Expansion type rotatable drilling liner hanger

A liner hanger and expansion technology, which is applied in the direction of wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problems of small contact area, poor liner stability effect, and affect the use of liner, etc. Achieve the effects of not easy to settle and stratify, good cementing effect, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

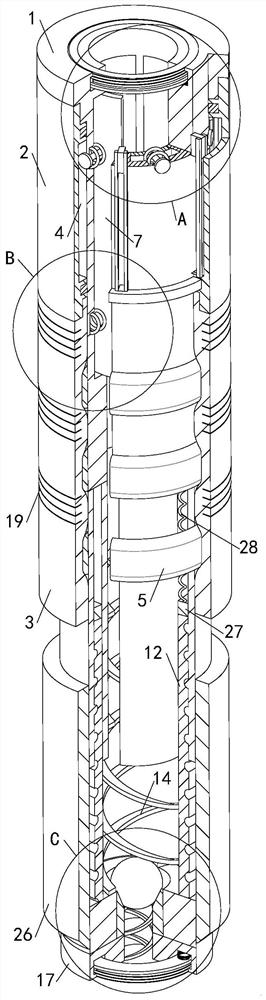

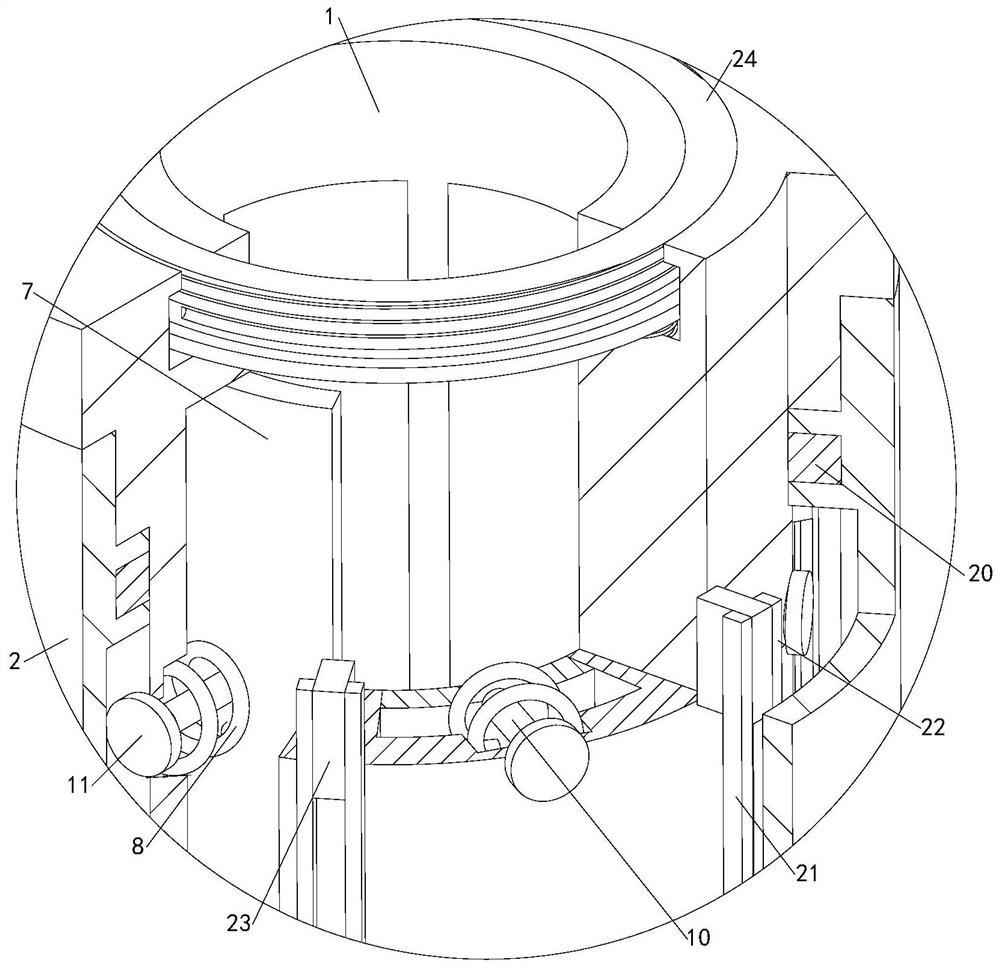

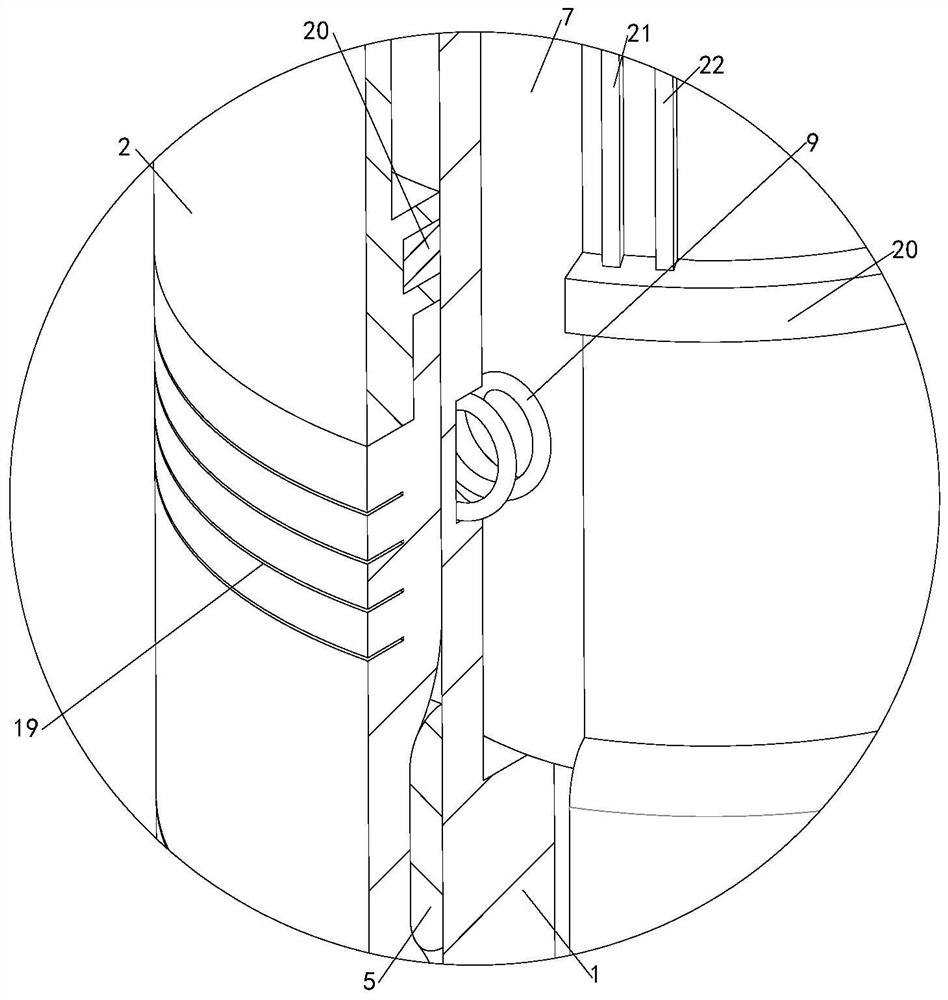

[0032] see Figure 1-6, an expandable rotatable liner hanger, comprising a liner 1 and a hydraulic cylinder mount mechanism 2, and also includes an elastic slip pipe 3, the hydraulic cylinder mount mechanism 2 is installed on the tail pipe 1, and the hydraulic cylinder mount mechanism A plurality of first guide strips 21 and a plurality of second guide strips 22 are fixedly connected to the inner wall of the tail pipe 2, and a plurality of guide blocks 23 are fixedly connected to the outer wall of the tail pipe 1, and the first guide strips 21 and the second guide strips 22 are respectively The two ends of the guide block 23 are slidably fitted, so that the directionality of the hydraulic cylinder mounting mechanism 2 relative to the tail pipe 1 is better, which is more practical. Two concave ring grooves are provided in the hydraulic cylinder mounting mechanism 2, and the two A seal ring 20 is arranged in each concave ring groove, and the inner wall of the seal ring 20 is sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com