Method for preparing concavo-convex rod soil/zinc oxide nanometer composite material

A nano-zinc oxide, attapulgite technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of inability to reflect the adsorption performance of nano-attapulgite, weakening the effect of acidification modification, and large attapulgite particles, etc. Achieve the effect of not easy precipitation and stratification, low processing cost and good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

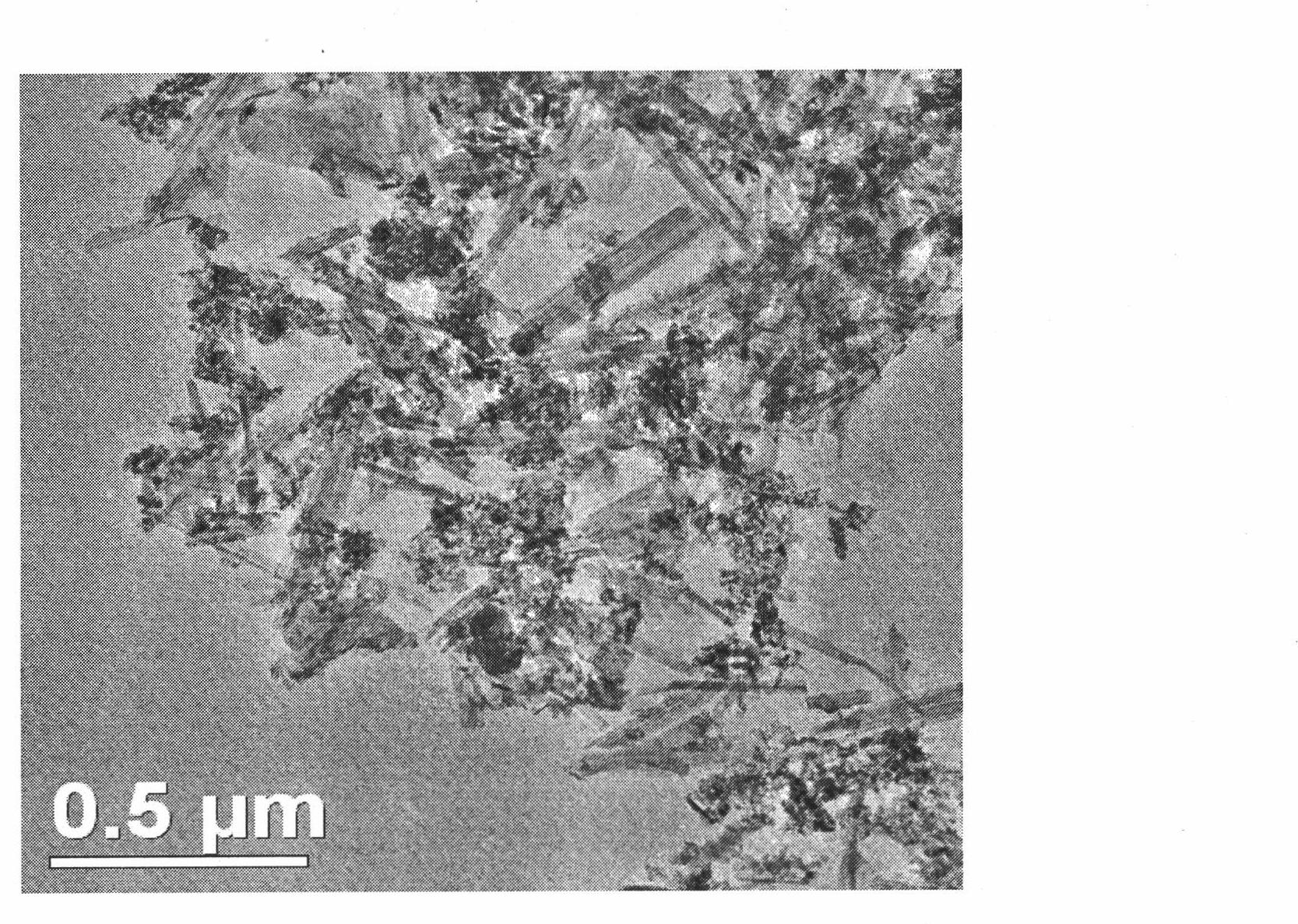

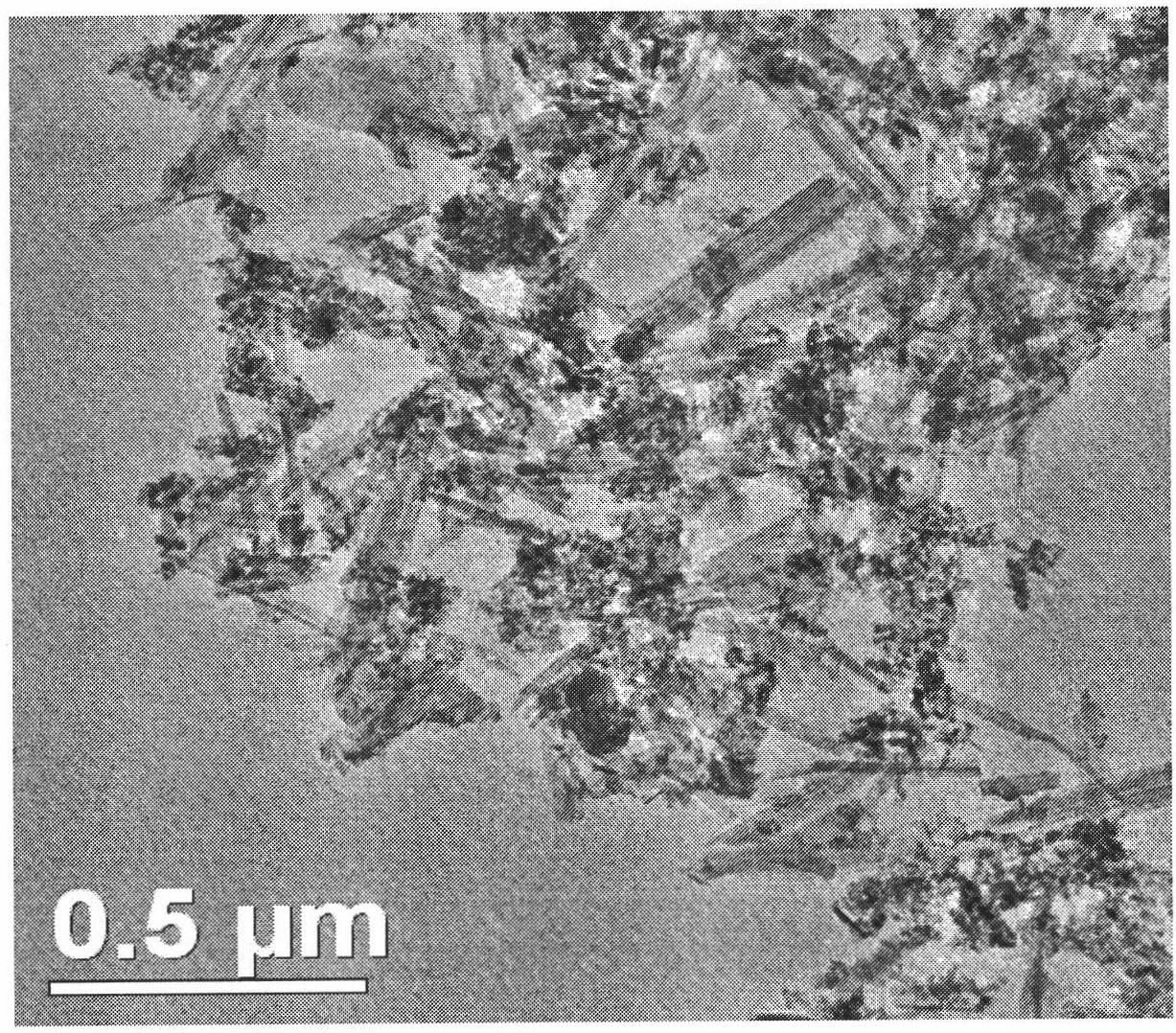

Image

Examples

Embodiment 1

[0032] Add attapulgite to deionized water to prepare attapulgite containing 100g L -1 Add 4L of the suspension of attapulgite to 3% sodium hexametaphosphate, use ME-100 high-shear mixing and emulsifying machine (US Ross Company) to disperse for 2 hours at a speed of 6000 rpm, let it stand for 100 hours, and remove the lower part The impurity precipitated, and the obtained solid content was 75g·L -1 nano-attapulgite dispersion. Measure 400mL of nano-attapulgite dispersion and place it in a 1000mL four-necked flask. -1 Aqueous solution of zinc sulfate and a concentration of 0.3mol L -1 sodium carbonate aqueous solution, the control reaction temperature is 30 ℃, the pH value of the reaction system mixed solution is 6.0, the consumption of zinc sulfate is based on the mass of generating ZnO, accounts for 10% of the nano attapulgite quality, after the reaction solution is added dropwise, Stirring was continued for 0.5 hours. Filter and wash repeatedly with deionized water until...

Embodiment 2

