Three-segment type abrasion-resistant and temperature-resistant bloom foot roller

A bloom, three-stage technology, applied in the field of foot rolls of bloom continuous casting machines, can solve problems such as failure of foot roll bearings, jamming of foot roll bearings, inability to synchronize maintenance cycles, and influence on continuous casting machine operating rates, etc., to improve operating rates, The effect of shortening the heat stop time and shortening the equipment maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

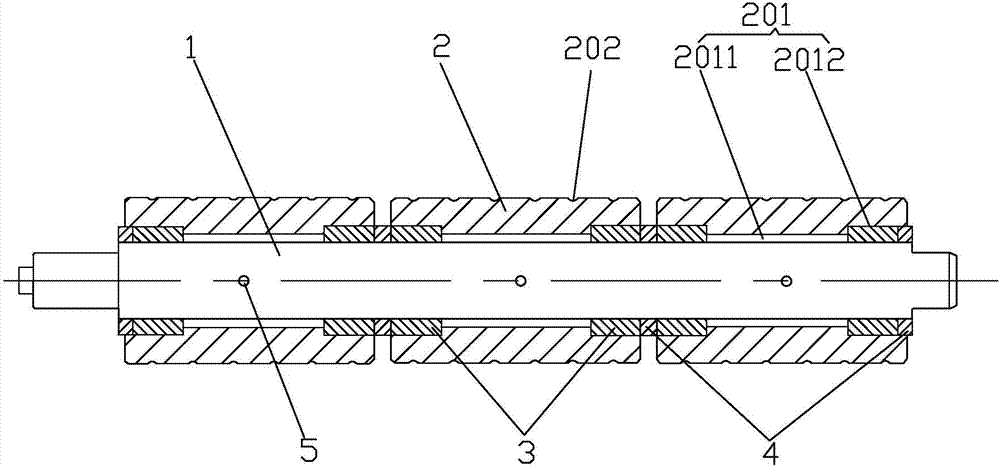

[0022] A three-stage wear-resistant and temperature-resistant bloom foot roll provided in this embodiment has a structure such as figure 1 As shown, a mandrel 1 is included, and a three-section single roller 2 is also included.

[0023] The surface of the single roller 2 is provided with evenly distributed cooling grooves 202, and the cooling grooves 202 are distributed in a spiral shape.

[0024] The center of the single roller 2 is provided with a mounting hole 201, the mounting hole 201 includes a through mounting hole 2011 and a mounting hole 2012, the aperture of the mounting hole 2011 is smaller than the aperture of the mounting hole 2012, and the mounting hole 2012 is located ends.

[0025] The mandrel 1 passes through the mounting holes 201 of the three-section single roller 2 in turn, and the two mounting holes 2012 are provided with copper sleeves 3, the diameter of the mounting hole 2012 is the same as the diameter of the copper sleeve 3, and the copper sleeve 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com