Method for preparing corona-resistant polyamide-imide enameled wire paint

A technology of polyamide-imide and wire enamel, which is applied in the field of wire enamel manufacturing, to achieve the effects of good compatibility, no precipitation and layering, and easy production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

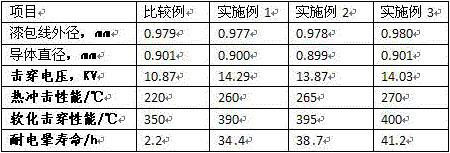

Examples

Embodiment 1

[0017] (1) Pretreatment of nano-scale inorganic oxide particles; put 4000 grams of water and ethanol mixture (including 2000 grams of water and 2000 grams of ethanol) into a reactor with a stirring device, gradually raise the temperature to 60 ° C, and put 1000 grams of nano Grade titanium dioxide powder, 20 grams of γ-aminopropyltriethoxysilane, stirring for 2-3 hours, and adjusting the pH value to 4-5.5, dehydrating the slurry through a centrifuge and then drying to a water content of less than 0.01 % powder;

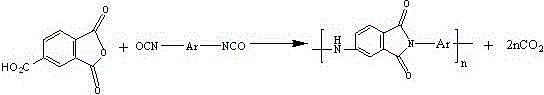

[0018] (2) Preparation of polyamide-imide resin solution; in a 30-liter reactor equipped with a stirring device and a reflux condensing device, 2502 grams of diphenylmethane diisocyanate, 1902 grams of trimellitic anhydride, and 13212 grams of methylpyrrolidone were added from When the room temperature rises to 70°C, carbon dioxide bubbles begin to escape, and then the temperature is raised to 190°C at a rate of 15-25°C per hour, and kept for 1-2 hours, the system gra...

Embodiment 2

[0022] (1) Pretreatment of nano-scale inorganic oxide particles; put 4000 grams of water and ethanol mixture (including 2000 grams of water and 2000 grams of ethanol) into a reactor with a stirring device, gradually raise the temperature to 60 °C and put 1000 grams of nano Grade silica powder, 40 grams of vinyl tris (methoxyethoxy) silane, stirred and reacted for 2-3 hours, and after adjusting the pH value to 4-5.5, the slurry was dehydrated by a centrifuge and then dried to Powder with water content less than 0.01%;

[0023] (2) Polyamide-imide resin solution preparation; In a 30-liter reactor equipped with a stirring device and a reflux condensation device, 2,502 grams of diphenylmethane diisocyanate, 1,960 grams of trimellitic anhydride, and 13,386 grams of methylpyrrolidone were added from When the room temperature rises to 70°C, carbon dioxide bubbles begin to escape, and then the temperature is raised to 190°C at a rate of 15-25°C per hour, and kept for 1-2 hours, the sy...

Embodiment 3

[0027](1) Pretreatment of nano-scale inorganic oxide particles; put 4000 grams of water and ethanol mixture (including 2000 grams of water and 2000 grams of ethanol) into a reactor with a stirring device, gradually raise the temperature to 60 ° C, and put 1000 grams of nano Grade aluminum oxide powder, 30 grams of isopropyl tris (dioctyl phosphate acyloxy) titanate, stirred for 2-3 hours, and after the pH value was adjusted to 4-5.5, the slurry was passed through a centrifuge Dehydration and then drying to a powder with a moisture content of less than 0.01%;

[0028] (2) Preparation of polyamide-imide resin solution; in a 30-liter reactor equipped with a stirring device and a reflux condensing device, 2502 grams of diphenylmethane diisocyanate, 1883 grams of trimellitic anhydride, and 13155 grams of methylpyrrolidone were added from When the room temperature rises to 70°C, carbon dioxide bubbles begin to escape, and then the temperature is raised to 190°C at a rate of 15-25°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com