[0035] Add attapulgite to deionized water to prepare attapulgite containing 50g L -1 Add 3L of the suspension of attapulgite mass 2% sodium pyrophosphate, use ME-100 high-shear mixing emulsifier (US Ross Company) to disperse for 10h at a speed of 4000 rpm, let stand for 80h, remove the lower Impurities were precipitated to obtain a solid content of 38g L -1 nano-attapulgite dispersion. Measure 600mL of nano-attapulgite dispersion and place it in a 1000mL four-necked flask. While stirring, add 3mol·L -1 Zinc chloride aqueous solution and concentration of 2mol L -1 Ammonium carbonate aqueous solution, control reaction temperature is 60 ℃, the pH value of reaction system mixed solution is 6.8, the consumption of zinc chloride is based on the mass meter that generates ZnO, accounts for 100% of nano attapulgite quality, after reaction solution is added, Stirring was continued for 5 hours. Filter and wash repeatedly with deionized water until the conductivity of the filtrate is ...

Embodiment 3

[0038] Add attapulgite to deionized water to prepare attapulgite containing 200g L -1 Add 3.5L of the suspension of attapulgite to 4% sodium polyacrylate, use a ME-100 high-shear mixing emulsifier (US Ross Company) to disperse for 4 hours at a speed of 5000 rpm, let it stand for 150 hours, and remove the lower part The impurity precipitates, and the obtained solid content is 150g·L -1 nano-attapulgite dispersion. Measure 300mL of nano-attapulgite dispersion and place it in a 1000mL four-necked flask. -1 Zinc nitrate aqueous solution and concentration of 1mol L -1 potassium carbonate aqueous solution, the control reaction temperature is 100 ° C, the pH value of the reaction system mixed solution is 8.0, the consumption of zinc nitrate is based on the mass of ZnO generated, accounting for 50% of the quality of nano attapulgite, after the reaction solution is added, continue Stir for 3 hours. Filter and wash repeatedly with deionized water until the conductivity of the filtra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com