Patents

Literature

33 results about "Chain walking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

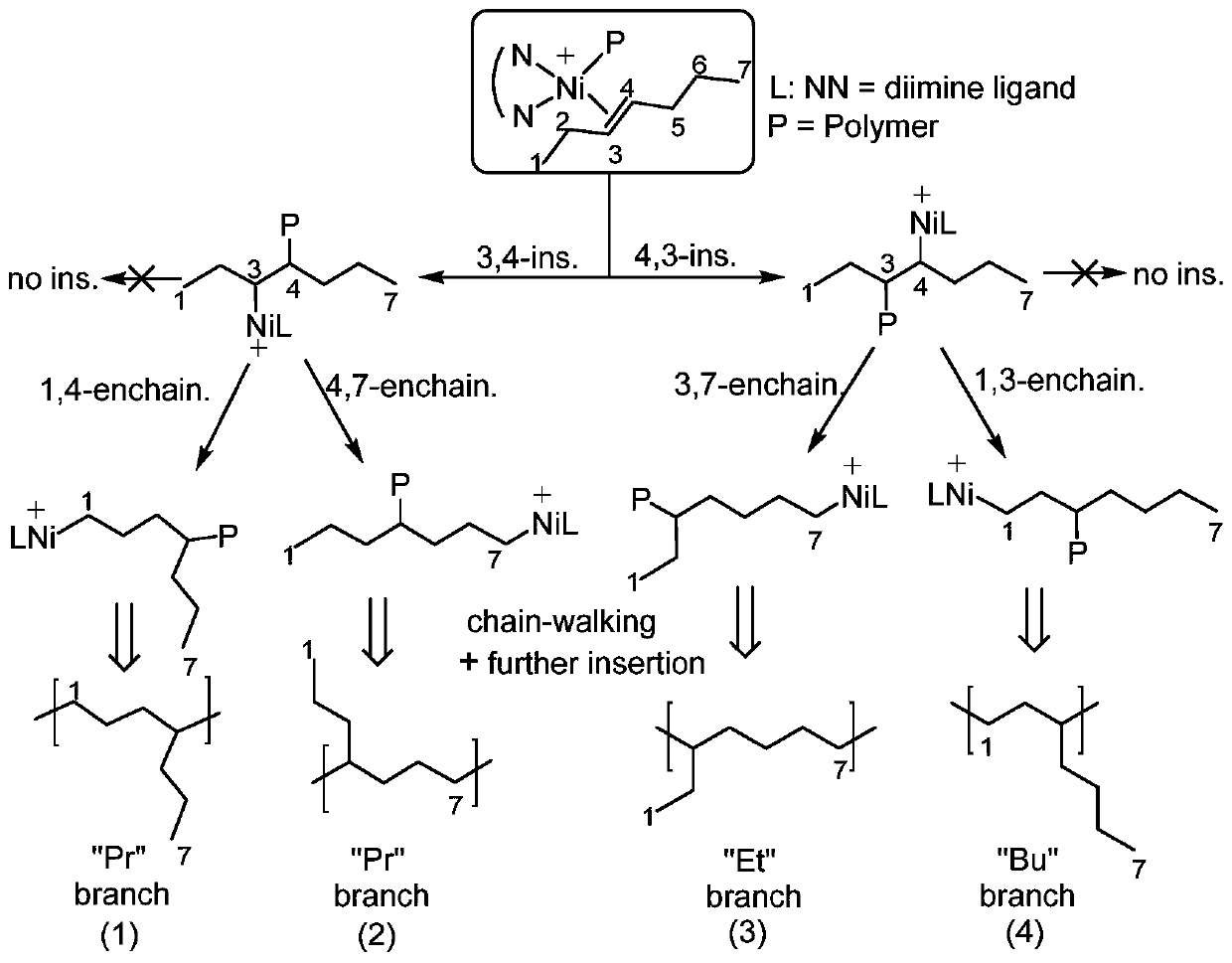

In polymer chemistry, chain walking (CW) or chain running or chain migration is a mechanism that operates during some alkene polymerization reactions. CW can be also considered as a specific case of intermolecular chain transfer (analogous to radical ethene polymerization). This reaction gives rise to branched and hyperbranched/dendritic hydrocarbon polymers. This process is also characterized by accurate control of polymer architecture and topology. The extent of CW, displayed in the number of branches formed and positions of branches on the polymers are controlled by the choice of a catalyst. The potential applications of polymers formed by this reaction are diverse, from drug delivery to phase transfer agents, nanomaterials, and catalysis.

Catalyst composition comprising shuttling agent for ethylene copolymer formation

ActiveUS7915192B2Improve efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChain walkingOlefin polymerization

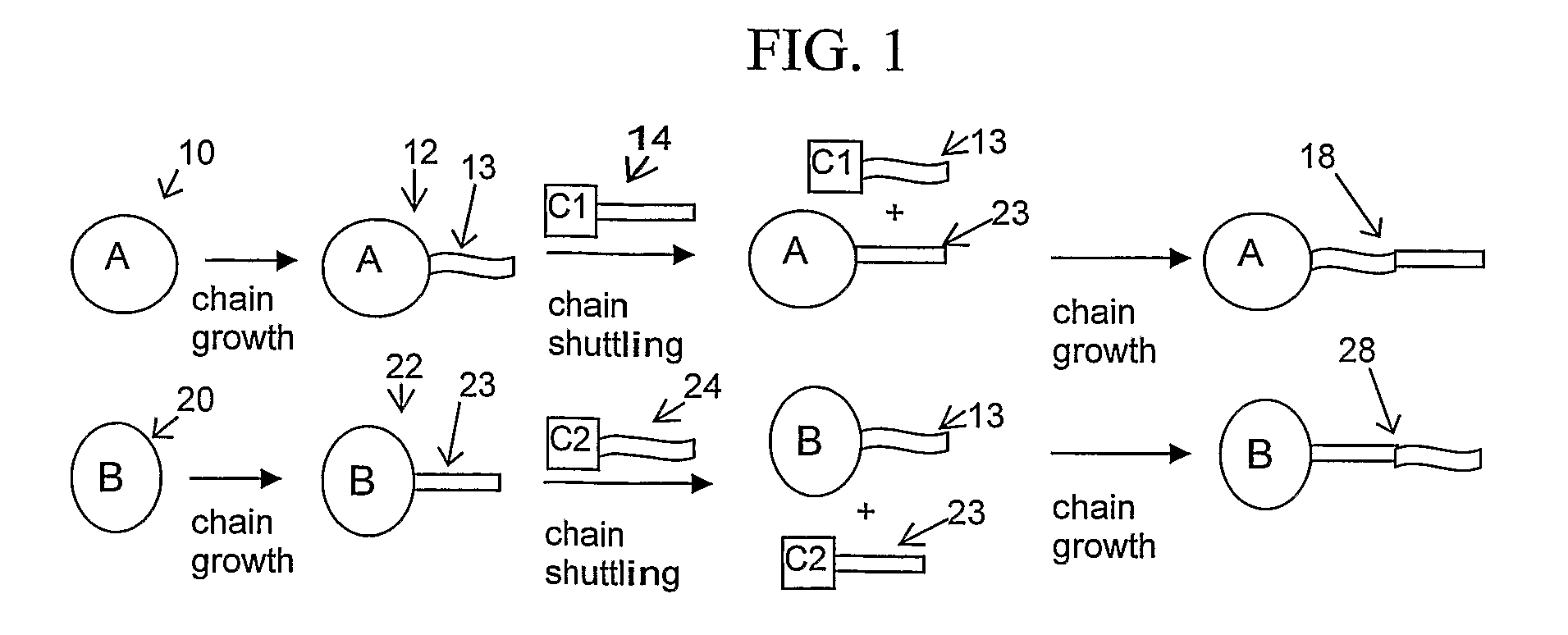

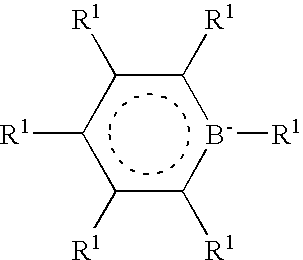

A composition for use in forming a multi-block copolymer from a single polymerizable monomer, said copolymer containing therein two or more segments or blocks differing in branching index, a polymerization process using the same, and the resulting polymers, wherein the composition comprises the admixture or reaction product resulting from combining: (A) a first olefin polymerization catalyst, (B) a second olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, at least one of catalyst (A) or catalyst (B) being capable of forming a branched polymer by means of chain walking or reincorporation of in situ formed olefinic polymer chains, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

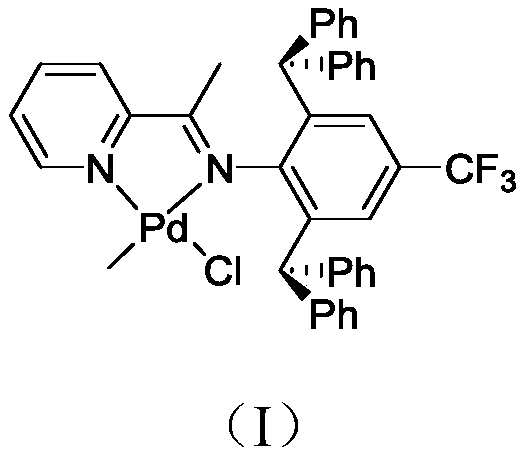

Complex catalyst, catalyst composition and preparation method of olefin polymer

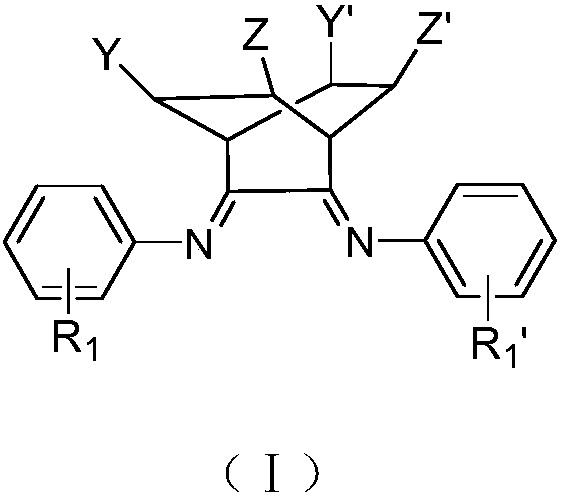

The invention provides a compound as shown in formula (I) and a complex catalyst. The compound is based on the ligand effect of second layer space among molecules, and ensures that the second layer coordination space strategy is applied to olefin body polymerization and the copolymerization of olefin and polar monomers, so as to obtain a good technical effect. The complex catalyst belongs to palladium, nickel and iron catalysts containing alpha-diimine ligands with second layer coordination space effect, in the system, beta-H and beta-X elimination is restrained through the second layer coordination space effect, but normal coordination of ethylene is not prevented, therefore, the occurrence of chain walking is restrained, the polyethylene branching coefficient is reduced, and the copolymerization of ethylene and more polar monomers is realized.

