Oil well liquid water content measuring apparatus

A measuring device and liquid volume technology, applied in measuring devices, liquid/fluid solid measurement, specific gravity measurement, etc., can solve the problems of many manual intervention factors, large measurement errors, troublesome operation, etc., to eliminate the influence of human factors and objective data , using reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

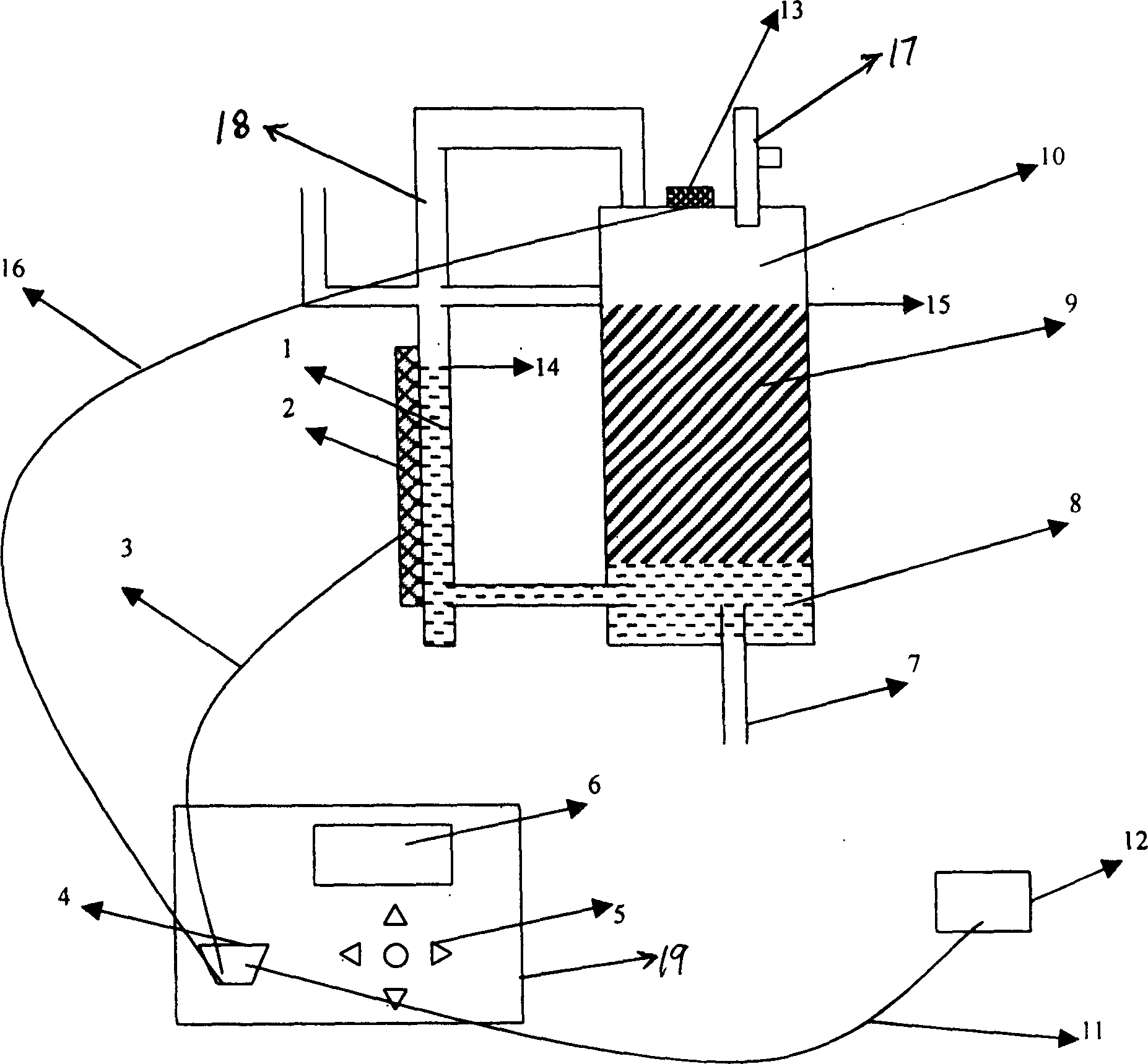

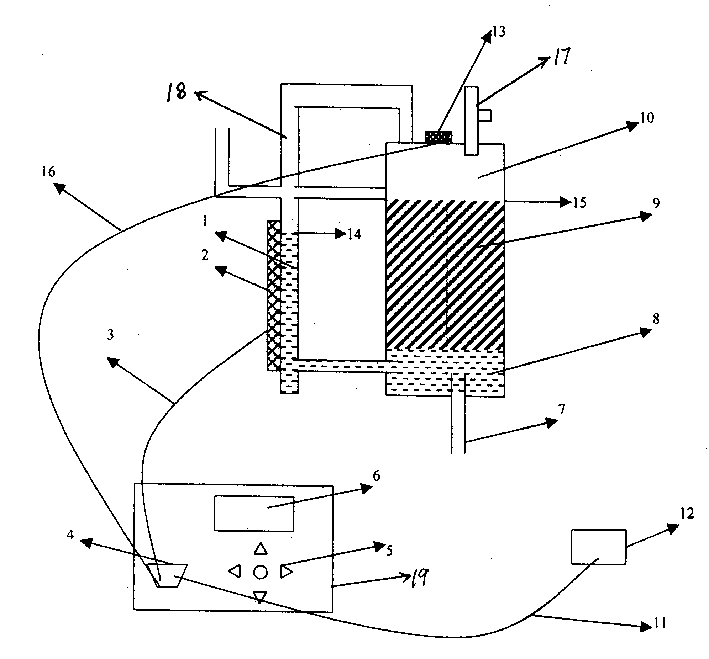

[0008] As can be seen from the figure, the data acquisition and processing instrument is mainly a liquid crystal display module 6 controlled by a single-chip microcomputer in the integrated circuit board 19, an RS232 serial port line 11, a clock module, and data storage and signal processing parts. The sensor part is composed of a liquid level sensor 2, a magnetic reversal liquid level gauge 1 installed on one side and an ultrasonic liquid level gauge 13 installed on the top of the separator 10, and is connected to the separator 10, and a drain is installed above the separator 10. Air valve 17 is equipped with liquid inlet pipe 7 below separator 10, and connecting pipeline 18 of the present invention is equipped with above; The liquid crystal display module 6 in the single-chip microcomputer in the integrated circuit board 19 is connected with the membrane switch 5 and controlled, one side The signal communication interface 4, the signal line 3 are connected with the liquid lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com