Heavy-load hydrodynamic drive lubricating oil composition

A technology of lubricating oil composition and hydraulic transmission, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of poor product versatility and limited use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

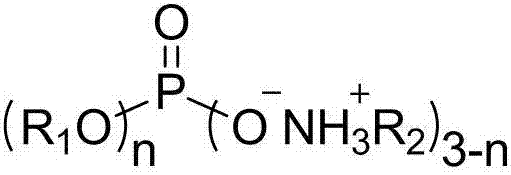

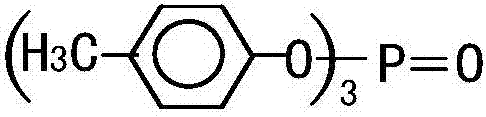

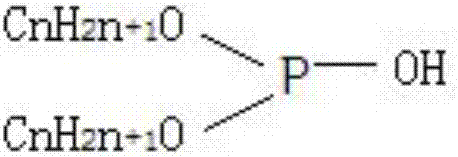

[0042] Add 84.53 parts of PAO4 synthetic base oil and 6.37 parts of HVIS150BS into the blending reactor in turn, start stirring, slowly raise the temperature to 70±5°C, then add T901 antifoam agent 20PPM, and keep stirring for 1 hour, then add LZ5957 antifoam agent in turn 50PPM, 0.3 part of T803B pour point depressant, and keep stirring for 1 hour, then add 0.7 part of phosphite, 0.1 part of alkylated phosphate ammonium salt extreme pressure antiwear agent, 0.2 part of high alkali value calcium sulfonate, 5 parts T161 polymer ashless, 0.5 part of boronized ashless dispersant, 0.8 part of L57, 1.2 part of L135 antioxidant, 0.3 part of multi-functional anti-oxidation and friction reducer, maintain the reaction temperature at 70±5℃, stir for 4-6 hours, ensure The oil is dispersed evenly.

Embodiment 2

[0044] Add 91.2 parts of PAO4 base oil in turn to the blending reactor, start stirring, slowly heat up to 70±5°C, then add T901 antifoam agent 20PPM, and keep stirring for 1 hour, then add LZ5957 antifoam agent 50PPM in turn, and keep stirring 1 hour, then add 0.7 parts of phosphite, 0.1 parts of alkylated phosphate ammonium salt extreme pressure antiwear agent, 0.2 parts of high alkali value calcium sulfonate, 5 parts of T161, 0.5 parts of boron ashless, 0.8 parts of L57 , 1.2 parts of L135 antioxidant, 0.3 parts of multifunctional anti-oxidation and friction reducer, maintain the reaction temperature at 70±5°C, stir for 4-6 hours to ensure that the oil is evenly dispersed.

Embodiment 3

[0046] Add 89.2 parts of PAO4 base oil to the blending reactor in turn, start stirring, slowly heat up to 70±5°C, then add T901 antifoam agent 20PPM, and keep stirring for 1 hour, then add LZ5957 antifoam agent 50PPM, T8-310 2.0 parts of viscosity-increasing pour point depressant, and kept stirring for 1 hour, then sequentially added 0.7 parts of phosphite, 0.1 part of alkylated phosphate ammonium salt extreme pressure anti-wear agent, 0.2 parts of high alkali value calcium sulfonate, 5 parts of T161 , 0.5 parts of boronized ashless, 0.8 parts of L57, 1.2 parts of L135 antioxidant, 0.3 parts of multifunctional anti-oxidation and friction reducer, maintain the reaction temperature at 70±5°C, and stir for 4-6 hours to ensure that the oil is evenly dispersed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com