Patents

Literature

38results about How to "Uniform lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

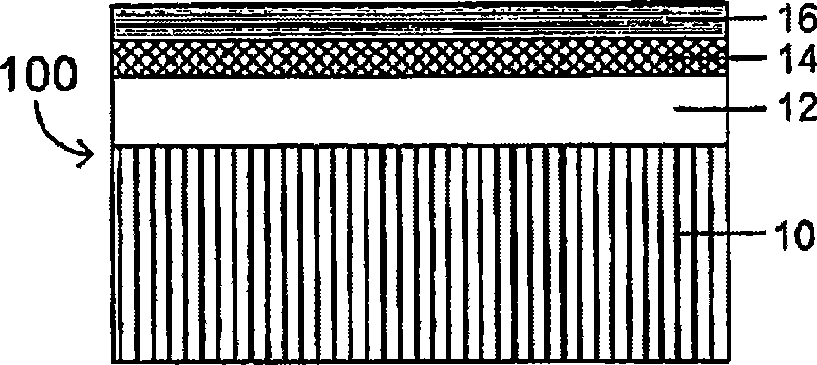

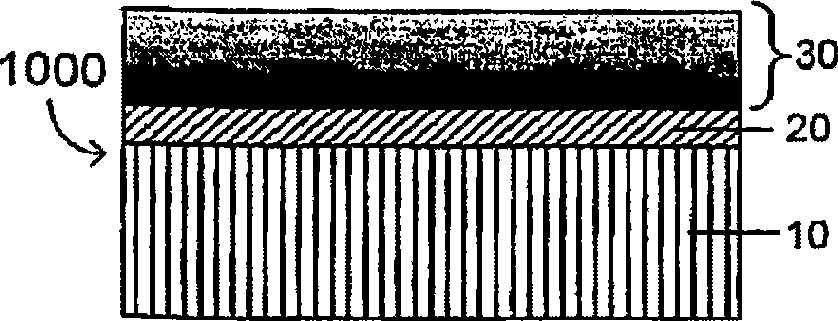

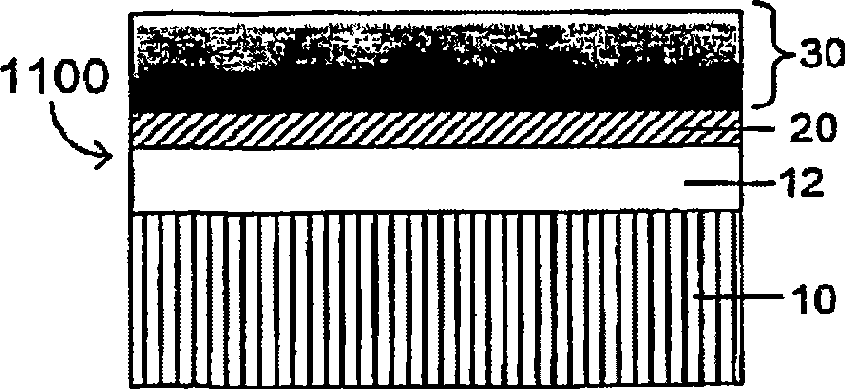

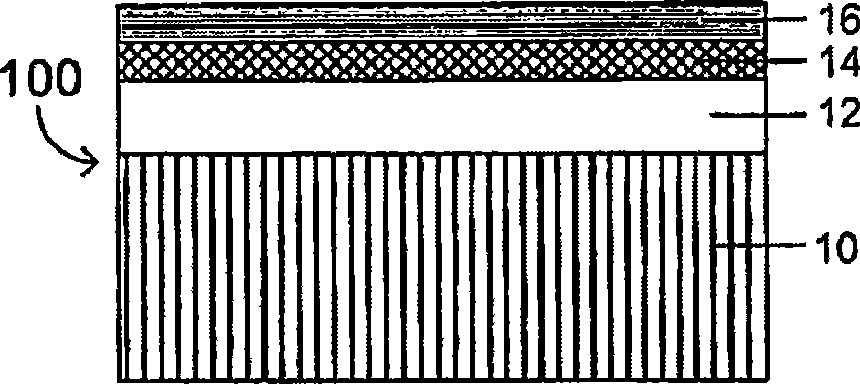

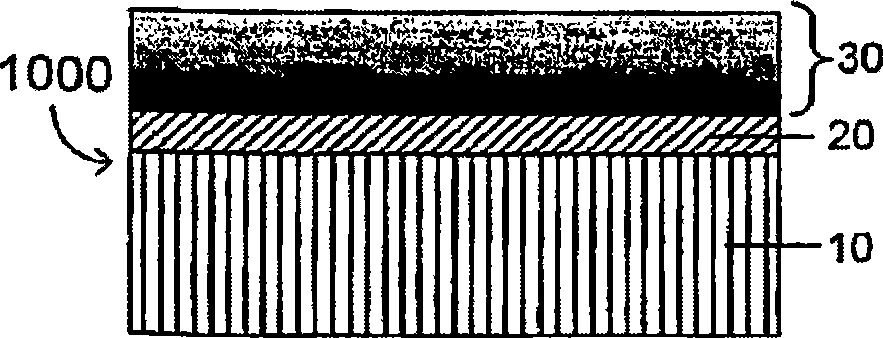

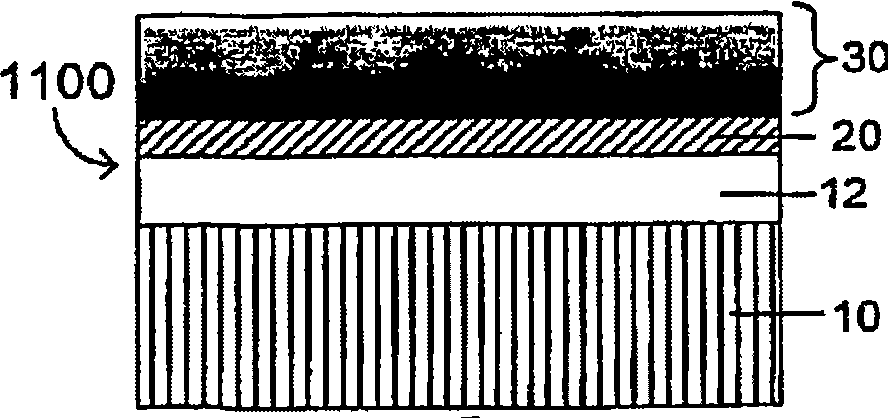

Antifriction coatings, methods of producing such coatings and articles including such coatings

InactiveCN101426590AUniform lubricationEvenly lubricated surfacePretreated surfacesMetallic material coating processesMetallurgyLubricant

A coated substrate and a process for forming the coated substrate, including a first lubricious coating layer overlying the substrate, the first lubricious coating layer including a first lubricant providing to the first lubricious coating layer a first coefficient of friction; and a second lubricious coating layer overlying the first lubricious coating layer, the second lubricious coating layer including a second lubricant providing to the second lubricious coating layer a second coefficient of friction, in which the second coefficient of friction is greater than the first coefficient of friction.

Owner:ATOTECH DEUT GMBH

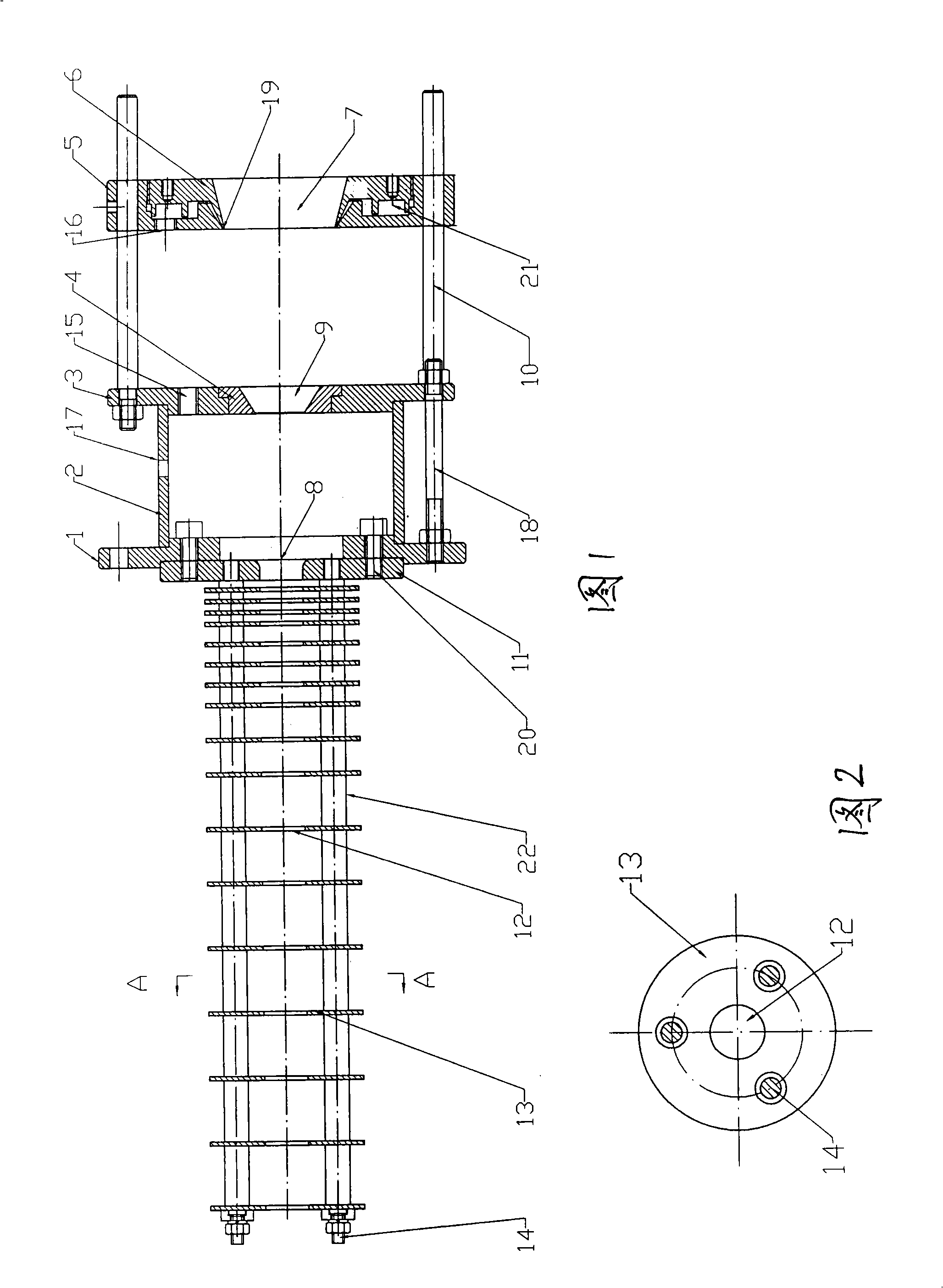

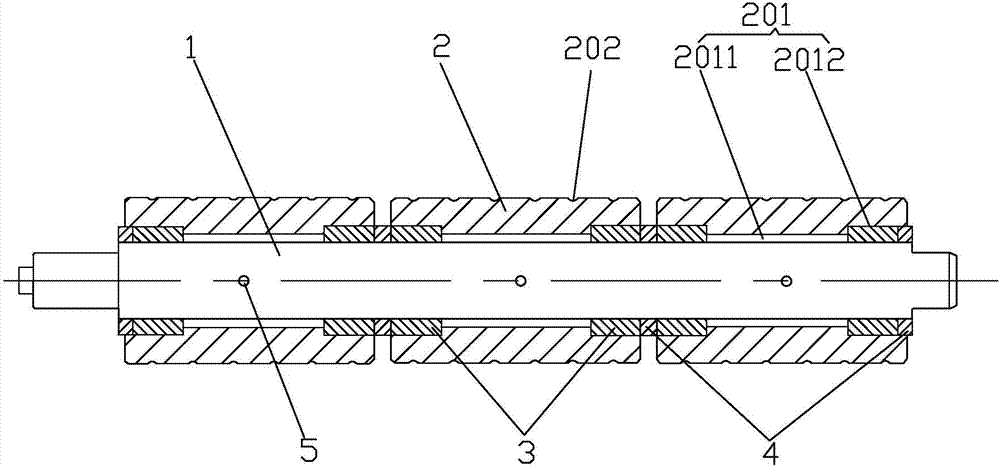

Immersion type plastic pipe sizing device

The invention discloses a sizing device of a submerged plastic tubular product. A lamination base is arranged at one side of a hollow fixing disk; the central part of the lamination base is provided with an inlet of the plastic tubular product; the other side of the hollow fixing disk is connected with a connection disk by a water bath hood; the middle position of the connection disk is provided with a guide sleeve; a supporting rod extending to the outside is arranged on the connection disk; a cooling water ring far from the connection disk is arranged on the supporting rod; the middle position of the cooling water ring is provided with an adjustable water disk; an adjustable water gap is formed between the cooling water ring and the adjustable water disk; the central position of the adjustable water disk is provided with a plastic tubular product feed opening corresponding to an extruding head of the extruder of the plastic tubular product; a supporting rod is parallel arranged on the lamination base; the supporting rod is sheathed and provided with a plurality of alternatively arranged laminations; the central position of the lamination is provided with a tubular product sizing opening corresponding to the aperture of the inlet of the plastic tubular product. The sizing device of the tubular product has fast cooling speed and the manufacture efficiency is improved by more than 2 times than that of the devices of the same category.

Owner:潍坊凯德塑料机械有限公司

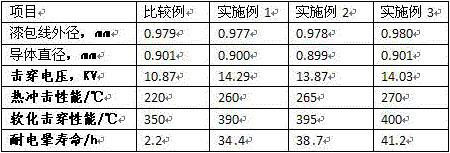

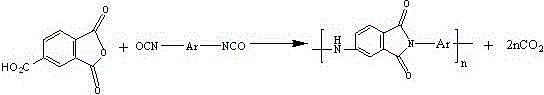

Method for preparing corona-resistant polyamide-imide enameled wire paint

InactiveCN106811112ANot easy to precipitate and stratifyEasy to controlCoatingsHeat resistanceLacquer

The invention relates to a wire enamel manufacturing technology, in particular to a preparation method of an enameled wire varnish with high temperature resistance, good corona resistance and flexibility. The method comprises four steps: (1) pretreatment of nanoscale inorganic oxide particles (2) preparation of polyamide-imide resin solution (3) preparation of slurry (4) preparation of corona-resistant polyamide-imide wire enamel. First, the inorganic nano-oxide particles are pretreated with a coupling agent, the second step is to prepare a polyamide-imide resin solution, and the third step is to combine the pretreated nano-scale inorganic oxide particles with the polyamide-imide resin solution In the grinding machine, the slurry is prepared by grinding and dispersing, and finally the slurry is evenly stirred with a general-purpose polyamide-imide wire enamel to obtain a corona polyamide-imide wire enamel. Compared with the prior art, the corona-resistant enameled wire varnish produced by the invention is not easy to precipitate and delaminate, the production process is easy to control, and the lubricity and heat resistance are balanced.

Owner:TIANHENGDA ELECTRICAL ENG SCI & TECH CO LTD

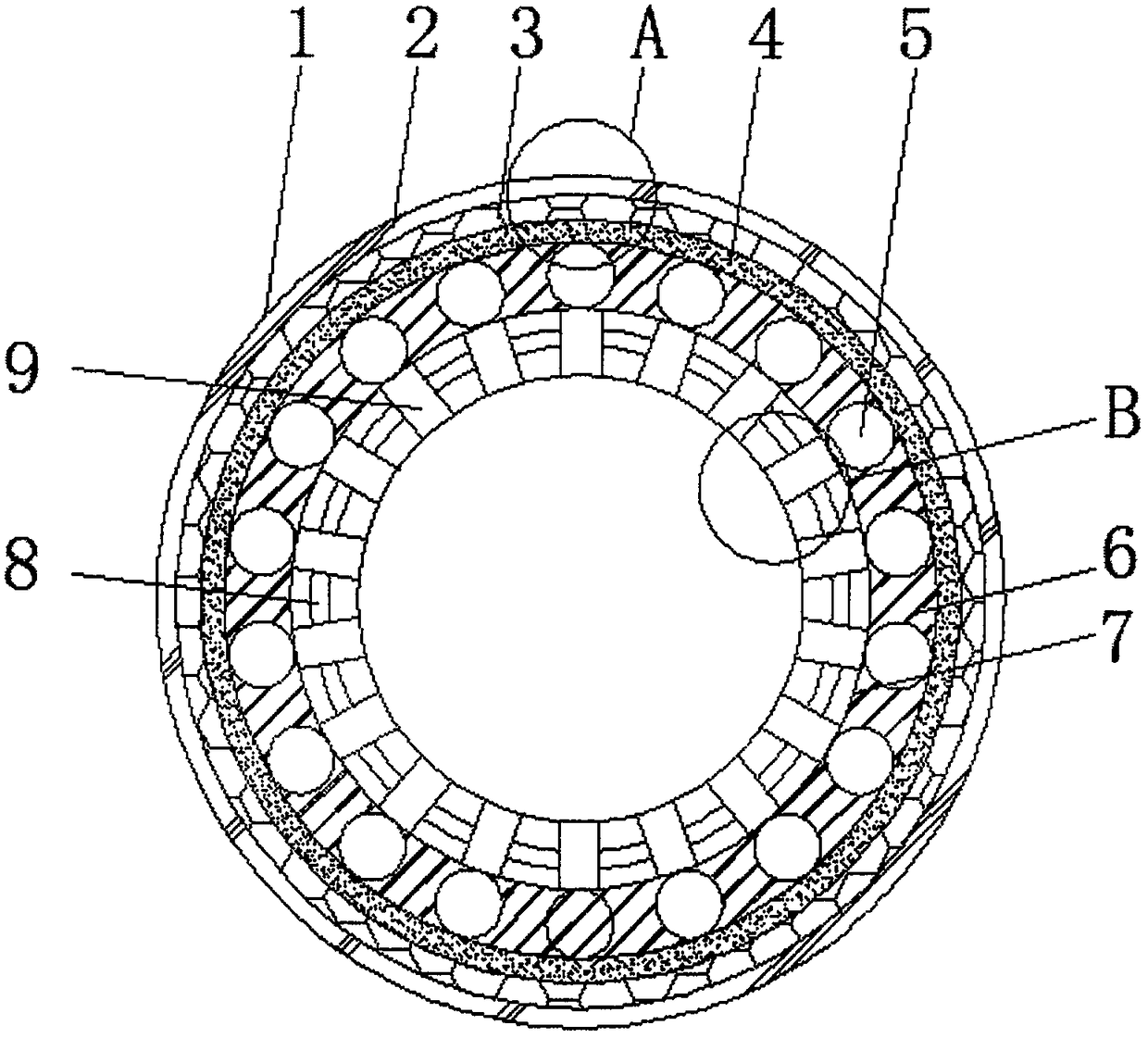

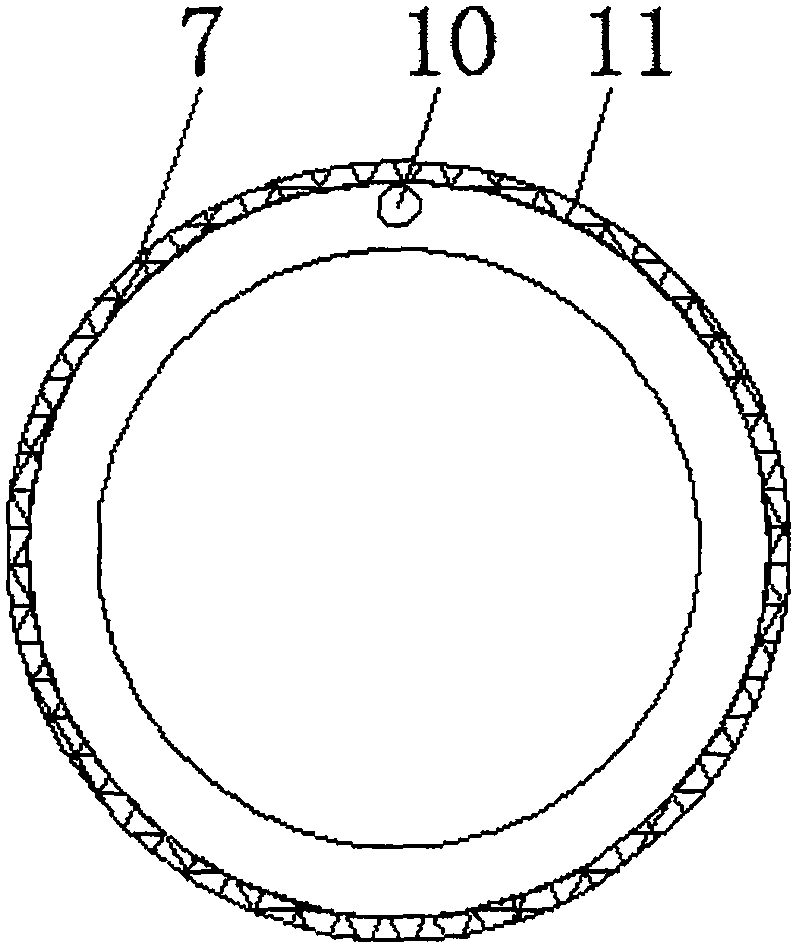

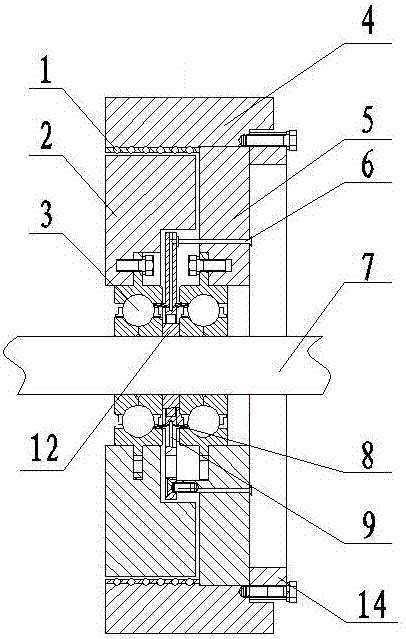

High-speed paper machine bearing

InactiveCN109236854AEasy to disassembleEasy to installRolling contact bearingsElastic bearingsInsulation layerWear resistant

The invention discloses a high-speed paper machine bearing, which comprises an outer ring, balls, an inner ring and a retainer; a wear resistant layer, a waterproof layer and a heat insulation layer are uniformly arranged on the inside wall of the outer ring; the inner ring is arranged on the inner side of the outer ring; anticorrosive layers are uniformly arranged on the outside wall of the innerring; oil guiding grooves are uniformly formed in the inner ring; an oil duct is connected between the oil guiding grooves; an oil inlet is formed in the top end of the inner ring; the retainer is mounted between the inner ring and the outer ring; the balls are uniformly arranged in the retainer; and sealing pieces are arranged at one end of a buffering piece. Clamping blocks, clamping grooves and bolt are mounted, so that dismounting and mounting of the balls are facilitated, clamping structures formed by the clamping blocks and the clamping grooves fix the balls in the retainer between theouter ring and the inner ring, and when the balls need to be taken out, all that is needed is to unscrew the bolts of the retainer and then pull out the clamping blocks from the clamping grooves, theballs can be taken out at any time.

