Stock bin arch breaking device

A silo and arch breaking technology, applied in the field of silo arch breaking equipment, can solve the problems of limited effect, limited effective area, poor effect, etc., and achieve the effects of simple structure, wide application range and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

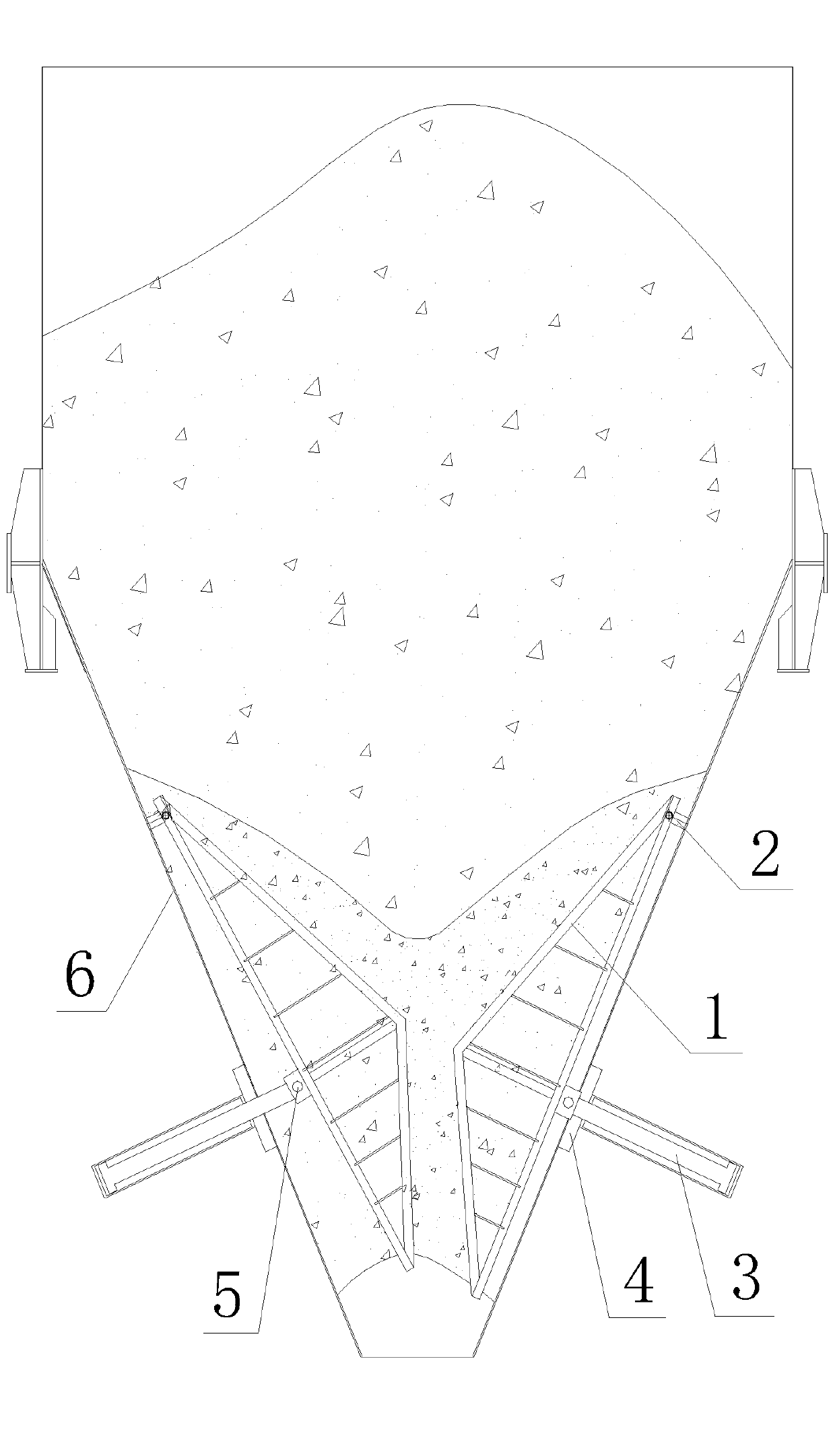

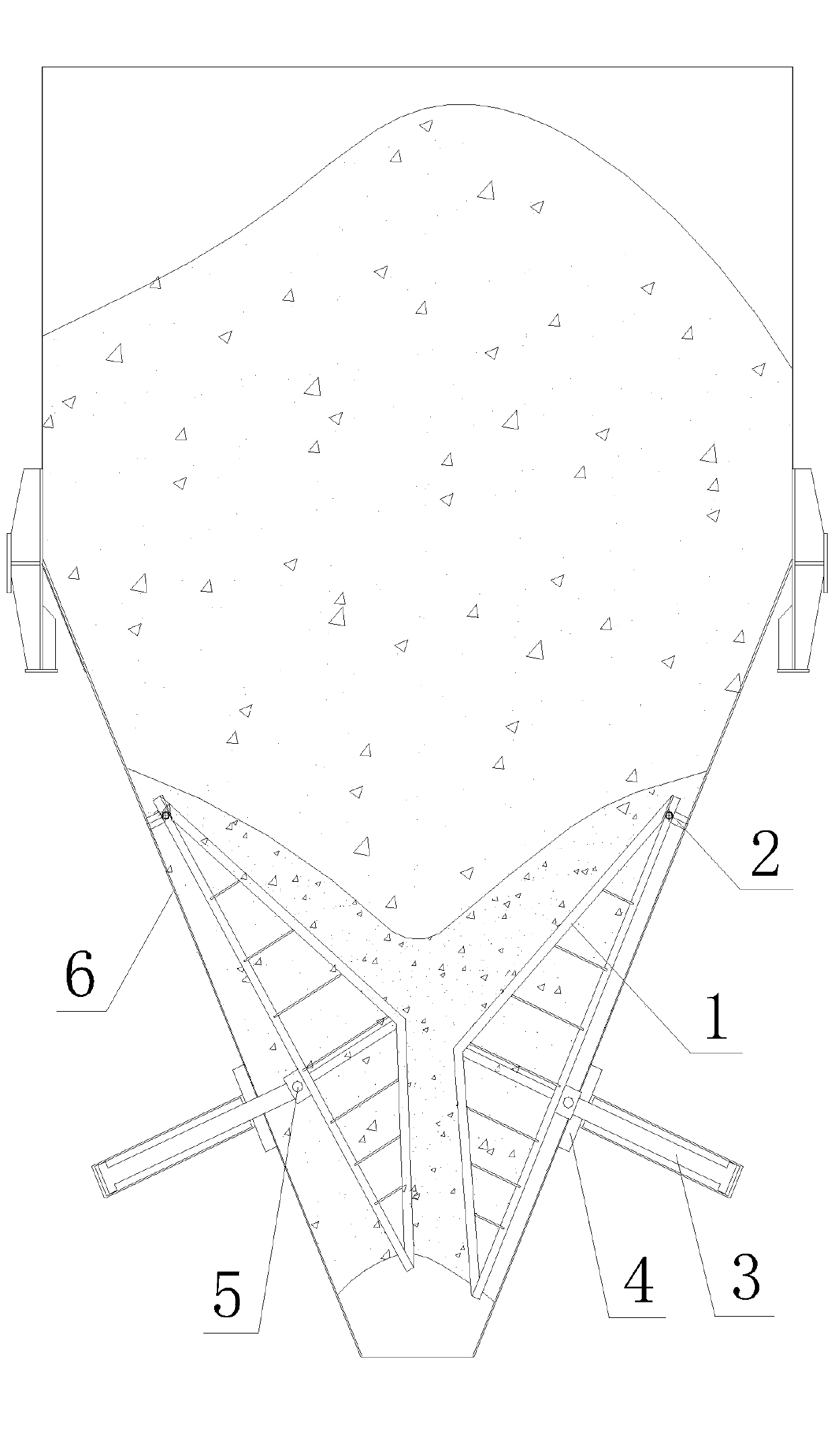

[0022] refer to Figure 1-Figure 2 , the bunker arch breaking device described in this embodiment includes an impact bracket 1 that matches the shape of the bin 6, and the upper part of the impact bracket 1 is connected to the connecting support 2 fixedly assembled on the inner wall of the bin 6. The silo is connected by 6 hinges. The middle and lower part of the impact bracket 1 is equipped with a power drive device that drives the impact bracket 1 to swing and break the arch with the connecting support 2 as the base point, and the power drive device is assembled on the side wall of the silo 6 .

