Device and method used for cutting brittle materials by multiple laser focuses and capable of producing dynamically adjustable optical field

A brittle material, multi-laser technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inability to generate thermal tensile stress, failure of cutting and separation, and inability to generate dynamic laser light fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

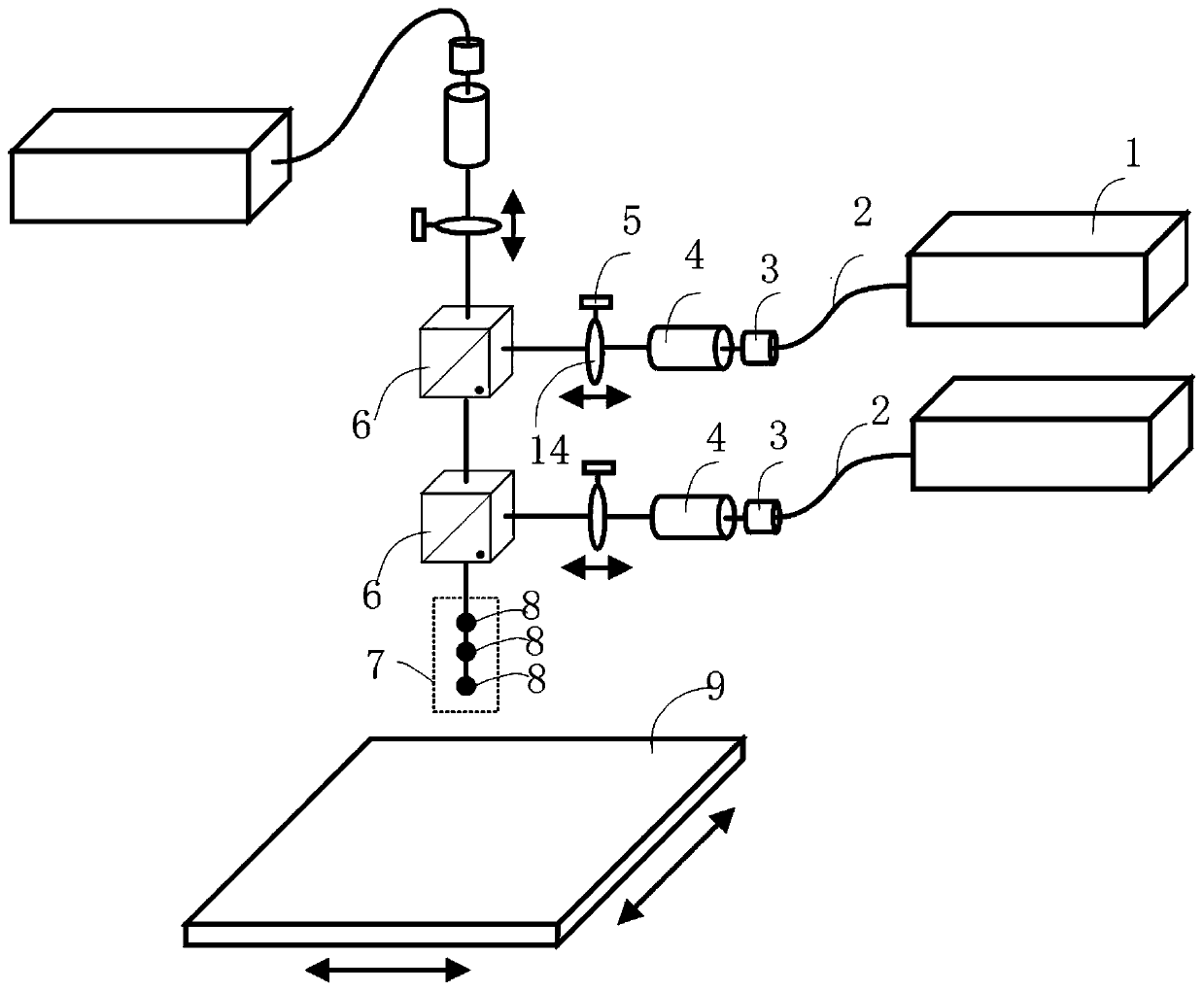

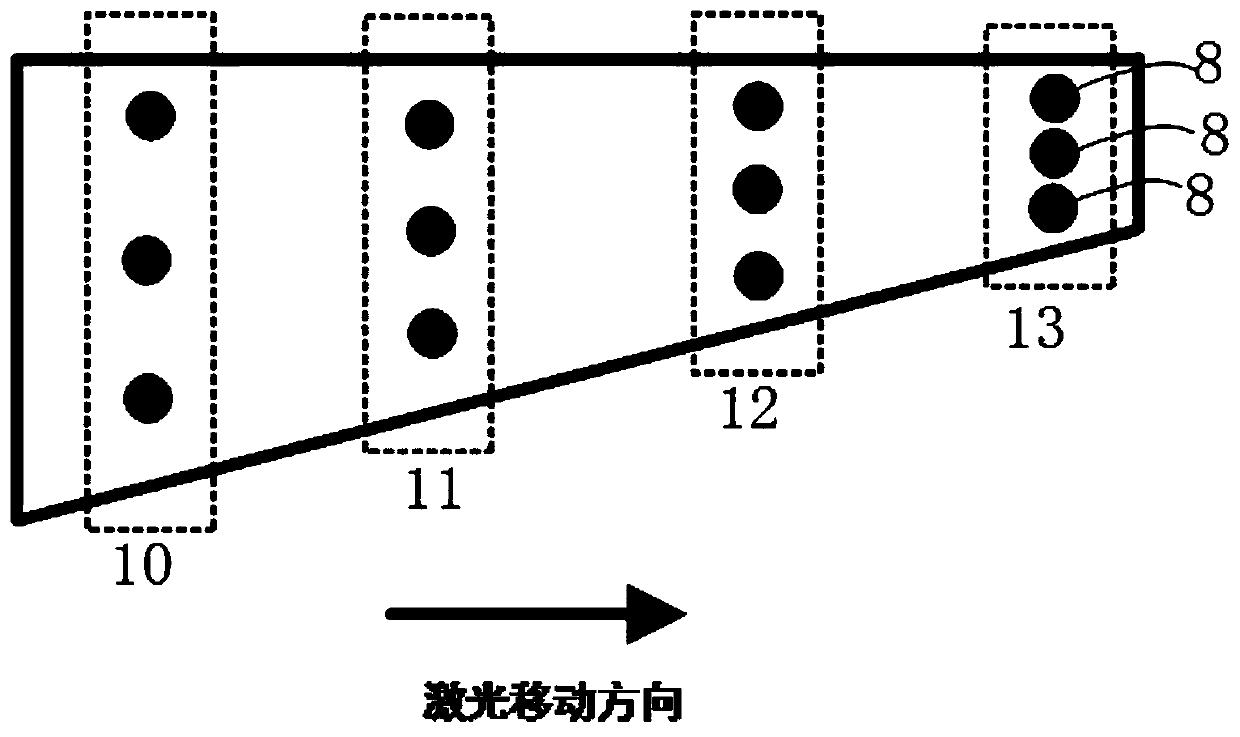

[0035] Such as Figure 1-2 As shown, the present embodiment provides a multi-laser focal point cutting brittle material device with dynamically adjustable light field, and the number of laser focal points 8 is designed according to the thickness range of the separated material to be cut; it includes a plurality of laser branches, and each laser The branches each include a laser 1 for providing a laser beam; the laser 1 is connected to a fiber coupler 3 through an optical fiber 2, and a beam expander 4 is arranged behind the fiber coupler 3 for expanding the laser beam; A focusing lens 14 is provided behind the beam expander 4, which is used to focus the laser beam; a beam splitting prism 6 is also included, and the beam splitting prism 6 is used in reverse to focus the laser beams in a plurality of laser branches. The beams are combined to generate multiple precisely adjustable laser focal points 8 on the same optical axis, which are used to cut the separation material to be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com