Owner:WAFANGDIAN OUDE BEARING MFG

Gear transmission structure

The invention provides a gear transmission structure comprising a rotating shaft and a gear. The rotating shaft is provided with an oil inlet channel and an oil communication groove. The oil inlet channel is arranged inside the rotating shaft. The oil communication groove is arranged on the outer wall of the rotating shaft and communicates with the oil inlet channel. Oil communication holes are formed inside the gear. The first end of each oil communication hole is arranged on a gear tooth of the gear or the surface where a root circle of the gear is located. The second end of each oil communication hole is arranged on the inner wall of the center hole. The gear is arranged on the rotating shaft in a sleeving manner, and the oil communication hole communicates with the oil communication groove. According to the gear transmission structure, lubricating oil is conveyed to the engagement position of the gear, so that the gear forms liquid dynamic pressure oil film at the engagement position, and the lubricating effect is guaranteed; it is guaranteed that the lubricating oil amount is uniform, the lubricating effect is uniform, and the lubricating oil is saved.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Ultra-hard laser crystal surface roughness machining method

The invention discloses an ultra-hard laser crystal surface roughness machining method. The method comprises the steps of grinding, rough polishing, precision ring polishing and the like. Through themethod, the grinding amount of each step in the grinding stage is strictly controlled by detecting the grinding particle size, and the subsurface defect is fundamentally overcome; and by adding a polishing aid, polishing liquid is dispersed and lubricated more uniformly, thus, the surface / subsurface defects are effectively prevented, the surface roughness of ultra-hard laser crystal is greatly lowered, and the roughness of two large surfaces of Nd:YAG crystals of the specifications of 125 mm*6 mm*6 mm and 133 mm*33 mm*3 mm reaches 0.3 nm.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

