Drive unit

A driving unit and driving gear technology, which is applied to electric vehicles, power units, motion deposition, etc., can solve the problems of the increased cost of the in-wheel motor 30 and the complex structure of the in-wheel motor 30, and achieves the realization of the number of parts and the shortening of the axial dimension. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] Hereinafter, embodiments of the present invention will be described with reference to the drawings. It should be noted that the drawings are viewed along the direction of the symbols.

[0094] 【Example】

[0095] The drive unit according to the present invention can be used as a drive source for an electric vehicle, a trolley, or an industrial machine, and its application is not particularly limited. An example of installation in an electric vehicle will be described below. Front, rear, left and right are based on the driver driving the electric vehicle.

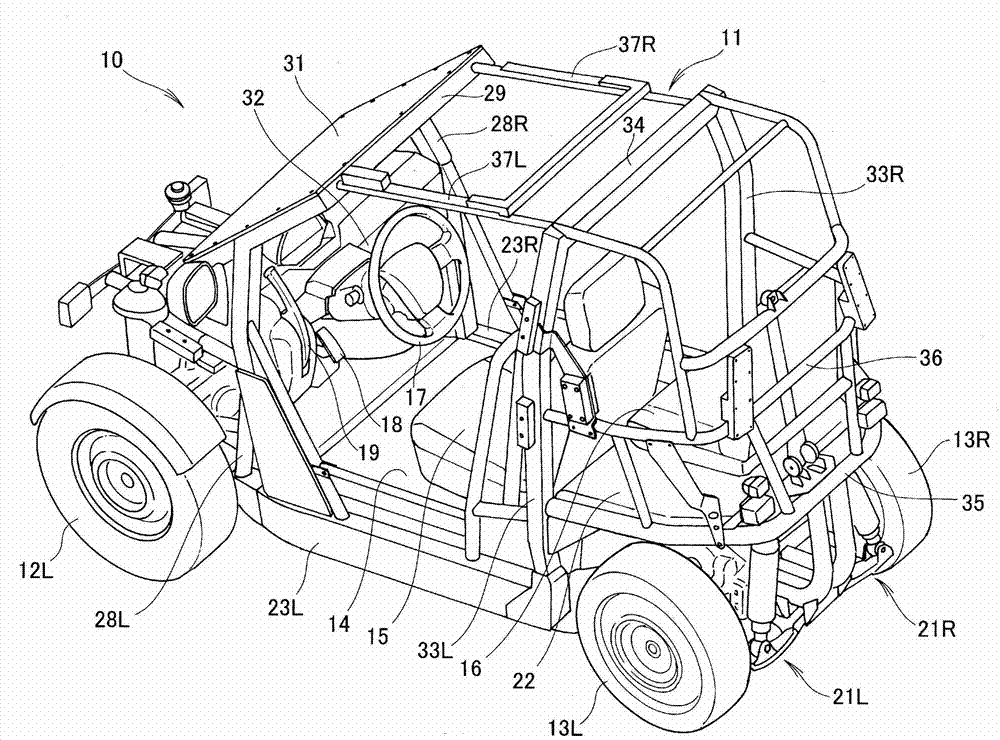

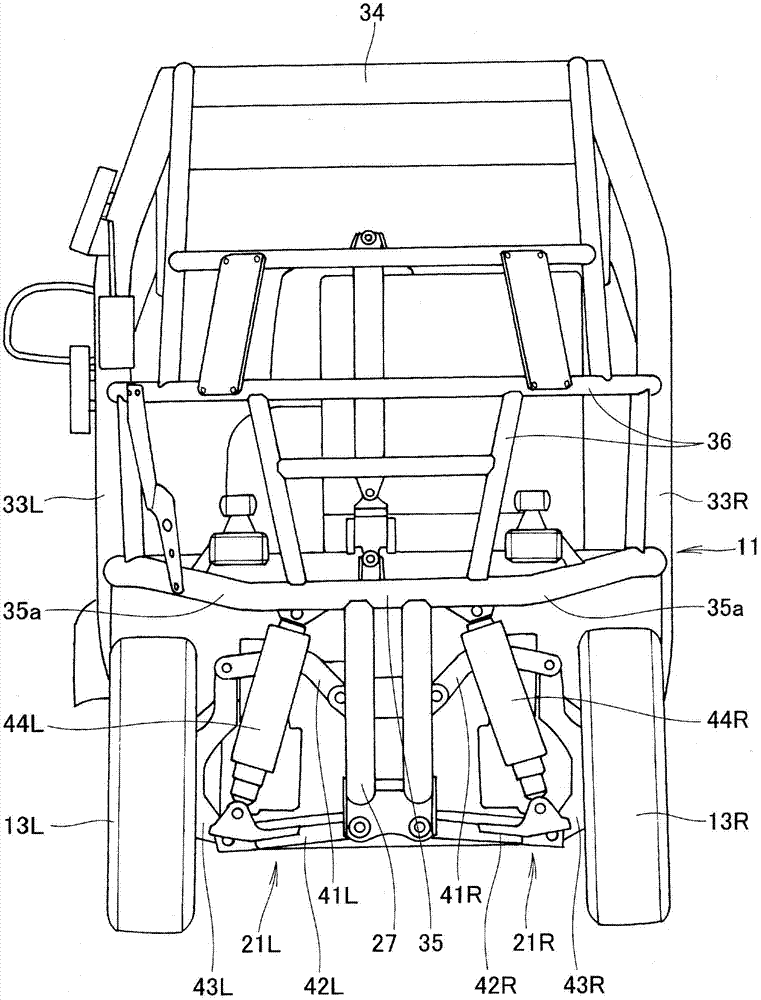

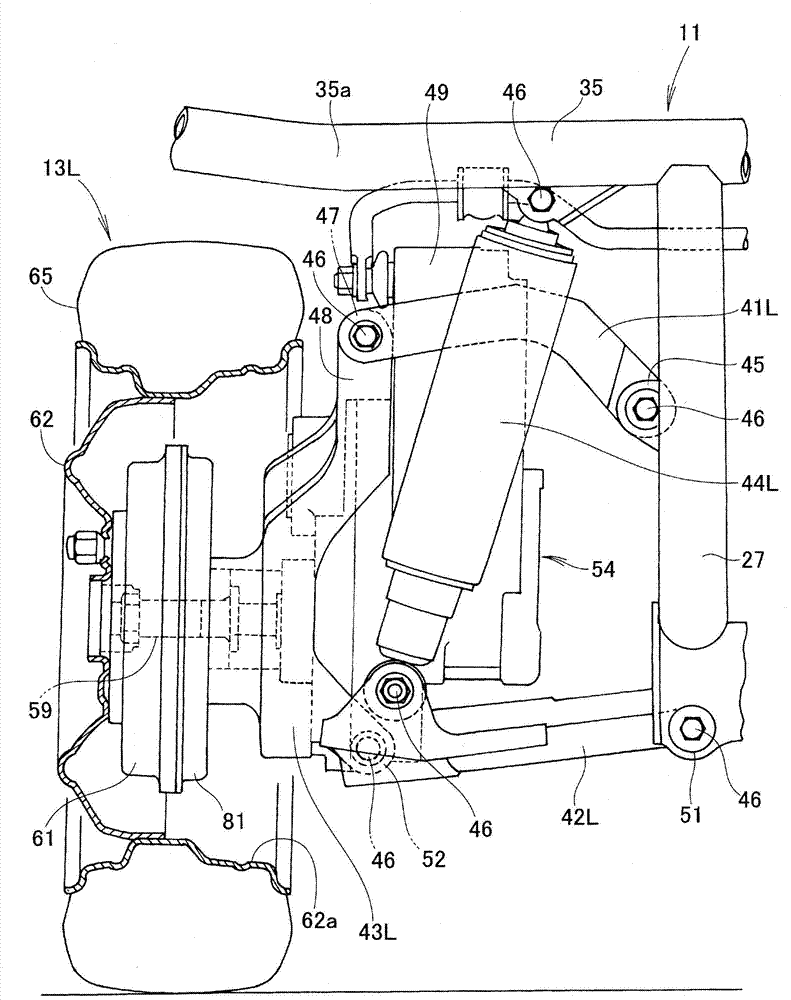

[0096] Such as figure 1 As shown, the electric vehicle 10 is a narrow vehicle, and the frame 11 is equipped with a front wheel 12L (L is a suffix indicating left. The same below) and rear wheels 13L, 13R (R is a suffix indicating right. The same below). A driver's seat 15 is provided on the floor 14, a passenger's seat 16 (Japanese: passenger's seat) is provided behind the driver's seat 15, and a steering wheel 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com