Spinneret provided with specially-shaped holes

A special-shaped hole and spinneret technology, which is used in filament/thread forming, textile and papermaking, fiber processing, etc., can solve the problems of insufficient uniformity of silk strands and insufficient distribution of spinning solution, and reduce equipment cleaning. The number of times, smoothness and dyeing uniformity are good, and the effect of improving the smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

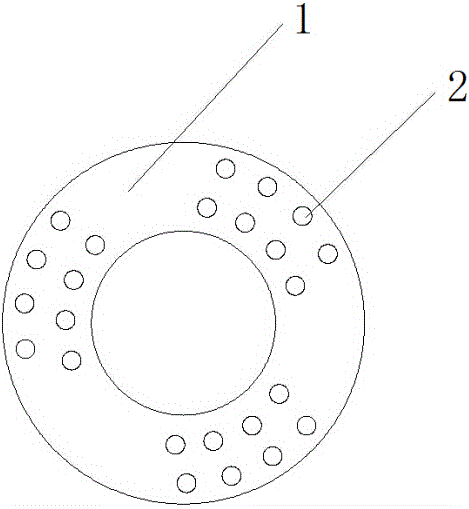

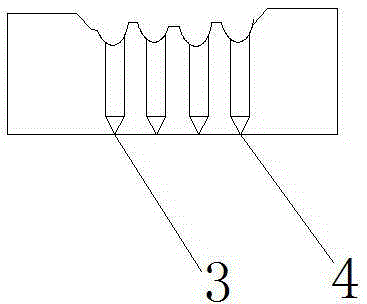

[0024] A spinneret with special-shaped holes, including a diversion groove 1 and a spinneret hole 2, the spinneret hole 2 is divided into three parts, each group of spinneret holes 2 is composed of a circular hole 3 and a special-shaped hole 4, The circular hole 3 and the special-shaped hole 4 are intersectingly distributed, and the difference between the circular hole and the special-shaped hole is that the silk outlet is circular and special-shaped.

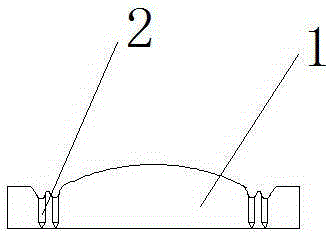

[0025] In order to better realize the present invention, the part between two adjacent groups of spinneret holes 2 is a guide groove 1, and the cross section of the guide groove 1 is an upwardly convex circular arc.

[0026] In this embodiment, the diameter of the circular hole 3 is 0.08mm; the total length of the special-shaped hole 4 is 0.08mm, and its shape is a circular arc raised in the middle at the upper and lower ends, parallel straight lines on both sides, and circles at the left and right ends. arc; wherein, the raise...

Embodiment 2

[0028] A spinneret with special-shaped holes, including a diversion groove 1 and a spinneret hole 2, the spinneret hole 2 is divided into three parts, each group of spinneret holes 2 is composed of a circular hole 3 and a special-shaped hole 4, The circular holes 3 and the special-shaped holes 4 are intersecting.

[0029] In order to better realize the present invention, the part between two adjacent groups of spinneret holes 2 is a guide groove 1, and the cross section of the guide groove 1 is an upwardly convex circular arc.

[0030] In this embodiment, the diameter of the circular hole 3 is 0.15mm; the total length of the special-shaped hole 4 is 0.15mm, the upper and lower ends of the special-shaped hole 4 have a raised arc in the middle, and the left and right ends of the special-shaped hole 4 are semicircular arcs , the circular arc and the semicircular arc are connected by a straight line; wherein, the raised circular arc accounts for one-third of the total length of th...

Embodiment 3

[0032] A spinneret with special-shaped holes, including a diversion groove 1 and a spinneret hole 2, the spinneret hole 2 is divided into 4 parts, each group of spinneret holes 2 is composed of a circular hole 3 and a special-shaped hole 4, The circular holes 3 and the special-shaped holes 4 are intersecting.

[0033] In order to better realize the present invention, the part between two adjacent groups of spinneret holes 2 is a guide groove 1, and the cross section of the guide groove 1 is an upwardly convex circular arc.

[0034] In this embodiment, the diameter of the circular hole 3 is 0.12 mm; the total length of the special-shaped hole 4 is 0.10 mm, the upper and lower ends of the special-shaped hole 4 have a raised arc in the middle, and the left and right ends of the special-shaped hole 4 are semicircular arcs. , the circular arc and the semicircular arc are connected by a straight line; wherein, the raised circular arc accounts for one-third of the total length of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com