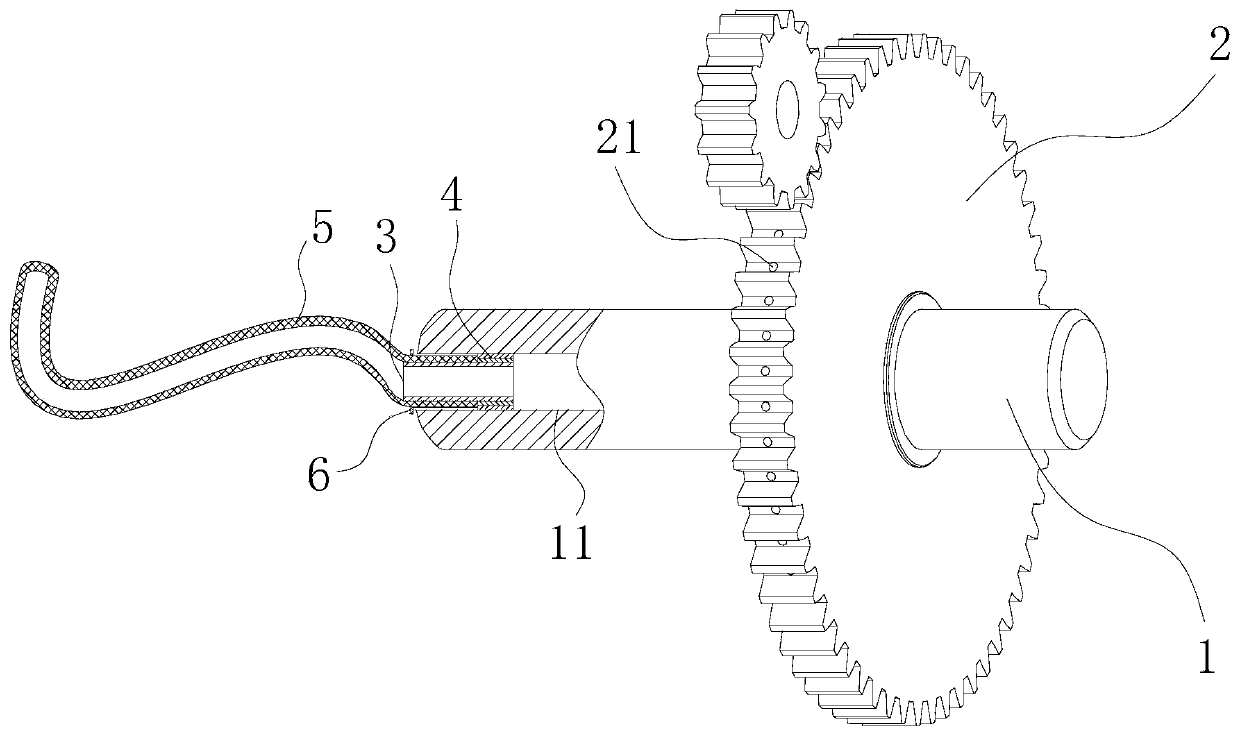

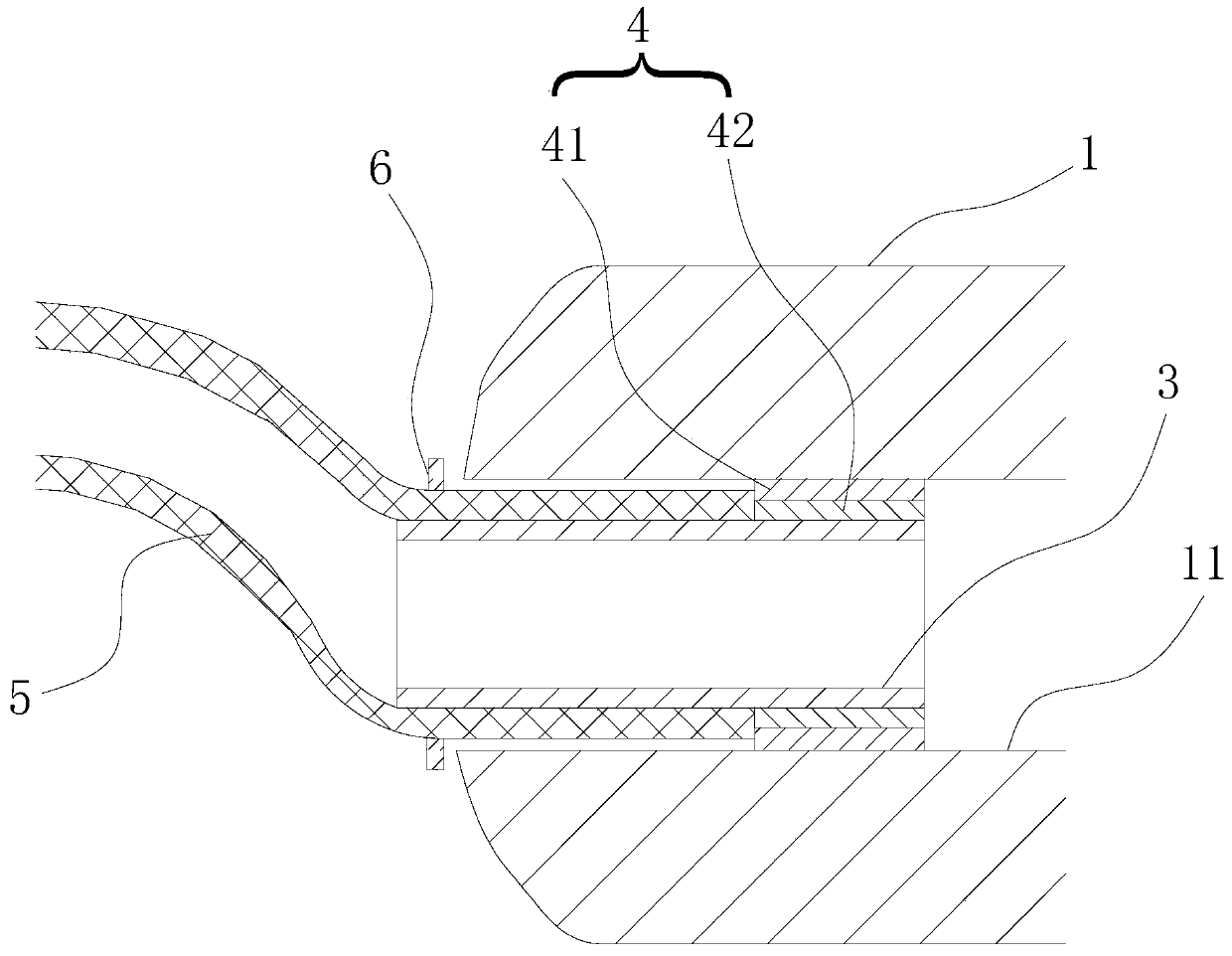

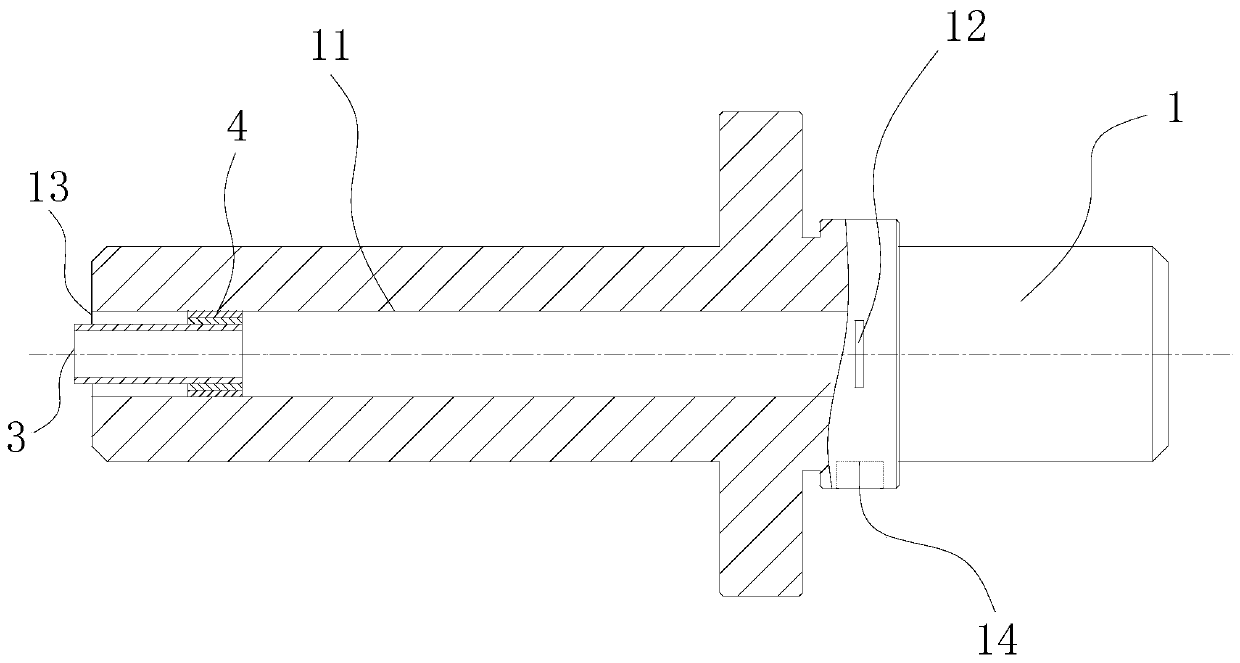

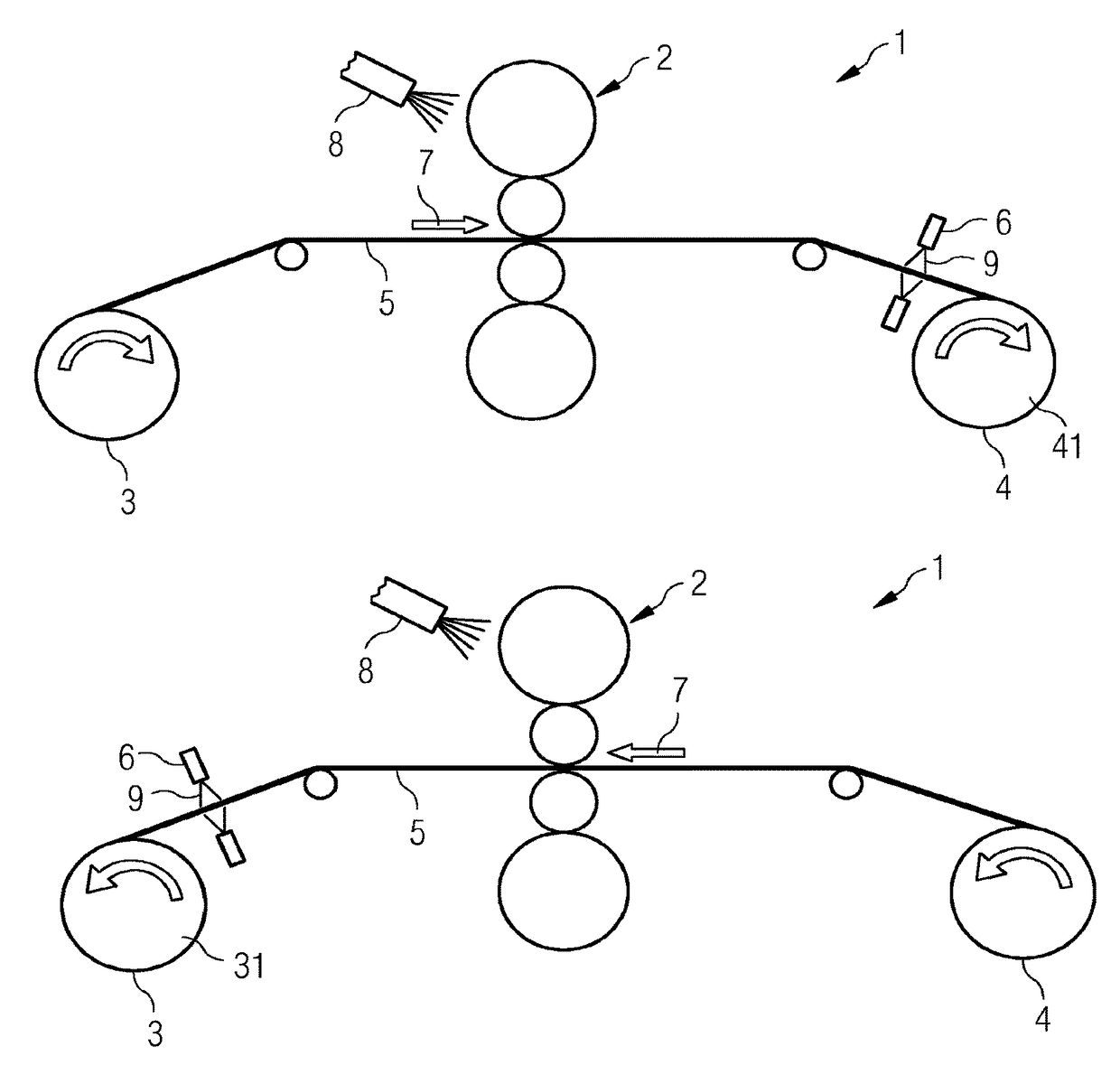

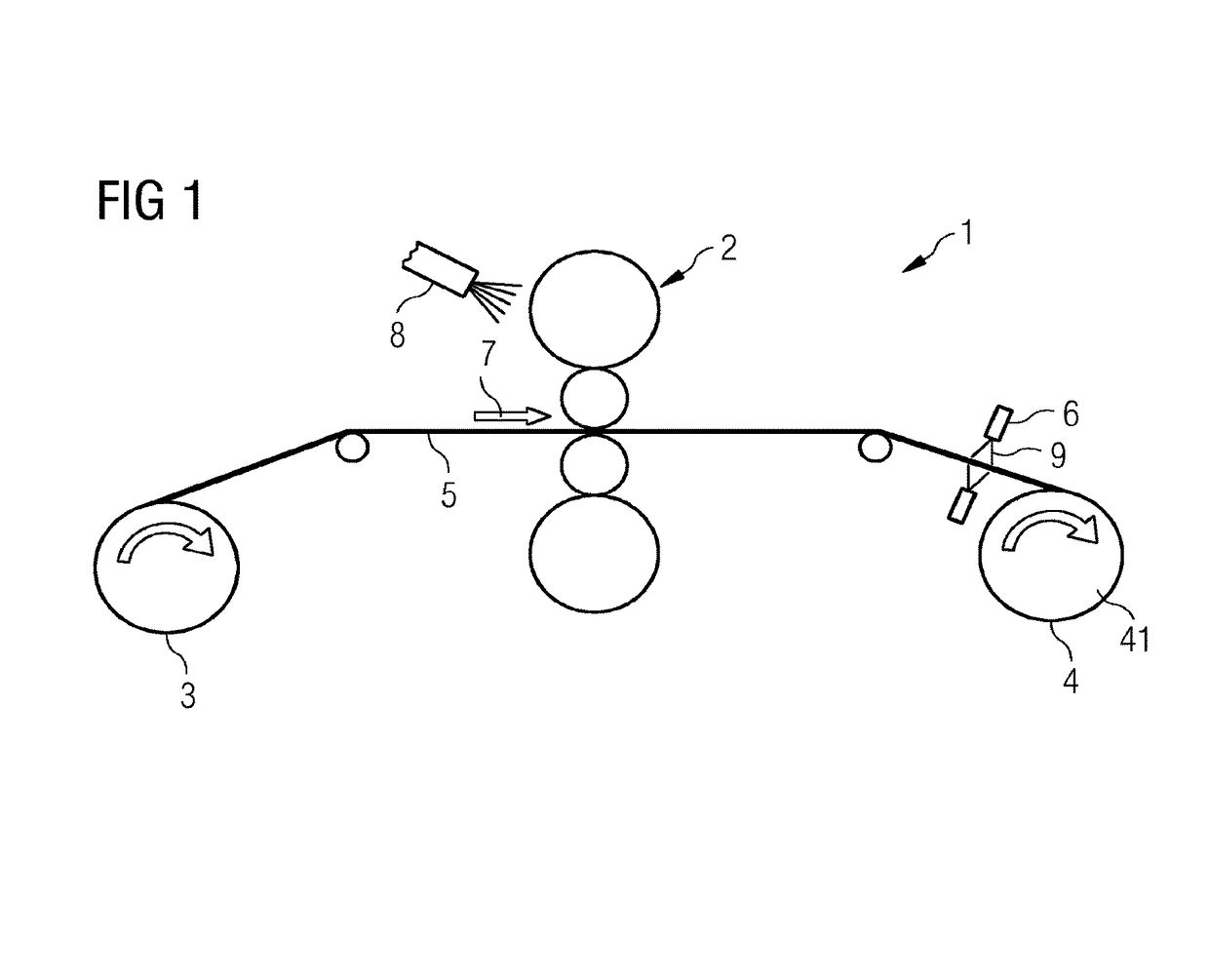

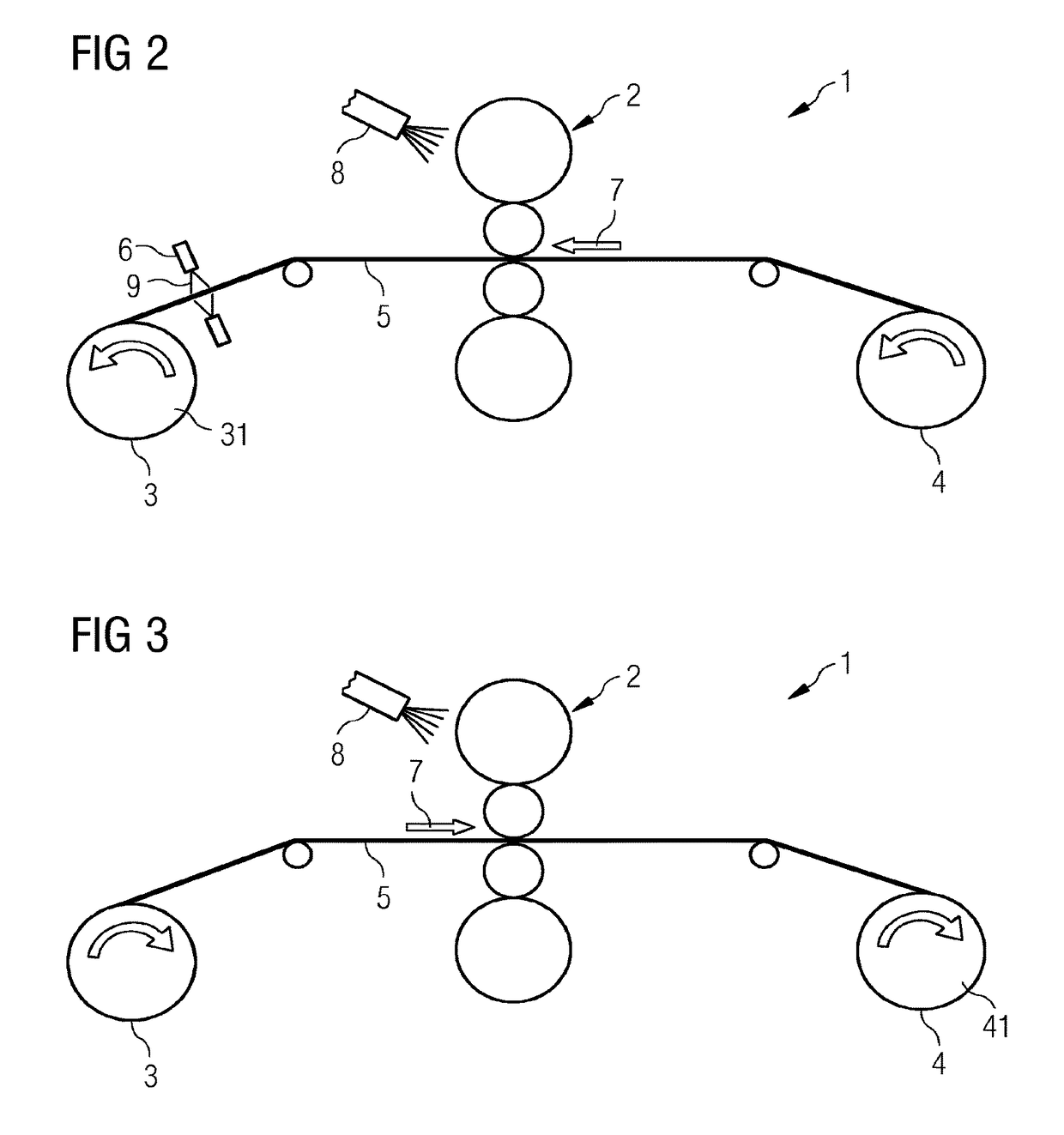

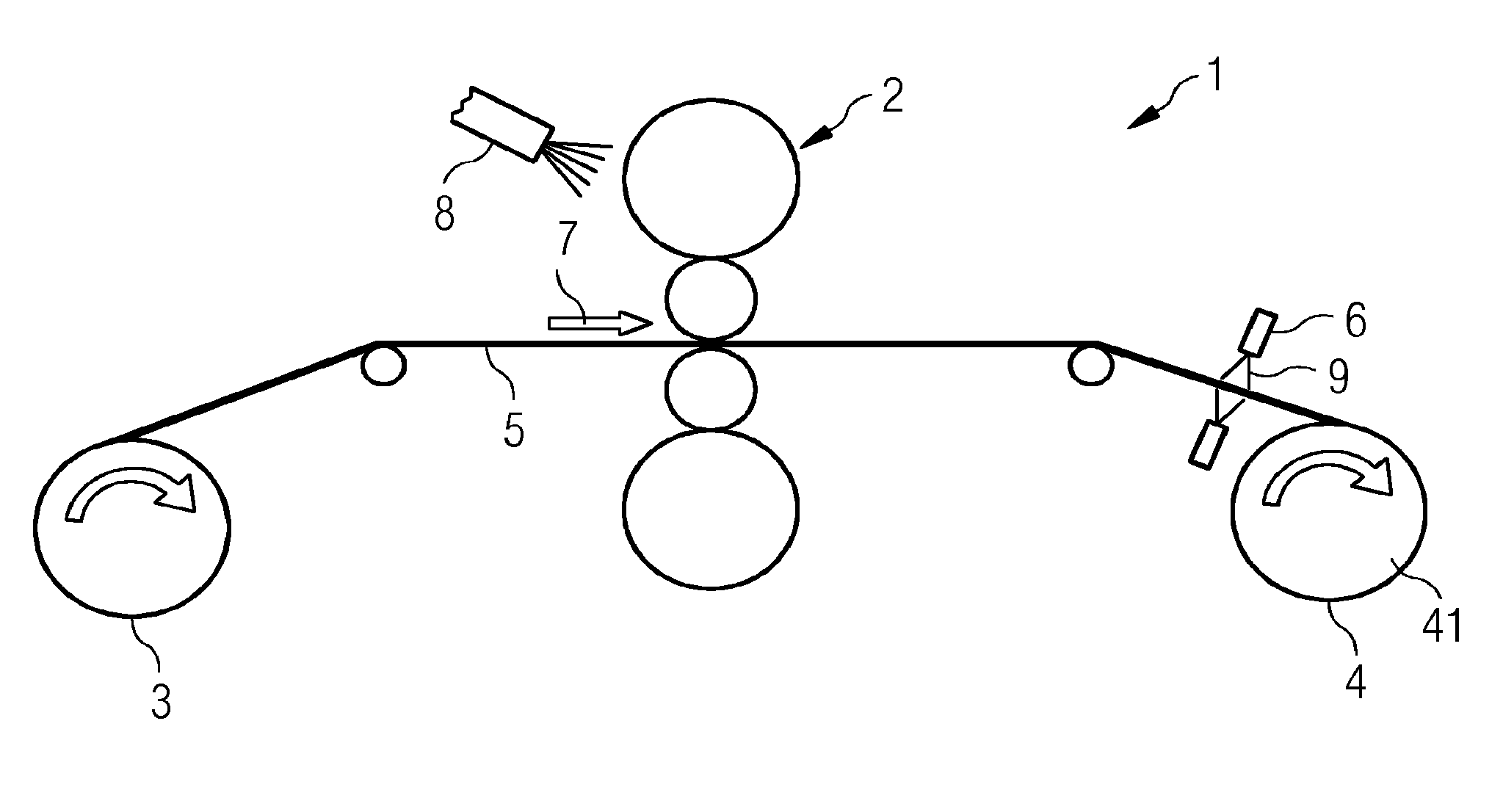

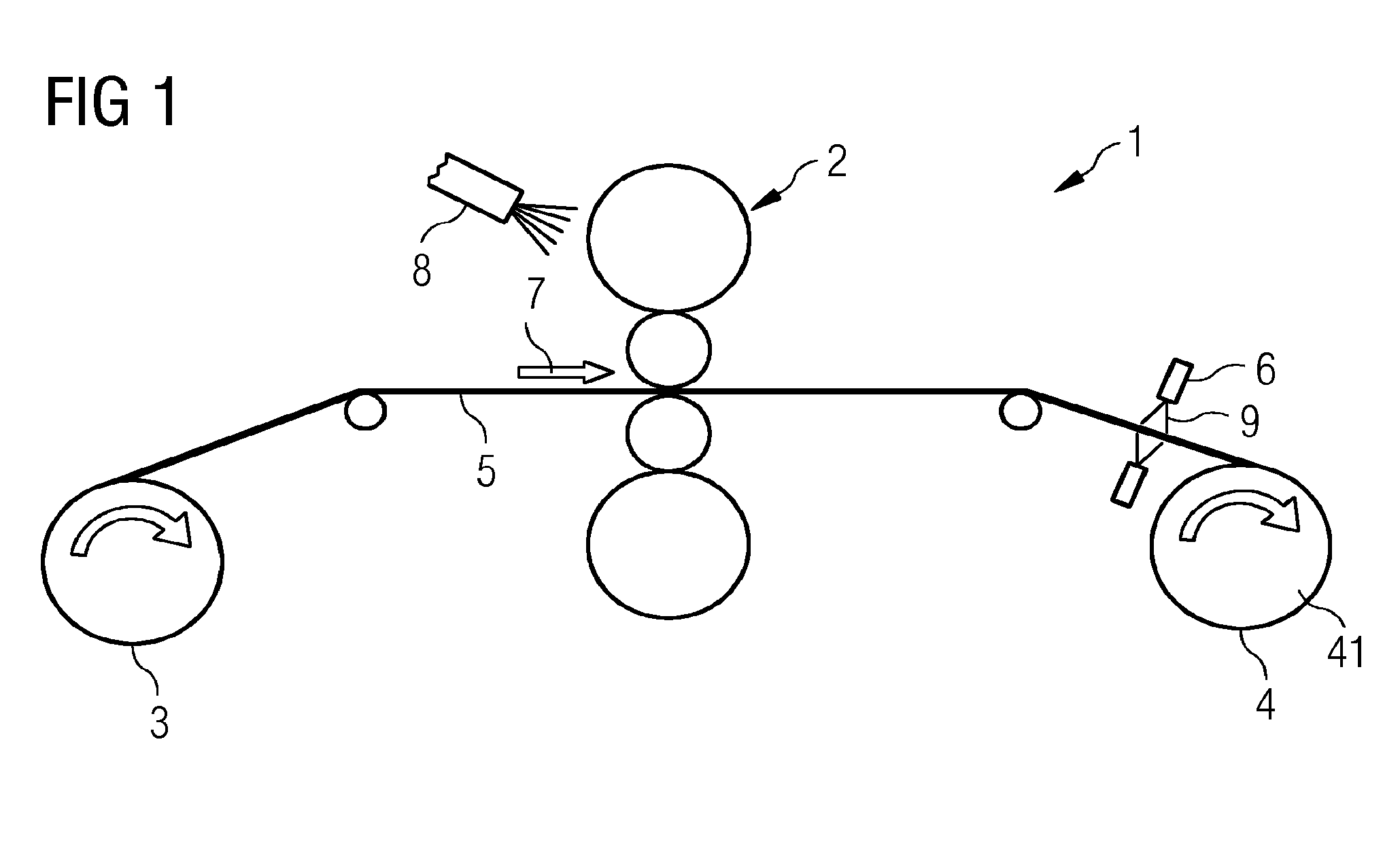

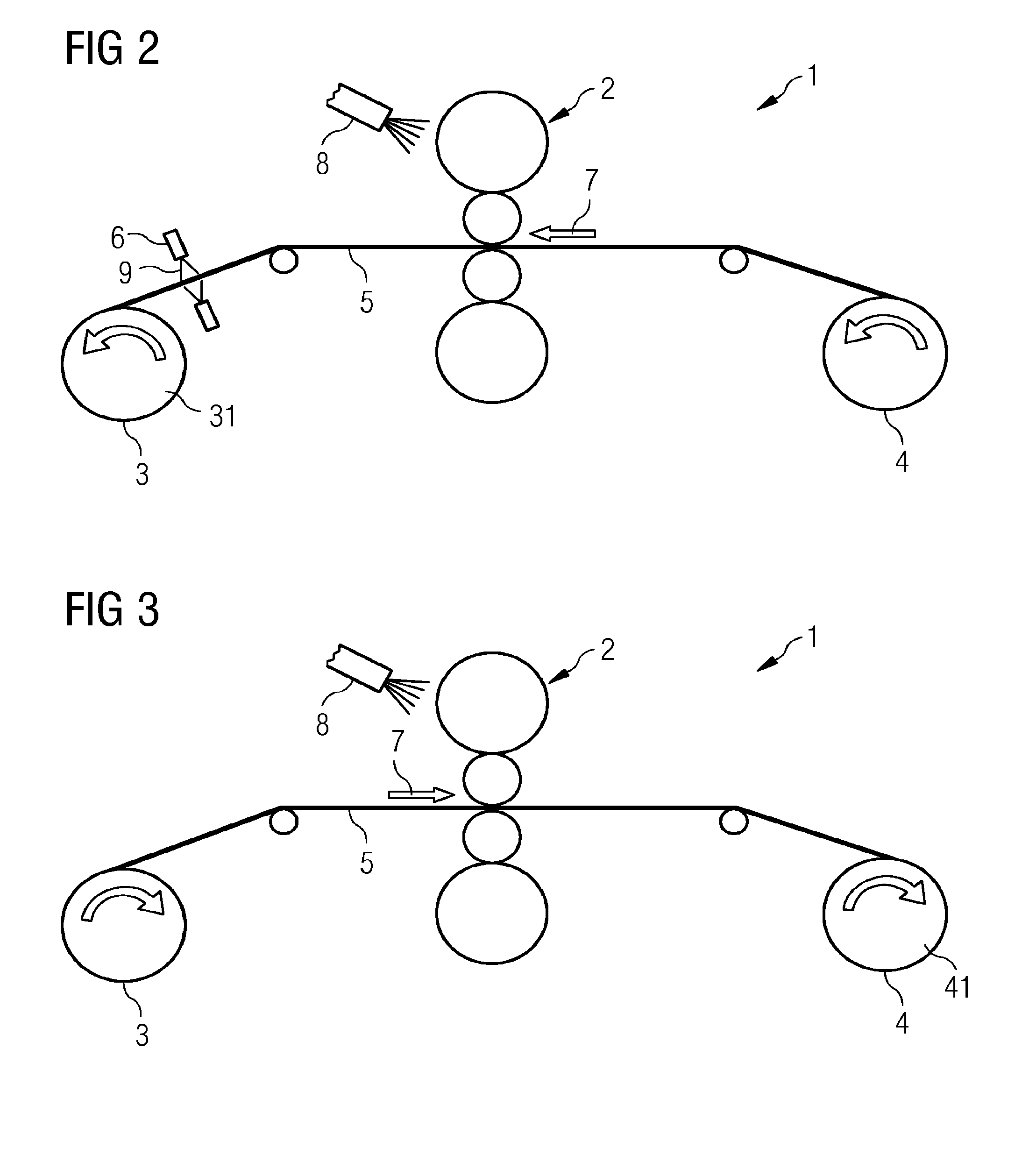

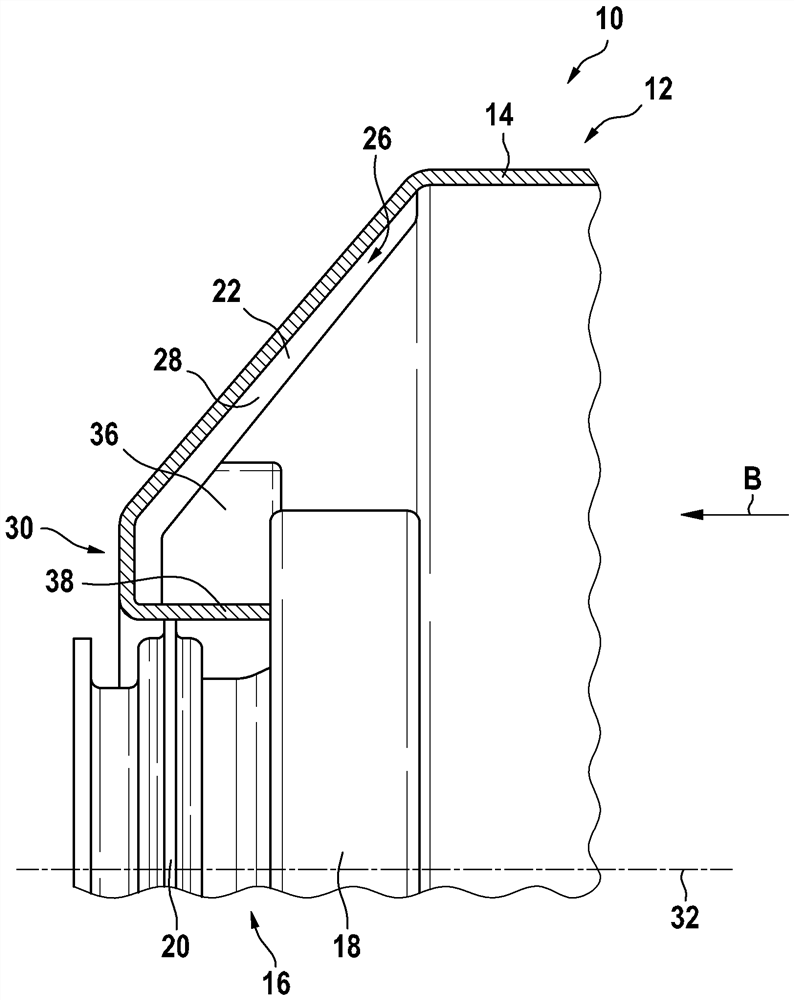

Reversing rolling mill and operating method for a reversing rolling mill

ActiveUS9815101B2Reduce fuel consumptionMaintaining good roll gap lubricationForging/pressing devicesWork cooling devicesStrip millEngineering

Operating method for a reversing rolling mill having at least one reversing rolling stand (2) for rolling a rolled metal stock (5), wherein the stock (5) passes the at least one reversing rolling stand (2) in a sequence of alternating direction passes (7) and after each pass, the stock is wound up by a reversing reel (3, 4), wherein only rolling oil, without water as a carrier medium, is applied to the stock (5) by rolling-oil applicator (6), between the at least one reversing rolling stand (2) and the winding-up reel (31, 41).

Owner:PRIMETALS TECH AUSTRIA GMBH

Antifriction coatings, methods of producing such coatings and articles including such coatings

InactiveCN101426590BUniform lubricationEvenly lubricated surfacePretreated surfacesMetallic material coating processesMetallurgyLubricant

A coated substrate and a process for forming the coated substrate, including a first lubricious coating layer overlying the substrate, the first lubricious coating layer including a first lubricant providing to the first lubricious coating layer a first coefficient of friction; and a second lubricious coating layer overlying the first lubricious coating layer, the second lubricious coating layer including a second lubricant providing to the second lubricious coating layer a second coefficient of friction, in which the second coefficient of friction is greater than the first coefficient of friction.

Owner:ATOTECH DEUT GMBH

Wide-adaptability double-mechanism self-lubricating bearing material

InactiveCN105400978AImprove plasticityImprove easy adhesionTransportation and packagingMetal-working apparatusStearic acidOleic Acid Triglyceride

The invention discloses a wide-adaptability double-mechanism self-lubricating bearing material. The material is prepared from, by weight, 85-90 parts of aluminum, 5-8 parts of zinc, 3-4 parts of copper, 1-2 parts of tin, 0.5-1 part of boron, 3-4 parts of polytetrafluoroethylene powder, 0.8-1.5 parts of molybdenum disulfide, 2-3 parts of stearic acid, 0.6-1 part of methylcellulose, 1-1.5 parts of graphite, 1-1.5 parts of talcum powder, 0.6-0.9 part of paraffin, 0.5-0.7 part of iron powder and an appropriate amount of oleic acid. The prepared material has good performance such as dry-grinding resistance, self-lubrication and inadhesion, and is uniform in structure and stable in performance.

