Whirling tool

A tool and cutting edge technology, applied in the field of rotary cutting tools, which can solve problems such as the limitation of coolant flow direction, and achieve the effect of reducing wear, high surface quality, and improving chip removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

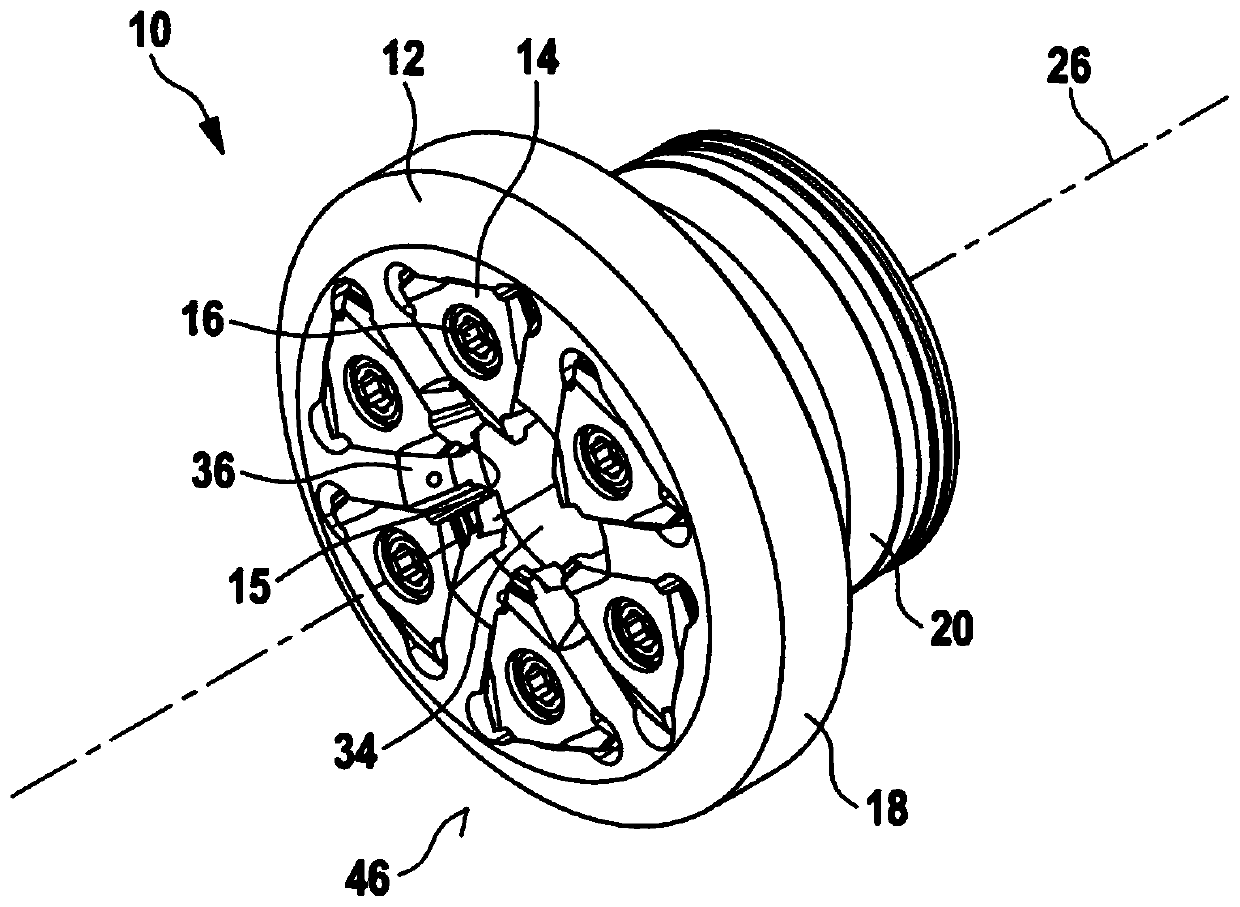

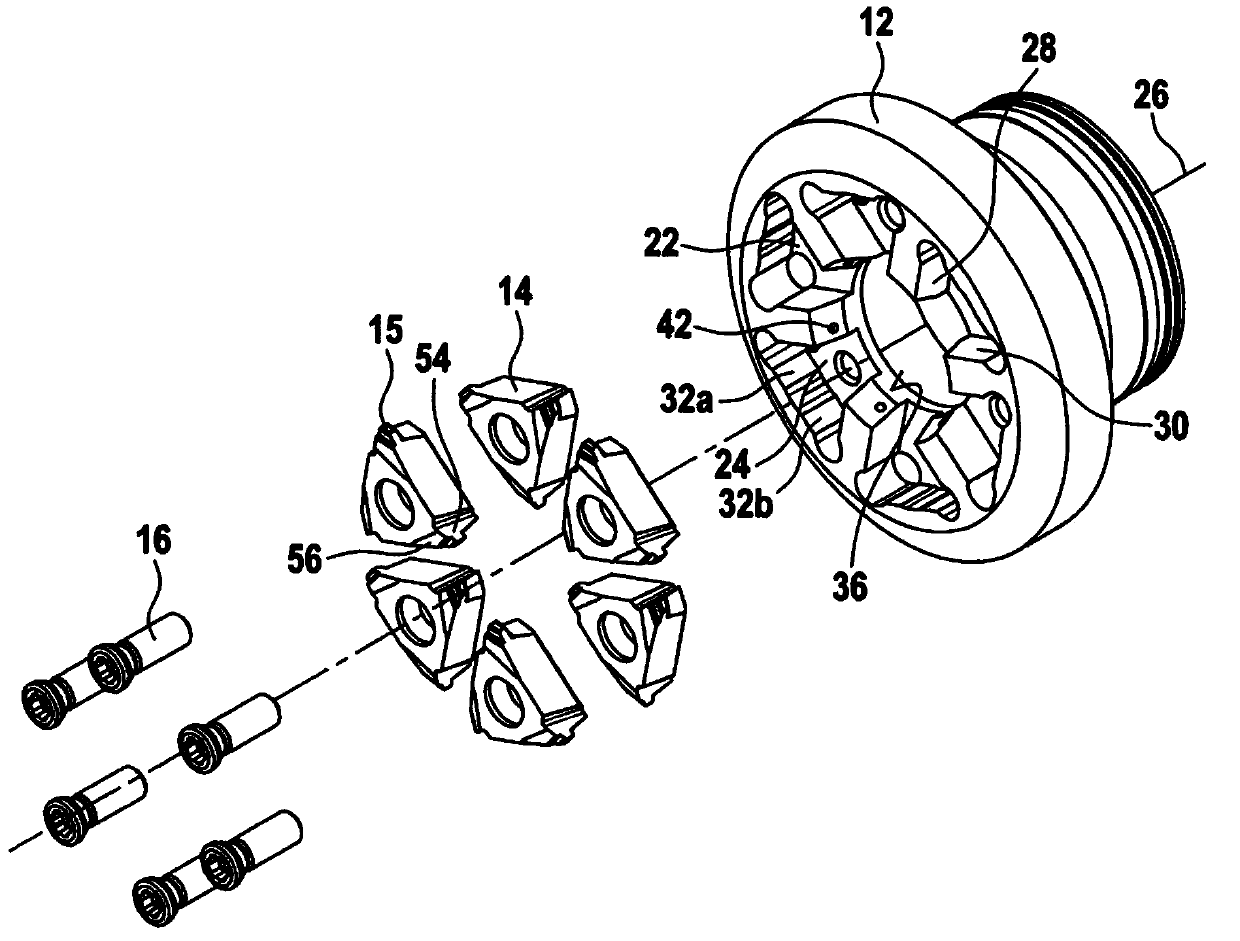

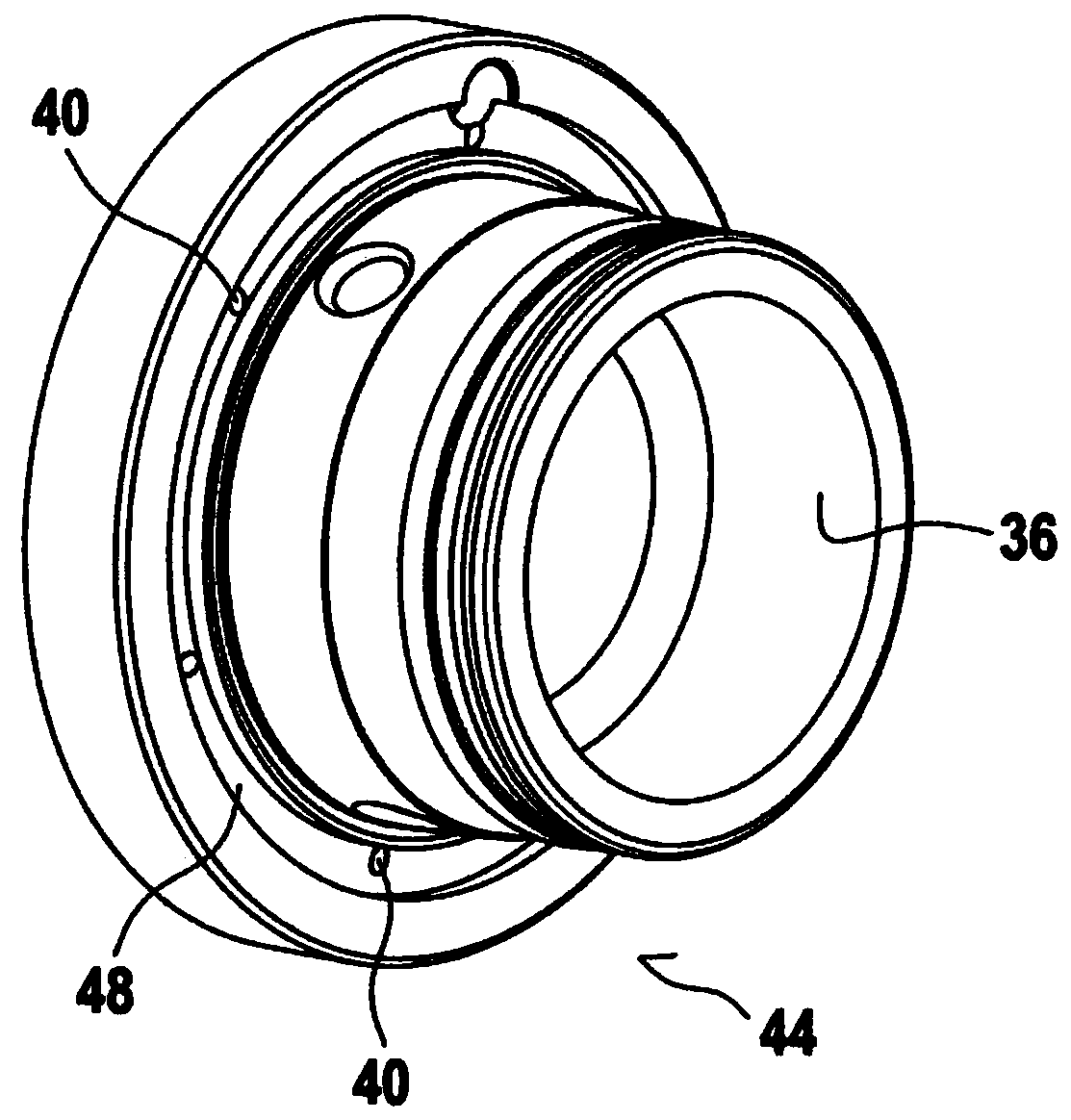

[0058] Figure 1 to Figure 18 Four different exemplary embodiments of rotary cutting tools according to the invention are shown. This exemplary embodiment differs substantially in the design of the internal coolant channels provided in the interior of the rotary cutting tool. Furthermore, there are small structural differences between the exemplary embodiments, especially with respect to the design of the connection flange of the rotary cutting tool, but these differences are not highlighted with respect to the present invention.

[0059] According to the rotary cutting tool of the present invention in Figure 1-18 The whole is indicated by reference numeral 10 .

[0060] The rotary cutting tool 10 includes a cutting blade carrier 12 to which a plurality of cutting blades 14 are releasably secured by fastening elements 16 . The cutting insert 14 is preferably an indexable insert made of hard metal. The fastening screw 16 is preferably configured as a self-tapping screw whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com