Method and device for fixing safety belt

A technology of fixing device and seat belt, applied in the direction of seat belt, life-saving equipment, etc., can solve the problems of hidden danger of operators and nowhere to hang the seat belt, and achieve the effect of ensuring personal safety, preventing falling, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

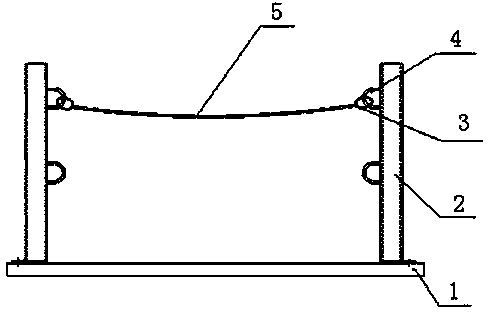

[0012] Refer to attached figure 1 , a safety belt fixing device, comprising a transformer oil tank edge 1, a column 2, a buckle 3, a mounting ring 4 and a rope 5, two columns 2 are vertically welded on the transformer oil tank edge 1, and the distance between the two columns Matching the size of the transformer oil tank, several mounting rings 4 are evenly welded on each column 2, and buckles 3 are provided at both ends of the rope 5, and the buckles 3 at both ends of the rope 5 are respectively stuck on the mounting rings on the same horizontal plane of the two columns On, the safety belt is slidably connected with the rope 5.

[0013] When the operator needs to operate on the top of the large transformer oil tank, the safety belt is hung on the rope 5, and the safety belt can also be moved on the rope, which eliminates potential safety hazards and ensures th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com