Owner:LIXIN JIANGHUAI YANGTIAN AUTOMOBILE

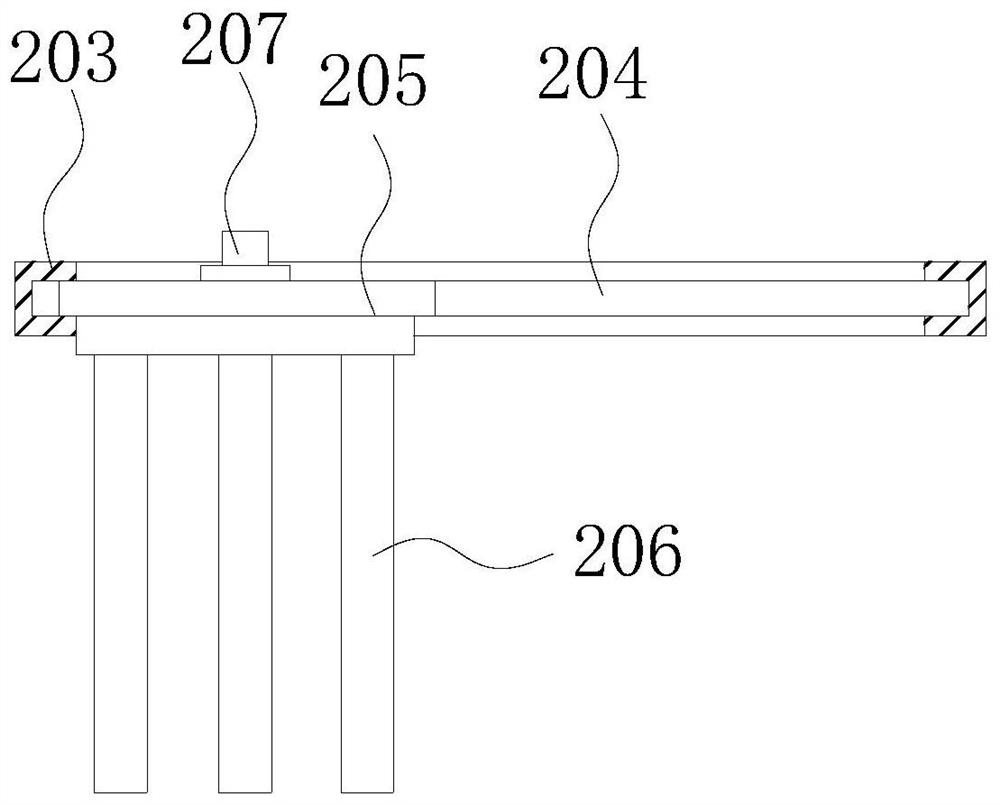

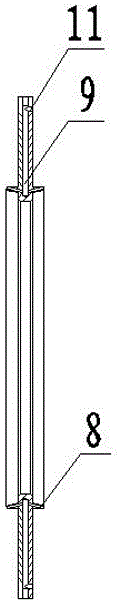

Drawing process of phosphatized steel wire for optical cable reinforcement

InactiveCN114289532AEasy lubricationImprove the lubrication effectMetallic material coating processesExtrusion cleaning devicesEngineeringBrush

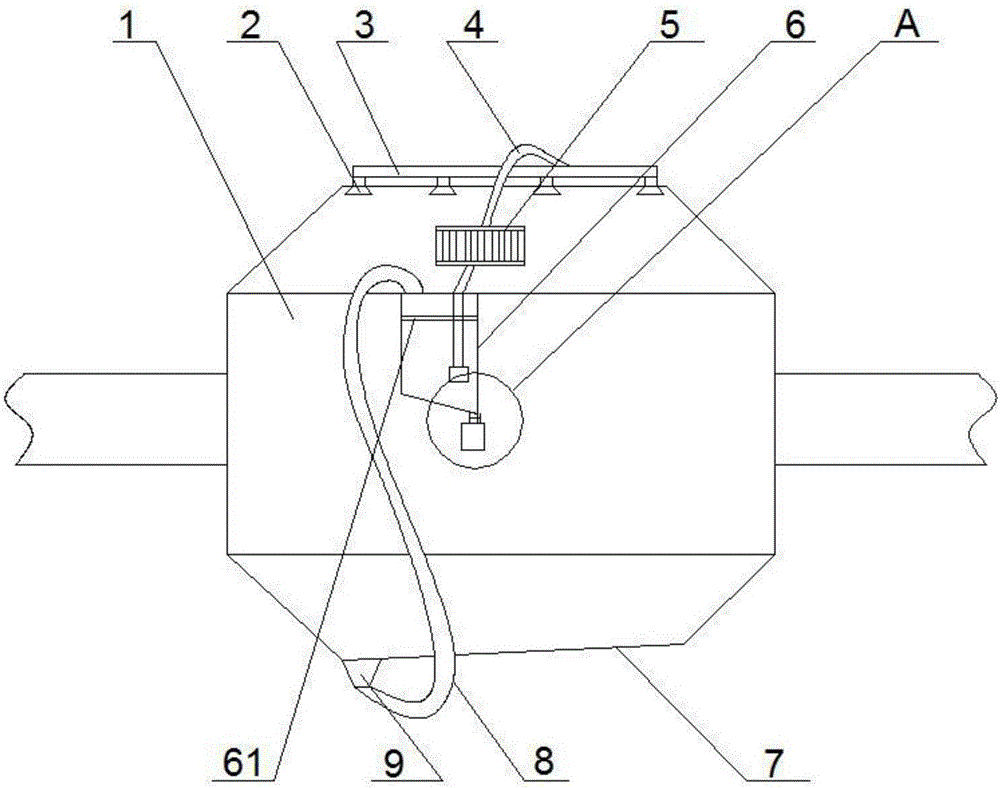

The invention discloses a drawing process of a phosphatized steel wire for optical cable reinforcement, and belongs to the field of phosphatized steel wires. According to the scheme, the phosphatized steel wire is fixed through a fixing mechanism, so that the phosphatized steel wire is not prone to moving, the influence on subsequent machining is avoided, then a sliding mechanism drives a lubricating box to move back and forth, lubricating treatment of the phosphatized steel wire is facilitated, and the production efficiency is improved. The lubricating and wrapping mechanism extrudes a hollow lubricating cylinder through carbon dioxide to release wire drawing powder to lubricate the hollow lubricating cylinder, and meanwhile, a wrapping brush wraps the outer end of the phosphatized steel wire with the released wire drawing powder, so that the phosphatized steel wire is fully lubricated by the wire drawing powder, the uniform lubricating effect is achieved, the lubricating effect of the phosphatized steel wire is effectively improved, and the service life of the phosphatized steel wire is prolonged. Meanwhile, waste of the wire drawing powder is reduced, the resource utilization rate is increased, the remaining material collecting mechanism adheres the falling wire drawing powder through cooperation of static electricity generated between a small touch ball and a fluff layer and an adhesion layer, the falling wire drawing powder is not prone to scattering everywhere, workers can conveniently clean the mounting base, and the cleaning effect is enhanced.

Owner:南通杰帆金属材料有限公司

Thermal-insulation adhesive for die-forging of forge pieces and preparation method thereof

The invention discloses a thermal-insulation adhesive for die-forging of forge pieces, which is used for forming die forging pieces and especially suitable for thermal-insulation forming of high-temperature alloy, titanium alloy and aluminum alloy die-forging pieces. The adhesive for thermal-insulation materials can form a continuous, uniform and compact film for thermal insulation and lubrication on the surface of a forge piece. The adhesive disclosed by the invention is prepared from the following components in percentage by weight: 20-40% of organosilicon heat-resistant resin or organic titanium epoxy resin, 20-40% of glass powder, 0-5% of trisodium phosphate, 2-6% of anhydrous borax, 0-5% of graphite, 1-3% of leafing aluminum paste, 1-5% of magnesium aluminum silicate suspending agent and 10-40% of xylene. The invention can accurately control the forging temperature, reduce the number of times of blank returning, prolong the forgeable time each time, lower the cost of the used coating materials, widen the optional range of the thermal-insulation coating materials, and the like. Meanwhile, the invention also provides a preparation method of the thermal-insulation adhesive.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND +1

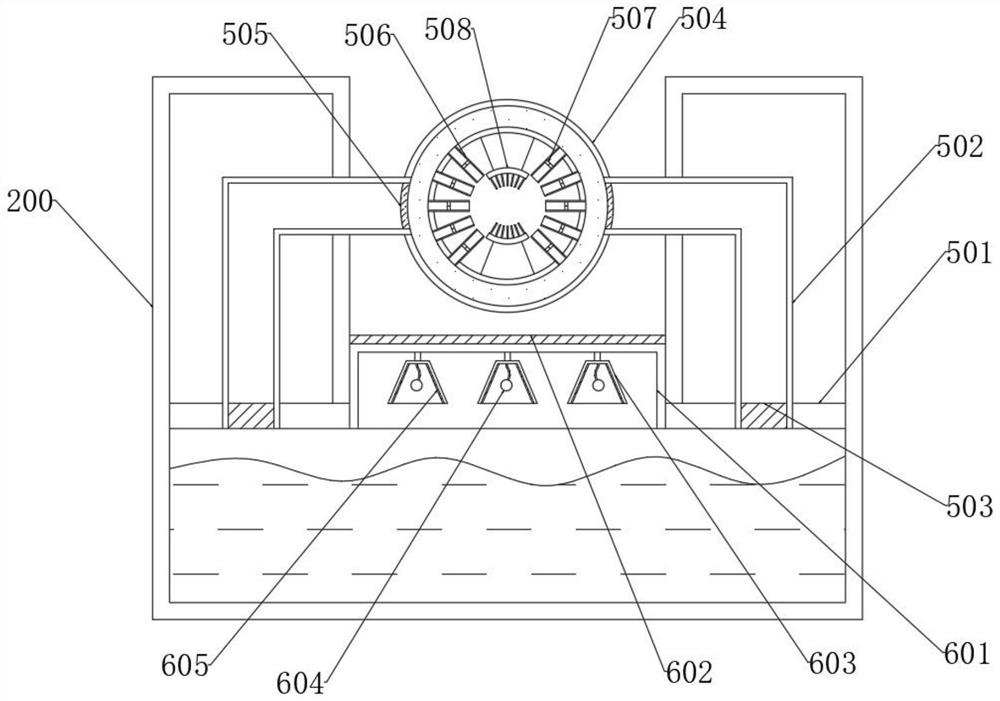

Lubricating oil recycling device of automobile gearbox

The invention provides a lubricating oil recycling device of an automobile gearbox. The lubricating oil recycling device comprises a gearbox body, a spraying mechanism, a circulating outlet and a filtering mechanism, wherein the spraying mechanism is arranged on the upper part of the gearbox body, the circulating outlet is formed in the lower part of the gearbox body, and the filtering mechanism is connected with the circulating outlet and the spraying mechanism. According to the lubricating oil recycling device, lubricating oil in the gearbox body is filtered and circulated, so that impurities in the lubricating oil are filtered, the lubricating oil is cooled, constant damage to a gear due to turbidity of the lubricating oil is effectively avoided, and heat on the gear can be removed in time, so that the gear is kept in an optimal operating state all the time, the service cycle of the lubricating oil at a time is extended, and the service life of the gearbox is prolonged.

Owner:高安市超鹰科技有限公司

Reversing rolling mill and operating method for a reversing rolling mill

ActiveUS20140238093A1Reduce fuel consumptionMaintaining good roll gap lubricationForging/pressing devicesWork cooling devicesEngineeringConductor Coil

Operating method for a reversing rolling mill having at least one reversing rolling stand (2) for rolling a rolled metal stock (5), wherein the stock (5) passes the at least one reversing rolling stand (2) in a sequence of alternating direction passes (7) and after each pass, the stock is wound up by a reversing reel (3, 4), wherein only rolling oil, without water as a carrier medium, is applied to the stock (5) by rolling-oil applicator (6), between the at least one reversing rolling stand (2) and the winding-up reel (31, 41).

Owner:PRIMETALS TECH AUSTRIA GMBH

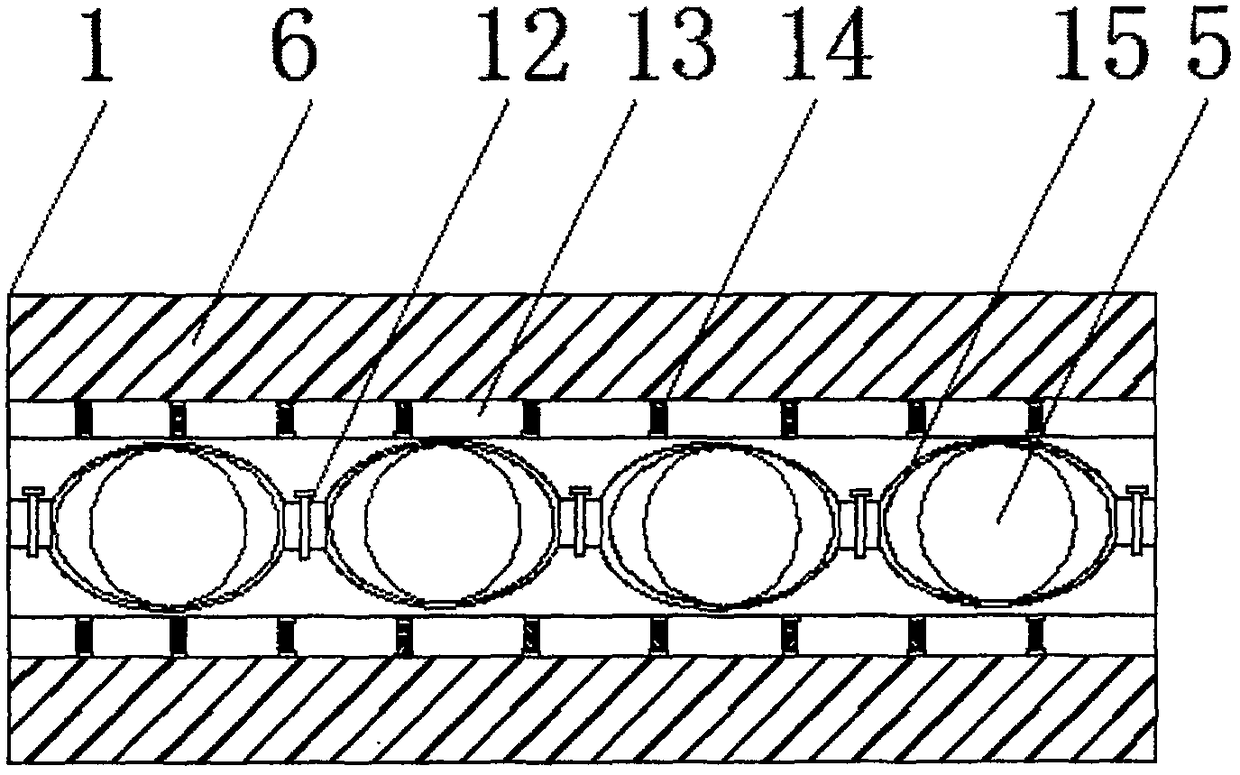

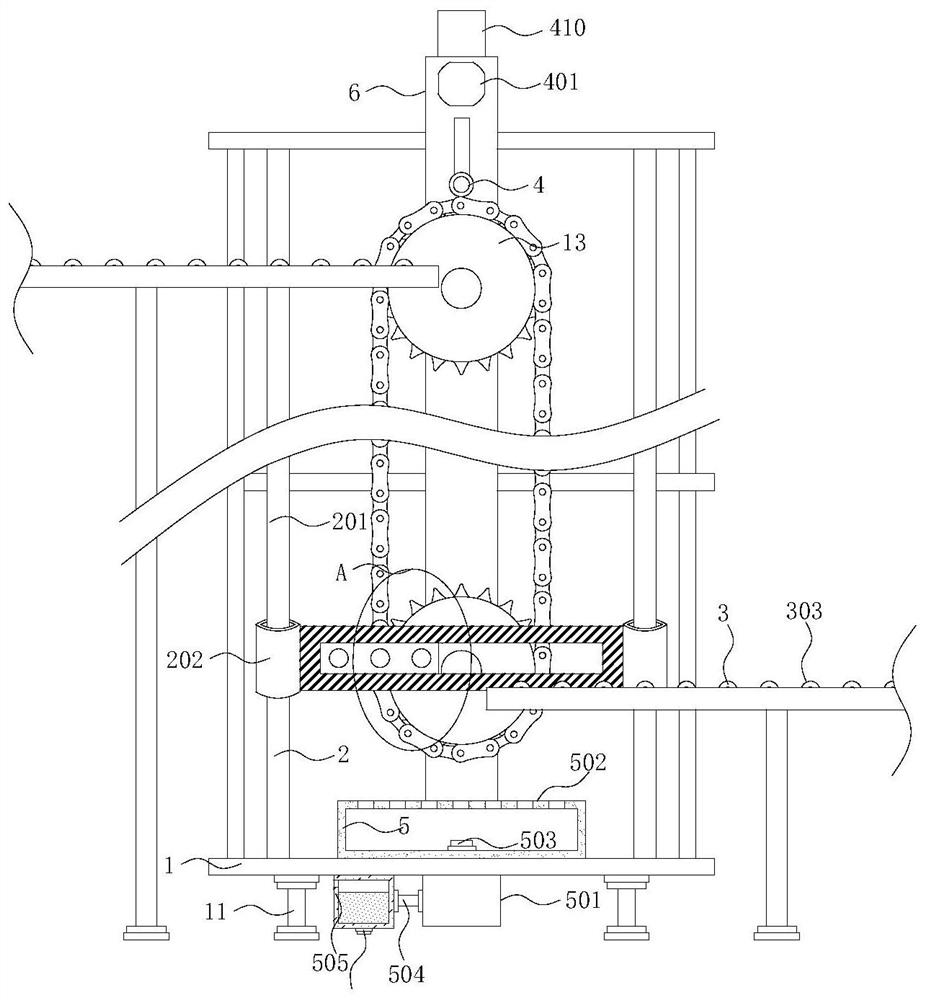

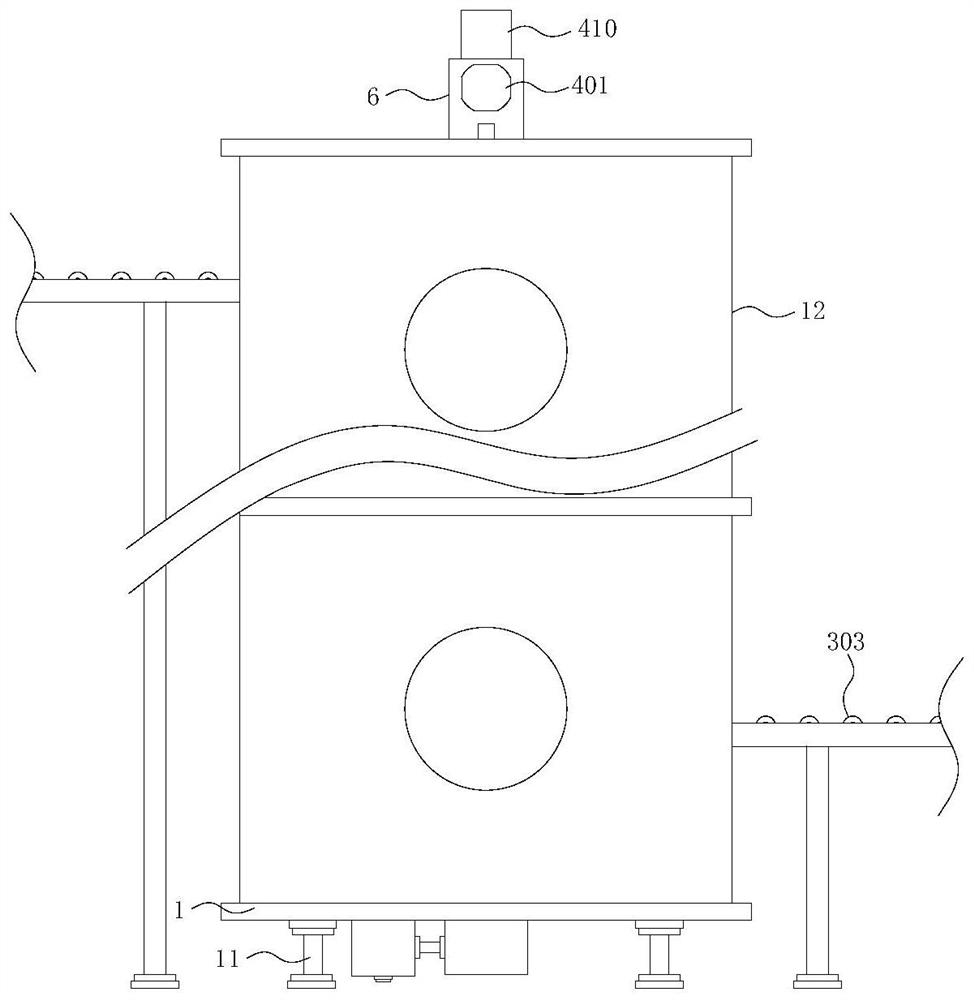

Continuous vertical conveyor

ActiveCN112777292AGuaranteed stabilityImprove delivery efficiencyLifting framesCleaning using gasesRotational axisControl engineering