Owner:合肥中科科乐新材料有限责任公司

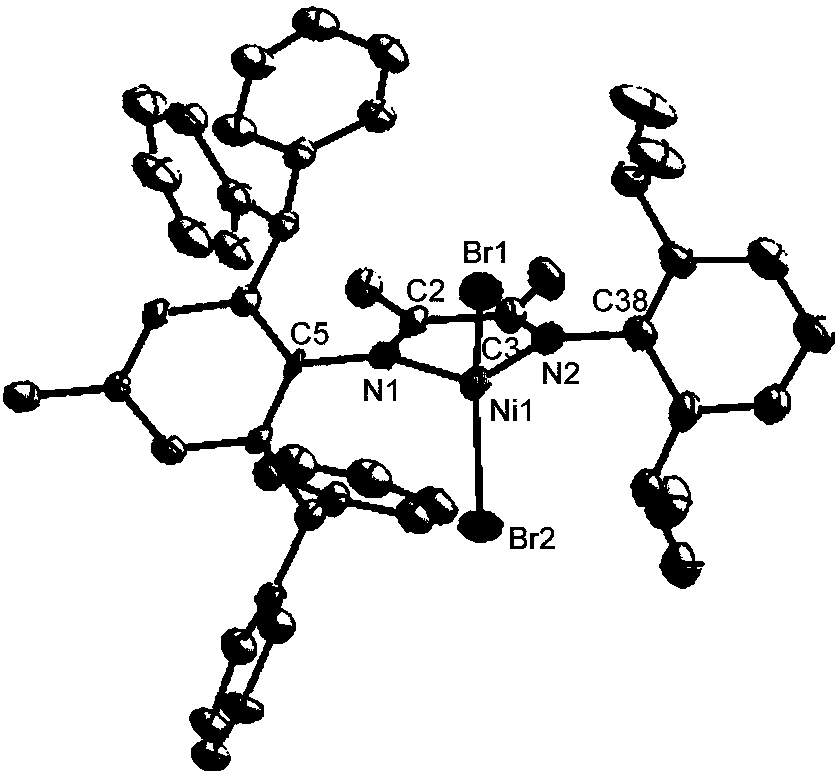

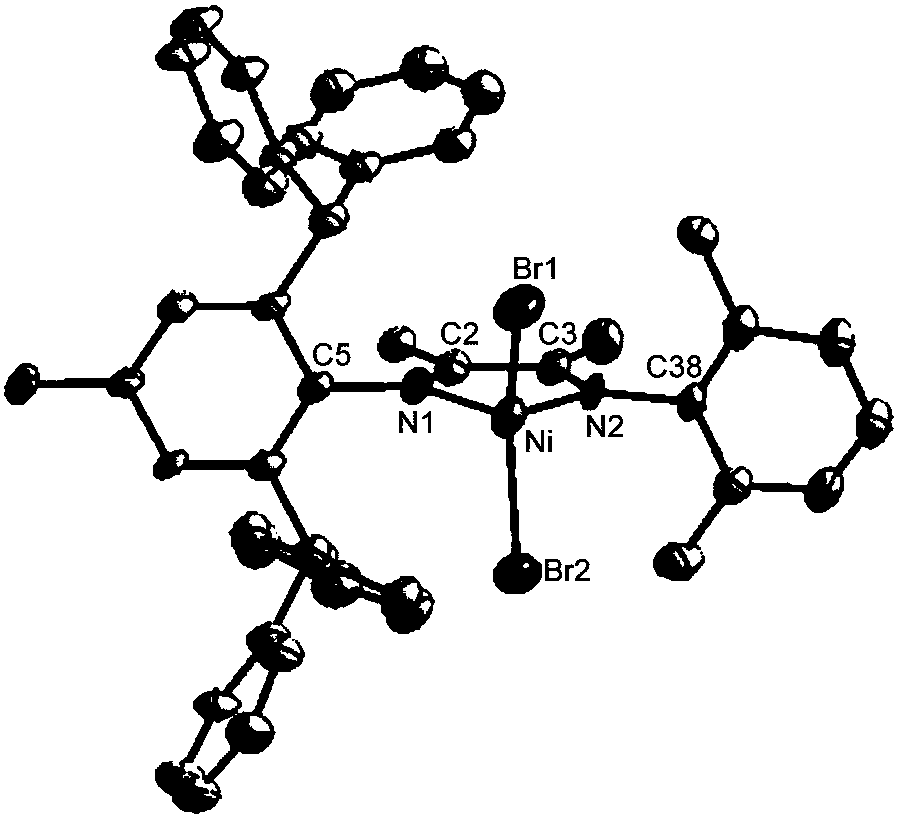

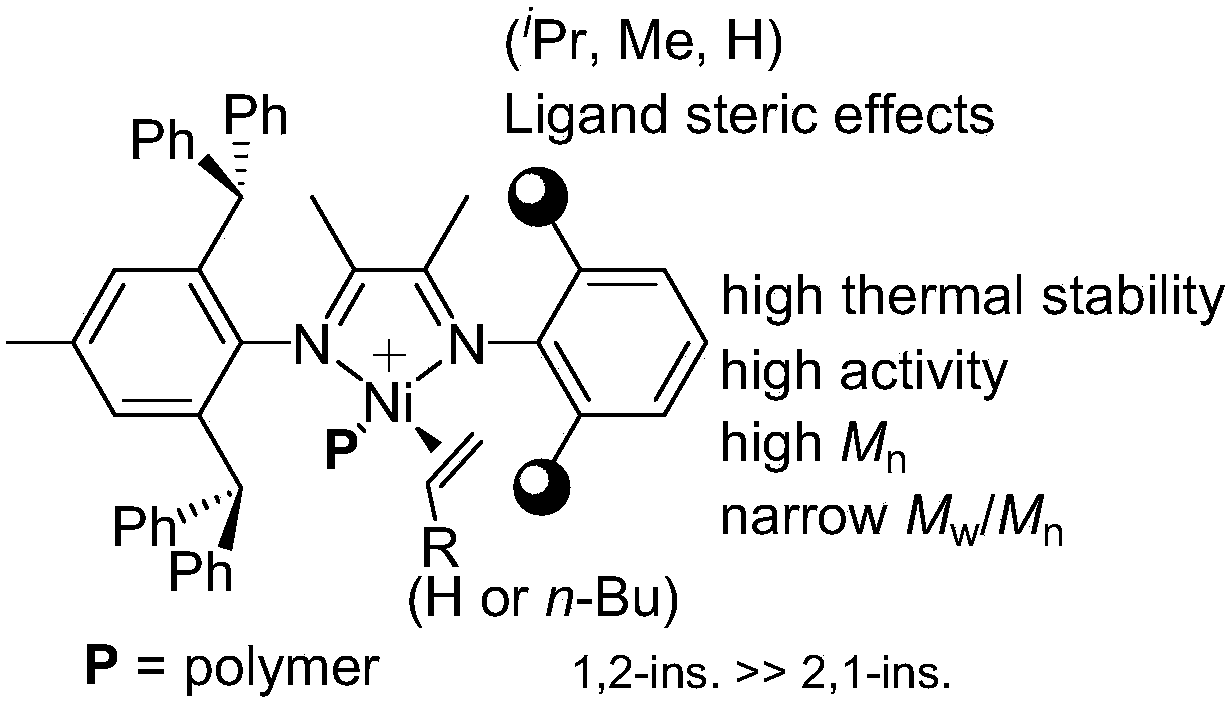

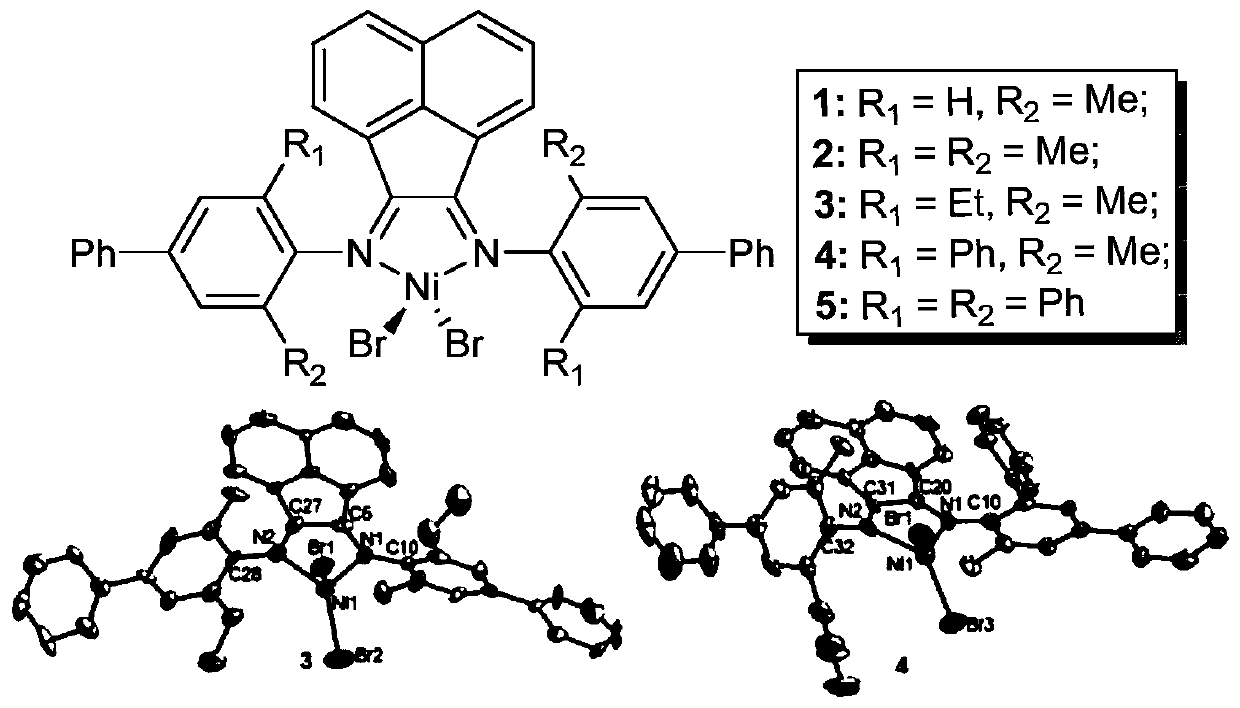

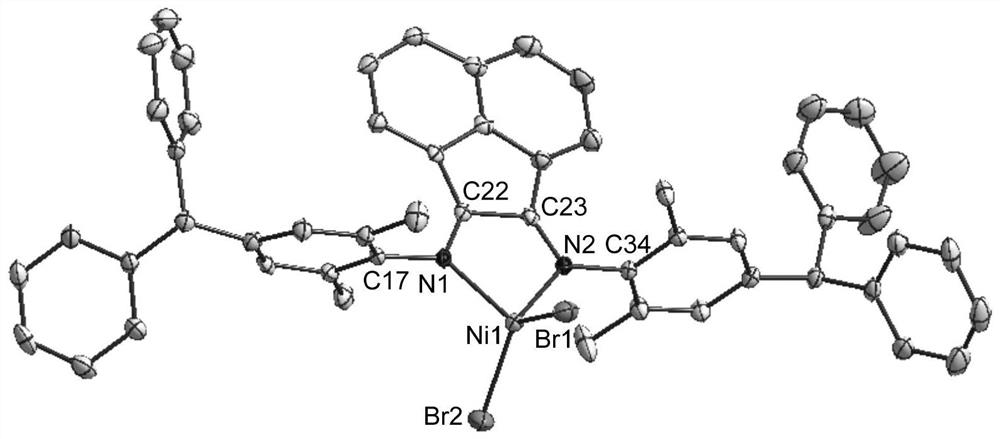

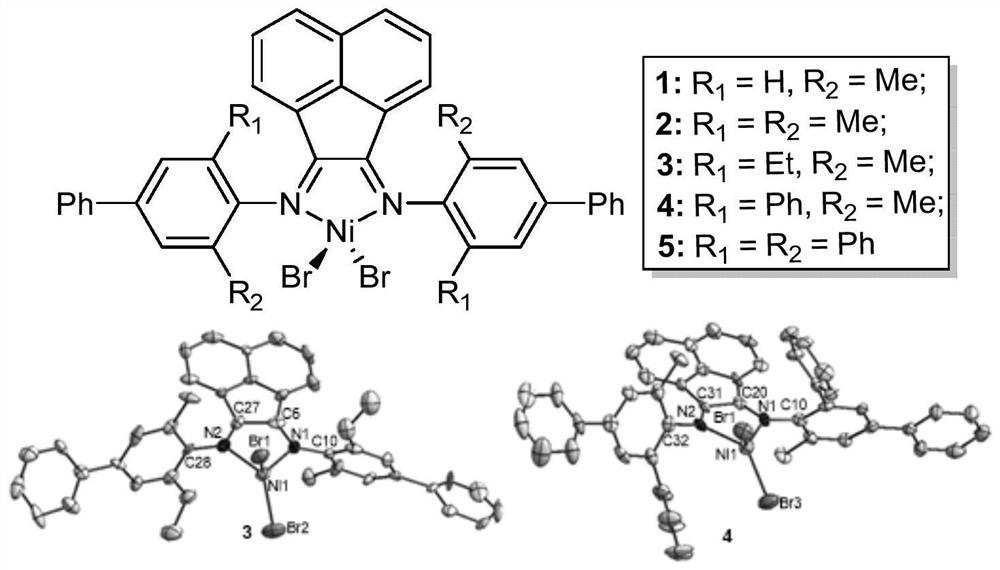

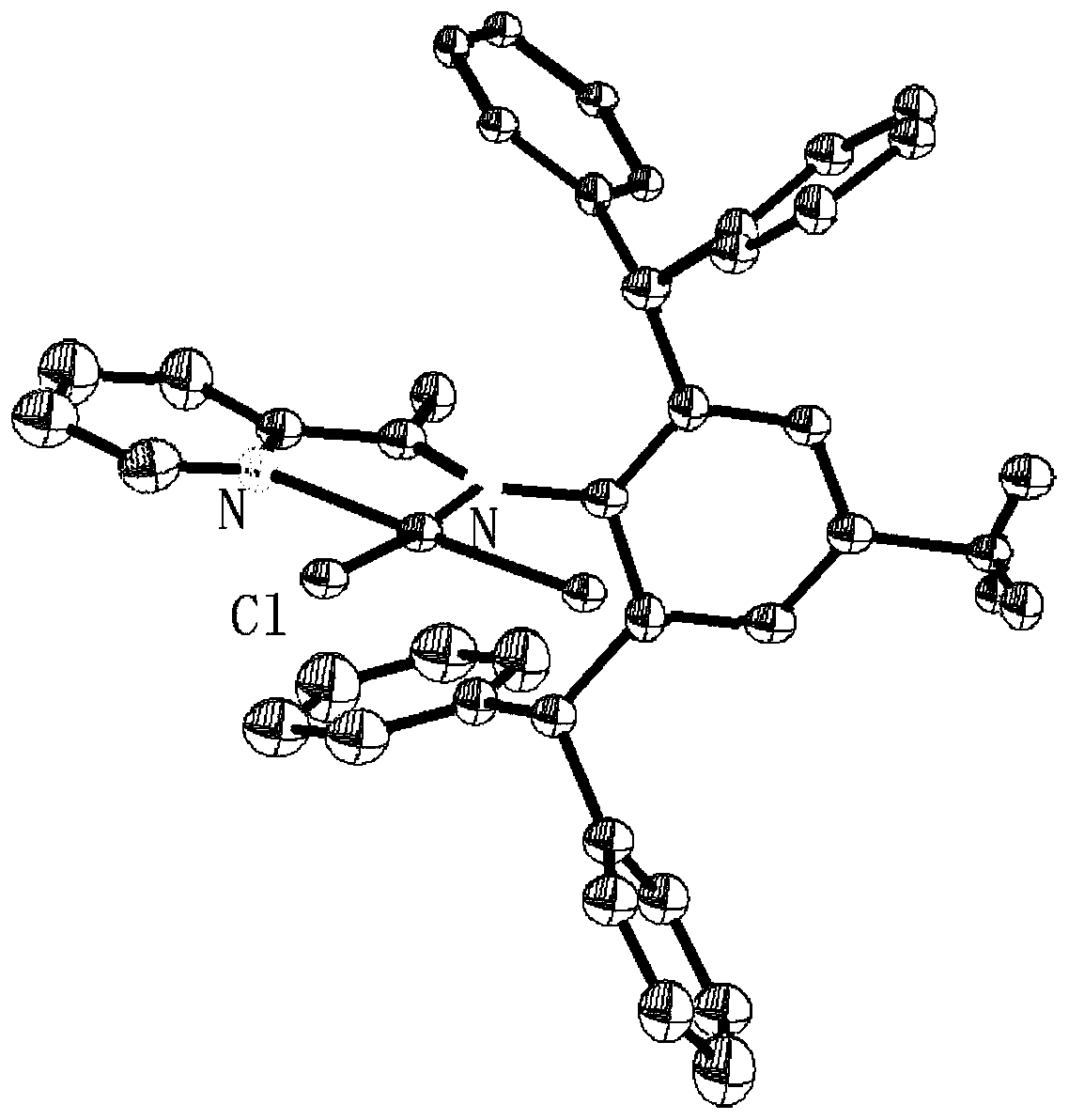

Asymmetric alpha-diimine nickel (II) complex for polymerizing ethylene and 1-hexene with o-benzhydryl substituent

InactiveCN107641138AHigh activitySpeed up the insertion processNickel organic compoundsChain walkingDispersity

The invention discloses an asymmetric alpha-diimine nickel (II) complex for polymerizing ethylene and 1-hexene with an o-benzhydryl substituent. By changing a complex, a coordination environment, a space effect and electronic density of a metal center are changed, the activity of polymerization of ethylene and 1-hexene is finally adjusted, and the microstructure of a copolymer is finally controlled. Under activation of a promoter, namely diethyl aluminum chloride, the complex is relatively good in thermal stability and catalysis activity in catalyzing vinyl polymerization, and in addition, polyethylene high in molecular weight and low in dispersity is prepared. By changing the steric hindrance and the polymerization condition of the complex, the catalysis activity and the molecular weight,the dispersity, the branching coefficient and the thermal performance of the polymer can be effectively operated. The catalyst system can also be applied to catalysis on chain walking polymerizationof long-chain 1-hexene, through variation of the steric hindrance and the polymerization temperature of the complex, the catalysis activity and the properties of the polymer can be very well operated,and in addition, by increasing the steric hindrance of the catalyst, intercalation of 2,1 into 1-hexene is facilitated.

