Shear thickening-electrophoresis composite polishing method

A composite polishing and electrophoresis technology, which is used in grinding/polishing equipment, grinding workpiece supports, metal processing equipment, etc., can solve the problems of low polishing efficiency and poor applicability, and achieve the effect of high polishing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

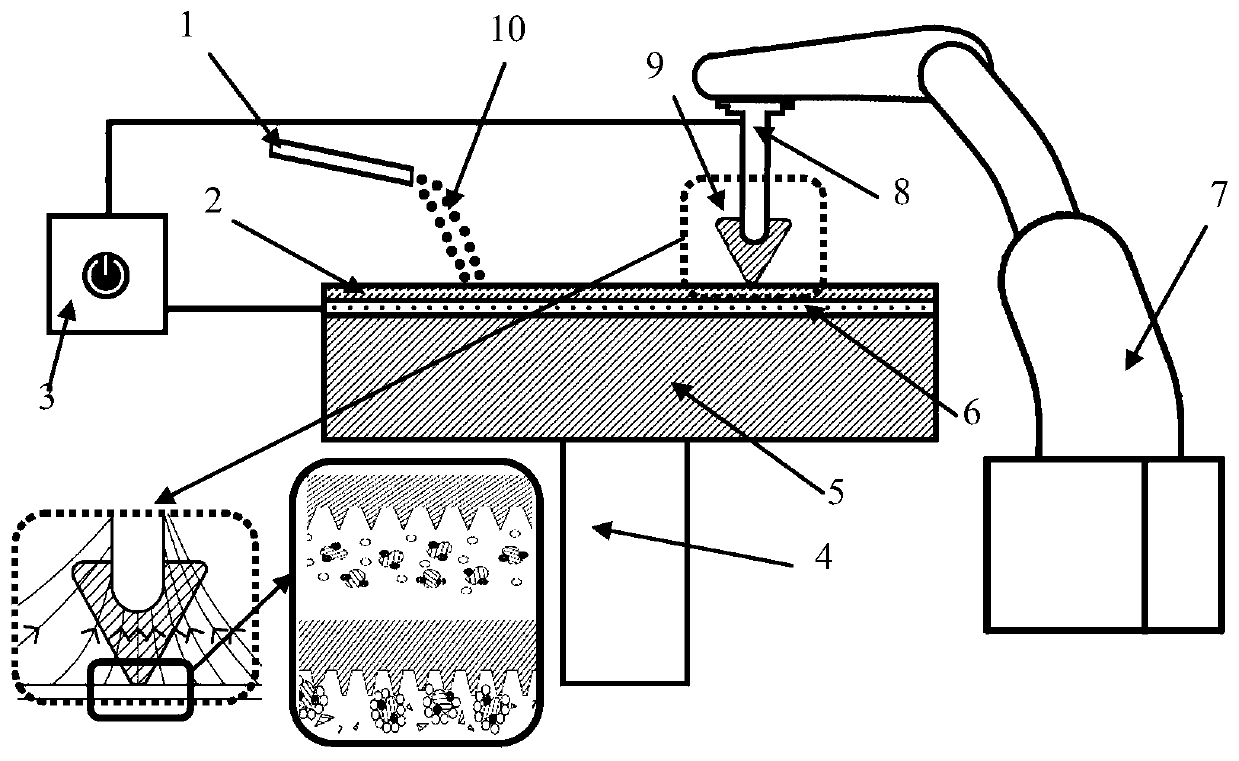

[0032] refer to Figure 1 ~ Figure 4 , a kind of shear thickening-electrophoresis compound polishing method, when being used for processing tool tip, bearing part curved surface workpiece (as cemented carbide tool tip arc, bearing part curved surface), its processing steps are as follows:

[0033] 1) select the workpiece fixture (second electrode) 8, and install it on the mechanical arm 7;

[0034] 2) Clamping the tool 9 on the workpiece holder (second electrode) 8;

[0035] 3) configuring a polishing solution 10 with shear thickening-electrophoresis composite effect, and placing the polishing solution 10 in the infusion tube 1;

[0036] 4) Input the polishing liquid 10 onto the polishing disc 5, start the spindle 4 to drive the polishing disc 5, so that the polishing liquid 10 moves relatively on the polishing disc 5;

