Method and system for polishing glass

一种浮法玻璃、抛光盘的技术,应用在适用于磨削工件平面的机床、磨削/抛光设备、光学平面磨床等方向,达到增强均匀度、改善抛光均匀度、抛光度差异改进的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

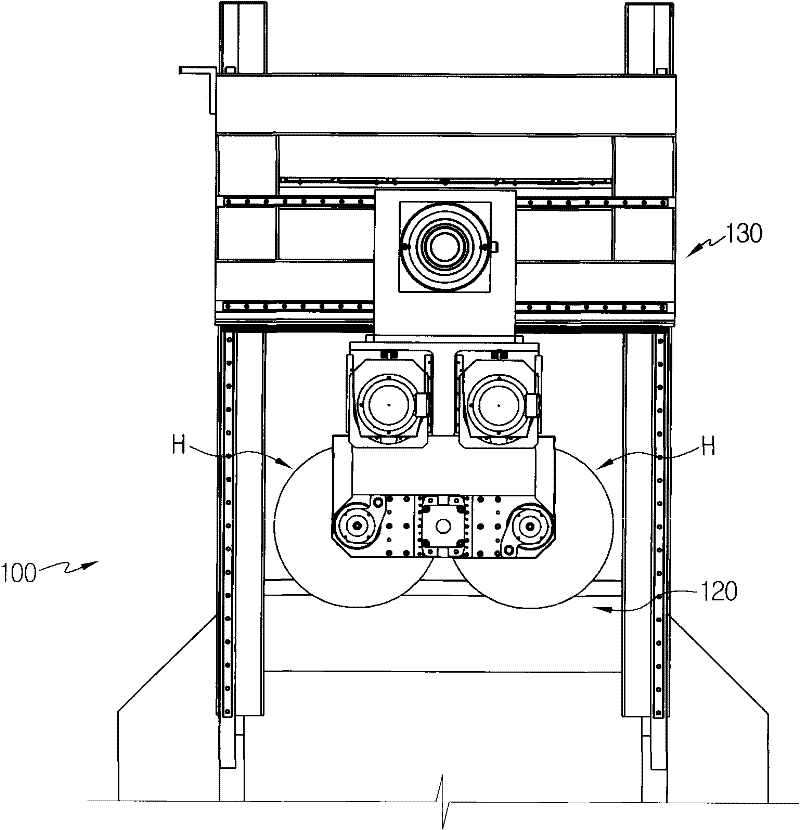

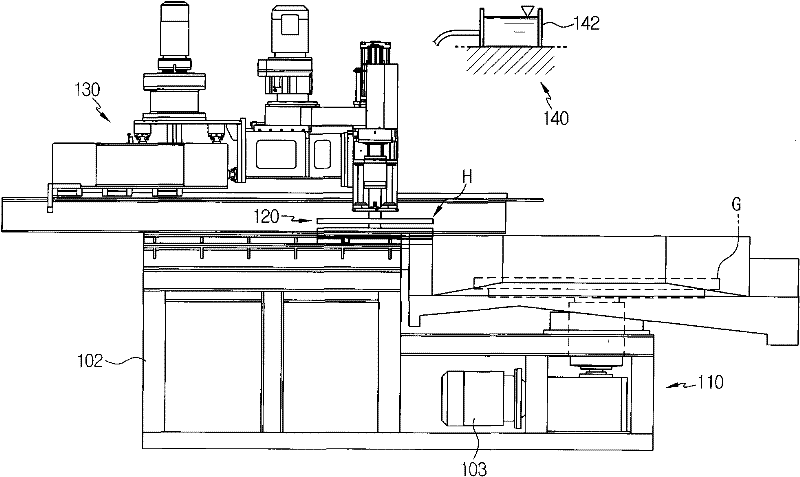

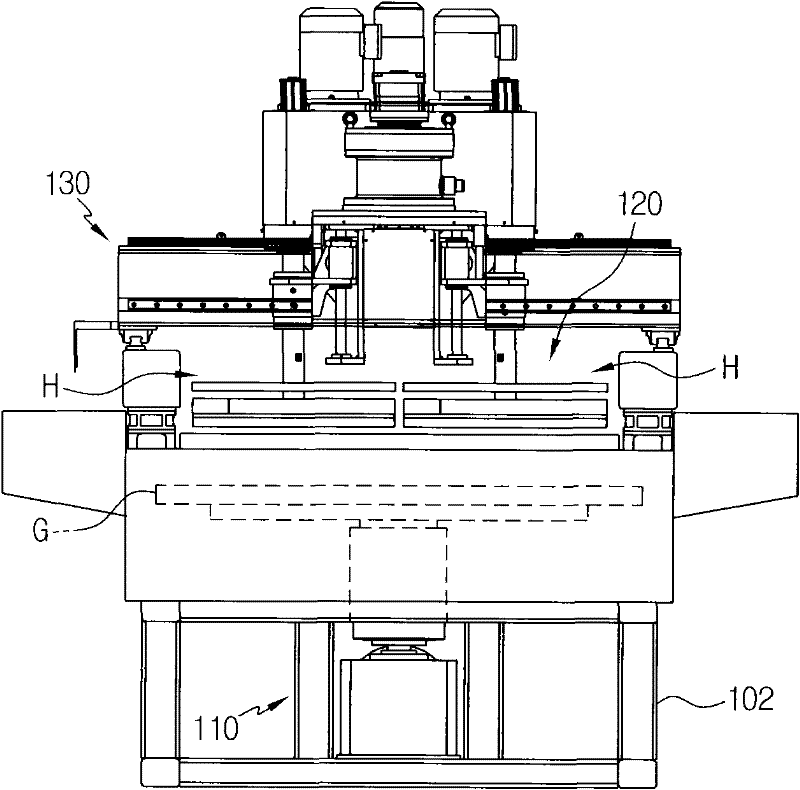

[0039] Hereinafter, a glass fixing plate for a glass polishing system according to a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0040] Before proceeding with the description, it should be understood that the terms used in this description and the appended claims should not be understood as being limited to the general meaning and dictionary meaning, but should be understood based on the meaning and concept corresponding to the technical solution of the present invention, based on The rationale is that the inventors of the present invention allow the terms to be appropriately defined for best interpretation. Therefore, the description given here is only a preferred embodiment for the purpose of illustration, and is not intended to limit the scope of the present invention, so it should be understood that the present invention can be modified without departing from the spirit and scope of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com