Gear transmission structure

A gear transmission and gear technology, which is applied to transmission parts, gear lubrication/cooling, belt/chain/gear, etc., can solve the problems of cost increase, gear damage, and low gear life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

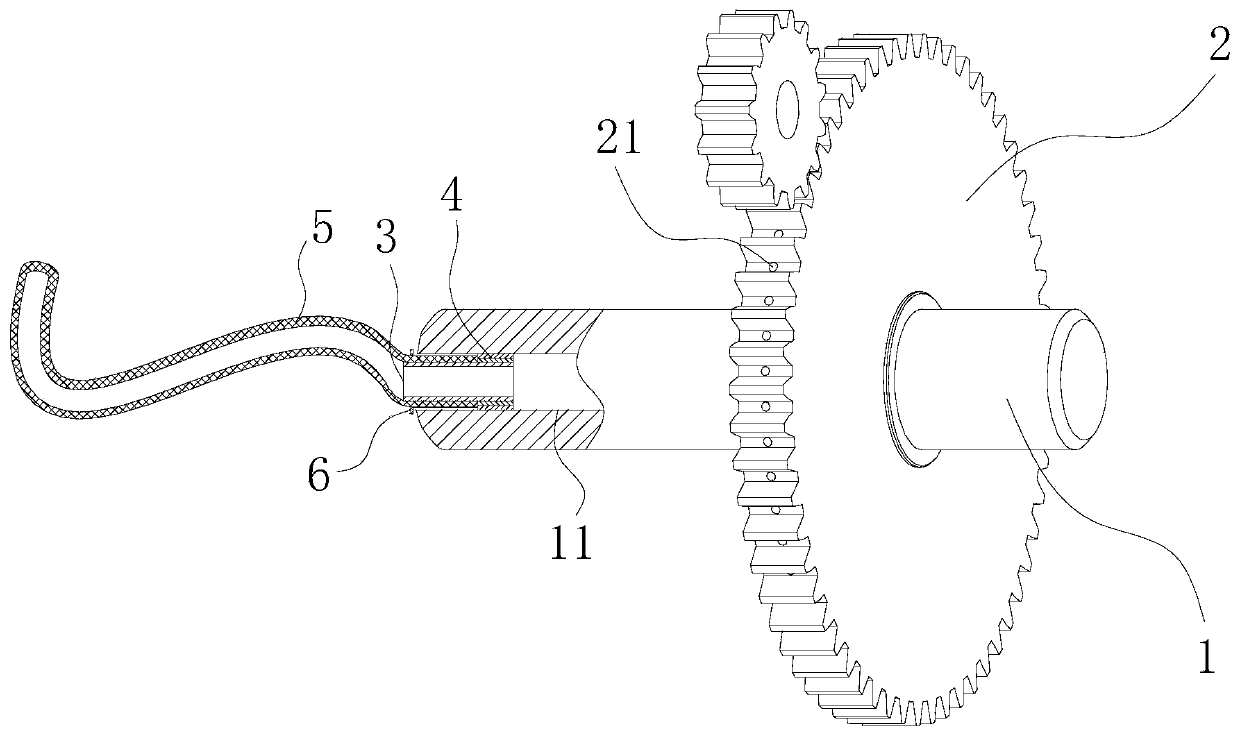

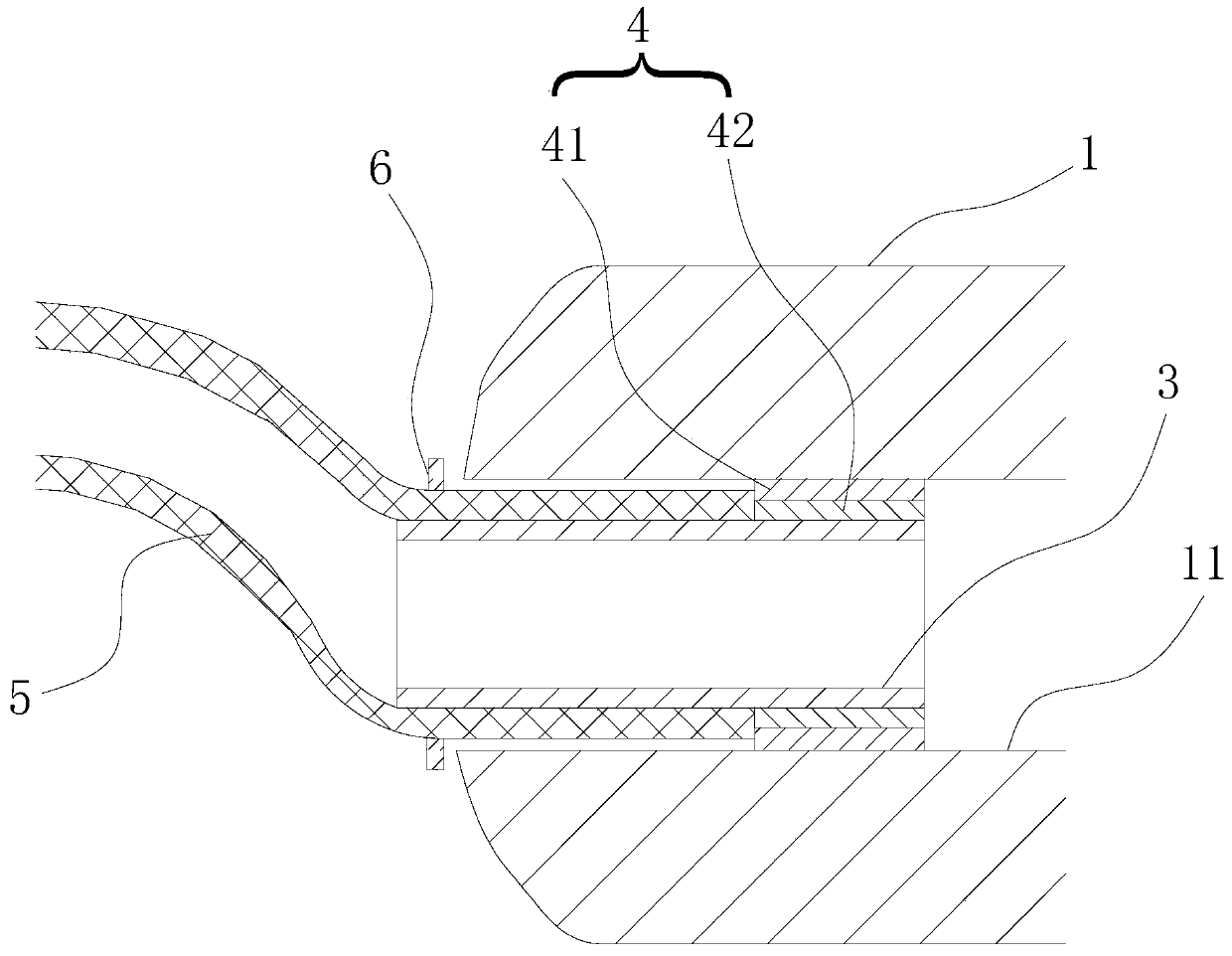

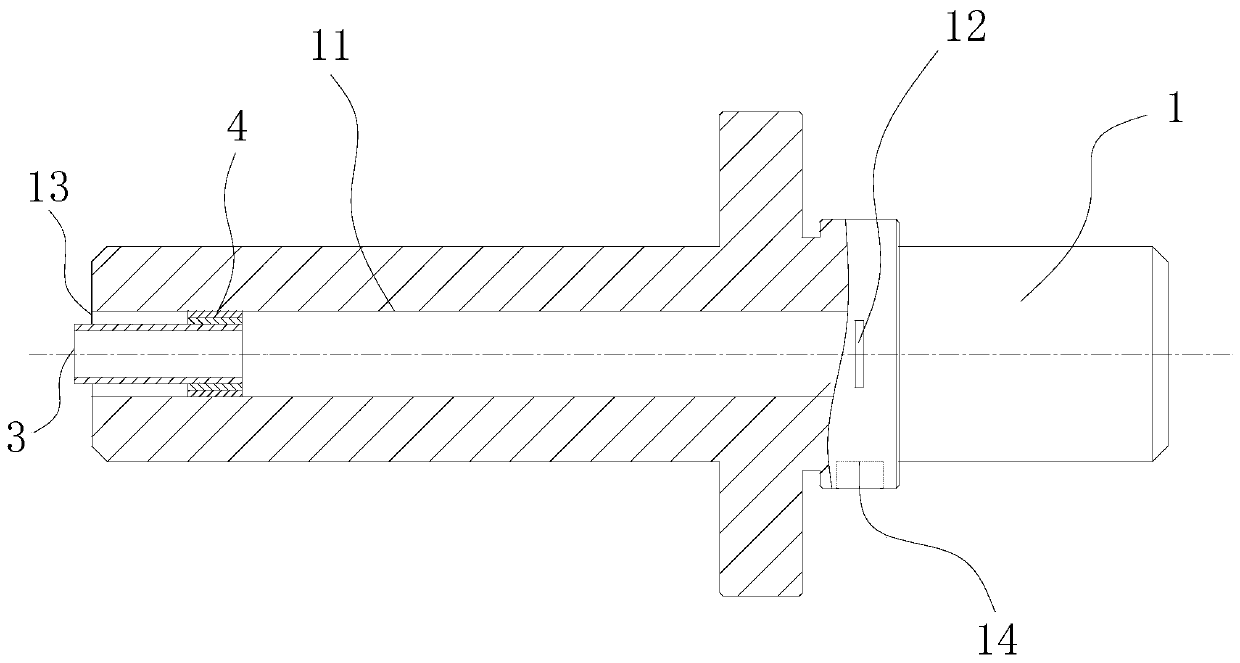

[0025] Please refer to Figure 1-Figure 3 , Embodiment 1 provides a gear transmission structure, including a rotating shaft 1 and a gear 2, the rotating shaft 1 has an oil inlet passage 11 and an oil passage groove 12, the oil inlet passage 11 is arranged inside the rotating shaft 1, and the oil passage groove 12 is arranged in The outer wall of the shaft 1, and the oil groove 12 communicates with the oil