Owner:江西博展自动化科技有限公司

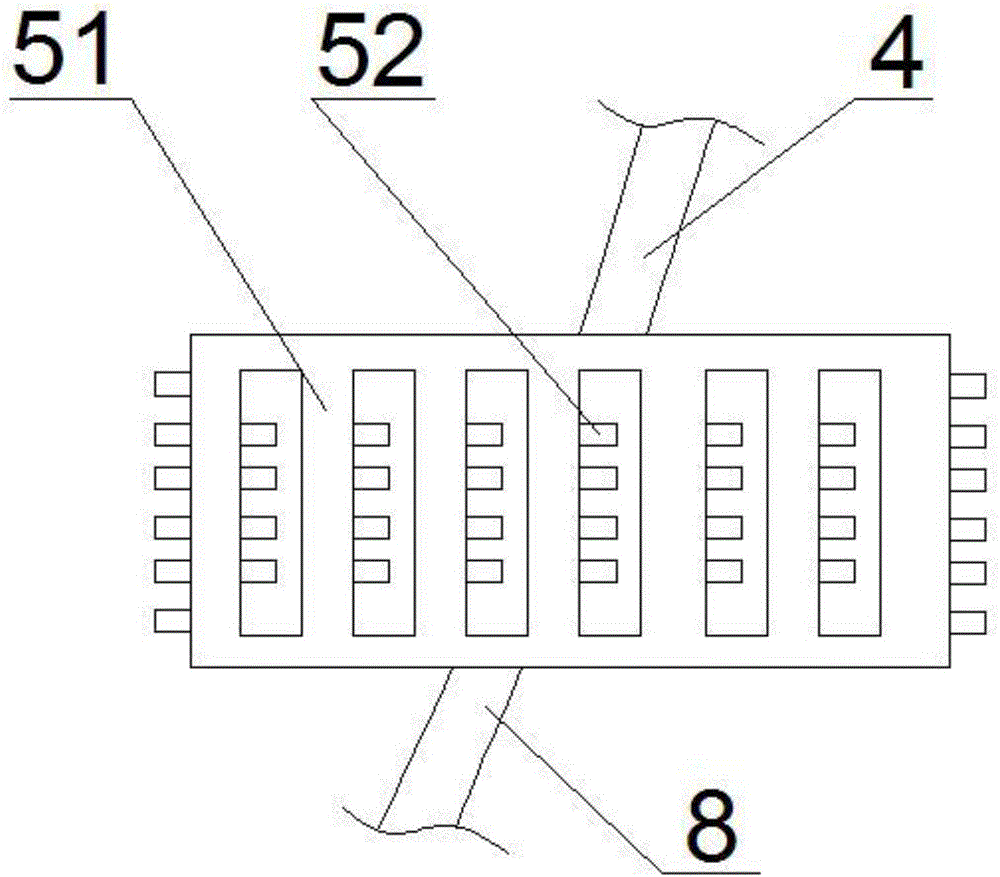

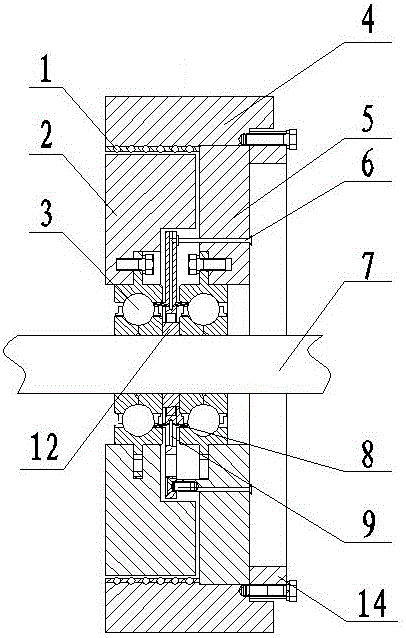

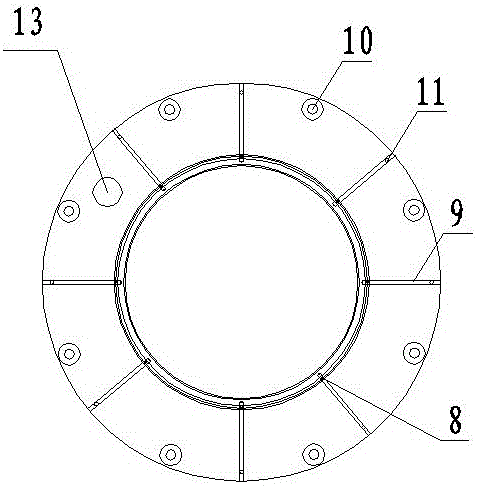

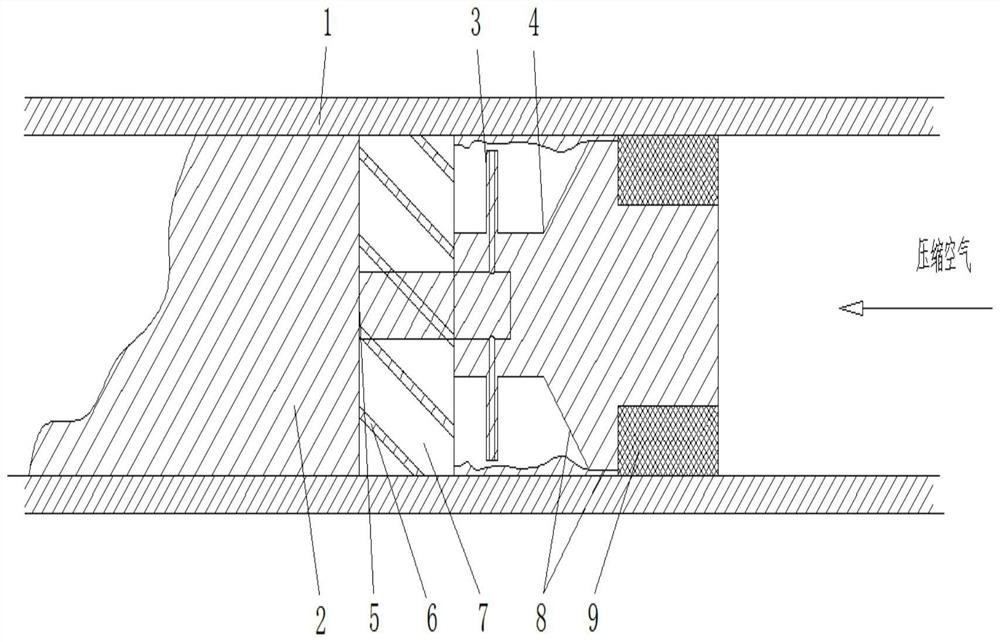

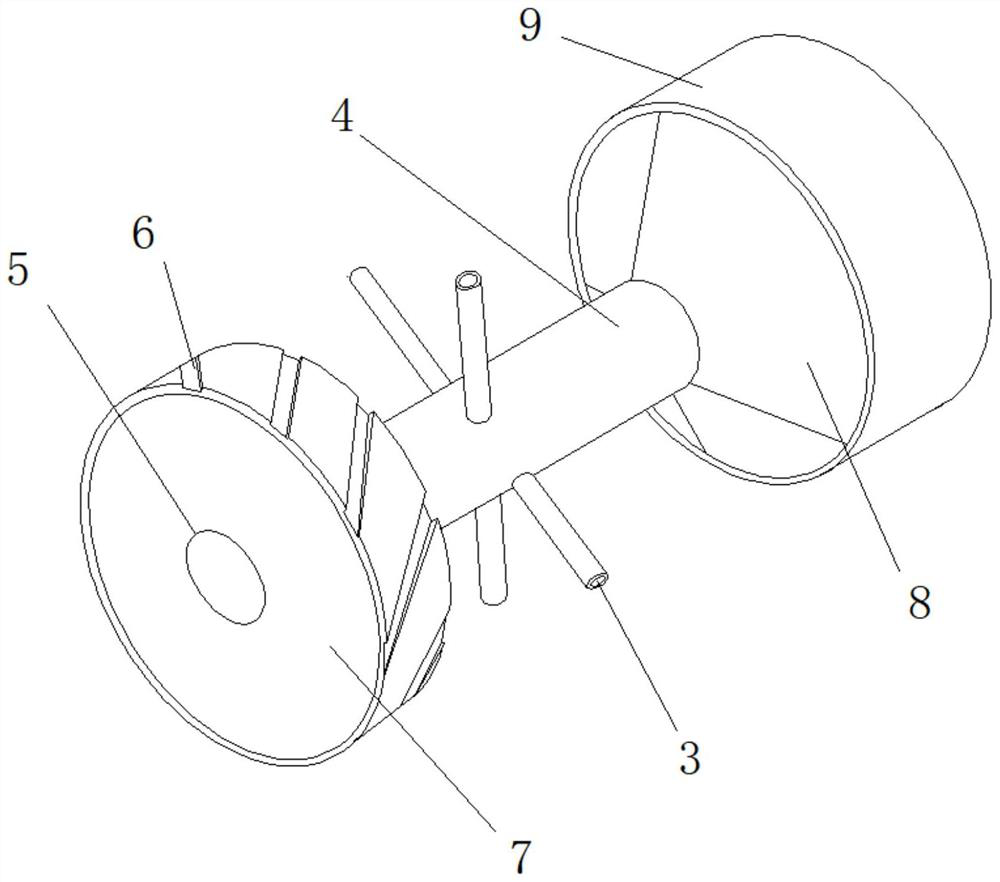

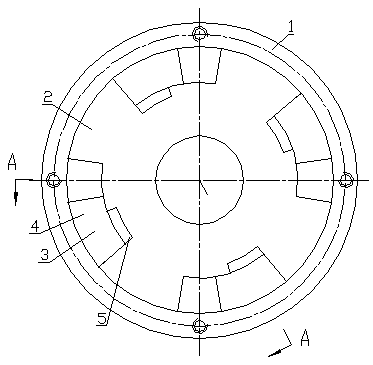

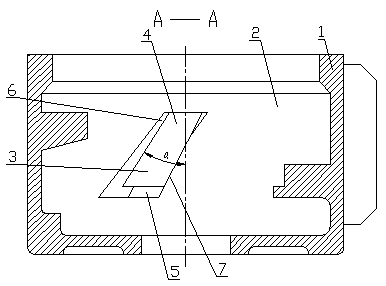

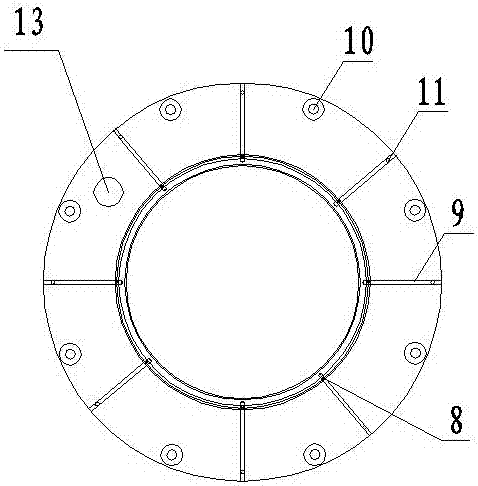

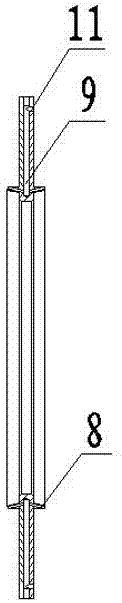

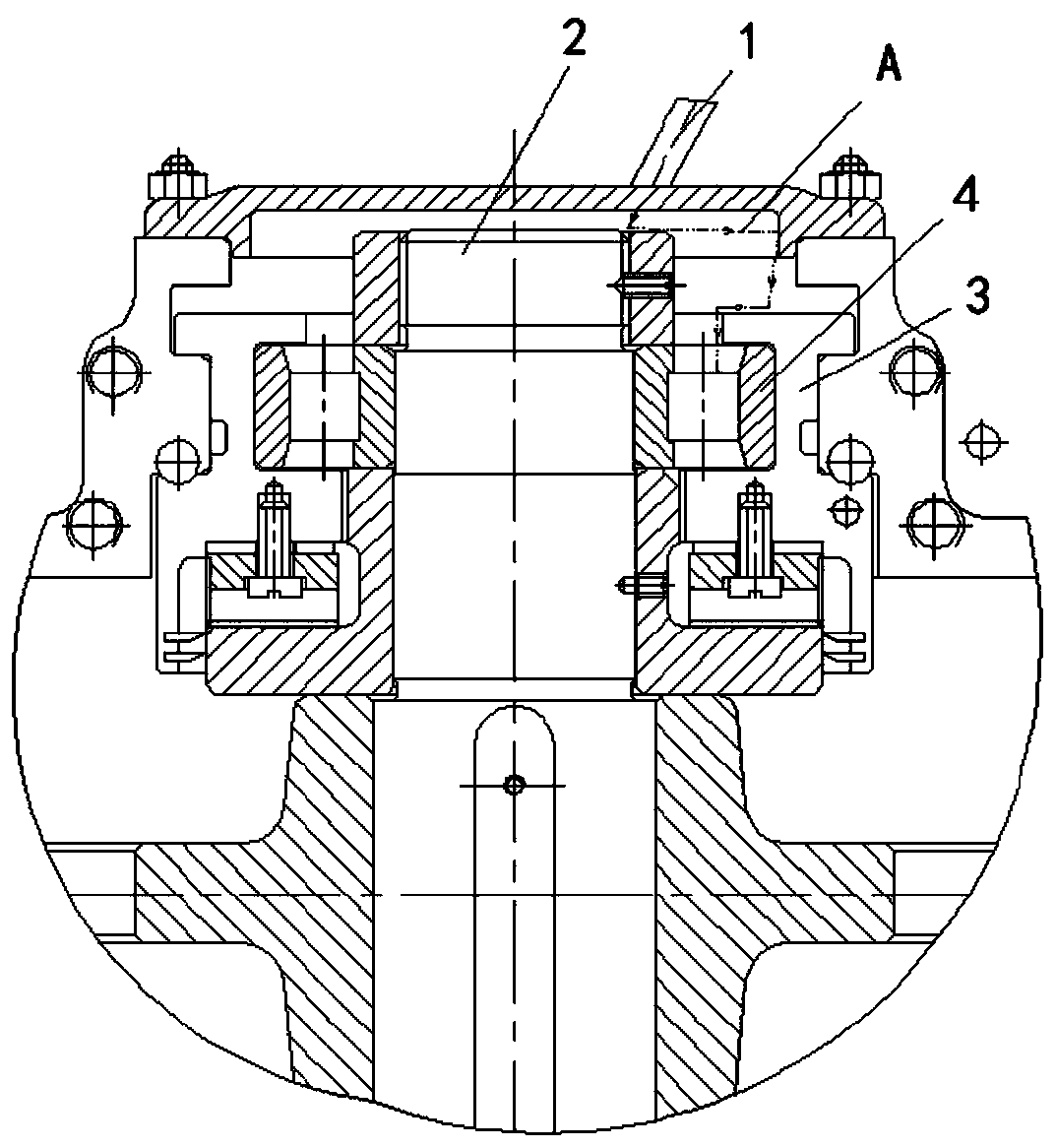

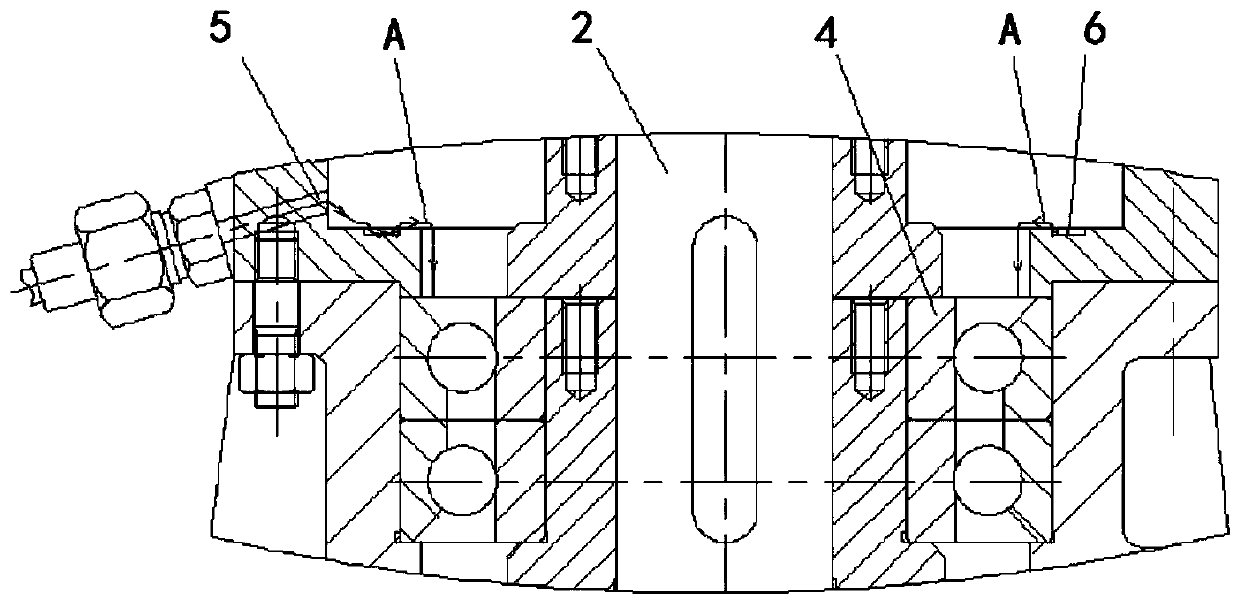

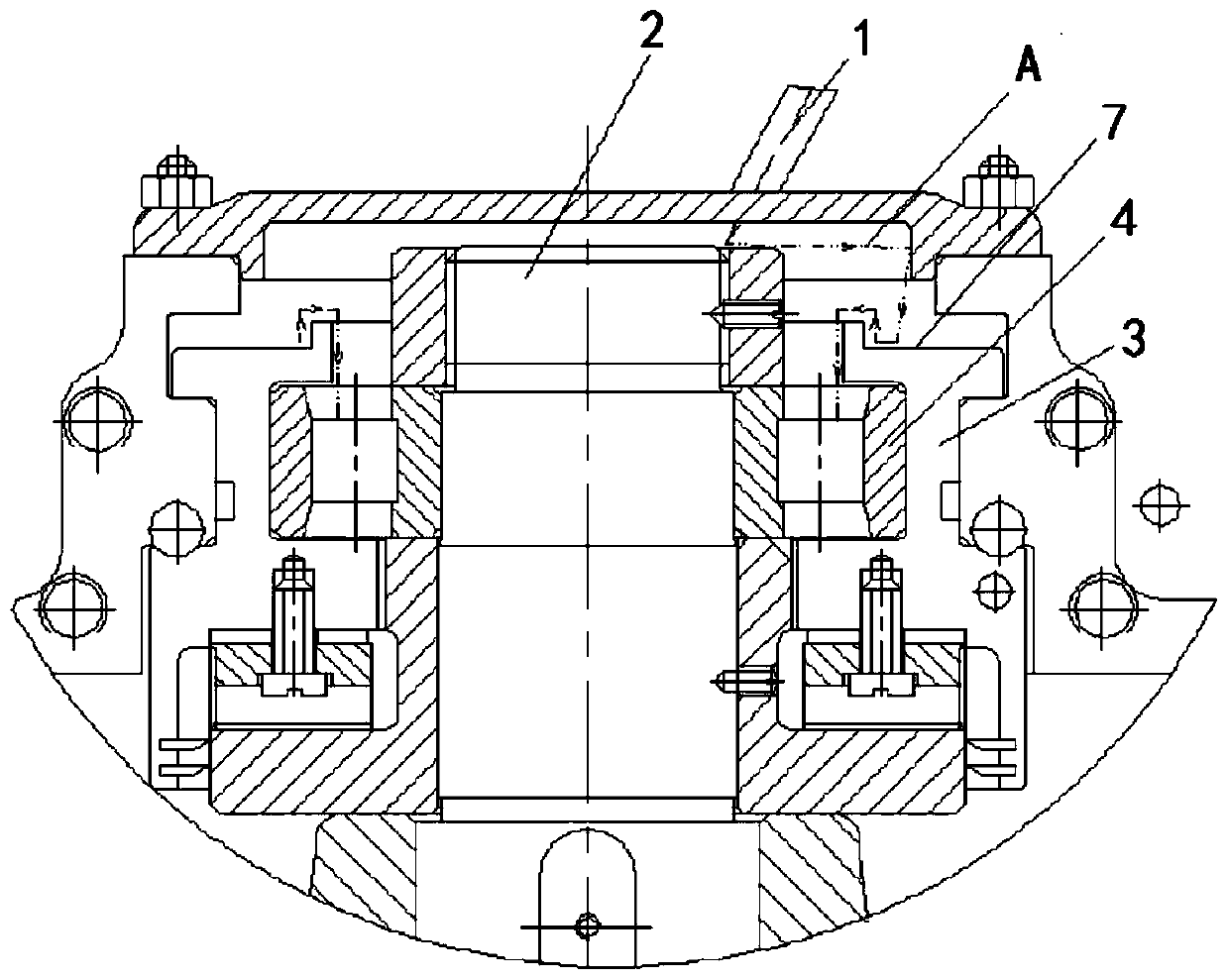

Oil-gas lubrication bearing pedestal with two-way nozzles, and using method of oil-gas lubrication bearing pedestal

ActiveCN106523532AMeet lubrication needsEvenly distributedShaftsRotary machine partsFixed bearingGas lubrication

An oil-gas lubrication bearing pedestal with two-way nozzles comprises a floating bearing pedestal body and a fixed bearing pedestal body, and the floating bearing pedestal body and the fixed bearing pedestal body are arranged in parallel. A plurality of oil inlet pipelines are arranged in the fixed bearing pedestal body in the axial direction in a through mode. The oil-gas lubrication bearing pedestal further comprises an oil injection disc arranged between the two bearing pedestal bodies. A plurality of oil injection holes are annularly and evenly formed in the side, close to the fixed bearing pedestal body, of the oil injection disc. A plurality of oil ducts are formed inside the oil injection disc in the radial direction. The oil inlet pipelines, the oil injection holes and the oil ducts communicate in a one-to-one correspondence mode. The flow-out end of each oil duct is further provided with the corresponding nozzle in a communicating mode. The nozzles are divided into two groups with opposite oil injection directions, the numbers of the two groups of nozzles are equal, and the nozzles are evenly arranged in the circumference direction at intervals. The outer wall of the fixed bearing pedestal body and the floating bearing pedestal body are sleeved with an integral gland, and a pressing ring is fixedly arranged at the end of the integral gland and used for conducting axial limitation on the fixed bearing pedestal body. The oil-gas lubrication and oil distribution mode of two-way oil injection is adopted, oil-gas supply paths are independent from one another, and adjustment is convenient.

