Return flow system of linear slide rail

A technology of linear slide rails and slide rails, applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., can solve problems such as uneven oil volume, difficulty, and uneven lubrication of rolling elements, so as to improve assembly efficiency and stress Uniform, reliability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to illustrate the structure and achieved effects of the present invention in detail, the following preferred embodiments are given below together with the accompanying drawings.

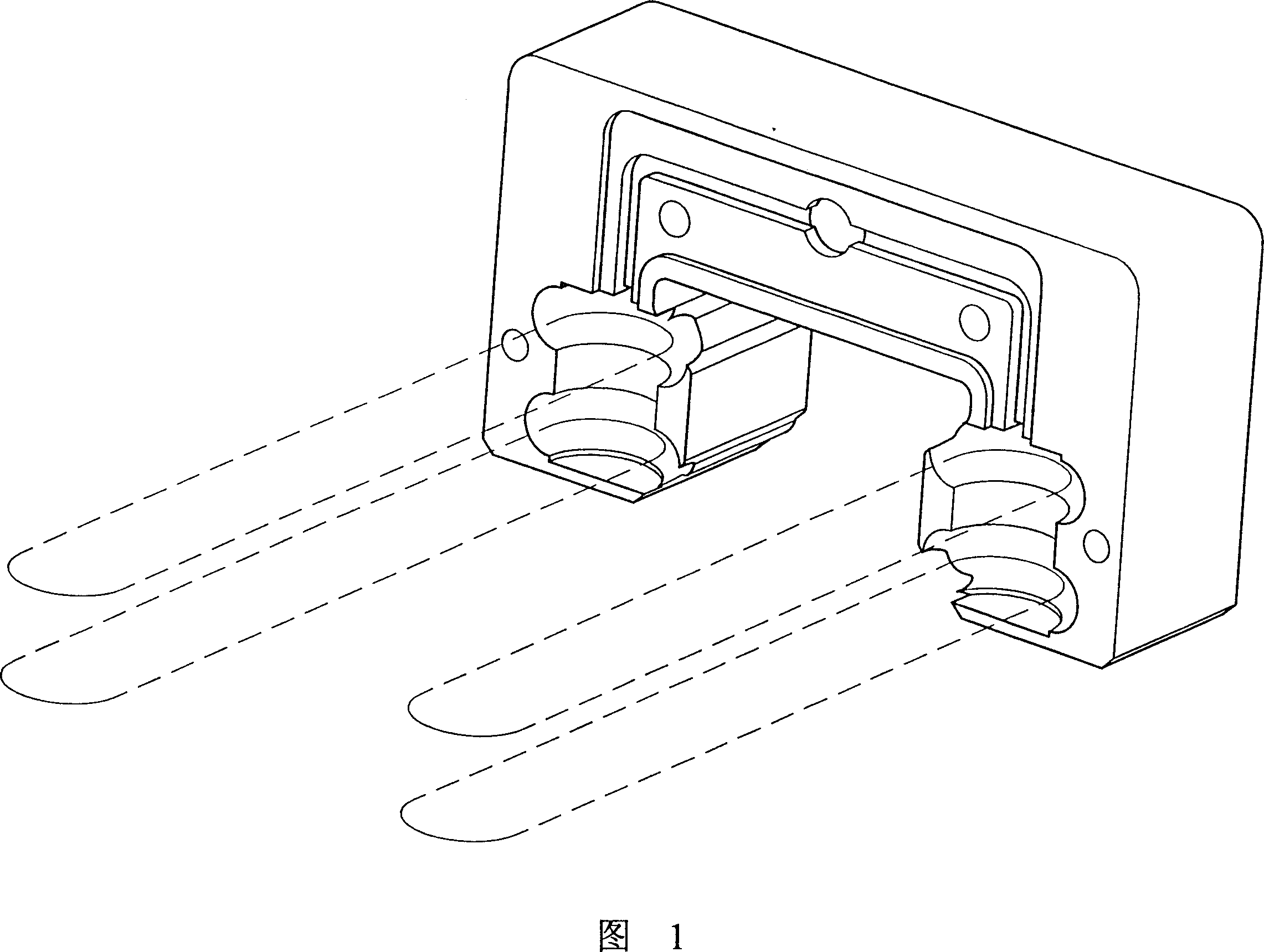

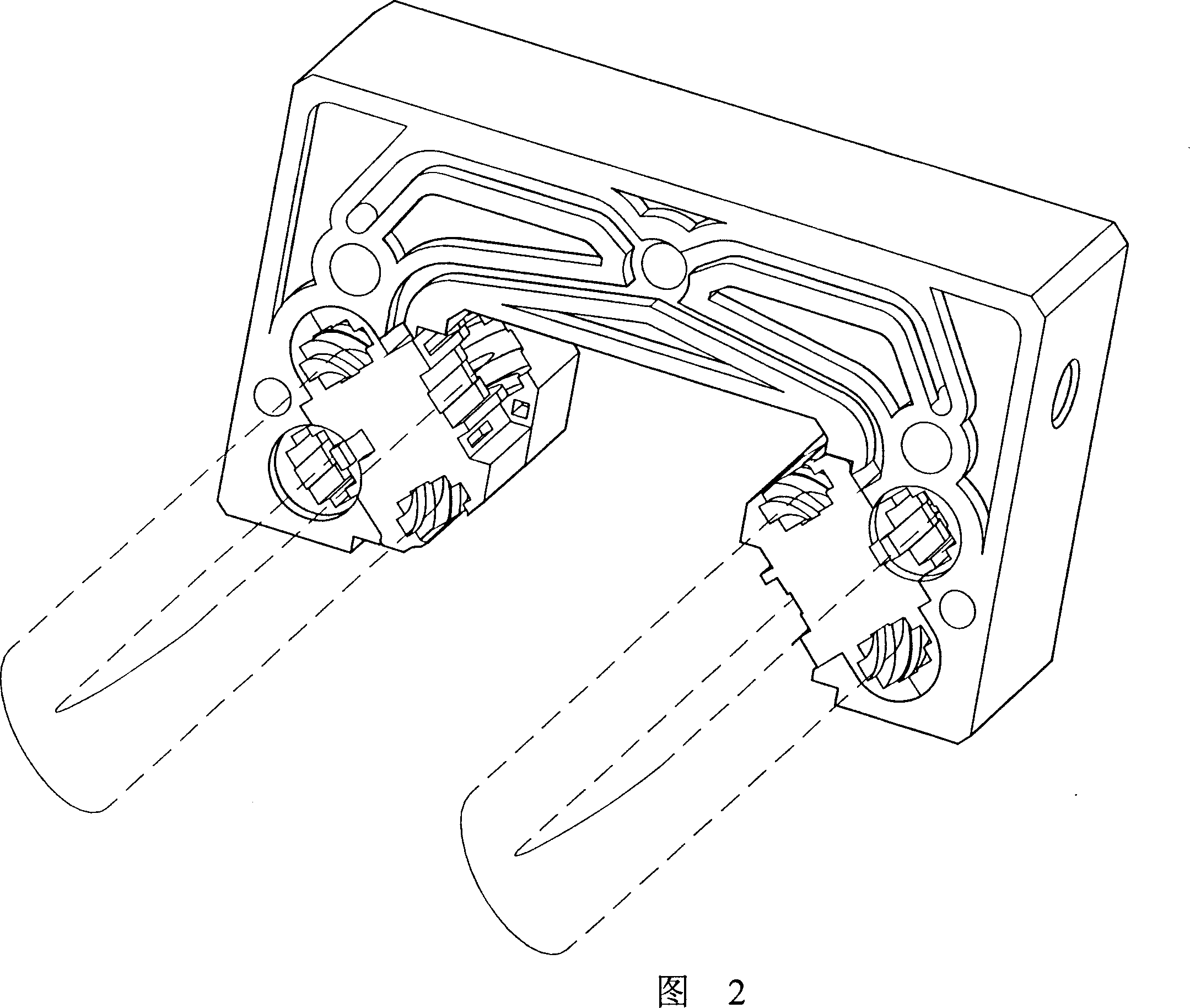

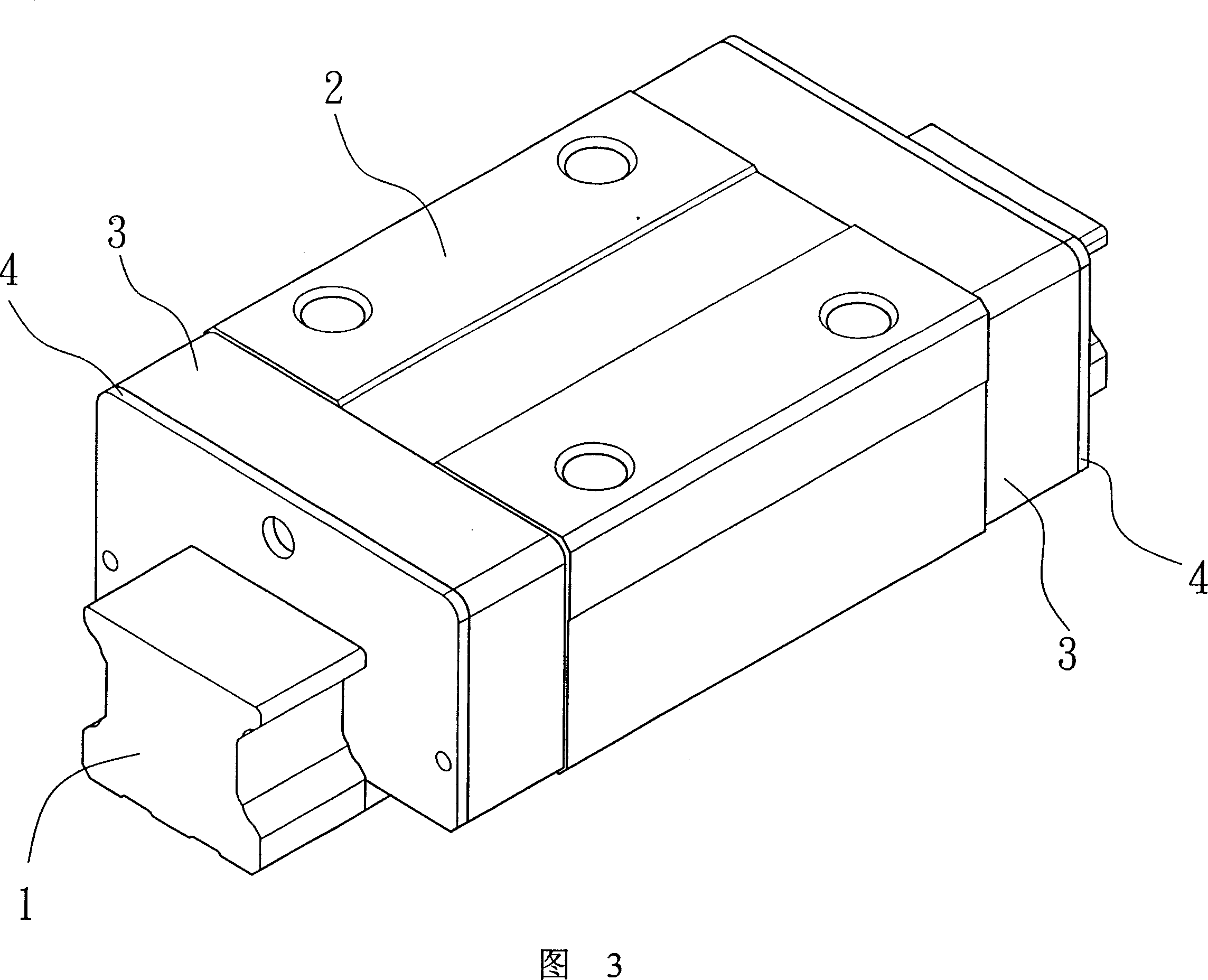

[0033] As shown in Figures 3 to 5, the return system of the linear slide rail provided by the present invention mainly includes: a slide rail 1, a set of sliders 2 that fit the slide rail 1, and two abutment sliders 2 The end cover 3 at the end, the oil scraper 4 and most of the rolling elements 5 that join the end cover 3. Between the two sides of the slide rail 1, the slide block 2 and the end cover 3, there are upper and lower loop spaces (no number in the figure, as shown in Figure 5), for infinite rolling cycles of most rolling bodies 5.

[0034] As shown in FIG. 6 , it is an exploded view of the assembly of the end cap of the present invention. The main key feature of the present invention is that the end cap 3 is composed of an end cap body 31, a cover plate 32 and an outer en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com