Outer sheath of fire-resistant cable, and production method thereof

A flame-retardant cable and production method technology, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as diffusion and threats to the life safety of rescuers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

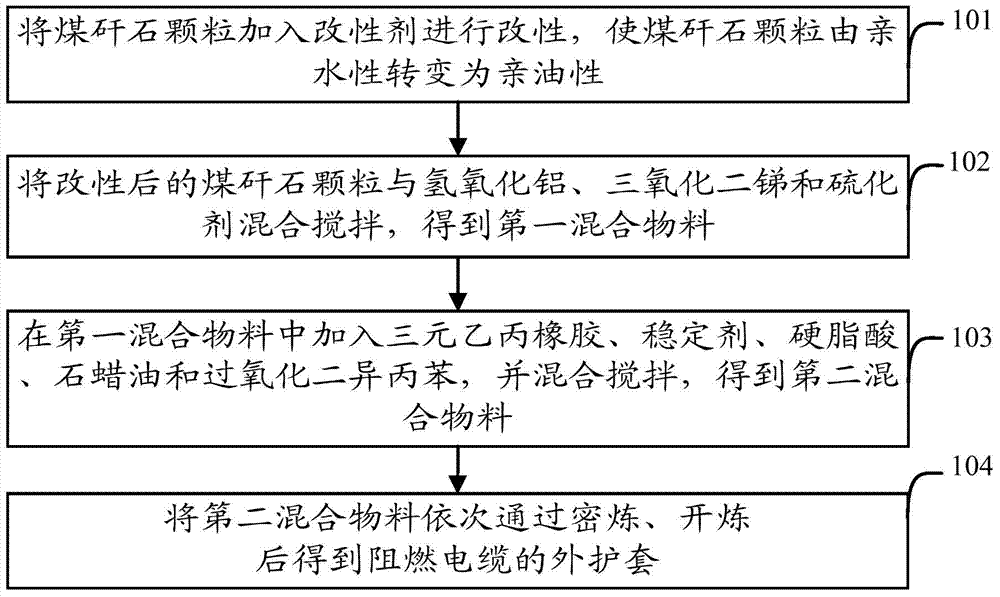

Method used

Image

Examples

Embodiment 2

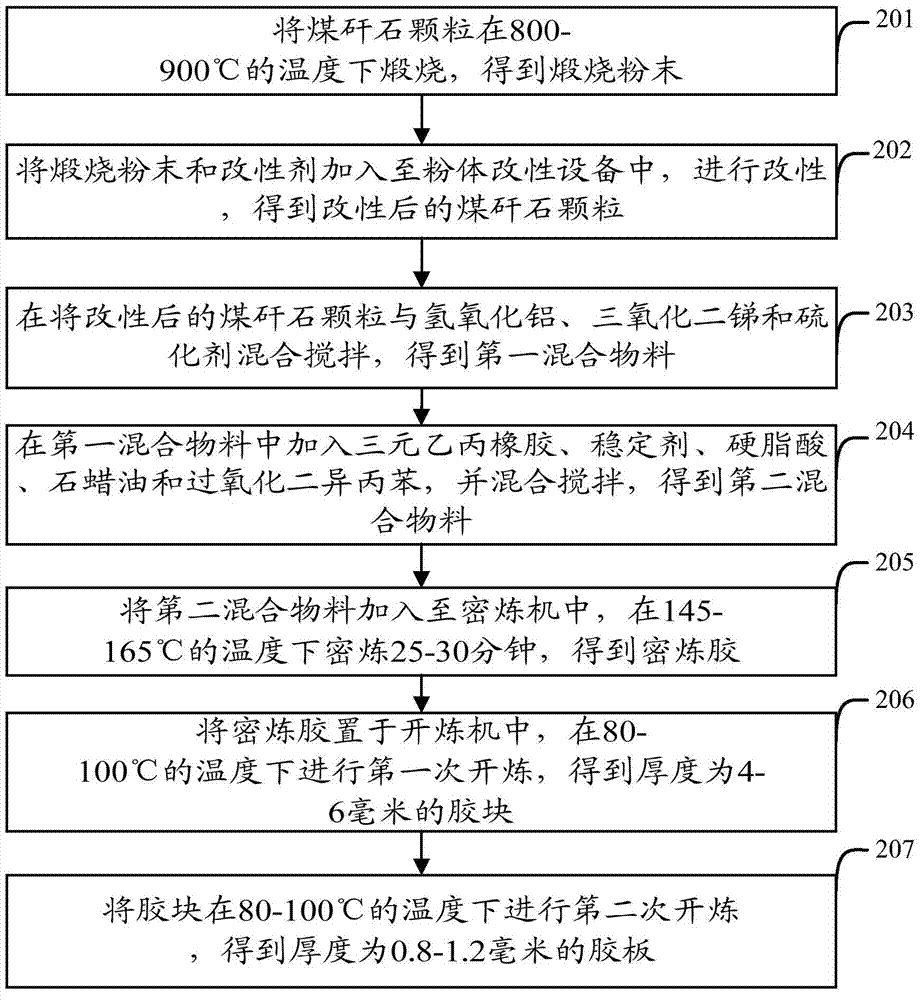

[0022] Please refer to figure 2 , the manufacturing method of the outer sheath of the present embodiment comprises the following steps:

[0023] Step 201: calcining coal gangue particles at a temperature of 800-900° C. to obtain calcined powder;

[0024] In step 201, the coal gangue particles are calcined to maximize the evaporation of the moisture contained in them, and during the calcination process, suspension calcination can be used during the calcination process at 800-900°C (preferably 850°C) The purpose of calcination is to remove the crystallization water (hydroxyl SUI) in the lattice of coal gangue particles through high temperature, volatilize organic matter, make the pores in the structure open, and improve the adsorption force and activity. Specifically, the coal after calcination The water content of gangue powder is less than 2%.

[0025] Step 202: adding the calcined powder and the modifier to the powder modification equipment for modification to obtain modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com