Owner:HENAN UNIV OF SCI & TECH

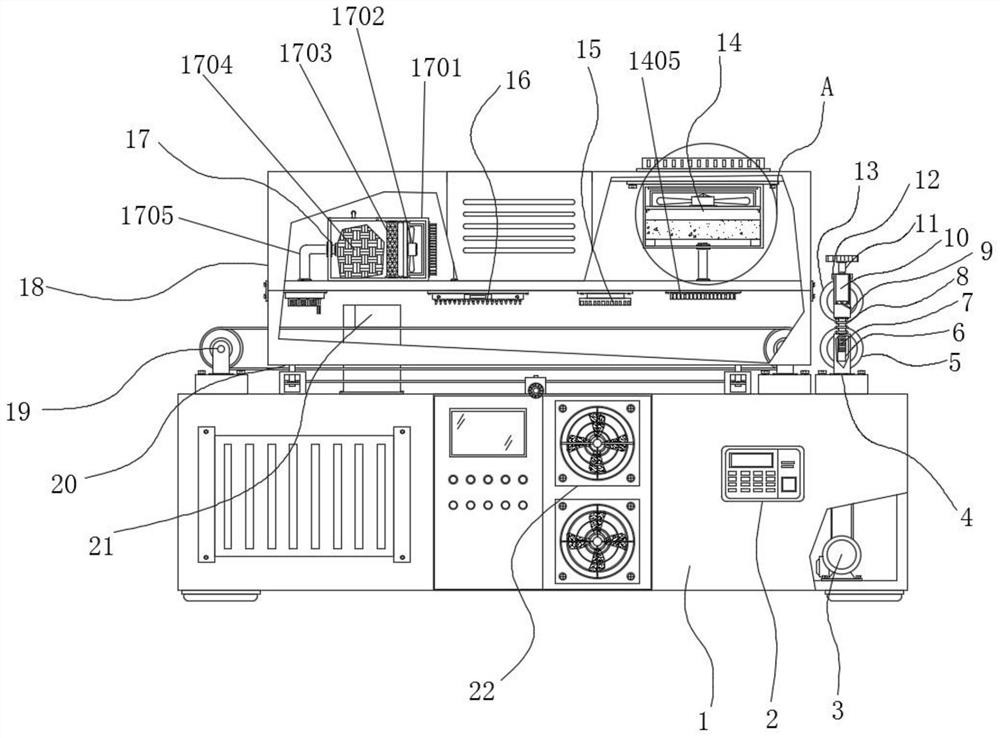

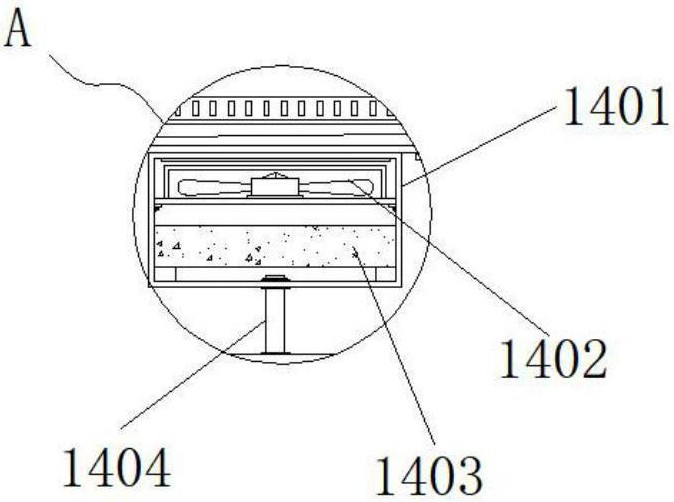

Lifting type printing and drying mechanism for corrugated boards

InactiveCN113442603ARealize the function of lubrication and anti-wearRealize the function of surface cleaningDispersed particle filtrationOther printing apparatusGear driveGear wheel

The invention discloses a lifting type printing and drying mechanism for corrugated boards, and particularly relates to the technical field of printing and drying machines. The lifting type printing and drying mechanism comprises a first box body, one side of the front end of the first box body is fixedly connected with a controller, and one side of the bottom end in a second box body is provided with a paperboard cleaning mechanism; and a pressing tightness adjusting structure is arranged at the top end of a supporting seat. A rotating handle is rotated to drive an adjusting shaft to rotate, the adjusting shaft drives a middle shaft to rotate through transmission of a middle gear, the middle shaft drives a transmission gear on a supporting plate to rotate when rotating, and due to the fact that the transmission gear is rotationally positioned on a transverse plate on a lifting sliding groove, when the transmission gear rotates, a lifting screw rod is pushed to move in a lifting sliding way; and when the lifting screw rod moves up and down, the second box body is driven to move up and down, so that the distances between a printing spray head, a pungent smell suction-away mechanism and the paperboard cleaning mechanism on the second box body and a conveying belt are adjusted to adapt to printing and drying of the corrugated boards with various thicknesses.

Owner:许金祥

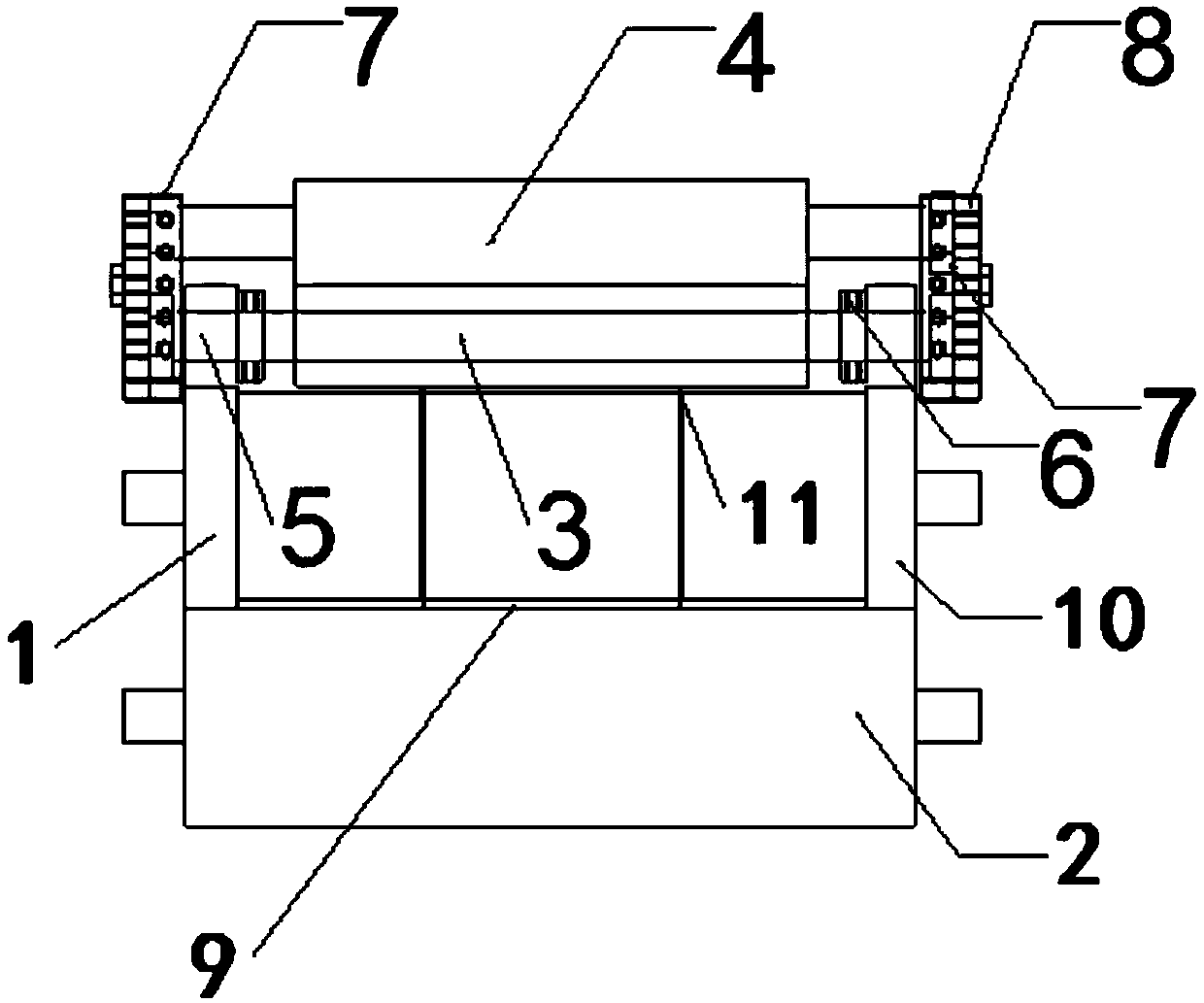

Three-segment type abrasion-resistant and temperature-resistant bloom foot roller

The invention discloses a three-segment type abrasion-resistant and temperature-resistant bloom foot roller and relates to the technical field of bloom continuous casting machine parts. The three-segment type abrasion-resistant and temperature-resistant bloom foot roller comprises a mandrel, and further comprises three segments of single roller bodies; the middle of each single roller body is provided with an installing hole, and the mandrel sequentially penetrates the installing holes of the three segments of single roller bodies; a pair of copper sleeves close to the end face of each installing hole are arranged in the installing hole, and the copper sleeves are arranged between the mandrel and the single roller bodies in a sleeved manner; the mandrel is provided with at leas three oil outflow holes which are evenly distributed; and high-temperature-resistant check rings are connected between the end faces, away from the oil outflow holes, of the copper sleeves and between the adjacent copper sleeves, and the high-temperature-resistant check rings are arranged outside the mandrel in a sleeving manner. The three-segment type abrasion-resistant and temperature-resistant bloom foot roller plays a guiding role in casting blank when the casting blank just goes out of a crystallizer, guarantees that the installing dimension and the maximum boundary dimension do not change, both the lubricating requirement can be met, and deformation can also be remarkably reduced, the service life is prolonged, the heat shutdown time is shortened, the operation rate of a continuous casting machine is increased, and scratches and indentation of the surface of the casting blank are reduced.

Owner:NANJING IRON & STEEL CO LTD

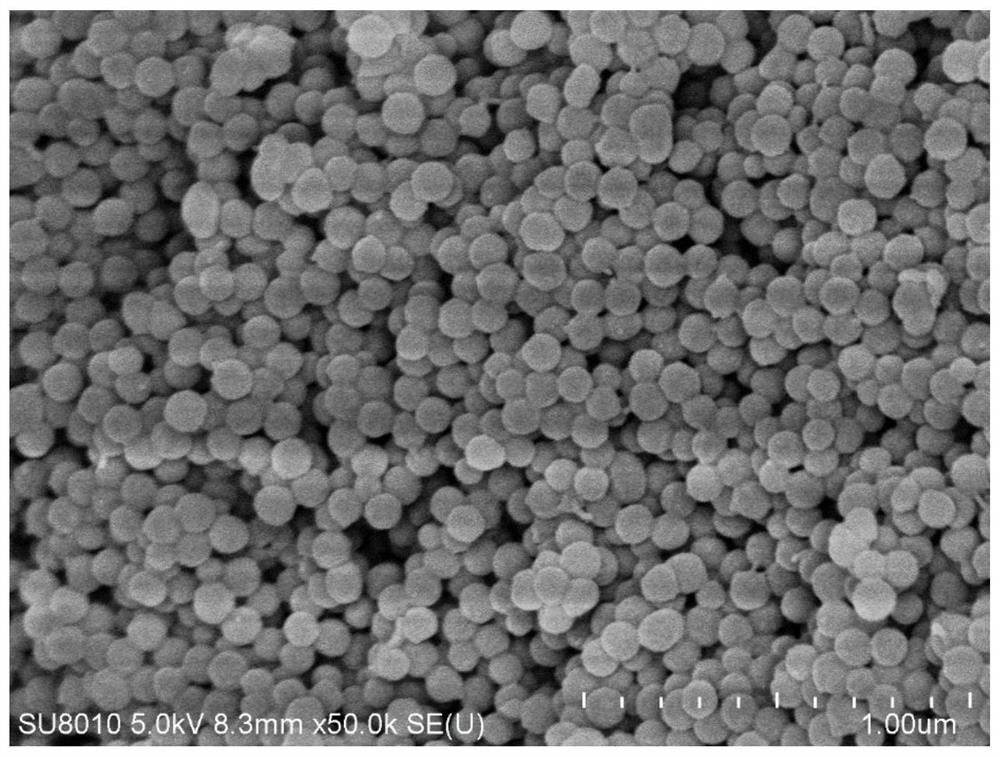

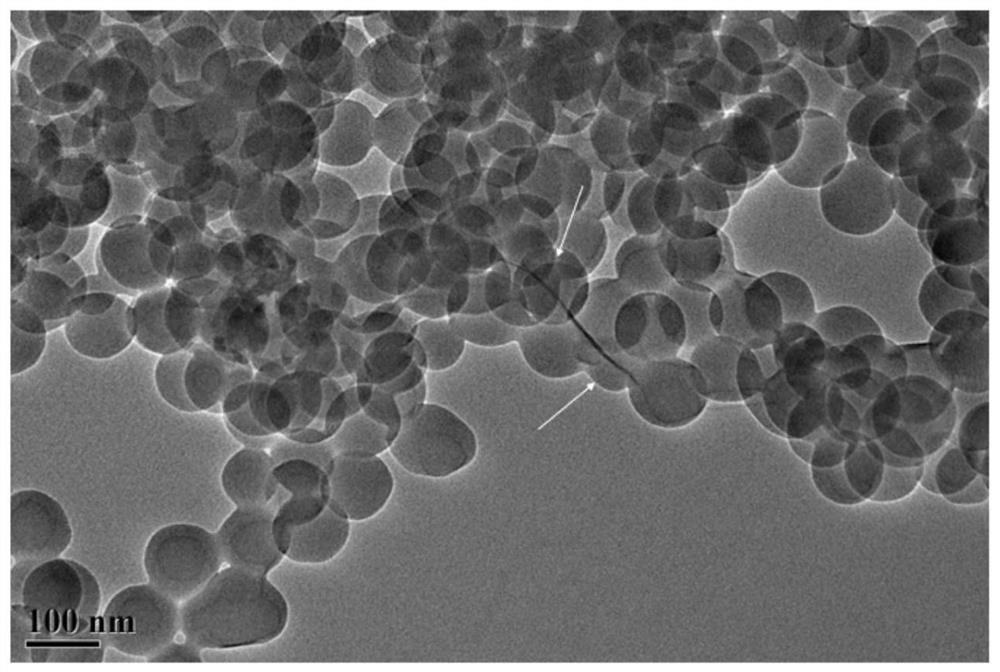

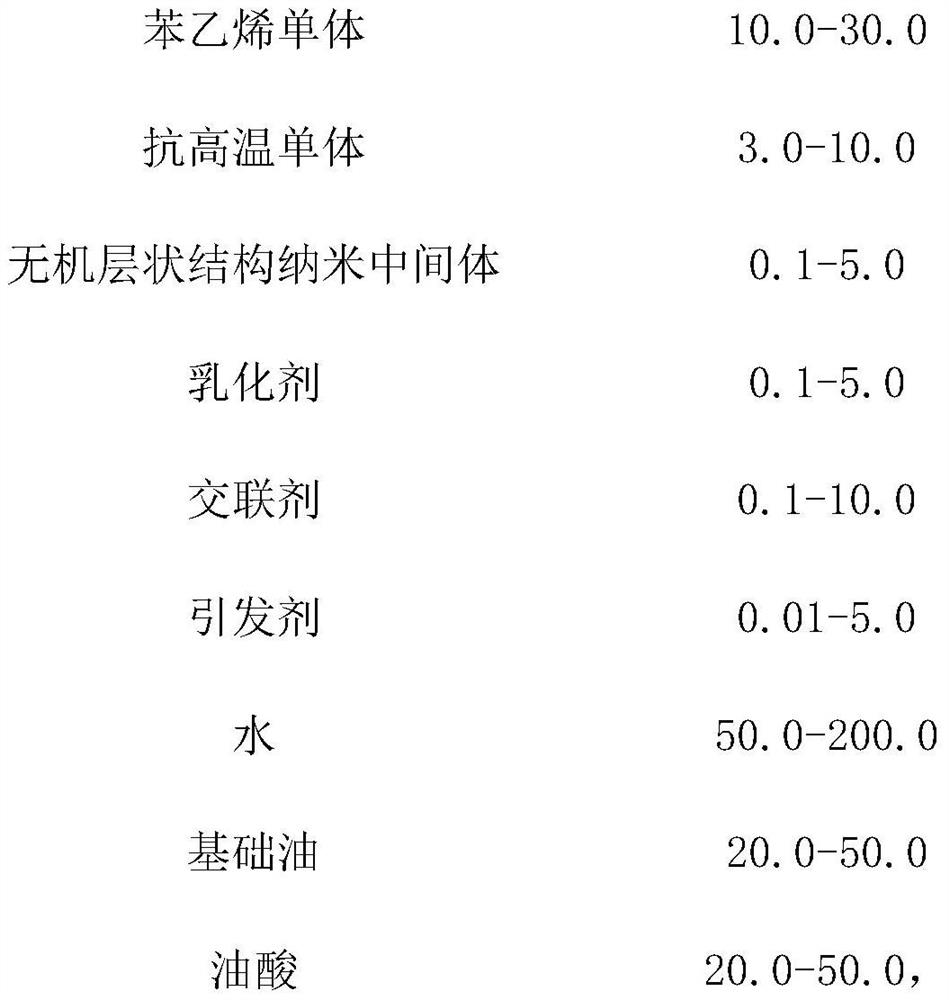

High-temperature-resistant nano composite lubricant, and emulsion preparation method and application thereof

ActiveCN112852532AImprove rigidityImprove temperature resistanceDrilling compositionLubricant compositionEmulsionPolymer chemistry

The invention provides a high-temperature-resistant nano-composite lubricant, and an emulsion preparation method and application thereof.A composition of a high-temperature-resistant monomer, a comonomer and a nano intermediate with a layered structure is adopted. The preparation method comprises the following steps: 1) mixing and stirring the high-temperature-resistant monomer, the comonomer, the inorganic layered structure nano intermediate, an emulsifier, a cross-linking agent and water in an inert atmosphere for 30 minutes to obtain a mixed system; 2) heating the mixed system to 70 DEG C, then adding an initiator, maintaining the temperature, continuously stirring for 7-10 hours, and carrying out a copolymerization intercalation composite reaction to obtain a nano composite emulsion; and (3) mixing the nano-composite emulsion, oleic acid and industrial base oil, stirring for 10 minutes at room temperature, and uniformly mixing, so as to obtain the high-temperature-resistant nano-composite lubricant. The nano-composite microsphere lubricant with extreme pressure anti-wear property has the advantages of nano high-efficiency nucleation property, high temperature resistance, easy dispersibility, good compatibility with a drilling fluid, and high-efficiency lubricity.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

