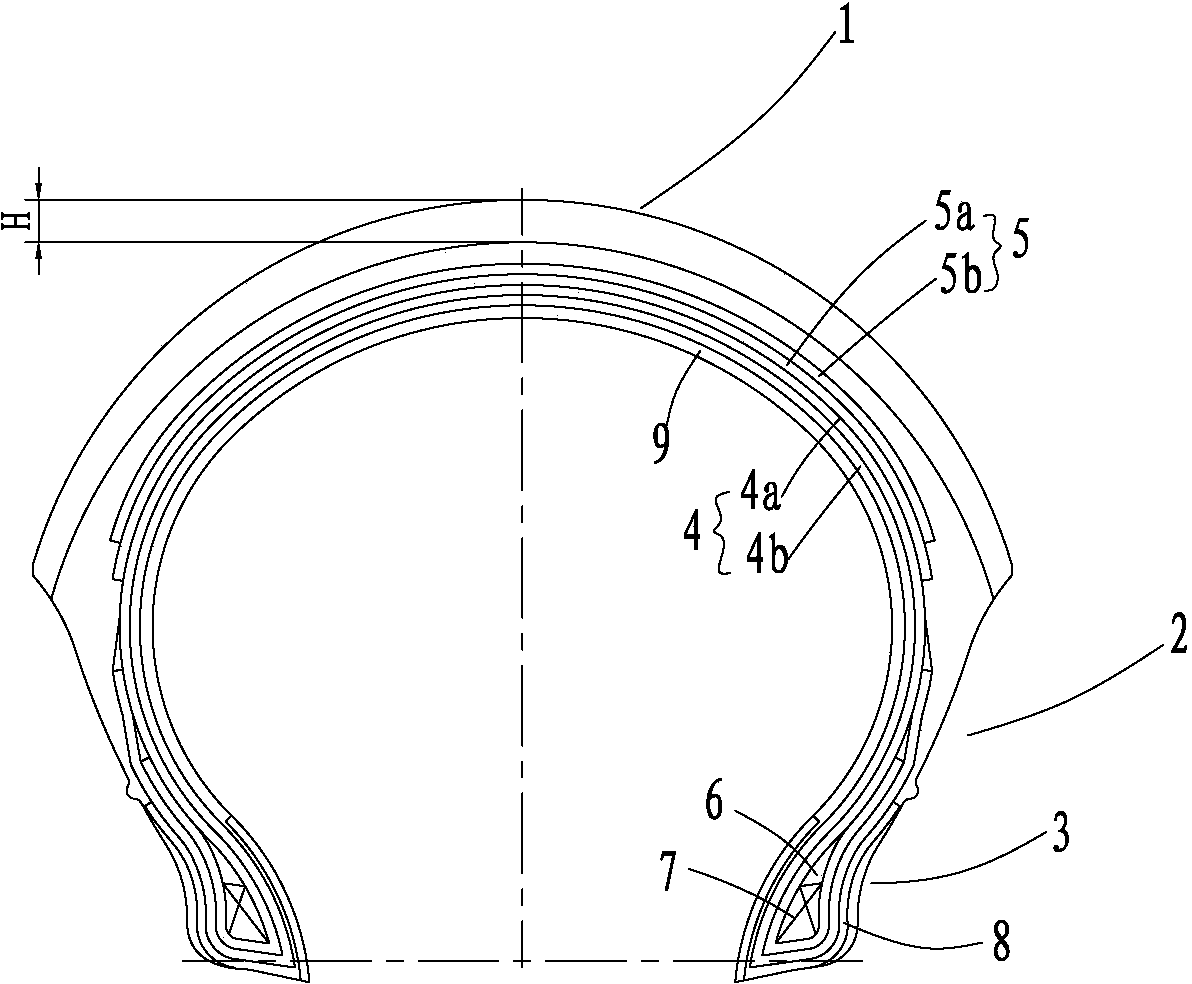

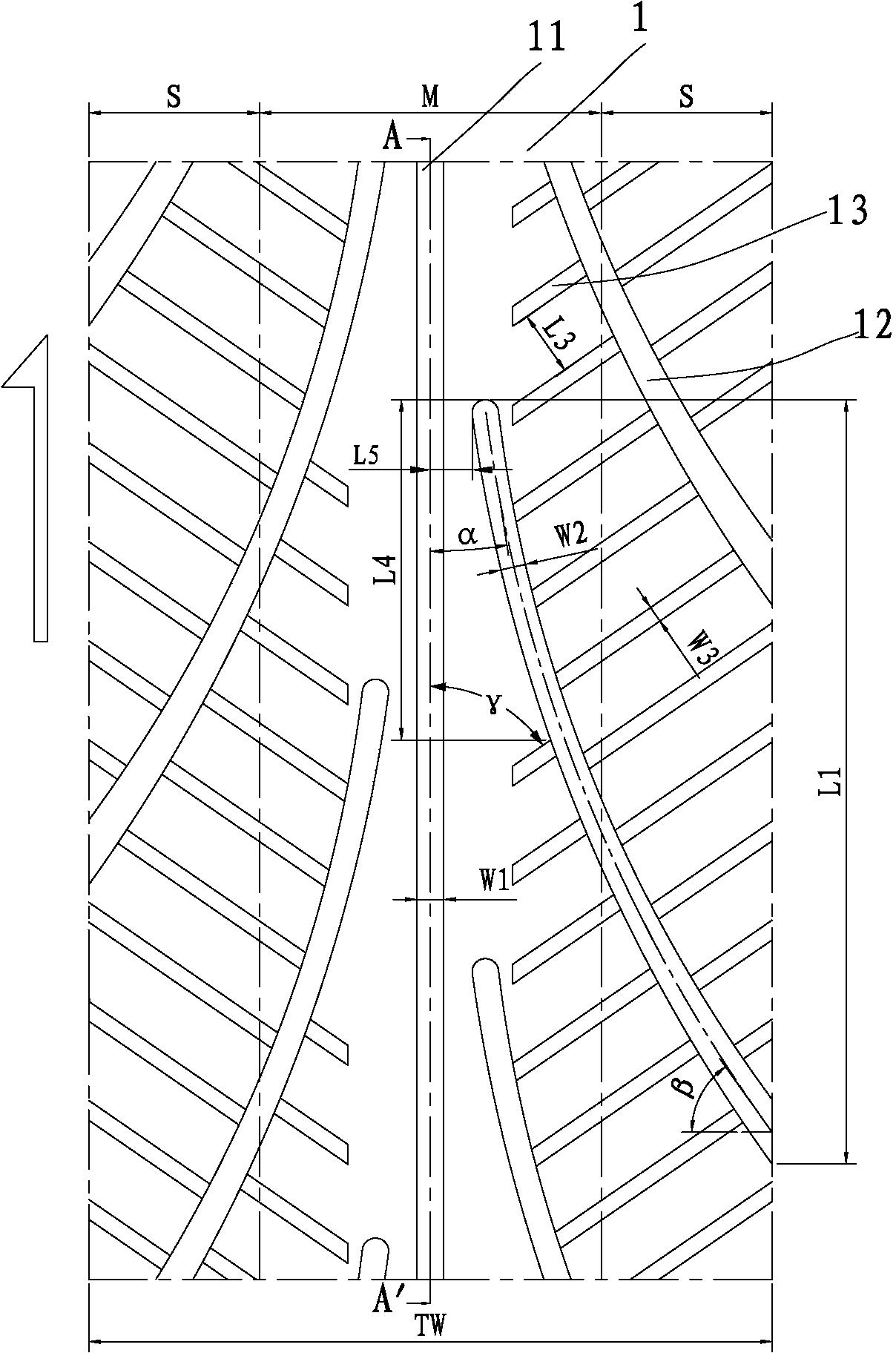

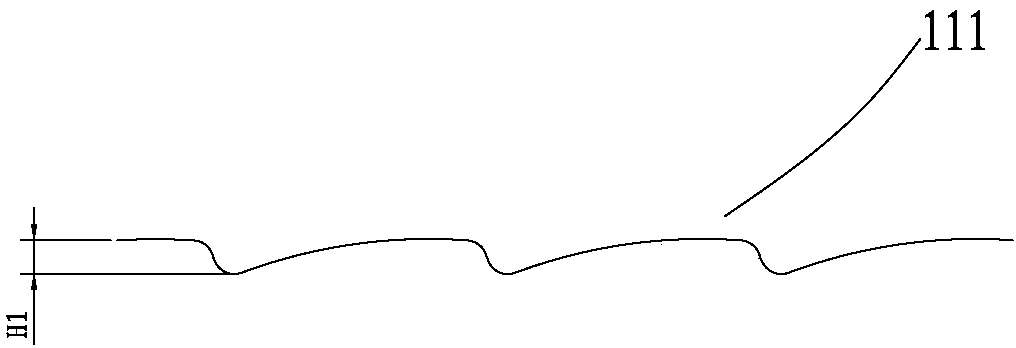

[0021] like figure 1 As shown, the tire is composed of a tread portion 1, a sidewall portion 2, and a bead portion 3, and the internal structure of the tire consists of two layers of carcass layers 4 (4a, 4b), two layers of belt layers 5 (5a, 5b) and a The inner surface layer 9 is composed of 9 layers, in which the carcass layer 4 adopts a high-stretch material meridian structure, and the cords of the carcass layer are arranged obliquely at an angle of 65°~90° relative to the equatorial plane. In order to ensure the rigidity of the tire tread, two layers Two layers of belt layers 5 (5a, 5b) are added to the carcass layer 4, and the belt layer cords are arranged obliquely at an angle of 15°~25° relative to the equator of the tire. The face portion 1 is wound around a bead core 7 to the sidewall portion 2, and a bead apex 6 made of hard rubber extends from the bead core 7 to the outside of the tire. At the same time, adding anti-scratch cloth 8 to the bead portion 3 can properl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Groove width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com