GaN-based light emitting diode (LED) array micro display device and fabrication method thereof

A technology for LED arrays and micro-display devices, applied in the direction of electric solid devices, semiconductor devices, electrical components, etc., can solve the problems of resolution limitation, affecting device luminous efficiency, micro-LED chip lattice damage, etc., and achieve ultra-high resolution , the effect of low leakage current and ultra-low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

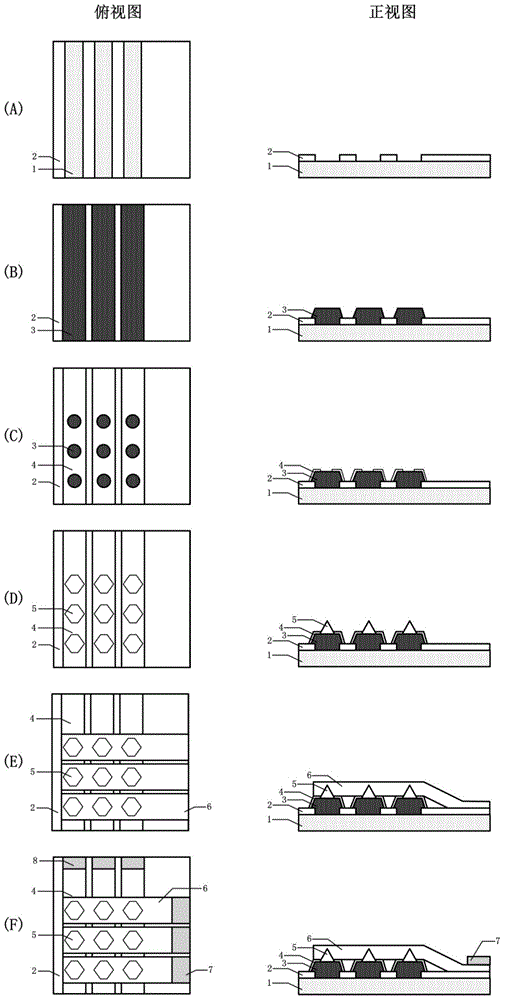

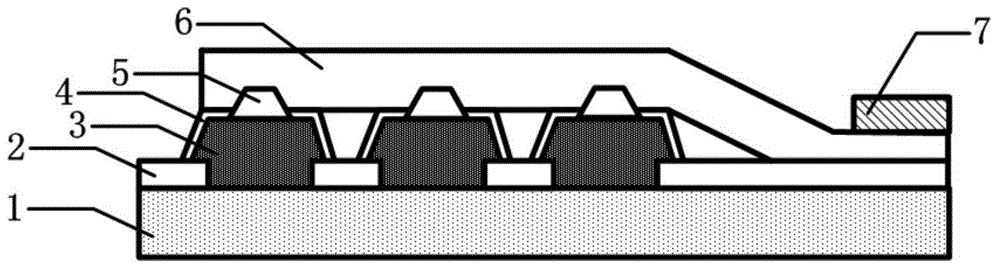

[0033] attached figure 1 Among them, 1-sapphire substrate, 2-masking film arranged in stripes, 3-striped n-type GaN array, 4-masking film with periodically arranged holes, 5-micro LED array in pyramid structure, 6- Strip-shaped transparent conductive layer, 7-positive electrode, 8-negative electrode.

[0034] Such as figure 1 As shown, a method for preparing a GaN-based LED array microdisplay device based on selective area epitaxial growth technology is provided, which includes the following steps:

[0035] (A): 100nm thick SiO deposited on sapphire substrate 2 Dielectric masking film, the SiO 2 The dielectric masking film is prepared as a masking film arranged in strips with a window area width of 10 μm and an interval of 5 μm;

[0036] (B): The selective area epitaxial growth technique by MOCVD, in the above SiO with stripe arrangement 2 Epitaxial growth of strip-structured n-type GaN arrays on the window region of the masking film;

[0037] (C): Deposition of 100nm th...

Embodiment 2

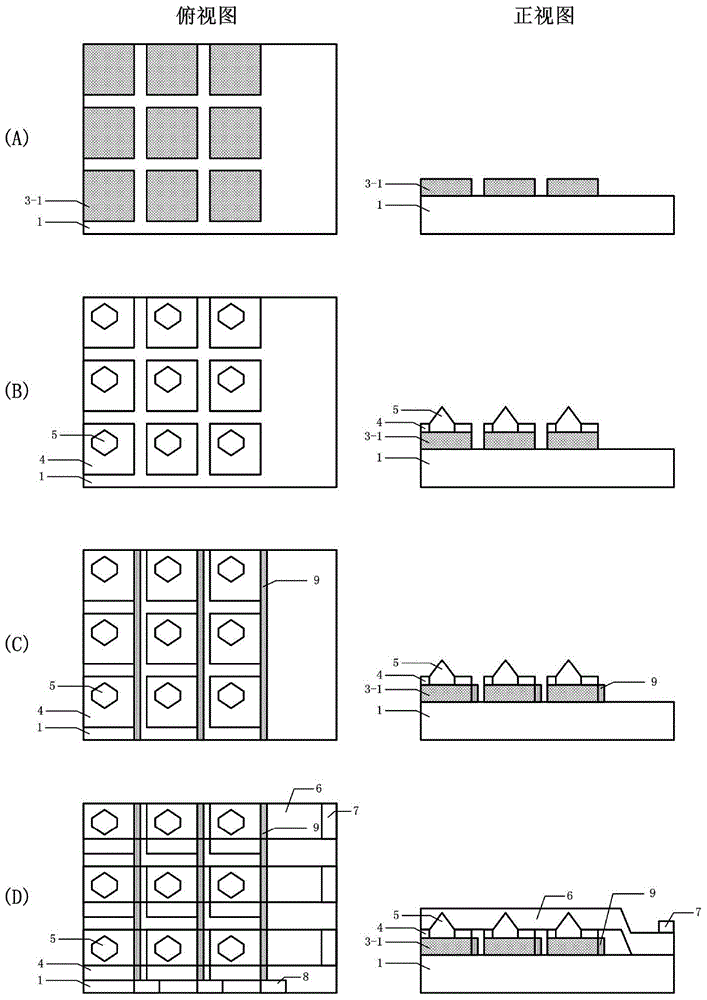

[0043] attached figure 2 Among them, 1-sapphire substrate, 3-1-n-type GaN epitaxial layer, 4-masking film with periodically arranged holes, 5-pyramid structure micro LED array, 6-strip transparent conductive layer, 7-positive Electrode, 8-negative electrode, 9-column interconnected conductive layer.

[0044] Such as figure 2 As shown, a method for preparing a GaN-based LED array microdisplay device based on selective area epitaxial growth technology is provided, which includes the following steps:

[0045] (A) An n-type GaN epitaxial layer with a thickness of 2 μm is grown on a sapphire substrate by MOCVD epitaxy, and the n-type GaN epitaxial layer is etched into an array of isolated blocks by ICP dry etching Shaped n-type GaN epitaxial layer, the size of each block n-type GaN epitaxial layer is 12x12 μm, and the interval between each other is 3 μm;

[0046] (B) On each bulk n-type GaN epitaxial layer, a masking film with periodically arranged openings is made, and at the...

Embodiment 3

[0050] Embodiment 3 adopts the same epitaxial structure, device structure and manufacturing process as Embodiment 1, wherein the pyramidal micro LED array in Embodiment 1 is replaced by the hexagonal truncated pyramid micro LED array in Embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bar width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com