Method and device of laser three-dimensional processing of ceramic body

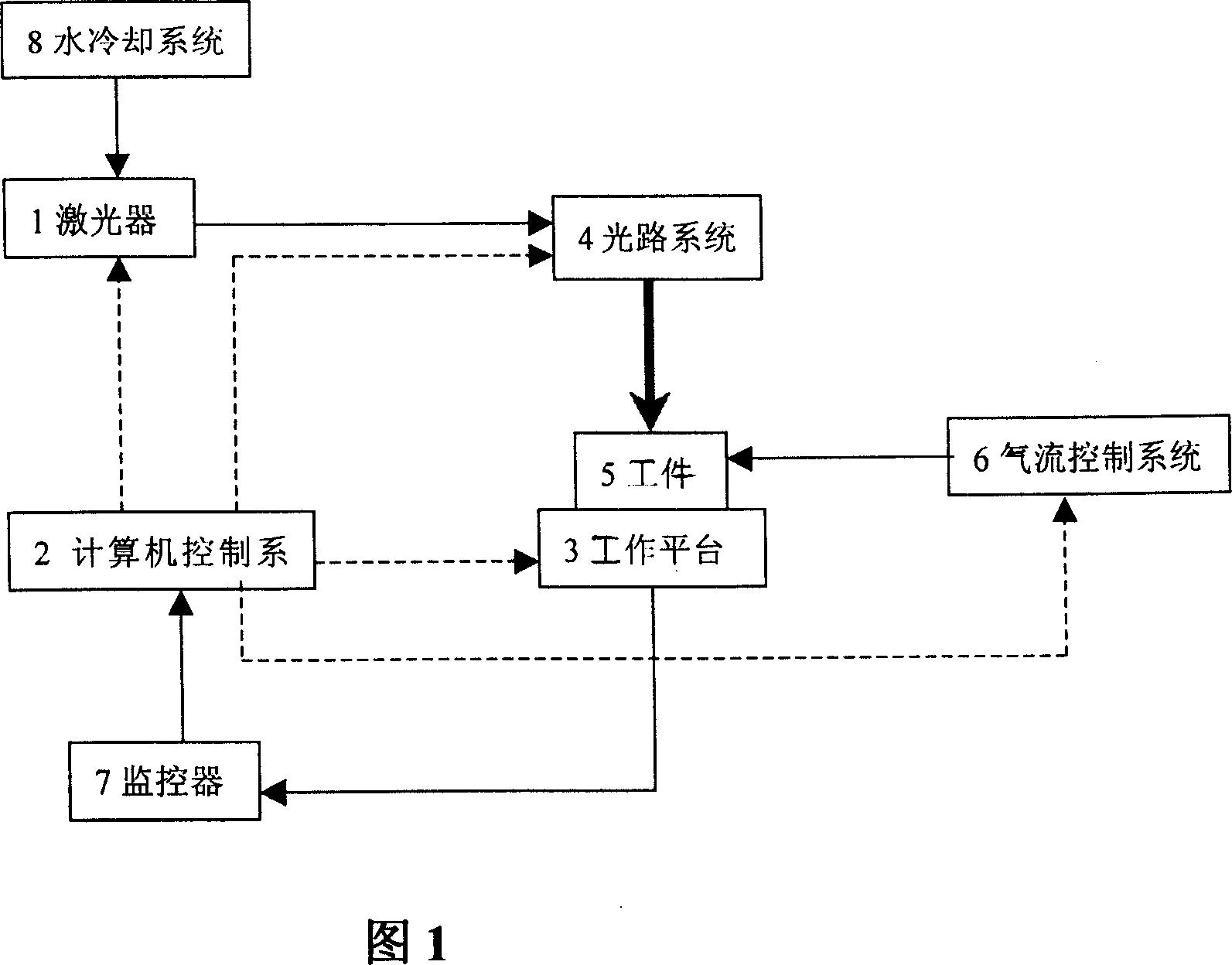

A ceramic body, laser three-dimensional technology, applied in the direction of ceramic extrusion dies, ceramic molding machines, manufacturing tools, etc., can solve the problems that the demoulding process cannot be completed, technical basic problems cannot be solved satisfactorily, and cannot be realized, and achieve processing quality Stable and reliable, small vibration, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1: Precise drilling by tilting and turning method