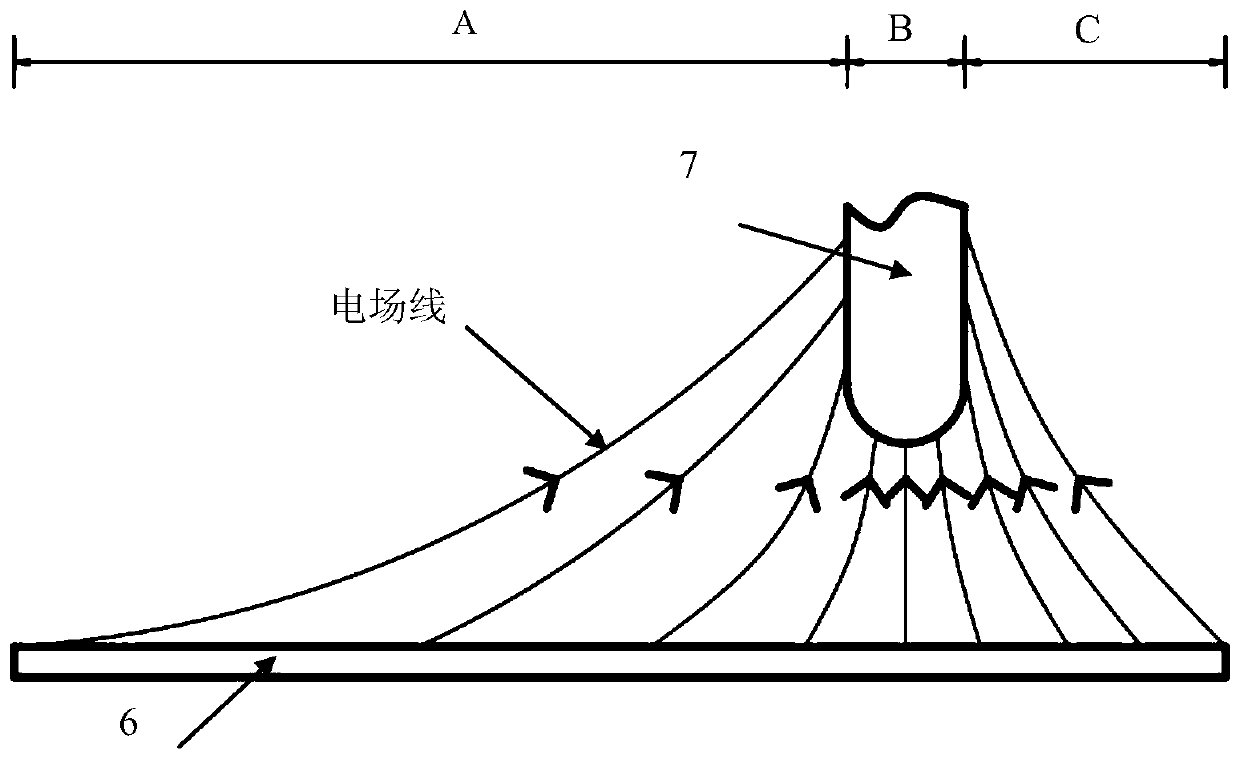

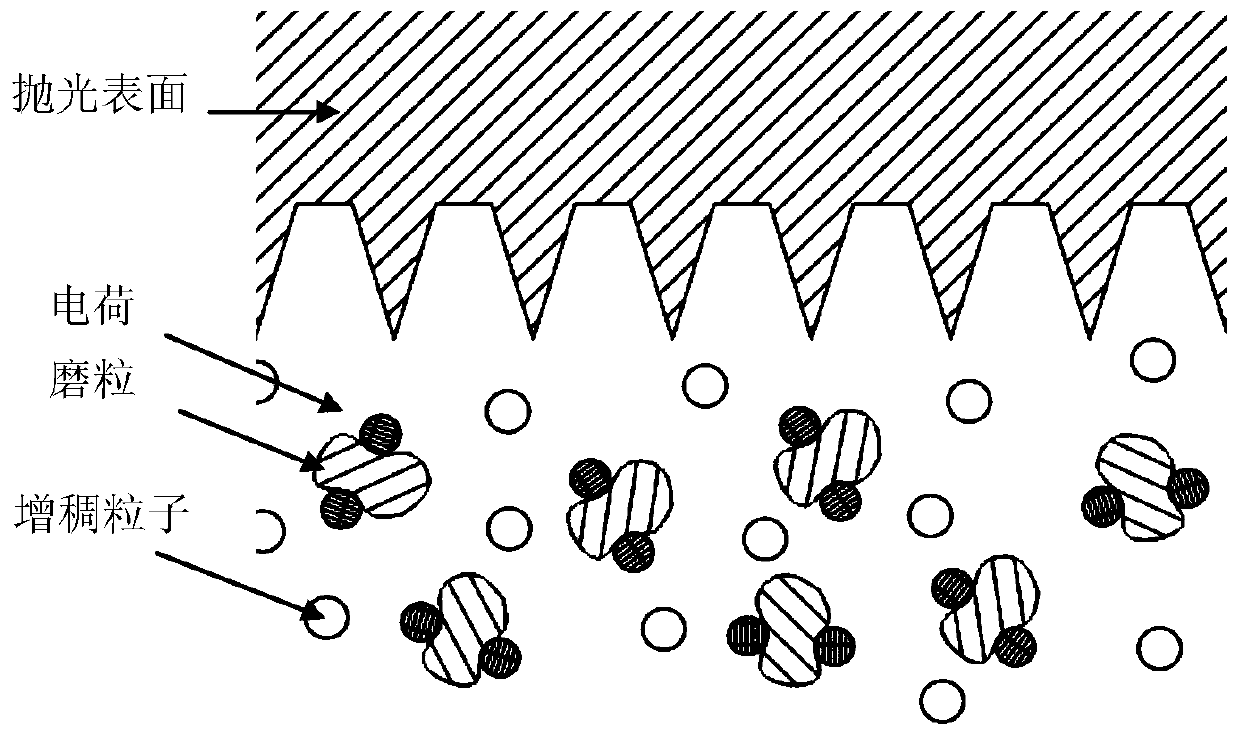

[0037] 5) Start the mechanical arm 7 for shear thickening effect control, and the DC power supply 3 for electrophoretic effect control. Under the action of th...

Embodiment 2

[0048] The present invention is used for processing planar workpieces (such as silicon materials, SiC, optical crystals, etc., and various difficult-to-process materials) whose dimensions are: length×width×height (such as 25mm×25mm×5mm)

[0049] Include the following steps:

[0050] 1) select the workpiece fixture (second electrode) 8, and install it on the mechanical arm 7;

[0051] 2) Clamping the workpiece 9 on the workpiece fixture (second electrode) 8;

[0052] 3) configuring a polishing solution 10 with shear thickening-electrophoresis composite effect, and placing the polishing solution 10 in the infusion tube 1;

[0053] 4) Input the polishing liquid 10 onto the polishing disc 5, start the spindle 4 to drive the polishing disc 5, so that the polishing liquid 10 moves relatively on the polishing disc 5;

[0054] 5) Start the mechanical arm 7 for controlling the shear thickening effect and the DC power supply 3 for controlling the electrophoretic effect. Under the acti...

Embodiment 3

[0057] When the present invention is used for processing size parameter and is: diameter 30mm, when the optical glass material plane workpiece of focal length 100mm, its operating steps are as follows:

[0058] 1) select the workpiece fixture (second electrode) 8, and install it on the mechanical arm 7;

[0059] 2) Clamping the workpiece 9 on the workpiece fixture (second electrode) 8;

[0060] 3) configuring a polishing solution 10 with shear thickening-electrophoresis composite effect, and placing the polishing solution 10 in the infusion tube 1;

[0061] 4) Input the polishing liquid 10 onto the polishing disc 5, start the spindle 4 to drive the polishing disc 5, so that the polishing liquid 10 moves relatively on the polishing disc 5;

[0062] 5) Start the mechanical arm 7 for controlling the shear thickening effect and the DC power supply 3 for controlling the electrophoretic effect. Under the action of the mechanical arm 7, the polished surface of the workpiece 9 contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com