inlet passage 11, and the gear 2 has an oil hole 21 inside, and the first end of the oil hole 21 is set on the tooth of the gear 2 or where the root circle of the gear 2 is. The second end of the oil hole 21 is set on the inner wall of the center hole, the gear 2 is sleeved on the rotating shaft 1 and the oil hole 21 communicates with the oil groove 12 . When supplying oil to the oil inlet passage 11, lubricating oil enters the oil inlet passage 11, flows into the oil passage groove 12 from the oil inlet passage 11, and then flows through the oil passage groove 12 through the...

Embodiment 2

[0030] The gear transmission structure provided by the second embodiment differs from the first embodiment in that the cross-sectional area of the first end of the oil through hole 21 is smaller than the cross-sectional area of the second end of the oil through hole 21 . Embodiment 2 is suitable for occasions with heavy loads, and the effect of the hydrodynamic oil film formed at the meshing position of the gears 2 under this working condition is better than that of Embodiment 1.

[0031] The above is the preferred embodiment of the present invention. In the preferred embodiment of the present invention, an oil passage 21 is provided inside the gear 2, and an oil inlet channel 11 and an oil passage 12 are provided in the rotating shaft 1 to deliver the lubricating oil to the meshing part of the gear 2. , so that the gear 2 forms a hydrodynamic oil film at the meshing point to ensure the lubricating effect, and at the same time, the amount of lubricating oil is uniform, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com