On-line cleaning method for oil injection compressor lubricating oil and system thereof

A technology for lubricating oil and compressor, which is applied in the field of online cleaning of lubricating oil to achieve the effect of realizing automatic control, improving the quality of lubricating oil and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

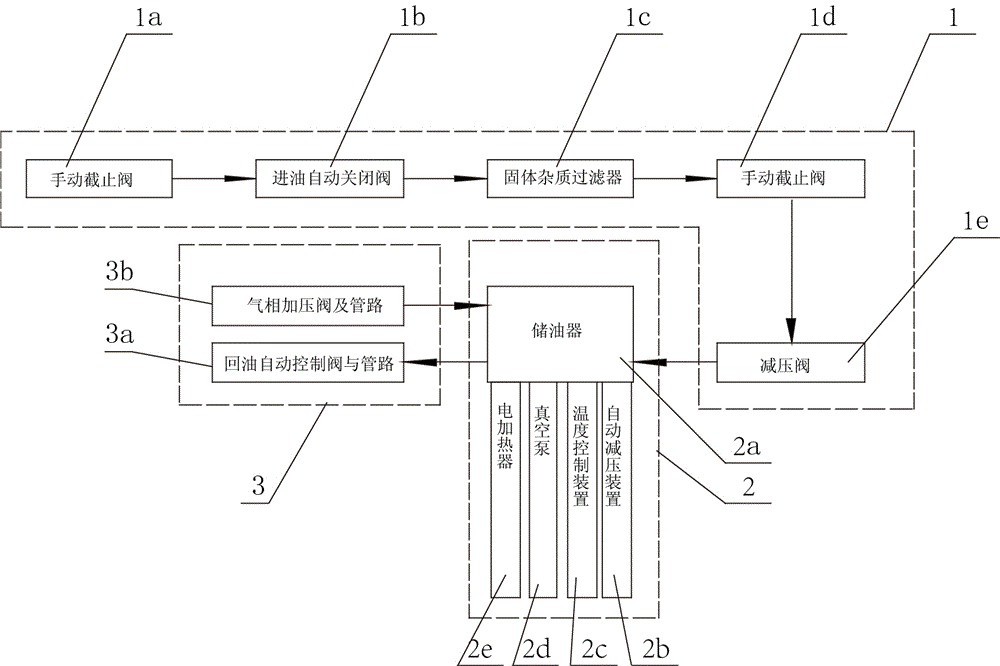

[0019] The online cleaning method for lubricating oil of oil-injected compressors of the present invention is to introduce the lubricating oil in the oil-injected compressors into the lubricating oil online cleaning system outside the oil-injected compressors under the working state of the oil-injected compressors. In the process, the liquid impurities brought by the inlet of the compressor are removed by the vacuum removal device;

[0020] At the same time, according to the impurity content of the inlet liquid detected by the inlet liquid impurity detection device, the automatic start and stop of the system is controlled. By detecting the impurity content of the inlet liquid in real time, and transmitting the data to the control device in real time, the control device controls the start and stop of the lubricating oil online cleaning system.

[0021] Alternatively, the automatic start and stop of the system is controlled according to the pressure at the suction end of the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com