Food grade bearing grease for hydraulic engineering as well as preparation method and application thereof

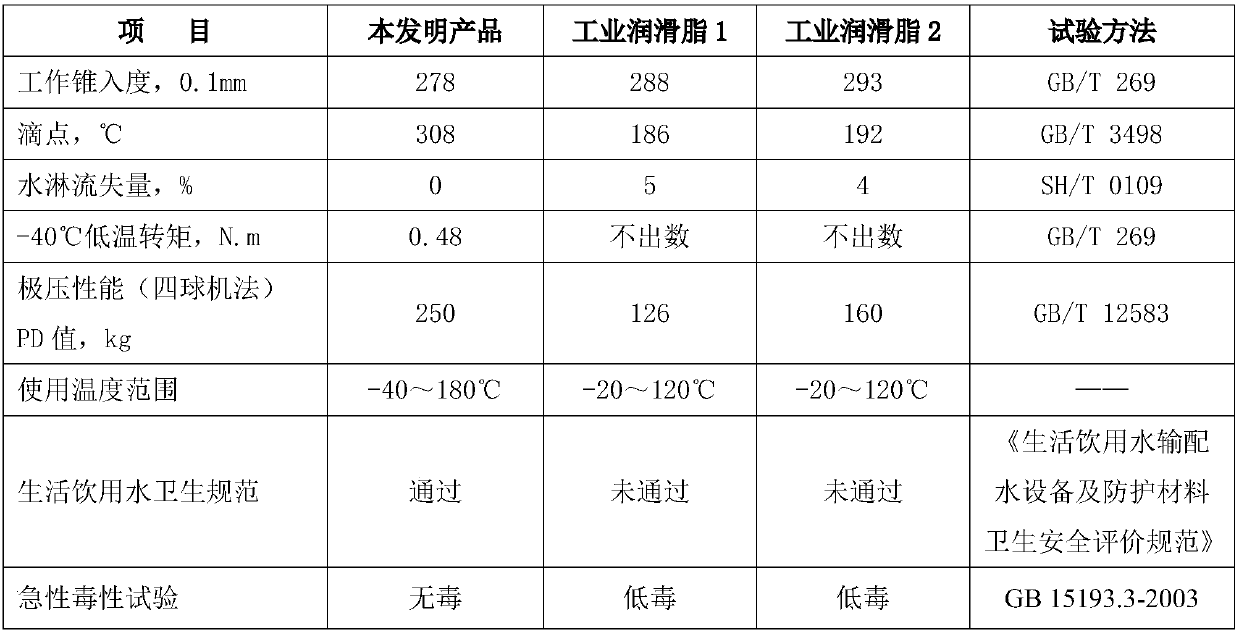

A bearing lubrication and hydraulic engineering technology, applied in the field of food-grade grease, can solve the problems of no food-grade grease literature and patent reports, and achieve the effect of good anti-wear extreme pressure, less oil splash and prolonging bearing life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

