Immersion type plastic pipe sizing device

A plastic pipe and sizing technology, which is applied to tubular objects, other household appliances, household appliances, etc., can solve the problems that the cooling speed cannot keep up, the pipe cannot be cooled, and the production cost of the pipe is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

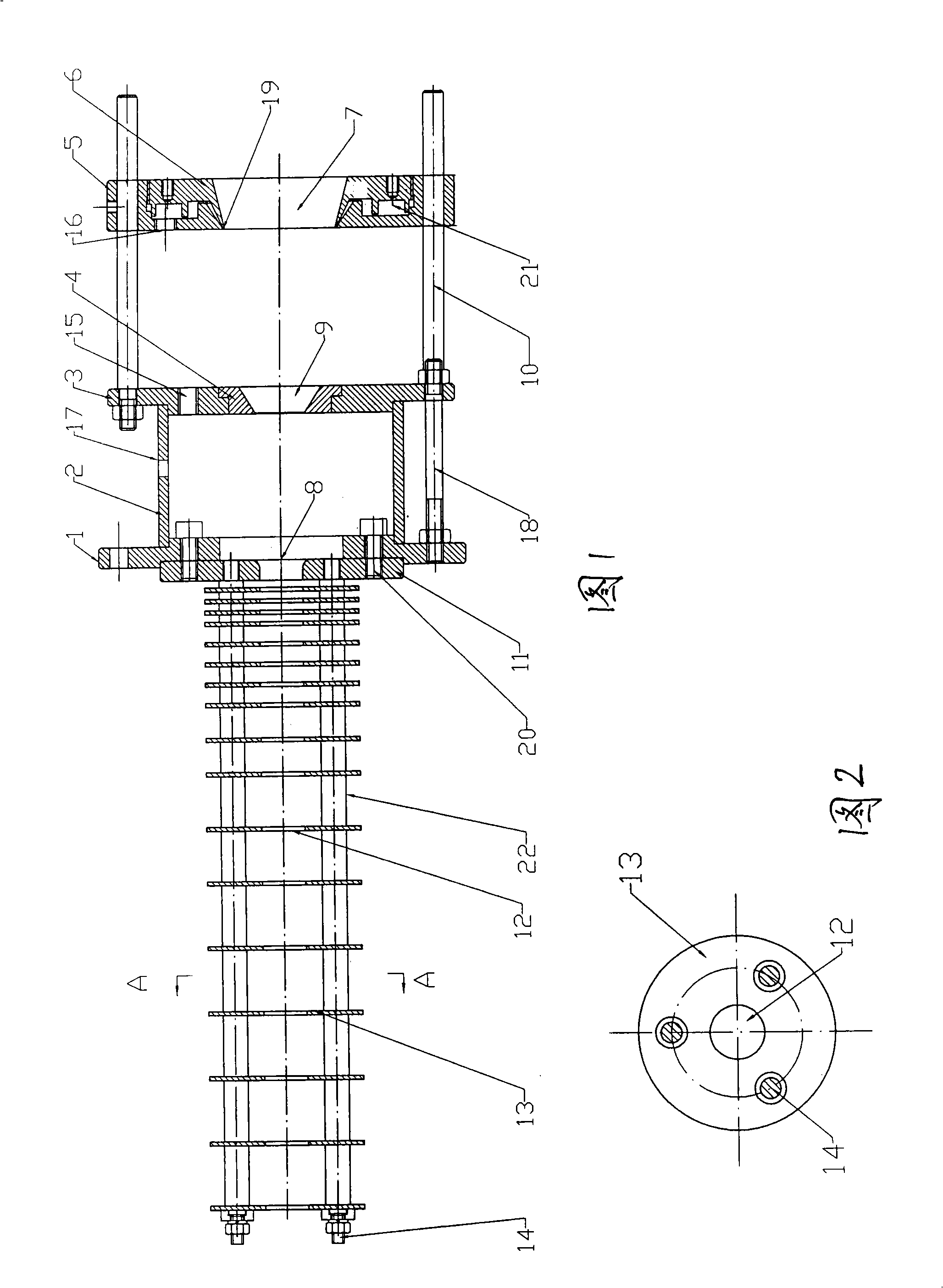

[0014] Referring to the accompanying drawings, the water-immersed plastic pipe sizing device includes a hollow fixed plate 1 connected to the side wall of the cooling tank. Along the advancing direction of the plastic pipe, a lamination base 11 is installed on the left side of the hollow fixed plate 1. The base 11 and the hollow fixed plate 1 are connected together by bolts 20, and the central part of the lamination base 11 is provided with a plastic pipe inlet 8, and the right side of the hollow fixed plate 1 is connected with a connecting plate 3 through a water bath cover 2, and the connecting plate 3 and the hollow fixed plate 1 are provided with connecting bolts 18, the middle part of the connecting plate 3 is equipped with a guide sleeve 4, the center of the guide sleeve 4 is provided with a plastic pipe guide port 9, the hollow fixed plate 1, the water bath cover 2 and the connecting plate 3 together form a water bath, a water inlet 15 is provided on the connecting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com