Oil-gas lubrication bearing pedestal with two-way nozzles, and using method of oil-gas lubrication bearing pedestal

A technology of oil-air lubrication and bearing seat, which is applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of inability to realize high-speed rotation with large loads, and achieve the effects of compact structure, stable operation, and reduced heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

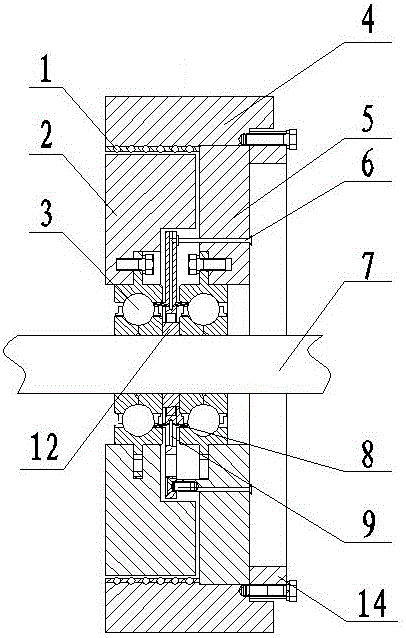

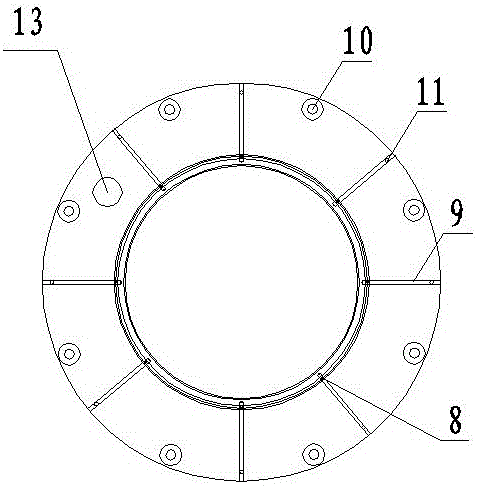

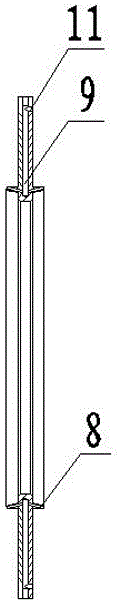

[0026] Embodiments of the present invention will be specifically described below with reference to the accompanying drawings.

[0027] Such as Figure 1 to Figure 3 As shown, a two-way oil-sprayed oil-air lubricated bearing seat includes a floating bearing seat 2 and a fixed bearing seat 5 arranged side by side, and several oil inlet pipelines 6 are arranged axially through the fixed bearing seat 5; On the oil spray plate between the two bearing seats, a number of oil injection holes 11 are evenly opened in a circular shape on the side of the oil spray plate close to the fixed bearing seat 5, and several oil injection holes 11 arranged radially are also arranged inside the oil spray plate. The oil passage 9, the oil inlet pipeline 6, the oil injection hole 11 and the oil passage 9 are connected in one-to-one correspondence, and the outlet end of the oil passage 9 is also connected with the nozzle 8; the nozzle 8 is divided into two groups with opposite directions of oil inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com