Transmission mechanism for drive unit

A transmission mechanism and drive unit technology, applied to transmission parts, mechanical equipment, belts/chains/gears, etc., to achieve the effects of minimizing agitation losses, benefiting efficiency, and saving structural space and materials or weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

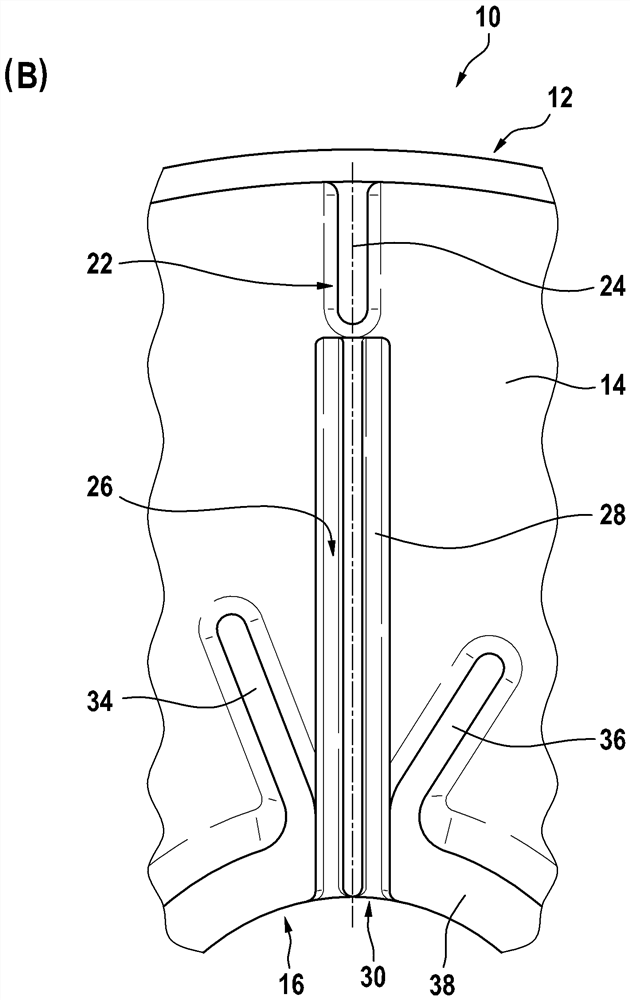

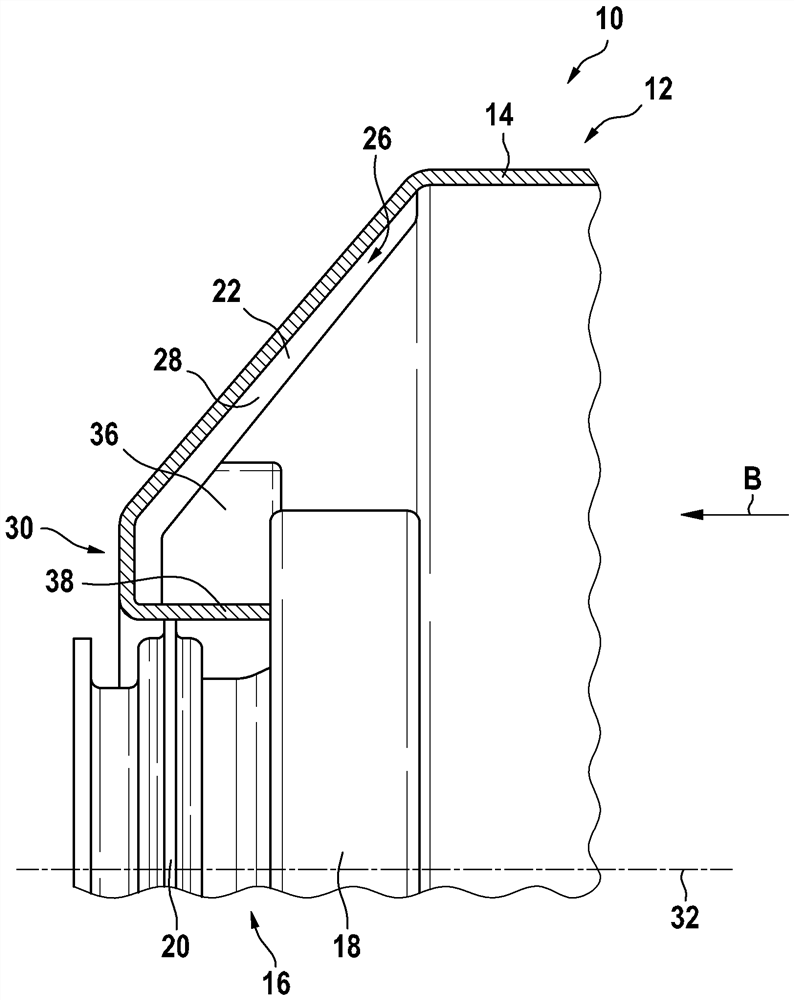

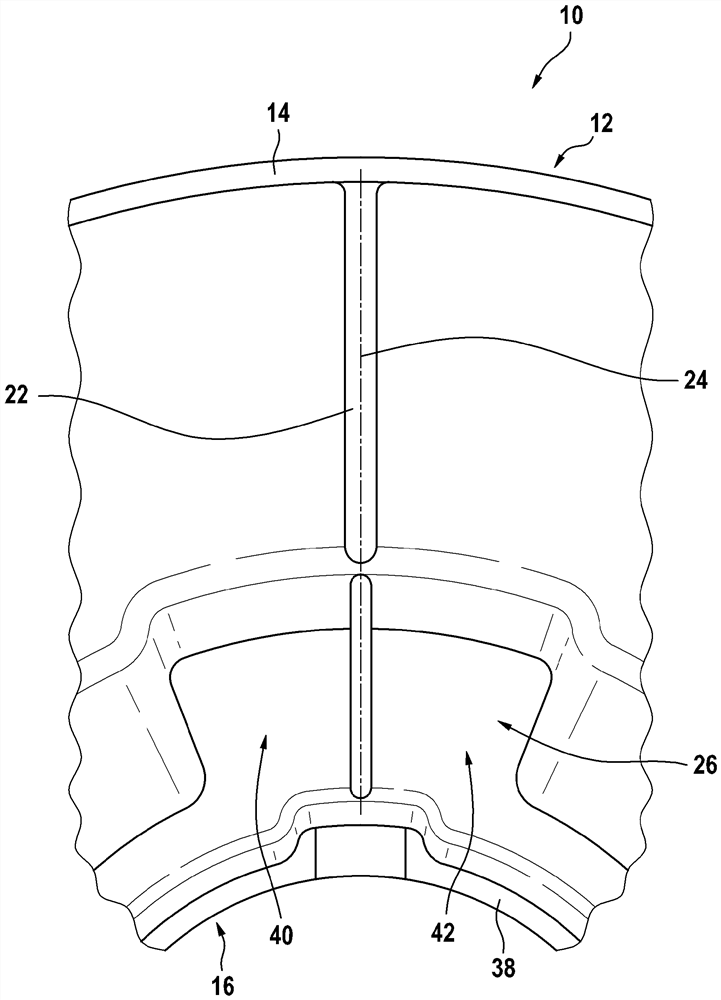

[0025] exist figure 1 and figure 2 In , a transmission for a drive unit of a vehicle generally bears the reference numeral 10 .

[0026] The transmission 10 has a transmission housing 12 with a wall 14 . A seat 16 for a rolling bearing 18 and / or a radial shaft sealing ring 20 is formed in the wall 14 . In this example, the rolling bearing 18 and the radial shaft sealing ring 20 are inserted into the carrier 16 (see figure 1 ).

[0027] Scraper ribs 22 protruding from the wall 14 are formed on the wall 14 and extend along a central longitudinal axis 24 (cf. figure 2 ). The central longitudinal axis 24 of the scraper rib 22 intersects (in its extension) the seat 16 for the rolling bearing 18 and / or the radial shaft sealing ring 20 . Between the scraper rib 22 and the seat 16 a recess 26 is formed in the wall, which extends between the scraper rib 22 and the seat 16 .

[0028] The transmission 10 can have further components, for example a transmission shaft with toothing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com