Grenade fixing device of front-loading type grenade launcher

A launcher, front-loading technology, used in weapon accessories, offensive equipment, etc., can solve the problems of projectile sliding, failure, fatigue, etc., and achieve the effect of using a stable and reliable bomb fixing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

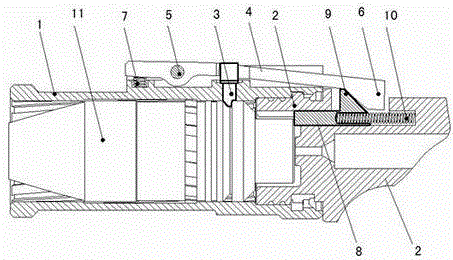

[0010] figure 1 As shown: the launch tube 1 is equipped with a locking pin 3 that can block the launch of the grenade 11. The locking pin 3 is constrained in the middle of a lever-type pressing rod 4 that can rotate around the pivot pin 5. One end of the pressing rod 4 has a An integrated inclined blocking ridge 6, a top spring 7 is installed between the other end and the launch tube 1, and a pneumatic piston 8 is installed above the transmitter base 2 at the tail of the launch tube 1. There is a block on the upper side of the pneumatic piston 8 tail. 6 coincide with the push sill 9 that touches, and return spring 10 is equipped with at the tail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com