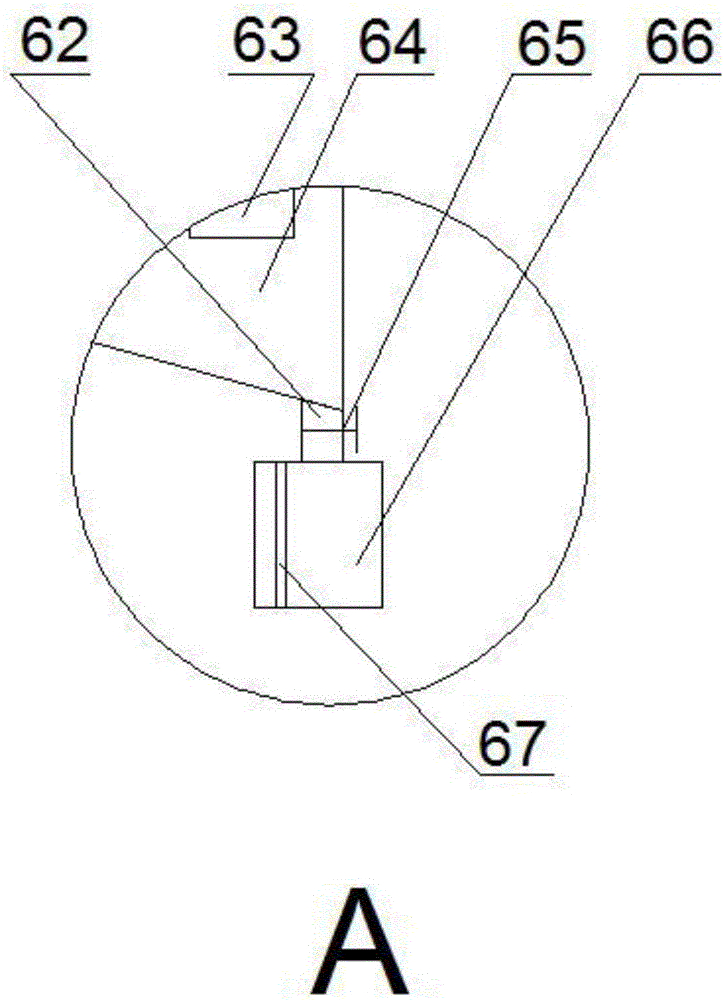

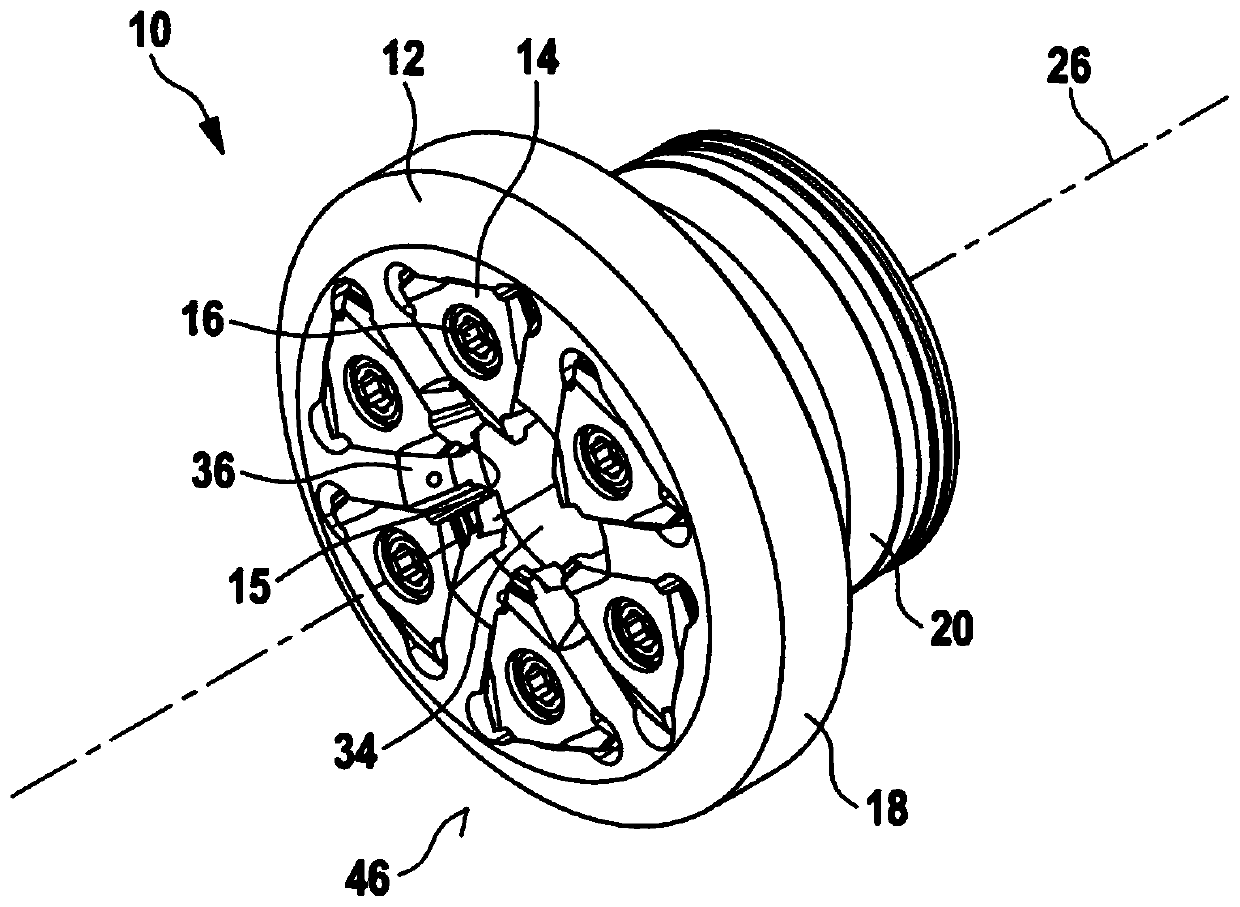

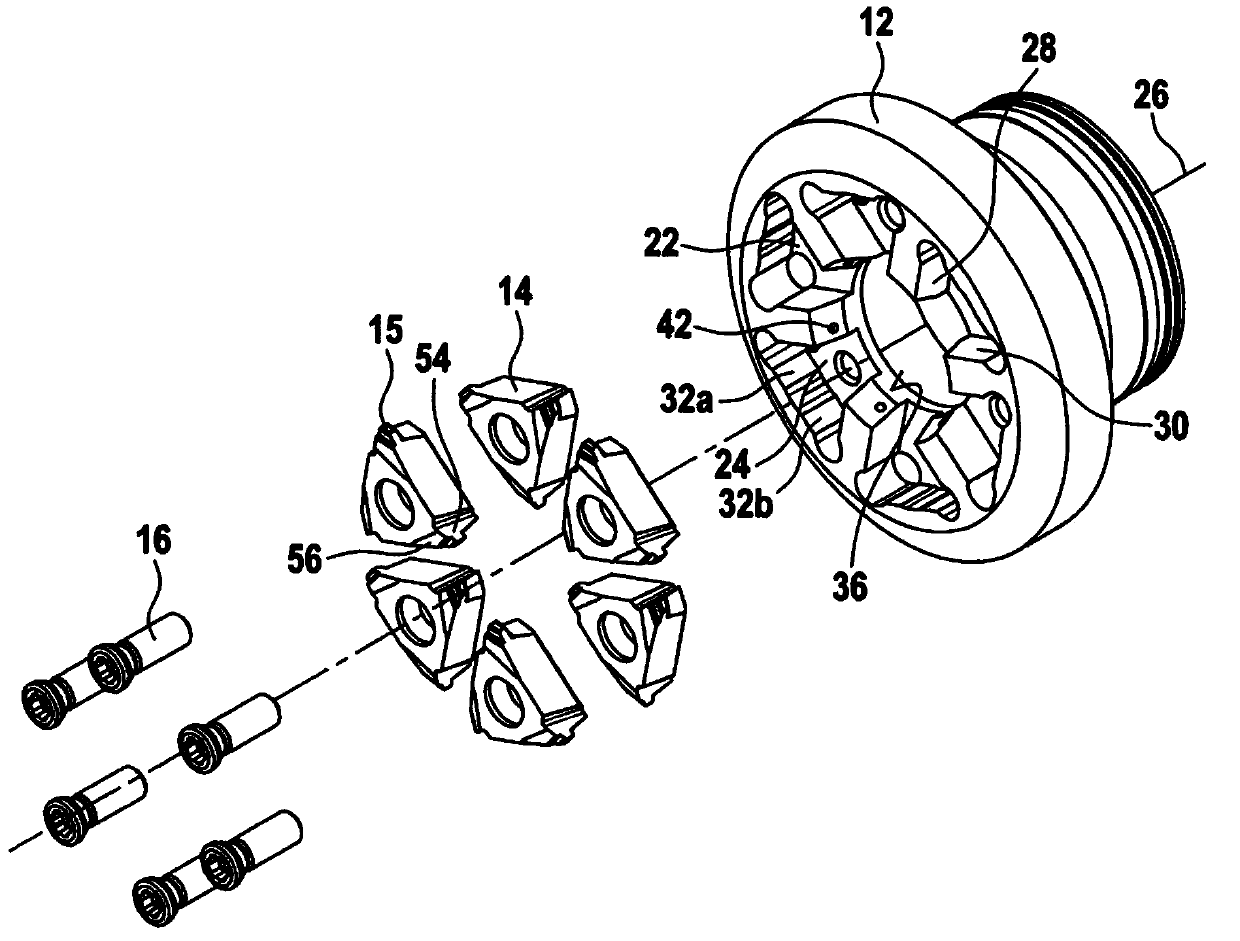

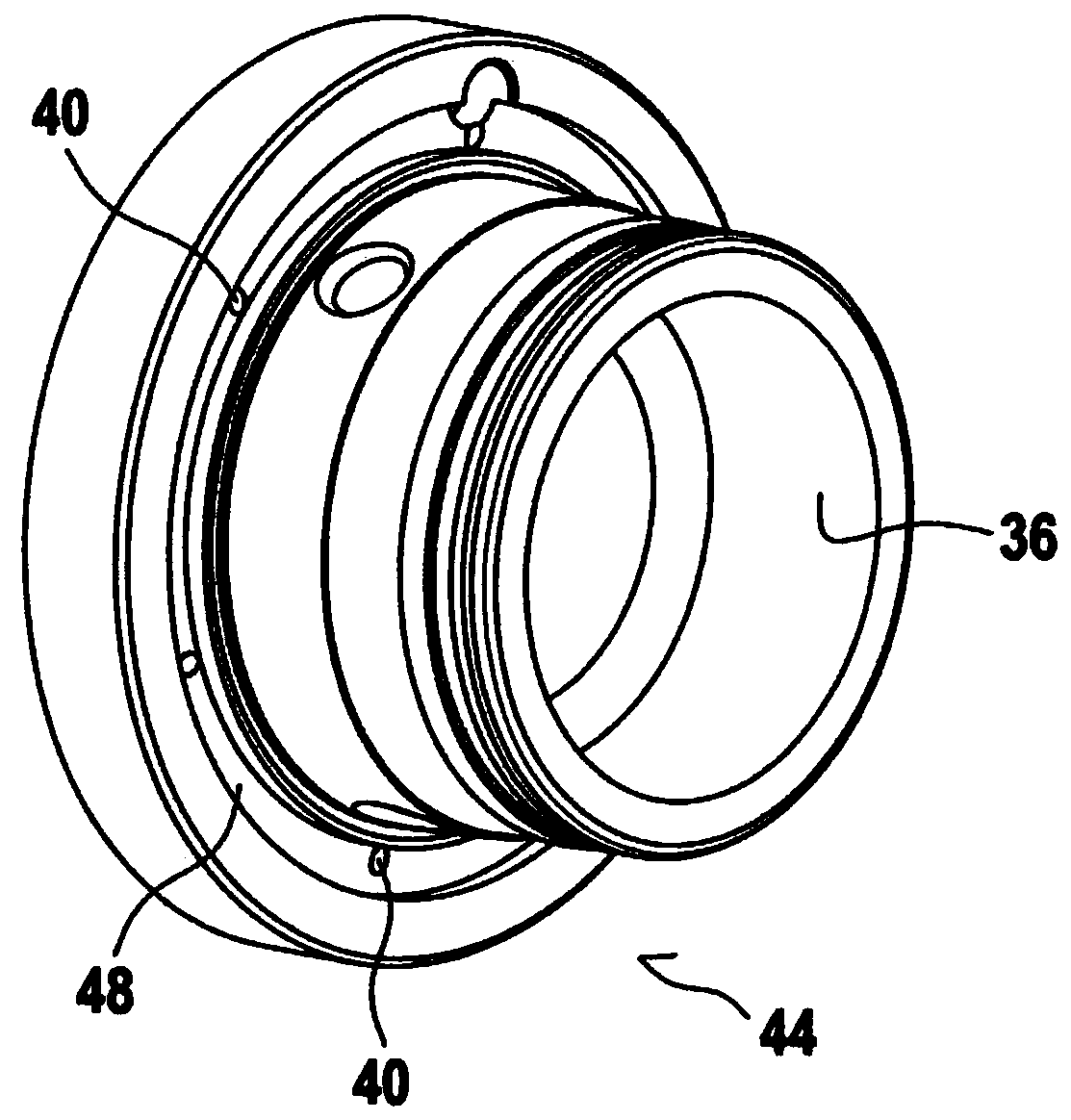

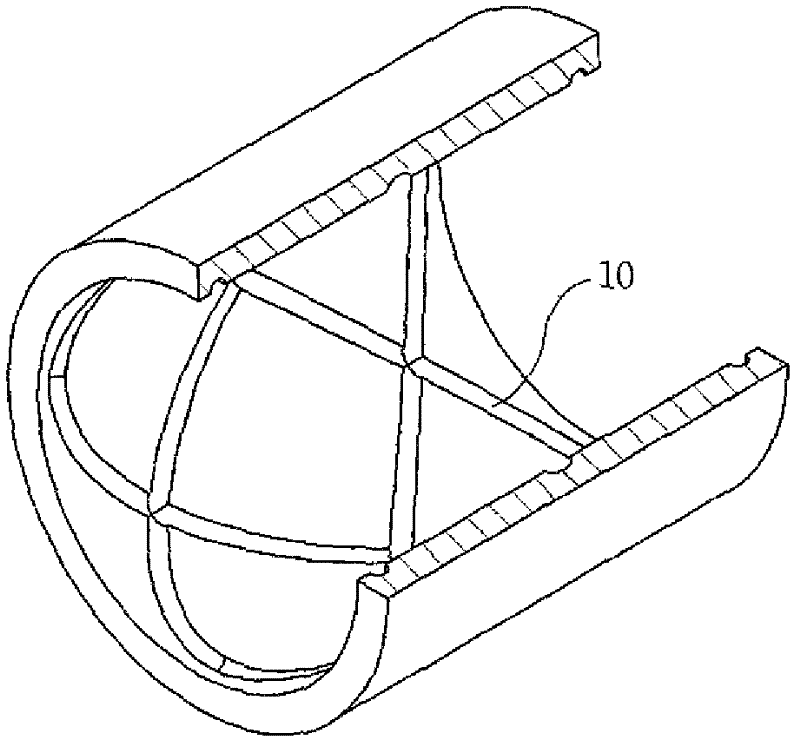

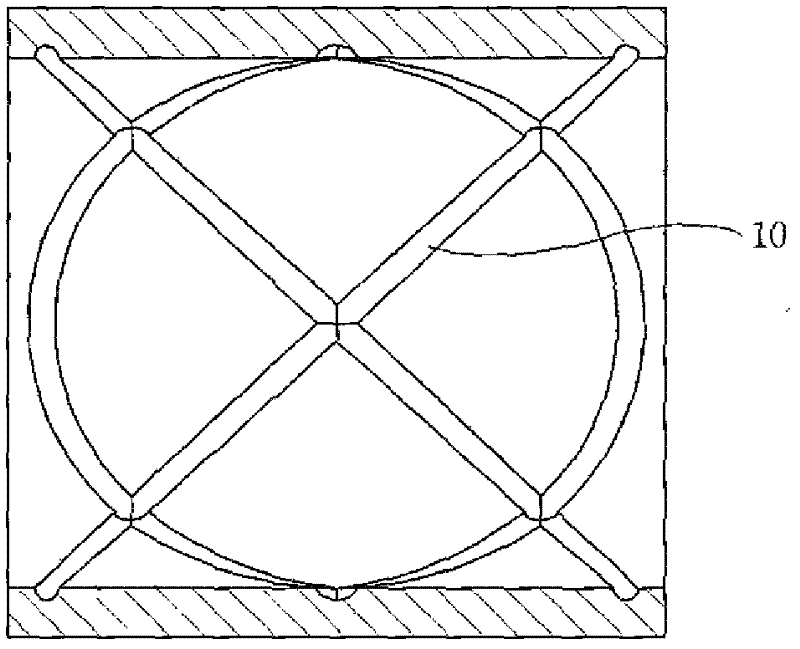

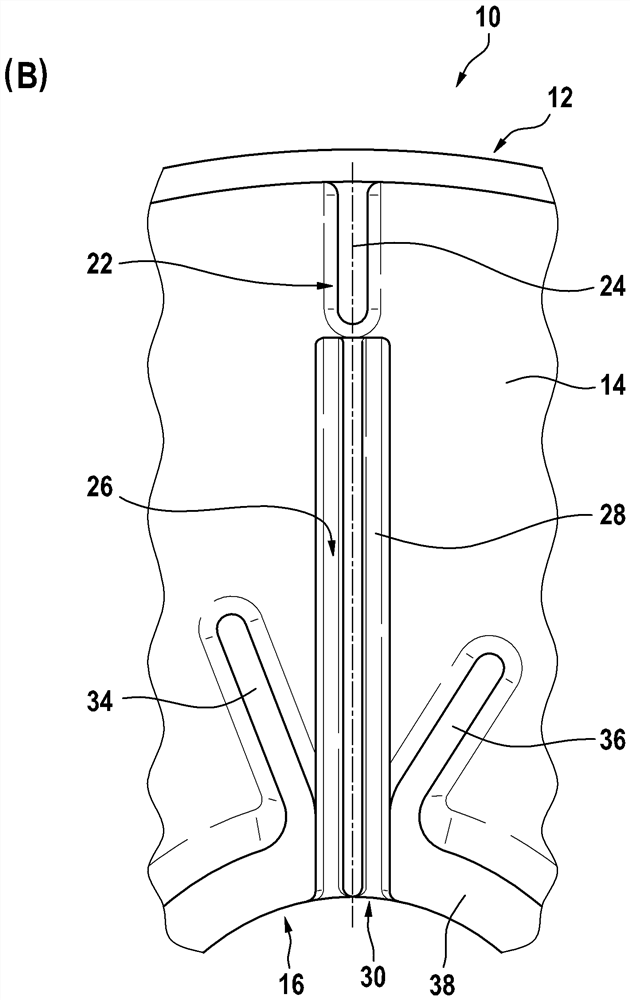

Whirling tool

ActiveCN111565875AUniform cooling effectUniform lubricationThread cutting toolsThread cutting machinesPhysicsCoolant

The invention relates to a whirling tool (10) for machining a workpiece, comprising: a plurality of cutting plates (14), each of the cutting plates (14) having at least one cutter (15); a cutting plate carrier (12) having a plurality of cutting plate holders (22) for holding and releasable fastening of a respective one of the cutting plates (14), the cutting plate holders (22) being arranged suchthat the cutting plates are distributed in the circumferential direction over the cutting plate carrier(12). The cutting plate carrier (12) has a through opening (34) which extends along a central axis (26) of the cutting plate carrier (12) and through which the workpiece can be passed during the machine, and in the installed state the cutting plates (14) protrude into the through opening (34). The tool also comprises a coolant channel (38) which is arranged in the cutting plate carrier (12) and extends between an inlet opening (40) and an outlet opening (42), the outlet opening (42) leading into the through opening (34) and / or being oriented in the direction of the through opening (34).

Owner:HARTMETALL WERKZEUGFAB PAUL HORN

Alkaline electrolyte-containing mine support hydraulic fluid

InactiveCN104673431AImprove the lubrication effectUniform lubricationAdditivesMineralogyAqueous solution

Owner:SHENZHEN FRANCOOL TECH

Bushing bearing

InactiveCN102537060AUniform lubricationImprove toleranceBearing componentsSliding contact bearingsEngineeringMechanical engineering

The present invention relates to a sliding bearing, and particularly to a bushing bearing which forms oil grooves at an inner peripheral surface. The brushing bearing of the invention comprises one kind of oil grooves which are formed parallelly with the axial direction, thereby replacing spiral grooves which form sharp edges on intersection points and may damage the object.

