Lubricating oil recycling device of automobile gearbox

A cyclic regeneration and gearbox technology, applied in the field of auto parts, can solve problems such as uneven cooling, gear damage, bearing damage, etc., to avoid the effect of impurities remaining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

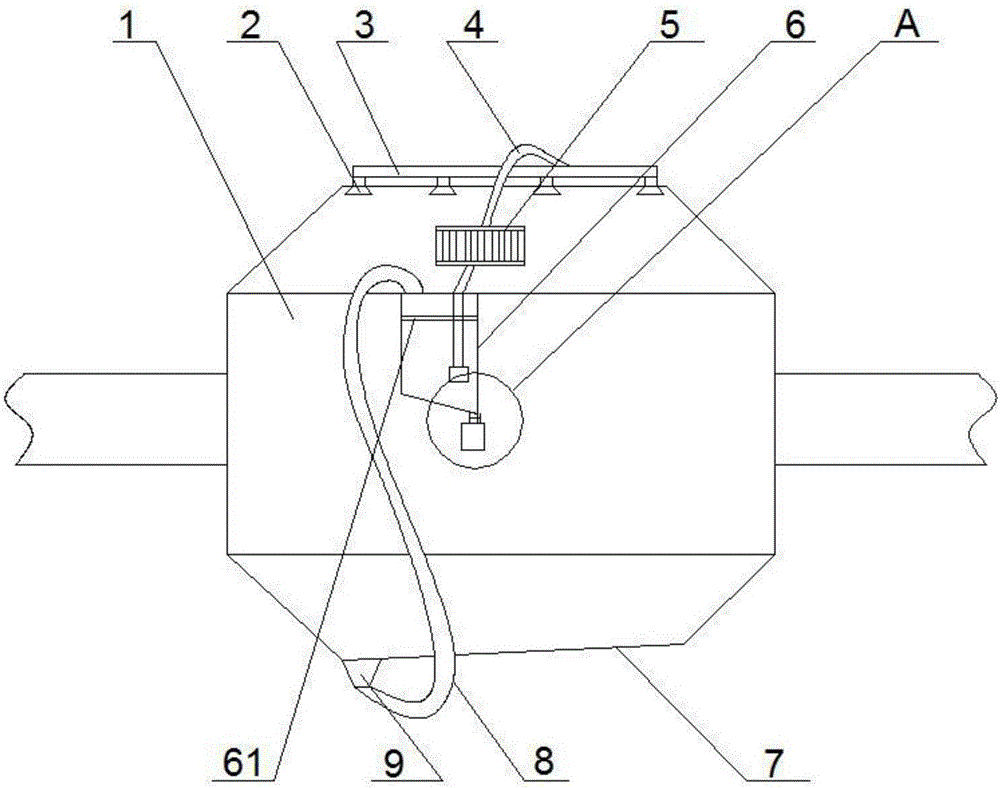

[0029] An automotive gearbox lubricating oil circulation regeneration device, comprising a gearbox body 1, a spray mechanism arranged on the upper part of the gearbox body 1, a circulation outlet 9 arranged at the bottom of the gearbox body 1, and connected to the circulation outlet 9 and the filter mechanism 6 of the spray mechanism;

[0030] The spray mechanism includes a spray pipe 3 arranged on the upper part of the gearbox body 1, and

[0031] One end penetrates the upper part of the gearbox body 1 and extends into the gearbox body 1, and the other end communicates with the spray nozzle 2 of the spray pipe 3;

[0032] The bottom surface of the gear case 1 is an inclined surface 7, and the circulation outlet 9 is provided at the low-lying end of the inclined surface 7;

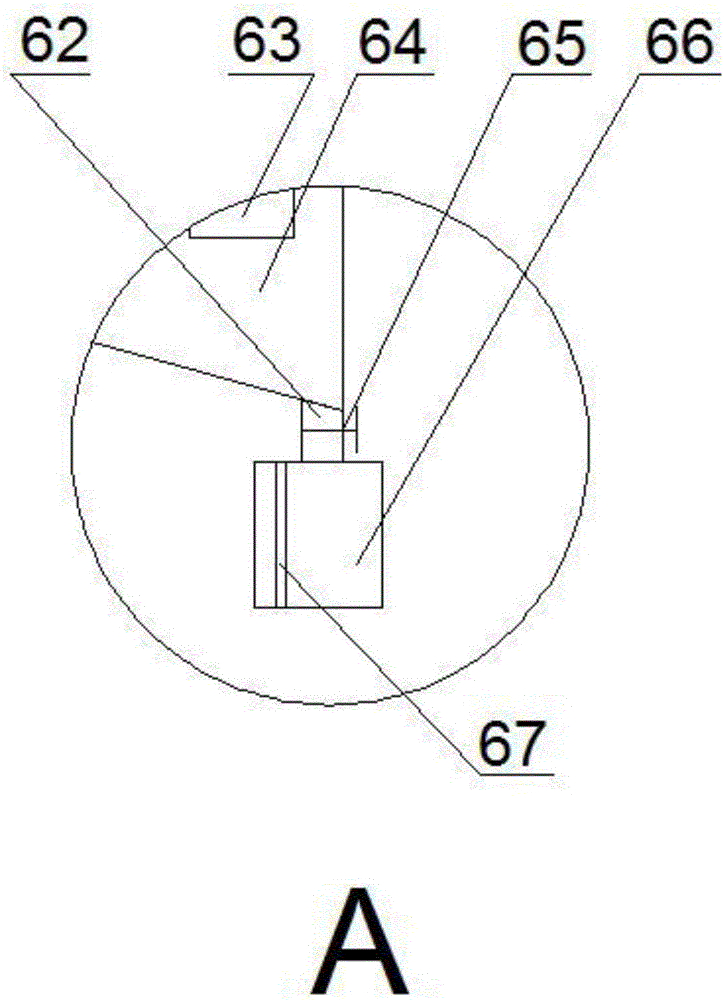

[0033] The filter mechanism includes a filter chamber 64, an oil inlet pipe 8 and an oil outlet pipe 4 arranged on the filter chamber 64, an oil pump 63 arranged at the end of the oil outlet pipe 4, and t...