[0052] Taking zirconia as an example, the average particle size of the particles is 1um, the slurry is configured with a volume fraction of 35%, the organic monomer acrylamide and the cross-linking agent methylene bisacrylamide content are 5%, and it is molded by gel injection molding Methods A ceramic ball green body with a diameter of 4.0 mm was prepared. After demoulding, the green body was dried in the shade at 15°C for 5 days, and then dried at 90°C for 2 days. After the green body is dried, it is fixed on the processing table, and a 30W, Nd:YAG solid-state laser is used. In order to avoid or reduce the taper after laser drilling and improve the shape accuracy of laser drilling, such as roundness and cylindricity, the tilt-rotation method is used.

[0053] The specific method is to tilt the universal rotary table at an angle of β in the direction of the Z axis, and make a fixed axis rotation around the op...

Embodiment 2

[0054] Example 2: Rapid processing of heterosexual parts

[0055] Using commercially available silicon carbide powder as a raw material, a ceramic green body with a length of 15 cm, a width of 8 cm and a thickness of 3.0 mm was prepared by injection molding. A 60W pulsed YAG laser is used to process ceramic gears. As shown in Figure 2, the specific processing method is to fix the demoulded ceramic body on the worktable, the laser moves in two dimensions on the XY axis plane according to the gear contour, the worktable rises slowly, and the laser beam is always perpendicular to the surface of the workpiece. The working voltage is 20MA, the spot diameter is 0.1mm, the linear speed of the laser is 60cm / min, the rising speed of the workbench is 1mm / min, and the auxiliary gas is oxygen.

example 3

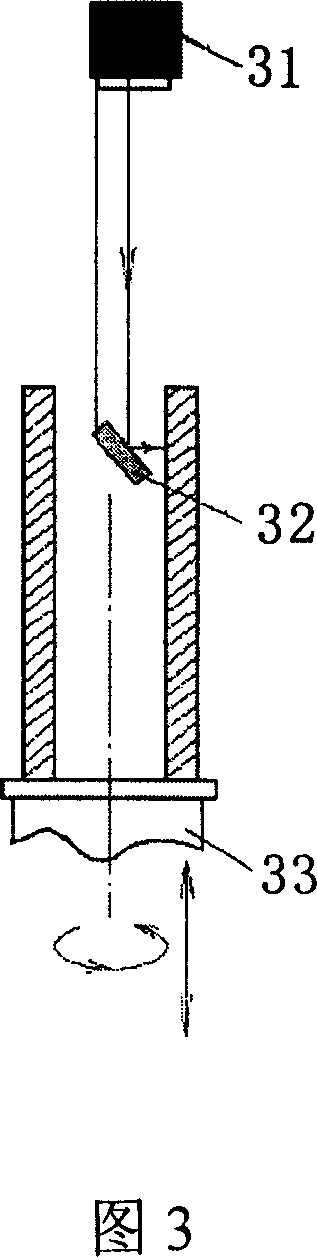

[0056] Example 3: Dressing of inner wall of ceramic tube with large length-to-diameter ratio

[0057] Commercially available titanium oxide is used as raw material, the crystal forms are rutile and anatase, the particle diameter is about 0.5um, and additive CaF is added 2 : 1wt%; BaCO 3 : 1wt%; ZnO: 22.5wt%; H 2 WO 4 : 1.5wt%; bentonite: 2wt%. After mixing and calcining at 1170°C, the particle size after ball milling is controlled at about 1.5um. A ceramic tube with an inner diameter of 25 mm, an outer diameter of 30 mm, and a length of 400 mm was prepared by extrusion molding. After drying in an oven at 90°C for 48 hours, a 40w laser 31 was used to trim the inner wall of the ceramic tube.

[0058] As shown in the processing schematic diagram 3, the reflector 32 in the figure forms an included angle of 45° with the direction of the laser beam, which can deflect the laser beam propagation direction by 90°. The specific processing method is to let the working platform 33 ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com