Owner:郑寅辅

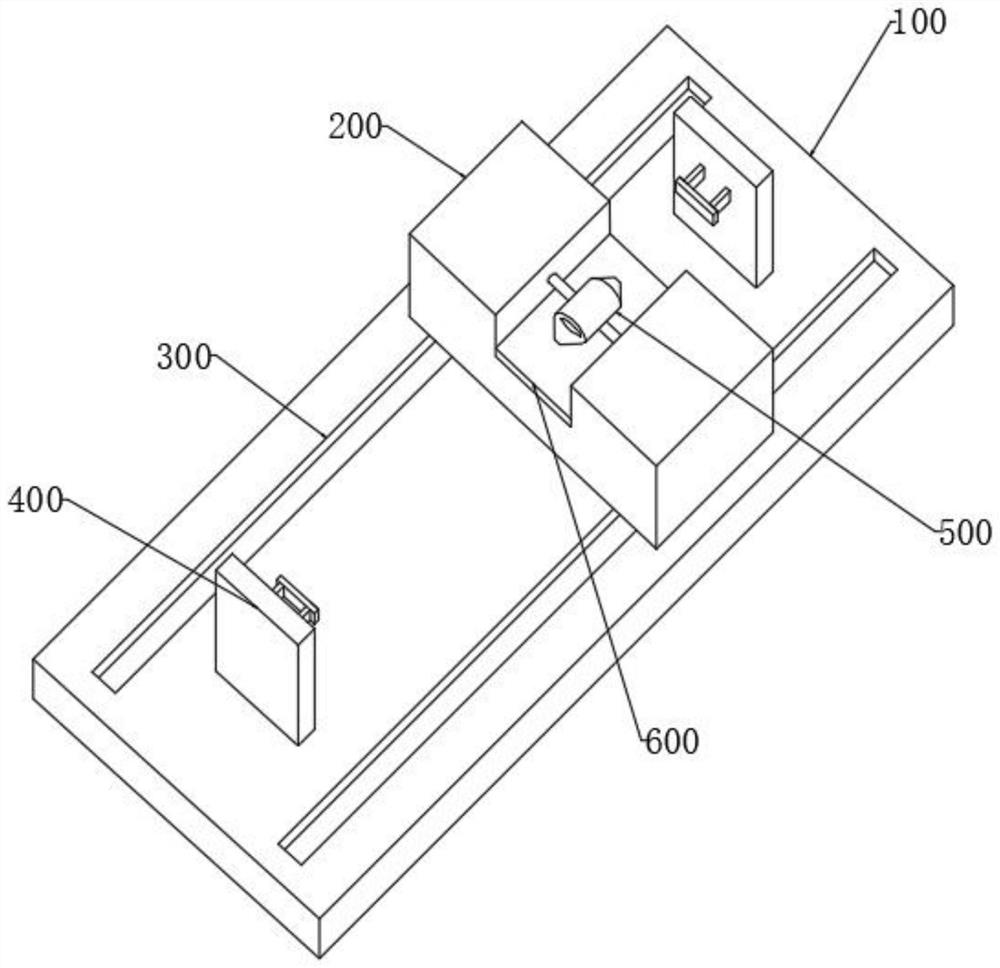

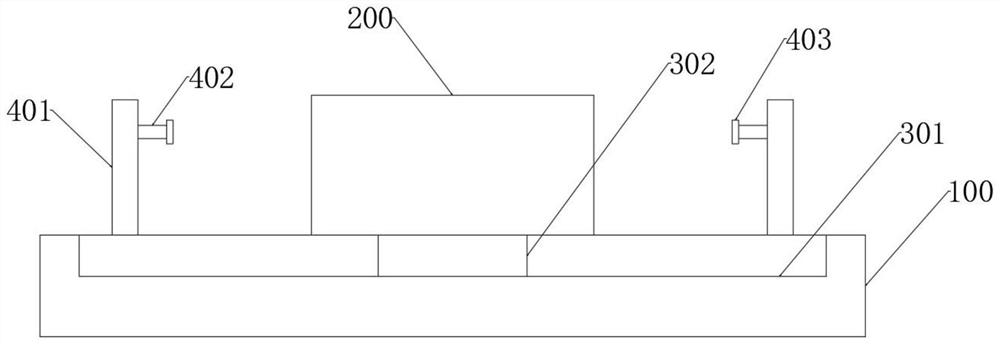

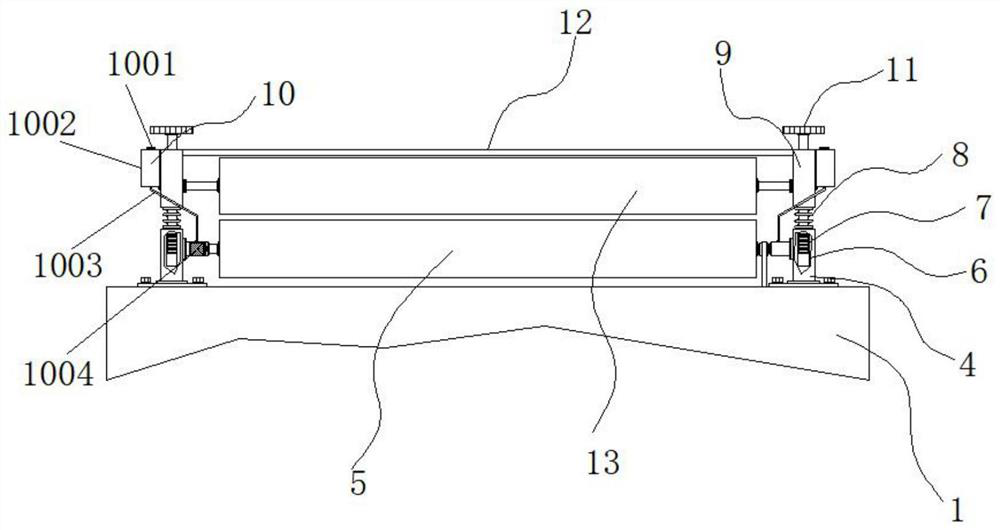

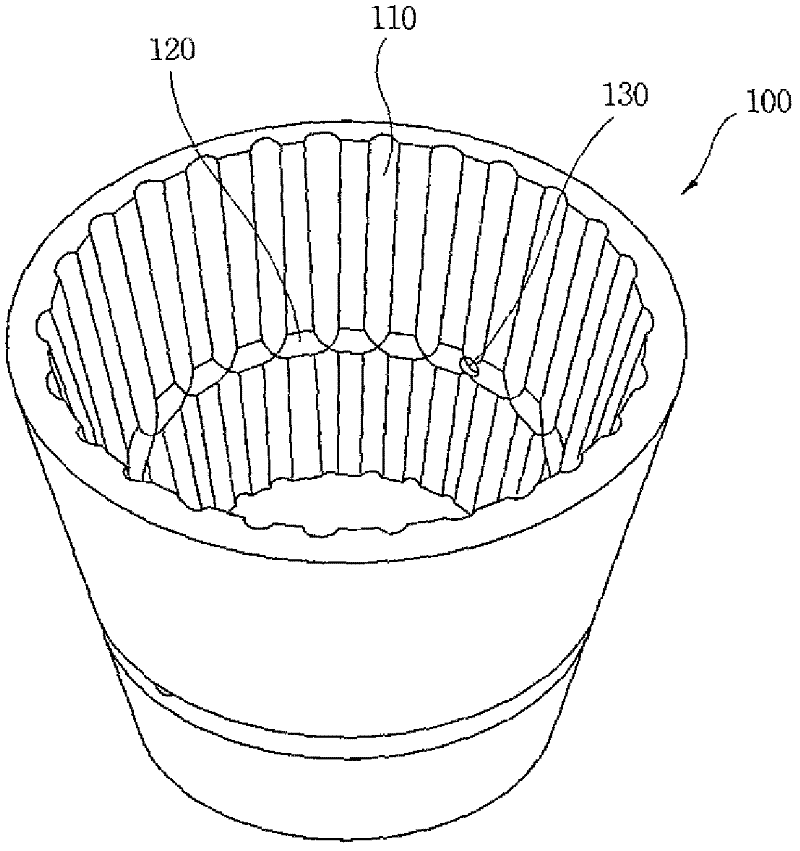

Coil pipe inner wall processing device

ActiveCN114260263AUniform lubricationEasy to handleHollow article cleaningLubrication elementsNonferrous metalEngineering

The invention relates to the technical field of non-ferrous metal processing equipment, in particular to a coil pipe inner wall processing device which comprises a guide head, an oil inlet is formed in the middle of the guide head in a communicating mode, and flow guide grooves are evenly embedded in the outer surface of the guide head; one end of the guide head is fixedly connected with a column body, a nozzle is embedded in the column body, a lubricating belt is arranged in the middle of the column body, a sponge is arranged at the other end of the column body and wraps the outer side of the column body, and the outer side of the sponge makes contact with the inner wall of the aluminum pipe. By arranging the flow guide groove and the nozzle, a cleaning agent or lubricating oil and the like can be guided into the inner wall of the aluminum pipe, the inner wall of the aluminum pipe is flushed or lubricated through pressure generated by compressed air, the flushing or lubricating effect is better, spraying flushing or lubricating of the nozzle is more uniform, and the treatment effect is better.

Owner:ASIA PACIFIC LIGHT ALLOY NANTONG TECH

Bearing chamber for vertical pump

The invention discloses a bearing chamber for a vertical pump. The bearing chamber comprises a vertical bearing chamber cavity provided with stepped holes. The bearing chamber is characterized in thatthe inner wall of the vertical bearing chamber cavity is fixedly connected with two or more inwards bulged bearing outer ring supporting rib plates in a spaced manner; each bearing outer ring supporting rib plate comprises a radial supporting block provided with an inner arc surface, and a longitudinal supporting step fixedly connected with the lower end of the radial supporting block; the innerends of the longitudinal supporting steps are located on the inner sides of the inner arc surfaces; and the two side surfaces of each radial supporting block are oblique surfaces and a certain included angle is formed between each oblique surface and the vertical direction. The contact areas between lubricating oil and the inner wall of the bearing chamber and between the lubricating oil and a bearing outer ring can be increased, the lubricating and heat dissipation effects are improved substantially, an oil storage space is increase d, and normal working of the vertical pump is ensured for along time.

Owner:SICHUAN ZIGONG IND PUMP

Processing method of surface roughness of superhard laser crystal

A method for processing the surface roughness of a superhard laser crystal, the method comprising the steps of grinding, rough polishing, precision ring polishing and the like. The method of the invention strictly controls the grinding amount of each process in the grinding stage through the detection of the particle size of the abrasive, and fundamentally removes subsurface defects; by adding polishing aids, the polishing liquid is more uniformly dispersed and lubricated, thereby effectively controlling the surface The generation of subsurface defects greatly improves the surface roughness of superhard laser crystals. For Nd:YAG crystals with specifications of 125mm×6mm×6mm and 133mm×33mm×3mm, the roughness of the two large surfaces reaches 0.3nm.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

A Lubricated Round Knife Die Cutting Fixture

The invention belongs to the technical field of mechanical jig equipment, and relates to a lubricating type circular-knife die cutting jig. The main body structure of the lubricating type circular-knife die cutting jig comprises a circular knife, a steel shaft, a rubber shaft, a sponge shaft, limiting rings, positioning rings, bearings, clamping grooves, a base body, a knife point and knife rests; the circular knife is arranged on the upper part of the base body; the knife point is arranged on the periphery of the circular knife; the knife rests are arranged on the left end and the right end of the circular knife respectively; the circular knife is fixedly connected to the base body through the knife rests; the steel shaft is arranged at the lower part of the base body; the rubber shaft and the sponge shaft are arranged at the top of the base body, wherein the rubber shaft and the sponge shaft are of cylindrical structures, the rubber shaft of a rubber coating type structure is arranged at the lower part, and the rubber shaft is arranged at the upper part; the left end and the right end of the rubber shaft are connected to the left end and the right end of the sponge shaft respectively through the bearings and the clamping grooves; and the limiting rings and the positioning rings are arranged at the positions, located on the inner sides of the bearings, of the left end and the right end of the rubber shaft respectively, wherein the limiting rings and the positioning rings are of circular ring structures. The lubricating type circular-knife die cutting jig is simple in structure, reliable in principle, novel in design, simple and convenient to operate, wide in application range, friendly to use environment, good in cutting effect and high in cutting efficiency.

Owner:青岛盈科精密橡塑有限公司

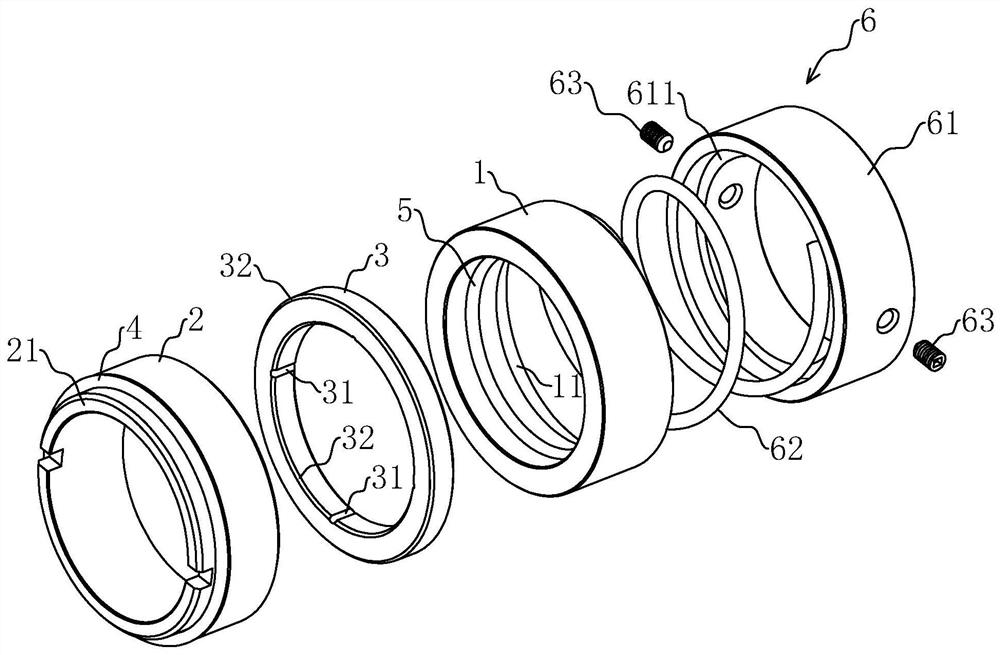

Self-lubricating mechanical seal

ActiveCN112682513AAvoid deformationImprove stabilityEngine sealsEngine lubricationSulfideDuctile iron

The invention relates to a self-lubricating mechanical seal, relates to the technical field of mechanical seals, and solves the problem of short service life of a common mechanical seal. The self-lubricating mechanical seal comprises a moving ring and a static ring, a self-lubricating ring is arranged between the moving ring and the static ring, and the surface hardness of the moving ring and the surface hardness of the static ring are both greater than the surface hardness of the self-lubricating ring. Sulfide is added into ductile iron / nodular cast iron / alloy steel to a saturated state to prepare the self-lubricating ring, and the sulfur content in the self-lubricating ring is 0.9%-2.5%. The self-lubricating mechanical seal has a self-lubricating function, and is not prone to abrasion and long in service life.

Owner:武汉宇格电力设备有限公司

Transmission mechanism for drive unit

PendingCN113757345AReduce spacingEnsure adequate lubricationBall bearingsGear lubrication/coolingRolling-element bearingStructural engineering

Owner:ROBERT BOSCH GMBH

An oil-air lubricated bearing seat with two-way nozzles and its application method

ActiveCN106523532BMeet lubrication needsEvenly distributedShaftsRotary machine partsFixed bearingGas lubrication

An oil-gas lubrication bearing pedestal with two-way nozzles comprises a floating bearing pedestal body and a fixed bearing pedestal body, and the floating bearing pedestal body and the fixed bearing pedestal body are arranged in parallel. A plurality of oil inlet pipelines are arranged in the fixed bearing pedestal body in the axial direction in a through mode. The oil-gas lubrication bearing pedestal further comprises an oil injection disc arranged between the two bearing pedestal bodies. A plurality of oil injection holes are annularly and evenly formed in the side, close to the fixed bearing pedestal body, of the oil injection disc. A plurality of oil ducts are formed inside the oil injection disc in the radial direction. The oil inlet pipelines, the oil injection holes and the oil ducts communicate in a one-to-one correspondence mode. The flow-out end of each oil duct is further provided with the corresponding nozzle in a communicating mode. The nozzles are divided into two groups with opposite oil injection directions, the numbers of the two groups of nozzles are equal, and the nozzles are evenly arranged in the circumference direction at intervals. The outer wall of the fixed bearing pedestal body and the floating bearing pedestal body are sleeved with an integral gland, and a pressing ring is fixedly arranged at the end of the integral gland and used for conducting axial limitation on the fixed bearing pedestal body. The oil-gas lubrication and oil distribution mode of two-way oil injection is adopted, oil-gas supply paths are independent from one another, and adjustment is convenient.

Owner:HENAN UNIV OF SCI & TECH

An environmentally friendly wet dyeing and finishing process for preparing original thick high-grade soft sofa leather

ActiveCN110923371BGood dispersionGood flexibilityTanning treatmentPre-tanning chemical treatmentOrganolepticPolymer

The invention discloses an environment-friendly wet-state dyeing and finishing process for preparing raw thick high-grade soft sofa leather, which comprises the following steps in sequence: batching of raw thick wet blue leather→squeezing, smoothing, weighing→rinsing→enzymatic softening①→ Water washing→chrome-free retanning→neutralization→enzyme softening②→water washing→dyeing→fatliquoring→water washing→finishing; this application uses aldehyde tanning agent, cationic polymer tanning agent and amphoteric polymer tanning agent for chrome-free retanning , Using acid protease and ammonia-free softening enzyme for secondary softening treatment, and reasonable matching design of neutralization and fatliquoring process, so that the prepared original thick type high-grade soft sofa leather is soft, plump and elastic, and the whole body is uniform and smooth Full of cotton foam, good softness, all physical and mechanical properties, physical and chemical properties and sensory properties meet the standard of sofa leather, and has good follow-up processing performance; and the process does not use chrome tanning agent, ammonium bicarbonate And other materials, and save the conventional filling process, can greatly reduce pollution.

Owner:XINGYE LEATHER TECH CO LTD

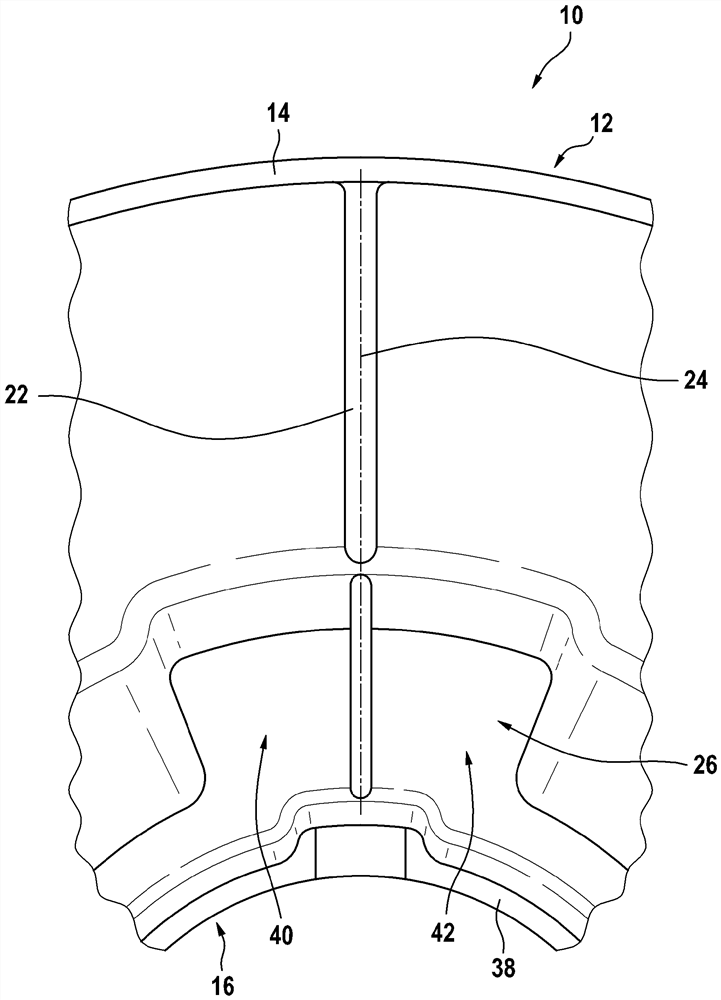

Circular-ring-shaped groove even oil supplying structure vertically provided with rolling bearings

PendingCN110173511AUniform cooling effectUniform lubricationEngine lubricationBearing unit rigid supportRolling-element bearingOil storage

The invention relates to a circular-ring-shaped groove even oil supplying structure vertically provided with rolling bearings. The circular-ring-shaped groove even oil supplying structure is providedwith a set of rolling bearings installed in a bearing seat, and an oil supply opening located above the rolling bearings. A circular-ring-shaped oil storage structure is arranged between the rolling bearings and the oil supply opening. Lubricating oil discharged from the oil supply opening is fully charged into the circular-ring-shaped oil storage structure firstly and overflows onto the rolling bearings. By means of the circular-ring-shaped groove even oil supplying structure vertically provided with the rolling bearings, compared with an existing direct single-side oil spraying manner of a conventional spray pipe, lubricating oil discharged from an oil supply pipe is charged into the circular-ring-shaped groove firstly and overflows onto the rolling bearings, and relatively even coolingand lubricating of a whole roller path can be achieved.

Owner:SHANGHAI MARINE EQUIP RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com