Embodiment 2

[0037] The difference from Embodiment 1 is that the bottom surface of the filter cavity 64 is an inclined bottom surface, and the deposition tube 62 is arranged at the lower end of the inclined bottom surface.

[0038] A transparent display column 67 for observing the internal state of the deposition tank 66 is arranged in the deposition tank 66 .

[0039]The filtering bottom surface adopted in this embodiment is an inclined bottom surface, and the sedimentation tube is arranged at the low-lying end of the inclined bottom surface, and can also be arranged in a funnel shape, and is used in the sedimentation tank to observe the transparent display column of the internal state of the sedimentation tank, which can be used in the sedimentation tank. The real-time situation of lubricating oil can be visually observed during daily inspections. Since the gears in the gearbox will generate a lot of heat due to high-load operation, if it is not dissipated in time, it will cause accelerat...

Embodiment 3

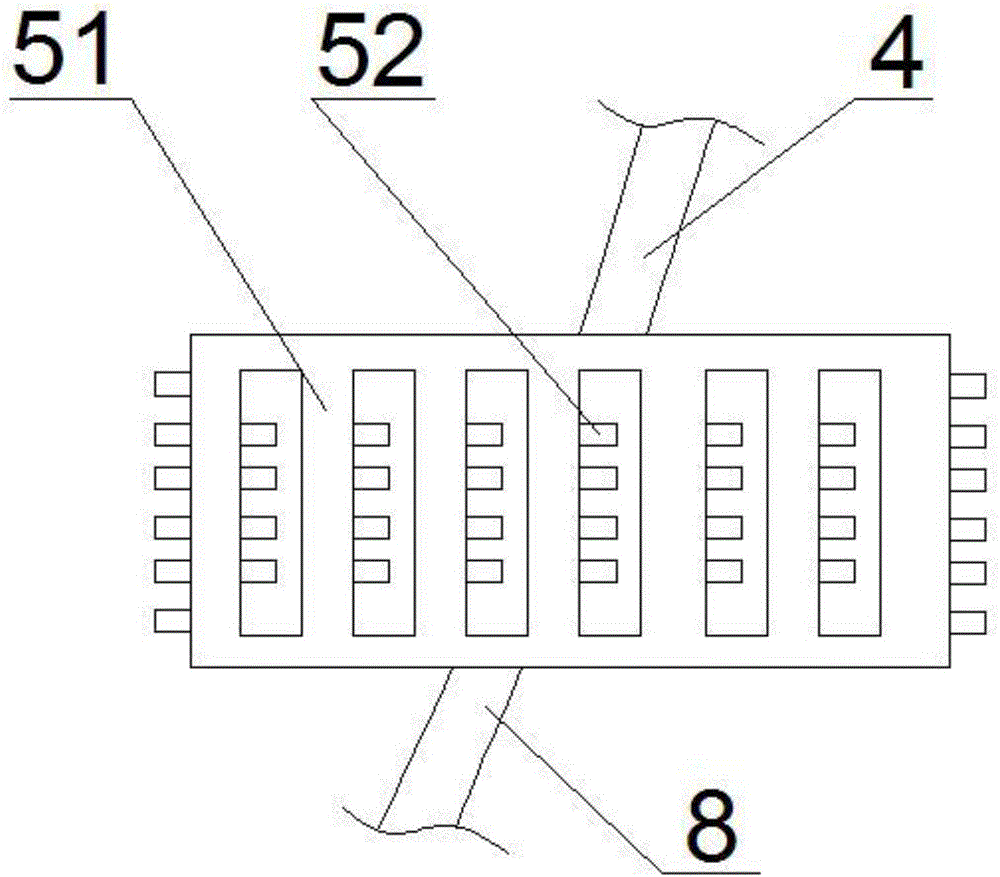

[0041] The difference between it and the second embodiment is that: the oil outlet pipe 4 is provided with a cooling mechanism 5 for cooling lubricating oil; Sheet 52.

[0042] The upper opening of the deposition tank 66 is provided with an internal thread, and the lower part of the deposition tube 62 is provided with an external thread matched therewith, and the surfaces of the internal thread and the external thread are provided with a polytetrafluoroethylene coating for sealing.

[0043] The transparent display column 67 is semi-cylindrical.

[0044] The upper part of the filter cavity 64 is provided with a filter screen 61 for filtering lubricating oil entering the filter cavity.

[0045] The working method of the present invention: through the oil pump, the lubricating oil in the filter cavity is sucked out and sent to the cooling mechanism, and after passing through the cooling mechanism, it enters the spraying mechanism to spray the gear box, and the lubricating oil at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com