Owner:CHANGZHOU UNIV

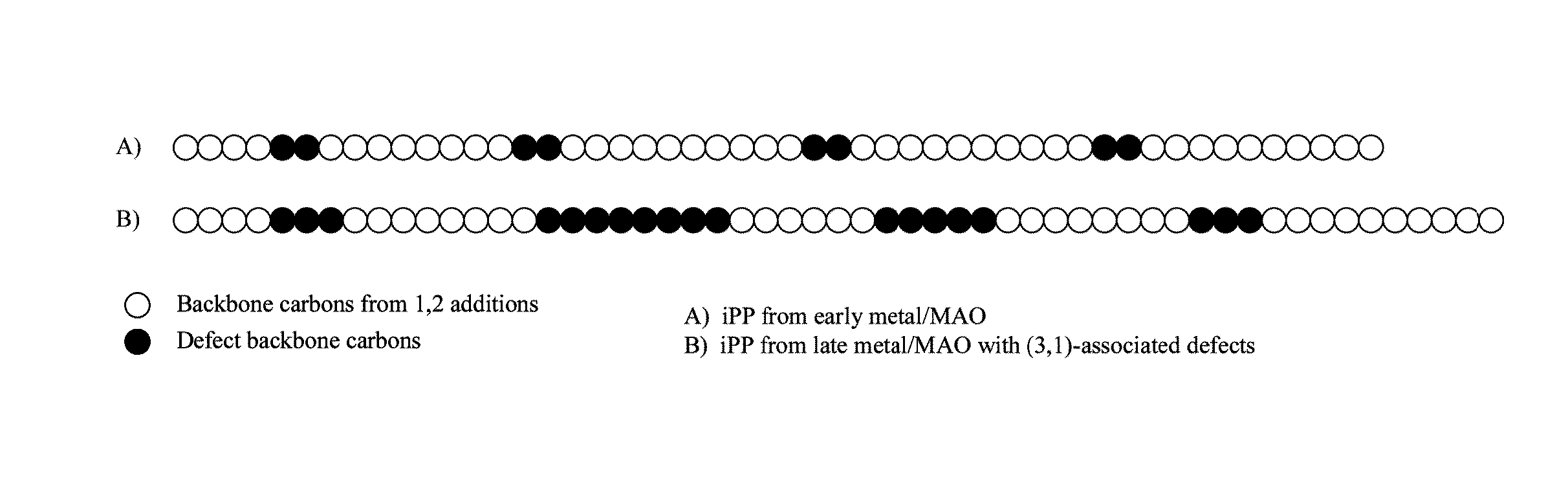

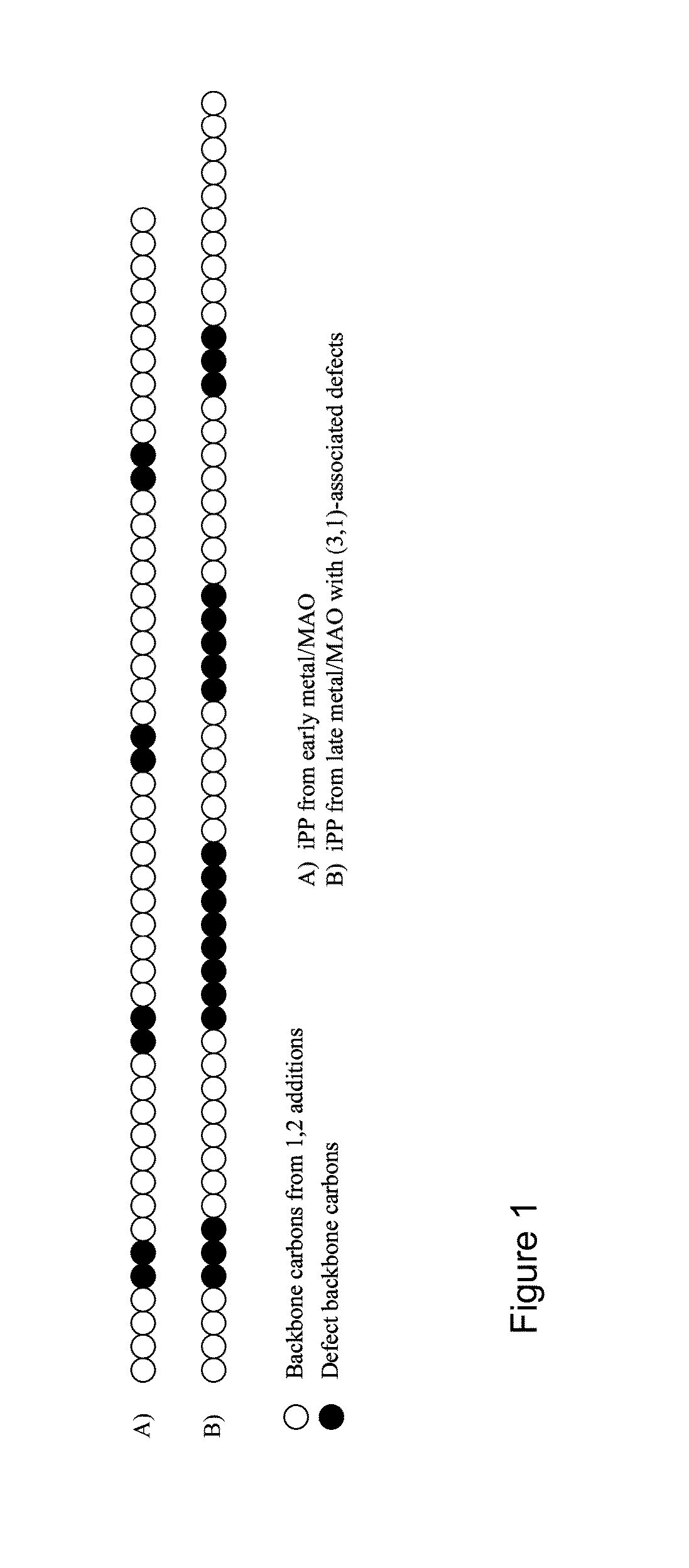

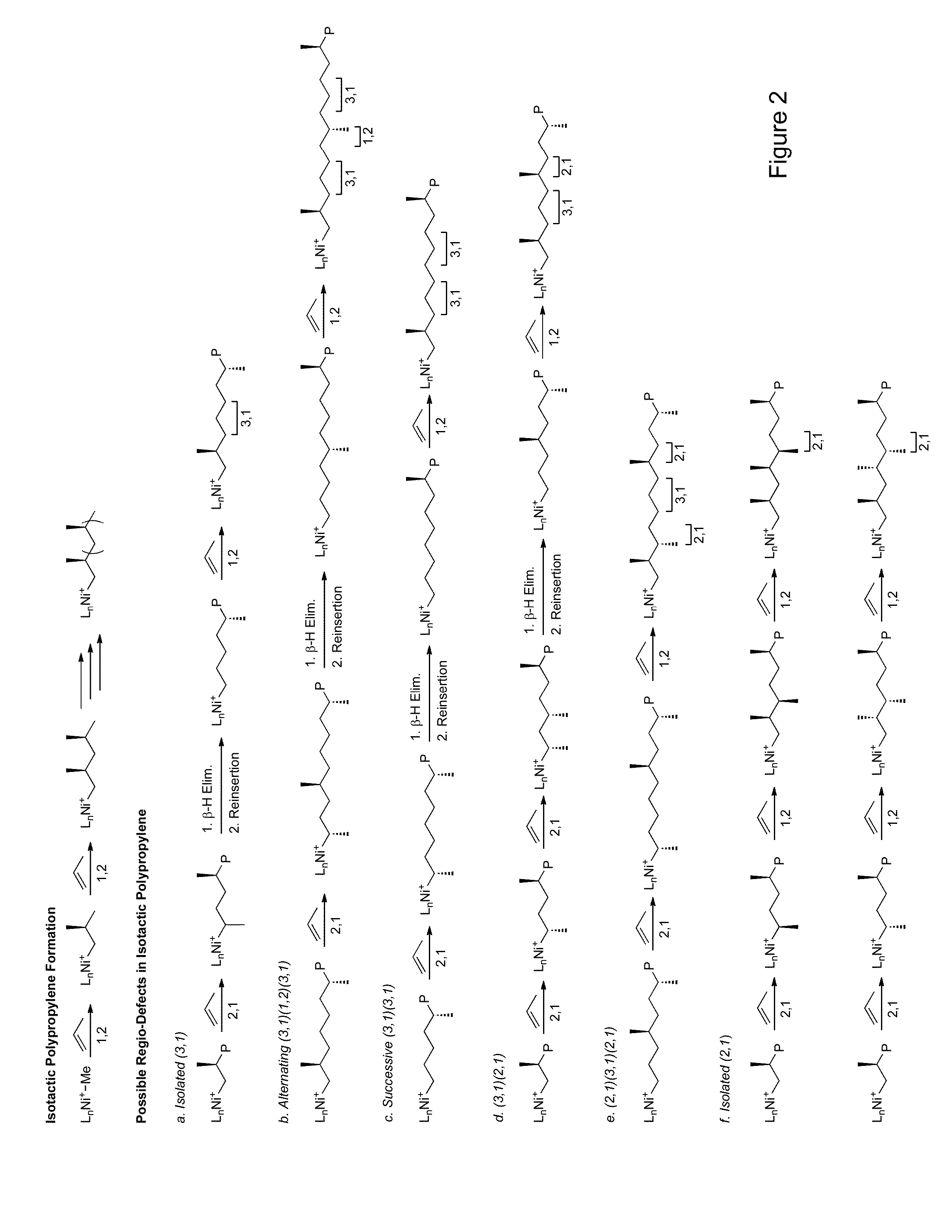

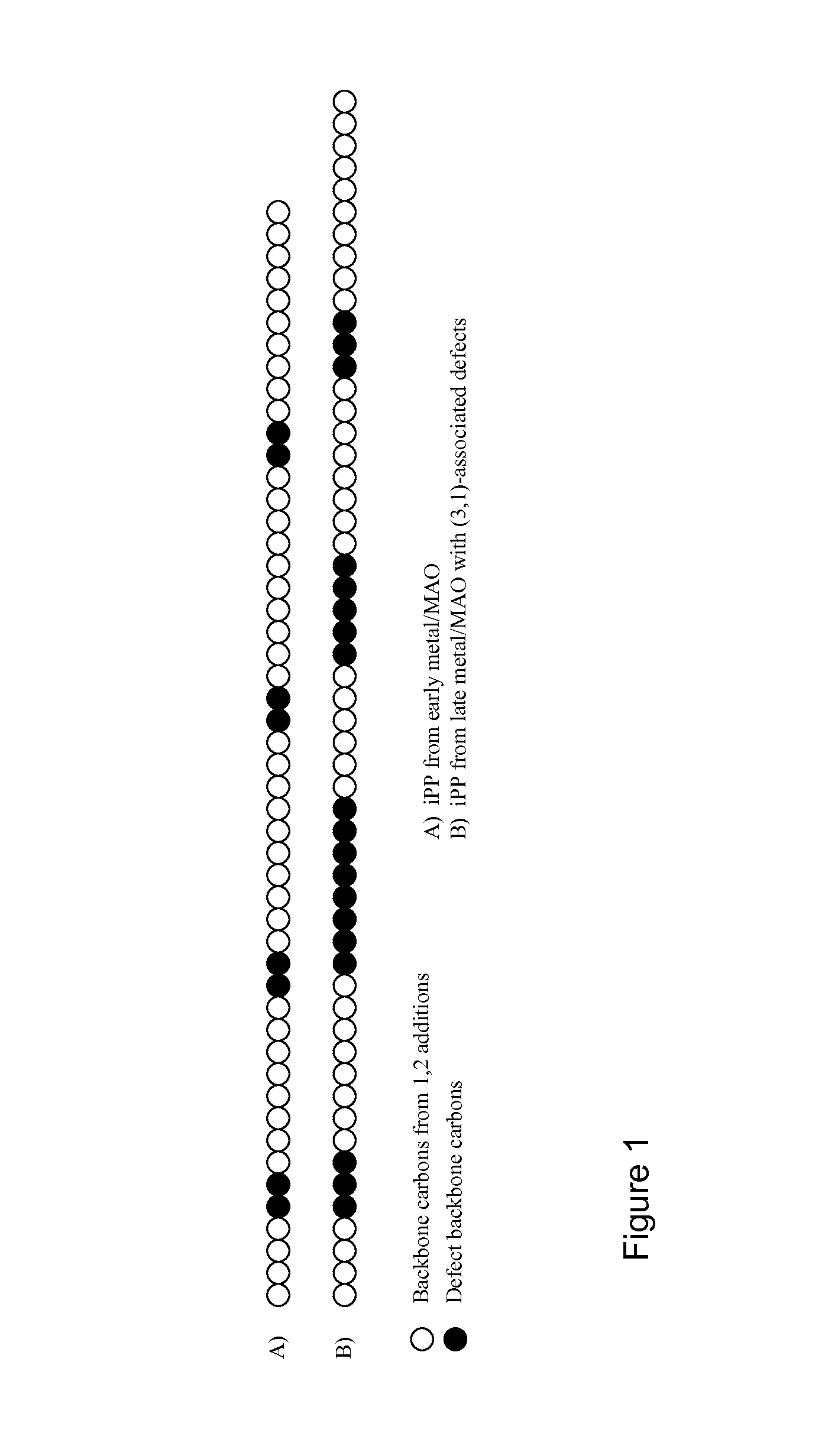

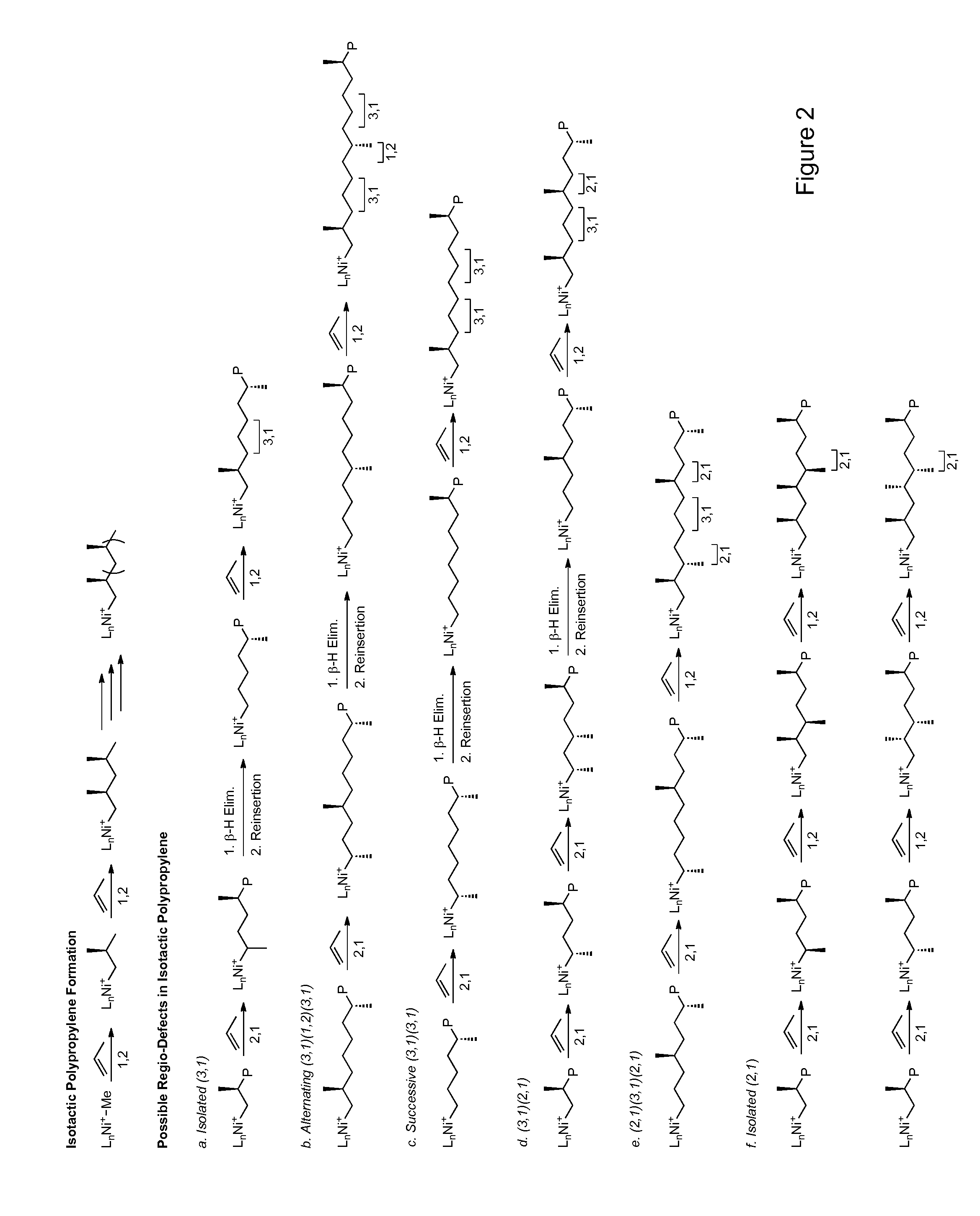

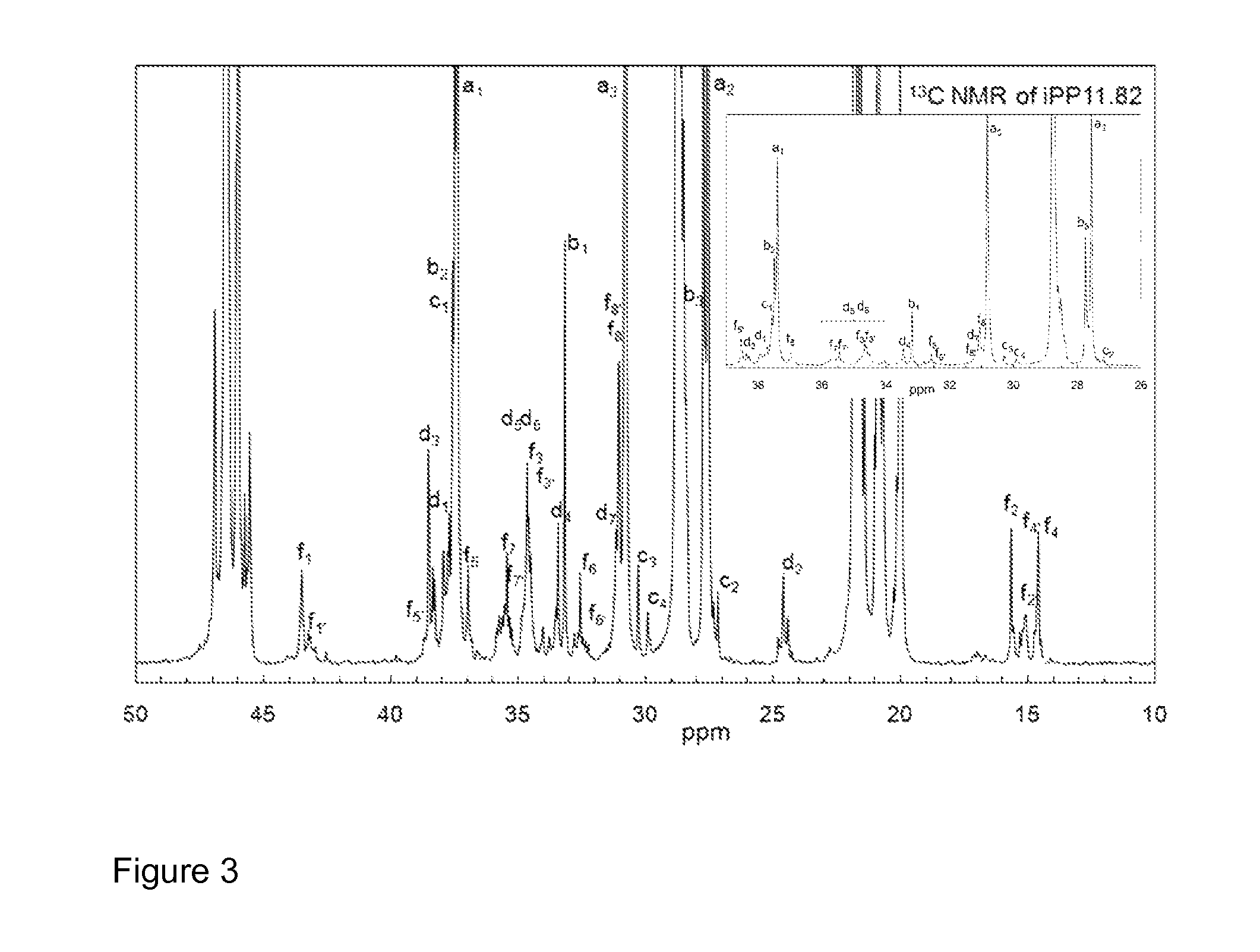

Methods of constructing alkene-based homopolymer polyolefins having reduced crystallinity

ActiveUS20130030121A1Reduced level of crystallinityLower Level RequirementsChain walkingPolymer science

The invention is a novel family of polyolefins characterized by chain-walking defects of the type that add extra backbone carbons per monomer. These polyolefins display a large decrease in crystallinity relative to polyolefins known in the art. Specifically, the reduction in crystallinity is much greater than for earlier polypropylenes with a matched content of stereo or 1-alkene type defects. The claimed polyolefins can be an alkene-based homopolymer. The defects in the polyolefin backbone are generated by a chain walking mechanism in which three or more carbons per monomer are added to the polymer backbone instead of two, as in conventional polymerization or copolymerization methods of alpha olefins. The novel polyolefins can be used in applications such as plastic wrapping, thin films, co-extrusion layers or molded parts in the absence of polymer blending or copolymerization. The cost of materials production can be reduced.

