Radial plunger type multiple-action inner curved hydraulic motor

A hydraulic motor, multi-action technology, applied in the field of hydraulic motors, can solve the problems of unstable hydraulic system, short service life of conventional motors, long pipeline layout of hydraulic system, etc., and achieve the effect of easy start-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

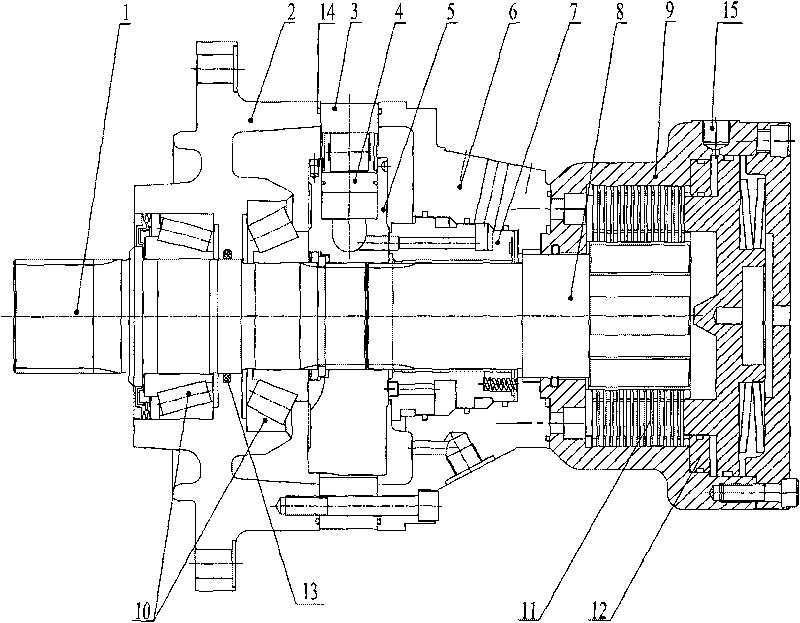

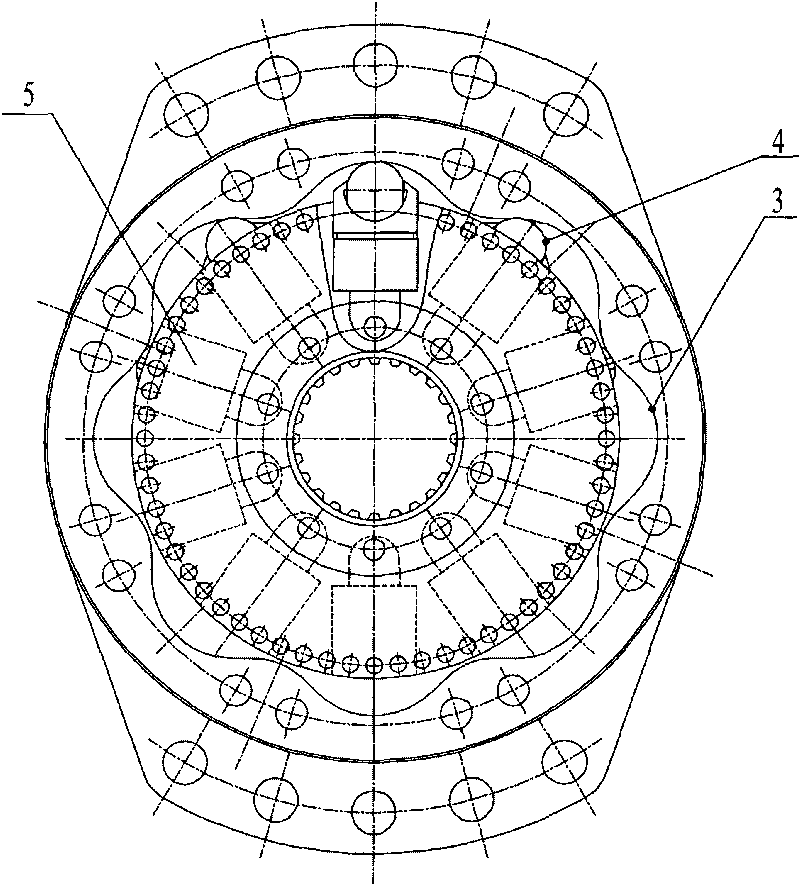

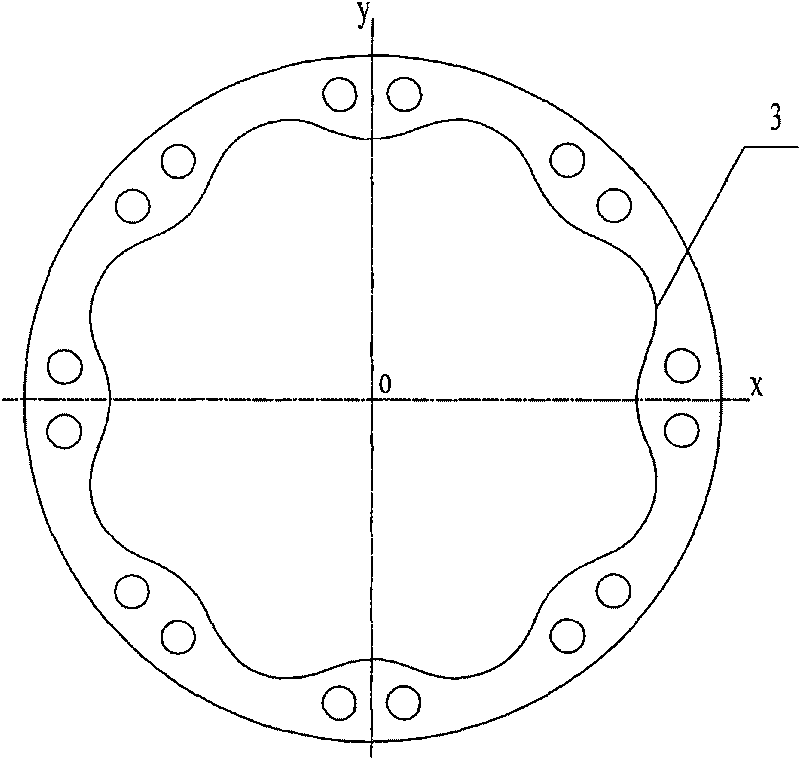

[0010] Such as figure 1 with figure 2 As shown, a radial plunger type multi-action internal curve hydraulic motor includes a mounting seat 2 and an output shaft 1, and is characterized in that the output shaft 1 is positioned and supported by the double tapered roller bearing 10 in the mounting seat 2, and The two bearings are sealed by a rotating sealing ring 13, the output shaft 1 is connected to the driving disc 5 through splines, the mounting base 2 and the rear seat 6 are connected to the ring gear 3 through bolts, and the ring gear 3 is provided with sealing rings 14 on both sides. A plurality of plungers 4 are arranged on the circumference of the drive disc 5, and the plunger 4 on the drive disc 5 and the upper teeth of the ring gear 3 together form a small-tooth differential transmission. The brake 9 and the rear seat 6 are connected by bolts, and the brake shaft 8 of the brake 9 passes through The spline is connected with the drive disc 5, and a brake pad 11 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com