Rail transit gearbox

A rail transit and gearbox technology, which is applied in gear transmission, gear lubrication/cooling, belt/chain/gear, etc. It can solve the problem of high noise of the gearbox, unbalanced lubrication of the supporting bearing of the gearbox, oil leakage, etc. problems, to achieve the effect of improving position accuracy, avoiding secondary clamping, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

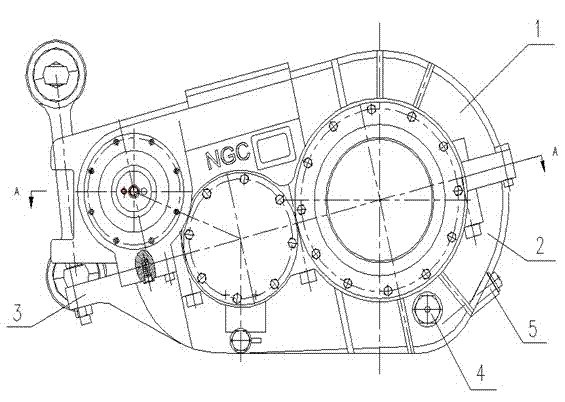

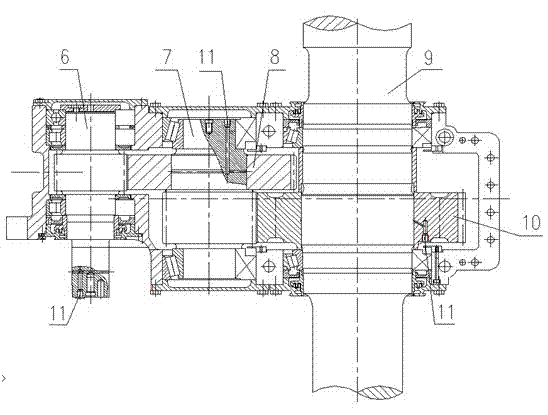

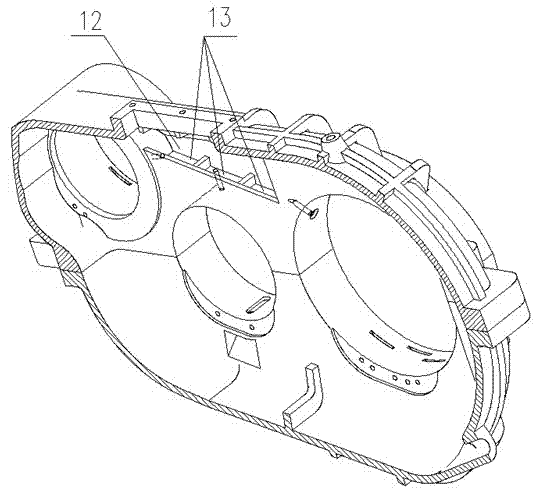

[0019] The accompanying drawing discloses a non-limiting structural diagram of a specific embodiment involved in the design invention, and the design invention will be further described below in conjunction with the accompanying drawings.

[0020] Depend on figure 1 and figure 2 It can be seen that the box body of the rail transit gearbox is composed of an upper box body 1 and a lower box body 2, and the lower box body 2 is provided with a boom mounting seat 3, and the axis lines of the input gear shaft 6, the intermediate gear shaft 7 and the main shaft 9 Parallel to each other, the connecting line of their axes forms a triangle, the joint surface of the upper box body 1 and the lower box body 2 passes through the axis line of the intermediate gear shaft 7 and the main shaft 9, and is parallel to the top of the upper box body 1; the input gear The shaft 6 is installed on the upper box body 1, the external journal of the input gear shaft 1 and the two ends of the main shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com