Owner:CORNELL UNIV CORNELL CENT FOR TECH ENTERPRISE & COMMLIZATION CCTEC +1

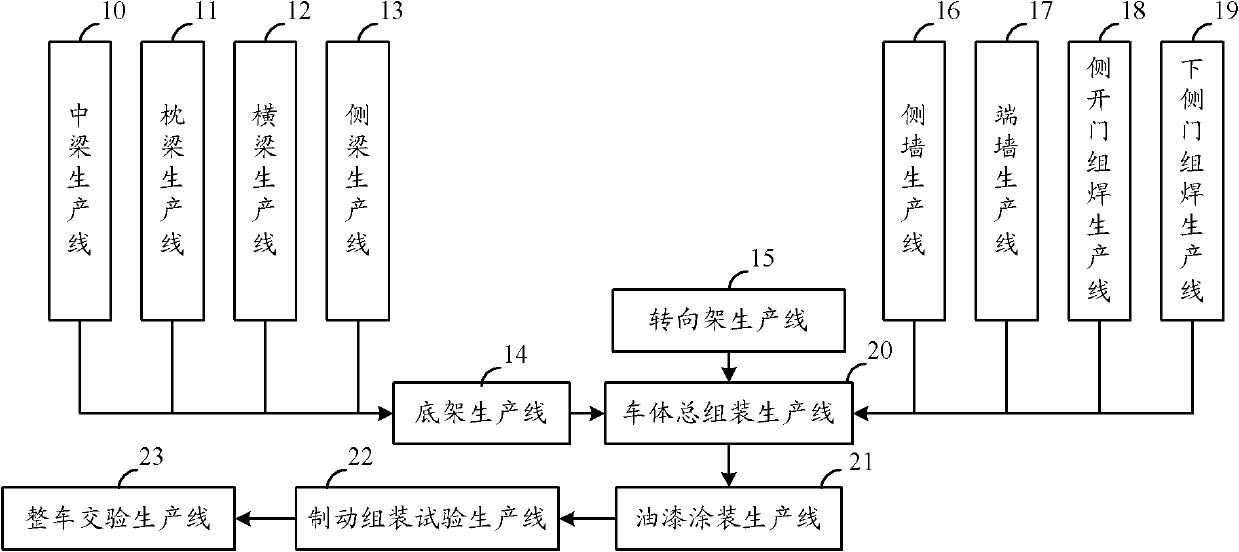

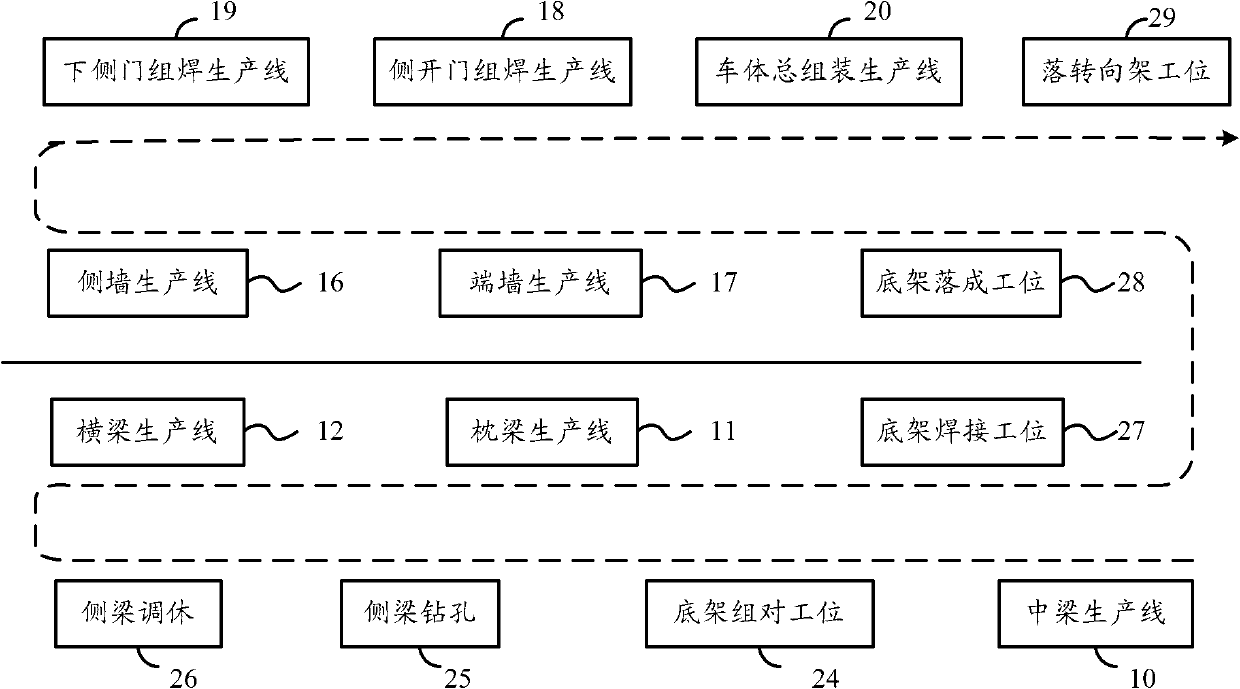

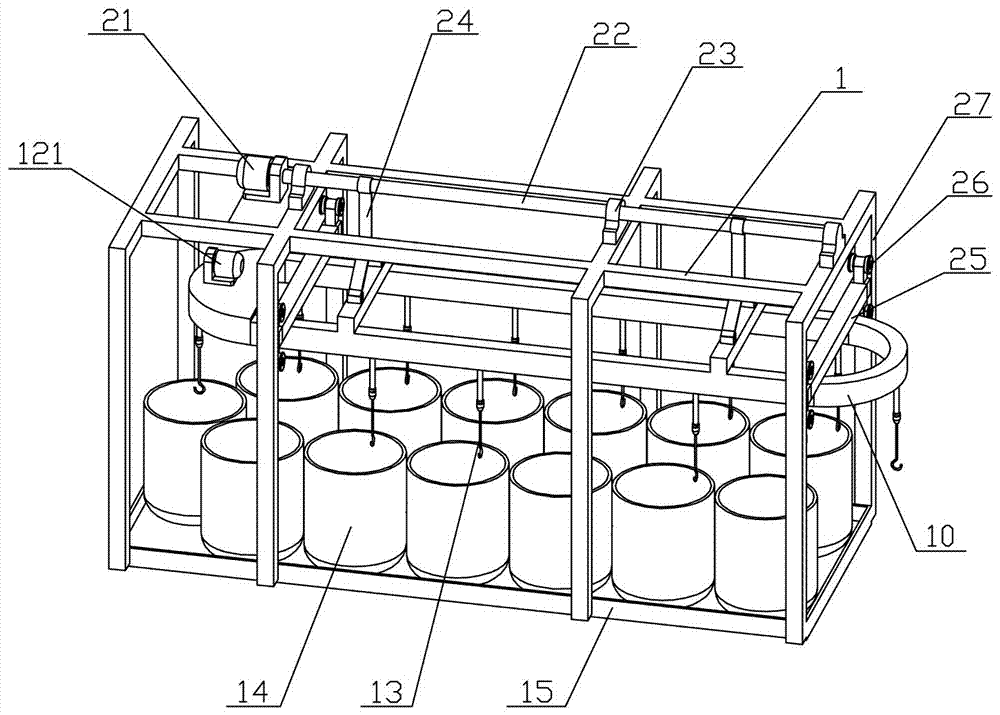

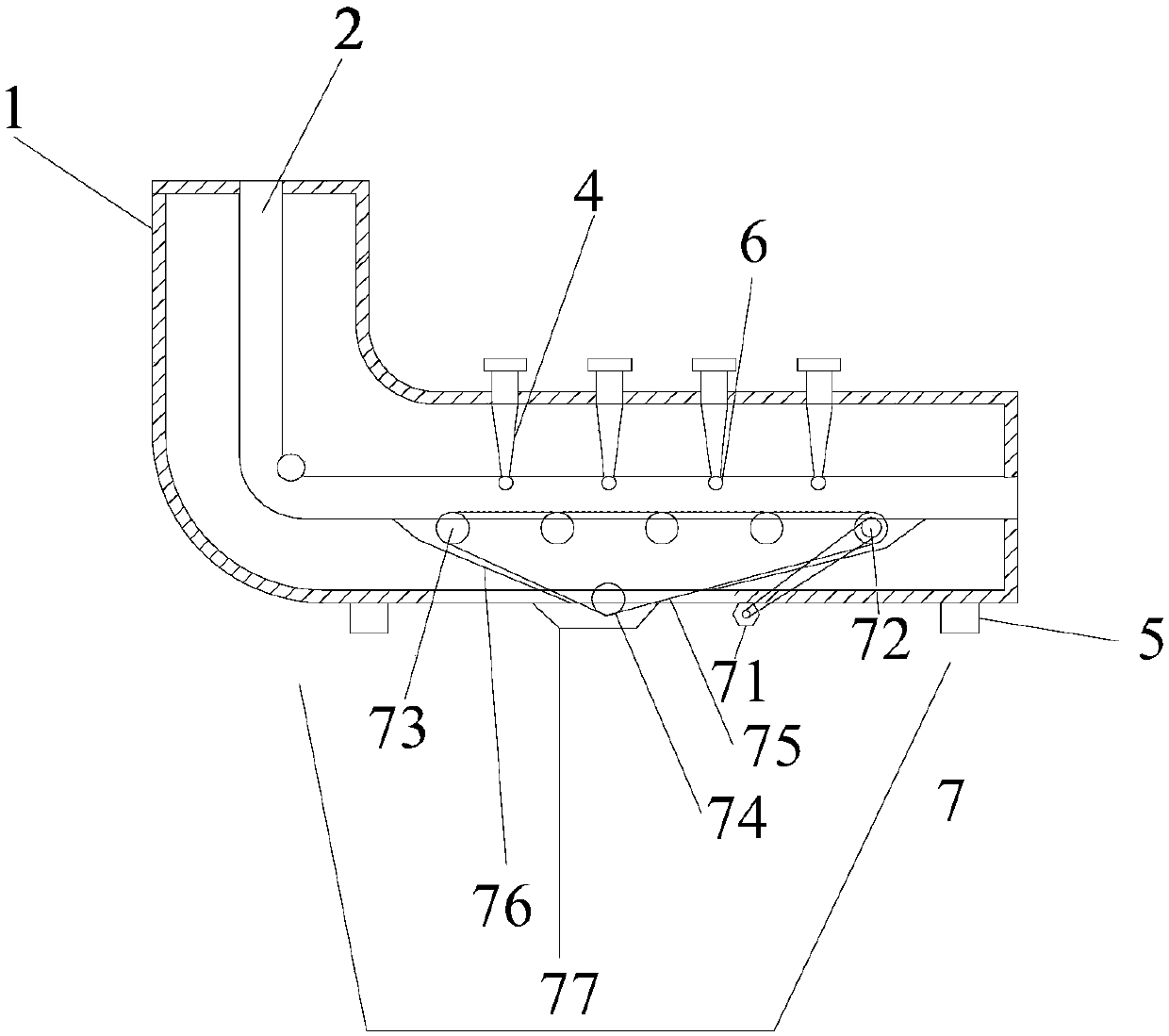

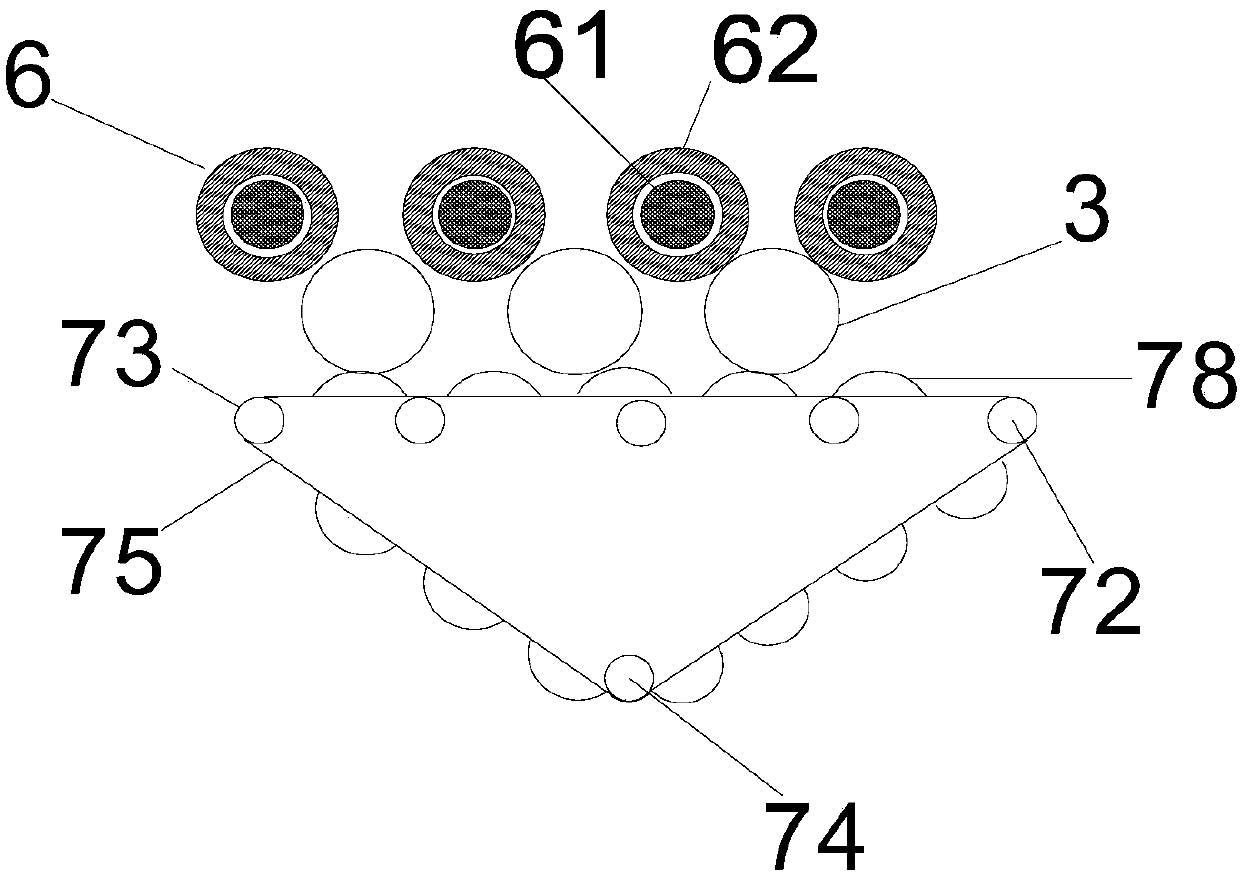

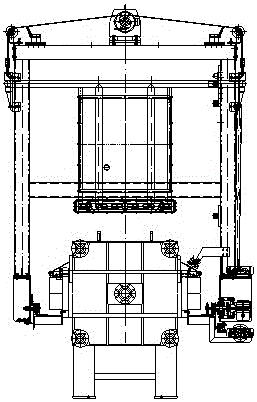

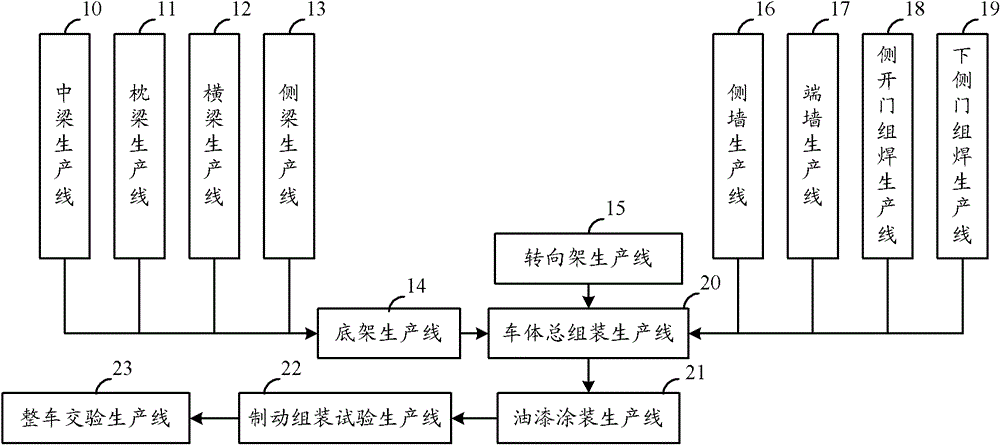

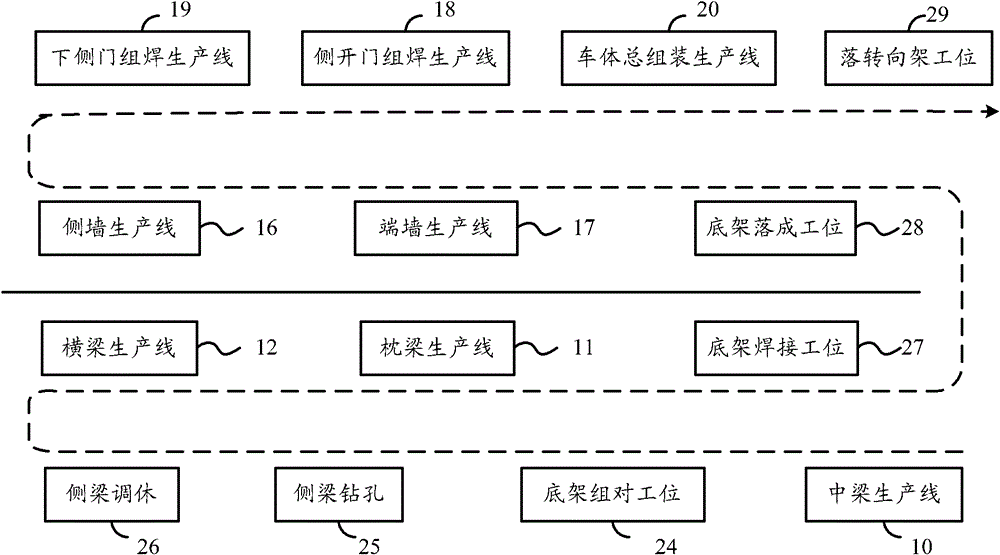

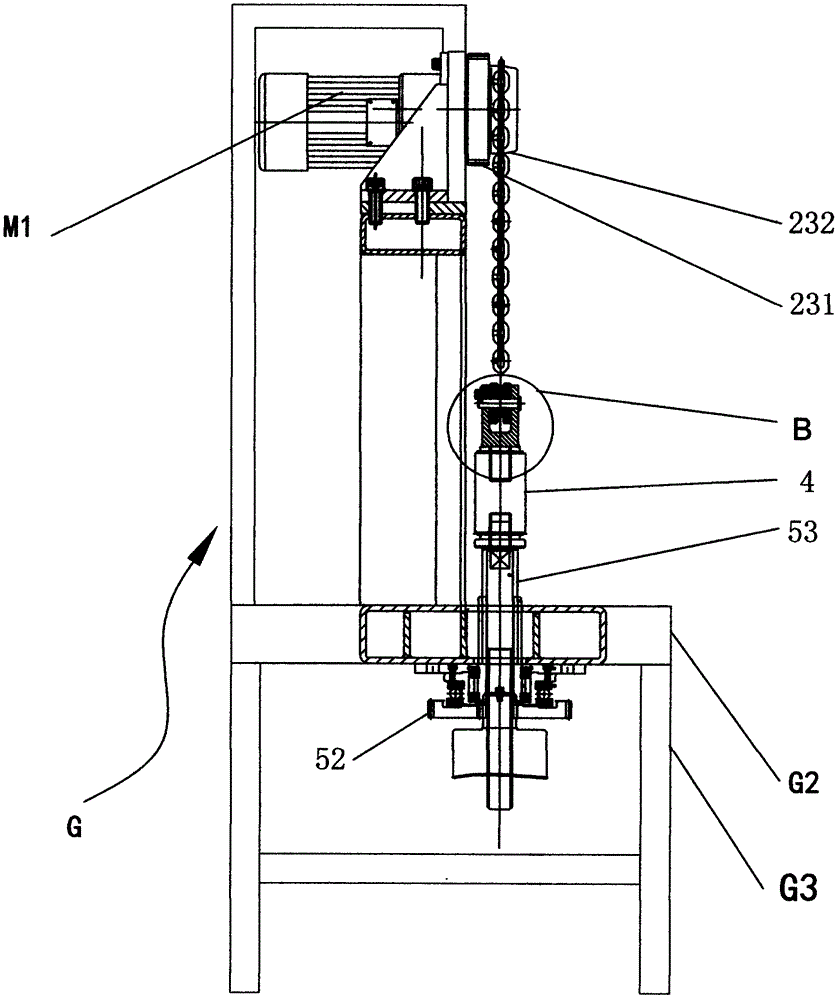

Newly-built truck production line

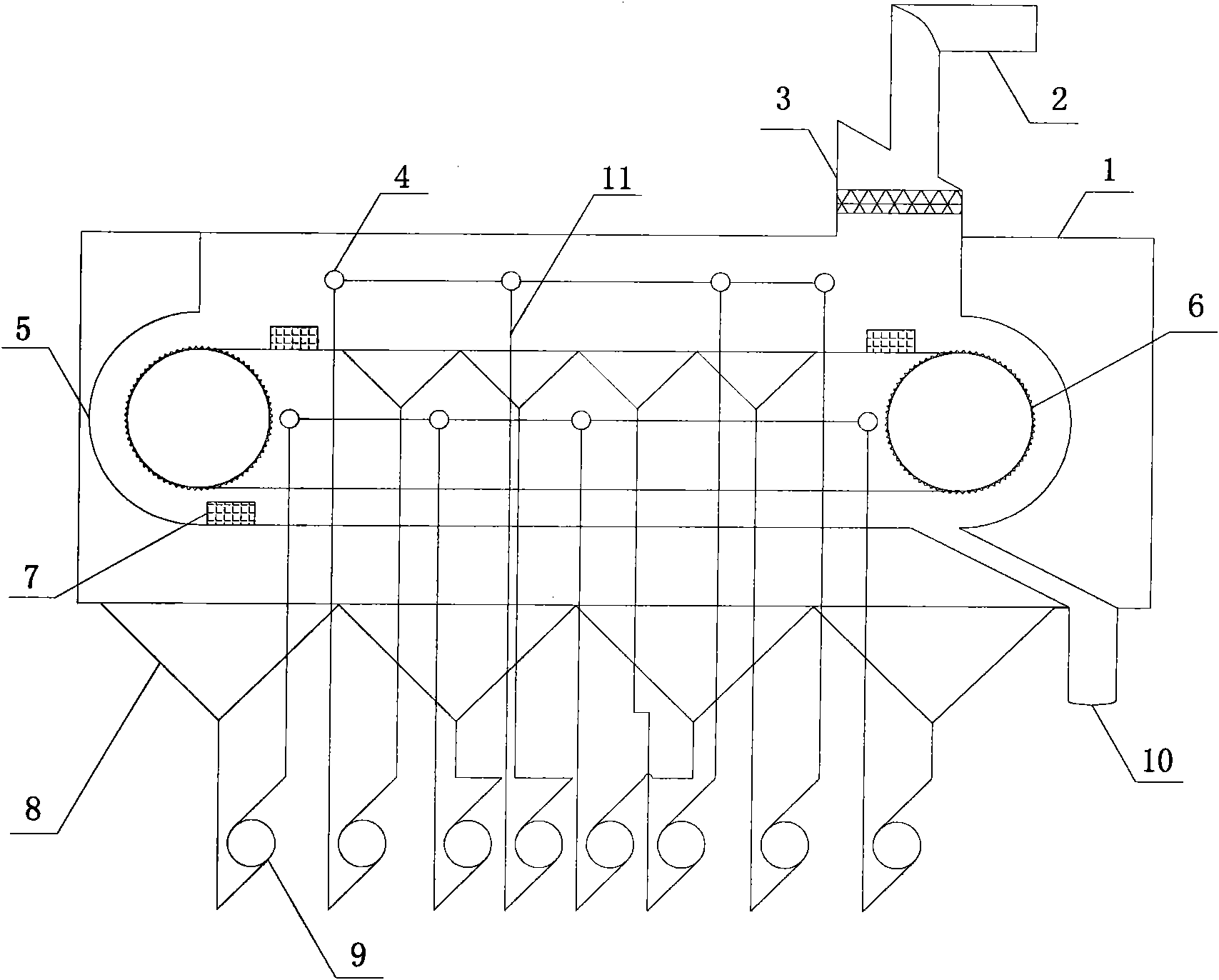

The invention provides a newly-built truck production line, comprising a centre sill production line, a sleeper beam production line, a beam production line, a side beam production line, an chassis production line, a bogie production line, a side wall production line, an end wall production line, a side-opening door installing and welding production line, a bottom side door installing and welding production line, a truck body total assembly production line, a paint coating production line, a brake assembly test production line and a finished truck inspection production