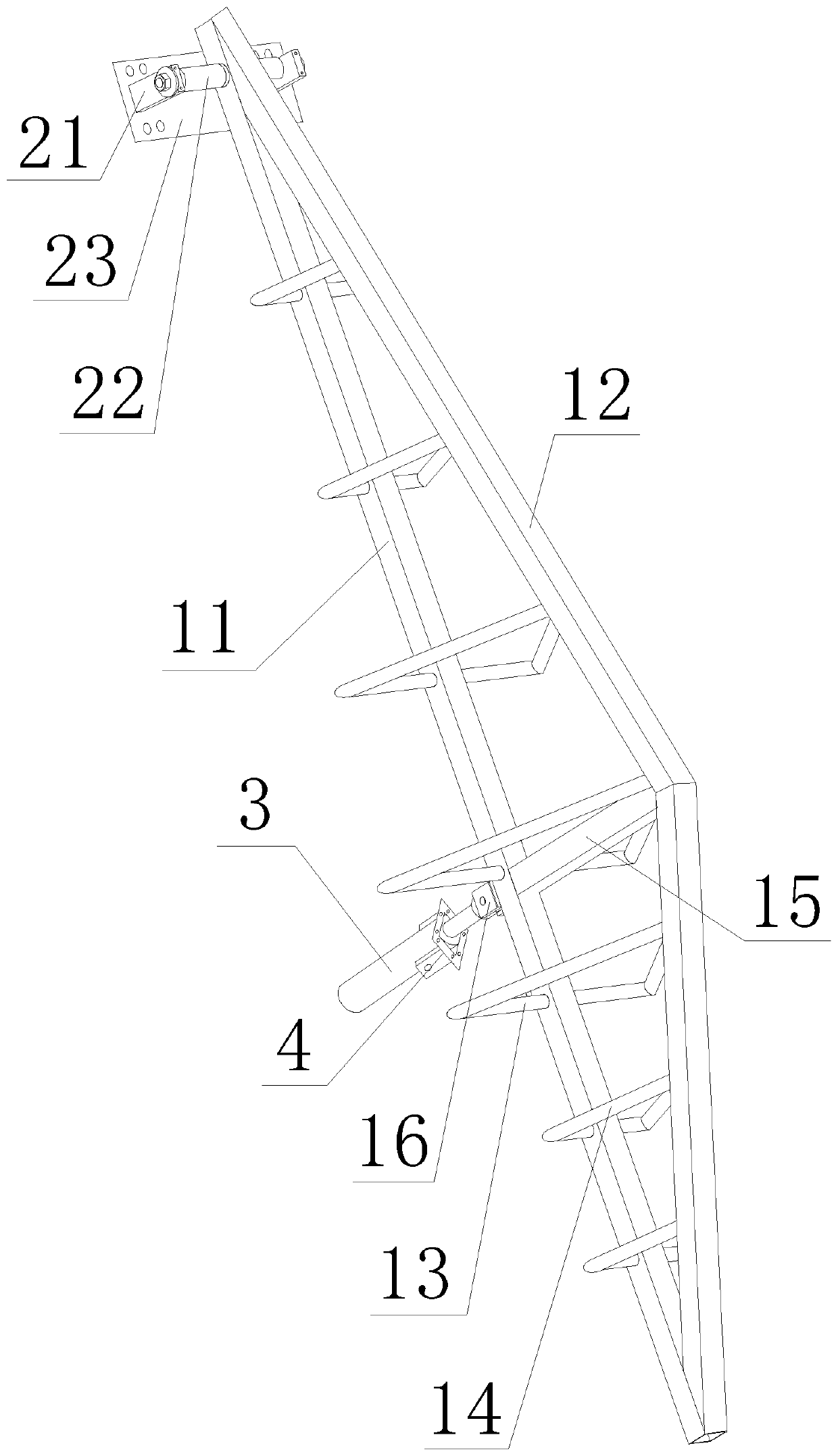

[0023] The impact support 1 includes a main frame, a supporting vertical beam 15 and several supports for increasing the section of the broken arch. in:

[0024] The main frame is in a triangular shape and includes a main frame beam 11 and two main frame side beams 12 , the main frame beam 11 and the two main frame side beams 12 are connected end to end.

[0025] The supporting v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com