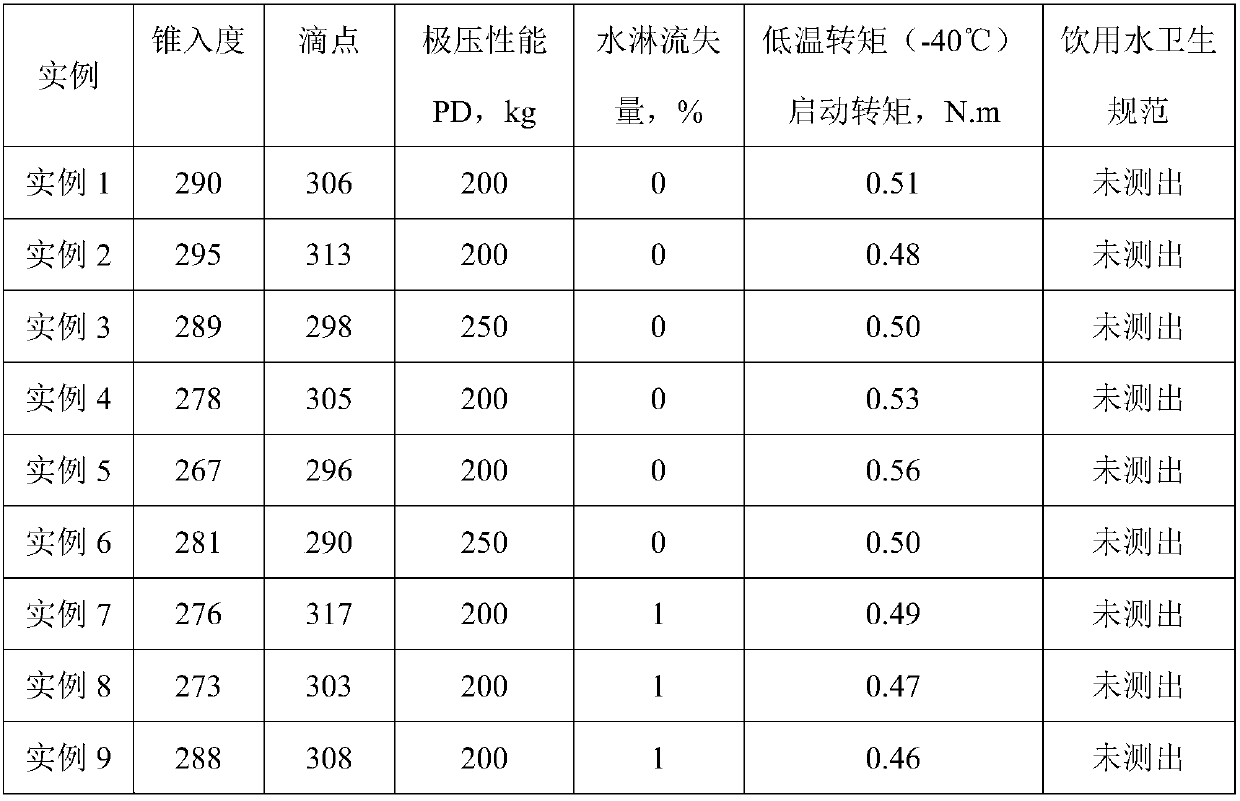

Examples

example 1

[0034] Base oil: 87%;

[0035] Thickener: 13%;

[0036] Sulfonate: 5% (additional);

[0037] The base oil is a food-grade synthetic oil, and the kinematic viscosity of the base oil at 100°C is 10 mm 2 / s and 40mm 2 / s; the thickener is composed of stearic acid, benzoic acid, and aluminum isopropoxide, and its molar ratio is 1:1.2:1.3; the organoaluminum is aluminum isopropoxide; the rust inhibitor is sulfonic acid calcium.

[0038] 150 grams of stearic acid, 77 grams of benzoic acid, and 140 grams of aluminum isopropoxide are added to 2000 grams of food-grade synthetic oil (ν 100 =10), heat to 80°C, react for 1 hour, continue to heat to 100°C, add 37 grams of tap water, keep the temperature constant for 1 hour, continue to heat up the material to 210°C, keep the temperature for 10 minutes, add 500g food-grade synthetic oil (ν 100 =40), when temperature dropped below 140 DEG C, add 143 grams of calcium sulfonate, carry out aftertreatment after stirring to obtain finished p...

example 2

[0041] Base oil: 94%;

[0042] Thickener: 6%;

[0043] Imidazoline: 0.5% (additional);

[0044] Phosphate amine salt: 0.5% (additional);

[0045] Triphenylthiophosphate: 0.5% (additional);

[0046] Calcium carbonate: 5% (additional);

[0047] The base oil is a food-grade synthetic oil, and the kinematic viscosity of the base oil at 100°C is 10 mm 2 / s and 60mm 2 / s; the thickening agent is composed of lauryl hydroxystearic acid, p-toluic acid, and aluminum isopropoxide, and its molar ratio is 1:1:1; the organoaluminum is aluminum isopropoxide; the The antirust agent is imidazoline; the extreme pressure antiwear agent is phosphate ester amine salt, triphenyl thiophosphate, calcium carbonate.

[0048] 150 grams of lauryl hydroxystearic acid, 68 grams of p-toluic acid, and 102 grams of aluminum isopropoxide are added to 3509 grams of food-grade synthetic oil (ν 100 =10), heated to 60°C, reacted for 1.5 hours, continued to heat to 120°C, added 18 grams of tap water, kept at...

example 3

[0051] Base oil: 85%;

[0052] Thickener: 15%;

[0053] Phosphate amine salt: 0.1% (additional);

[0054] Triphenylthiophosphate: 0.1% (additional);

[0055] Calcium carbonate: 10% (additional);

[0056] Calcium sulfonate: 10% (additional);

[0057] The base oil is a food-grade synthetic oil, and the kinematic viscosity of the base oil at 100°C is 10 mm 2 / s and 40mm 2 / s; the thickener is composed of palmitic acid, benzoic acid, and aluminum isopropoxide, and its molar ratio is 1:1.7:1.1; the organoaluminum is aluminum isopropoxide; the rust inhibitor is sulfonic acid Calcium; the extreme pressure antiwear agent is phosphate ester amine salt, triphenylthiophosphate, calcium carbonate.

[0058] 150 grams of palmitic acid, 109 grams of benzoic acid, and 119 grams of aluminum isopropoxide are added to 2035 grams of food-grade synthetic oil (ν 100 =10), heated to 100°C, reacted for 2 hours, continued to heat to 140°C, added 11 grams of tap water, kept at a constant temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com