line, wherein the centre sill production line, the sleeper beam production line, the beam production line and the side beam production line are respectively connected with the chassis production line, the chassis production line, the bogie production line, the side wall production line, the end wall production line, the side-opening door installing and welding production line and the bottom side door installing and welding production line are respectively connected with the truck body total assembly production line, the truck body total assembly production line, the paint coating production line, the brake assembly test production line and the finished truck inspection production line are connected in sequence. According to the invention, the production lines are connected by a hydraulic lifting mechanism and a power chain walking mechanism, so that the production efficiency of the newly-built truck production line is improved.

Owner:CRRC SHENYANG CO LTD

Alpha-diimine ligand compound, complex and preparation method of polyolefin lubricating oil base oil

ActiveCN111377827ASimple preparation processMild reaction conditionsNickel organic compoundsBase-materialsChain walkingSocial benefits

The present invention provides an alpha-diimine ligand compound having a structure represented by a formula (I), and further provides an alpha-diimine complex obtained from the ligand compound. In addition, the invention also provides a preparation method of polyolefin lubricating oil base oil taking the alpha-diimine complex as a catalyst and the prepared lubricant base oil. According to the ligand compound and the complex provided by the invention, a large steric hindrance group is introduced into a ligand skeleton, and the skeleton rigidity is increased, so that the chain walking capabilityof the complex as a catalyst is improved. The polyolefin lubricating oil base oil provided by the invention has high long-chain branch content and branching degree, can be used as medium-high viscosity lubricating oil base oil, simplifies the production process, reduces the production cost, is very suitable for industrial-scale production, and has excellent economic and social benefits.

Owner:LIAONING OXIRANCHEM INC +1

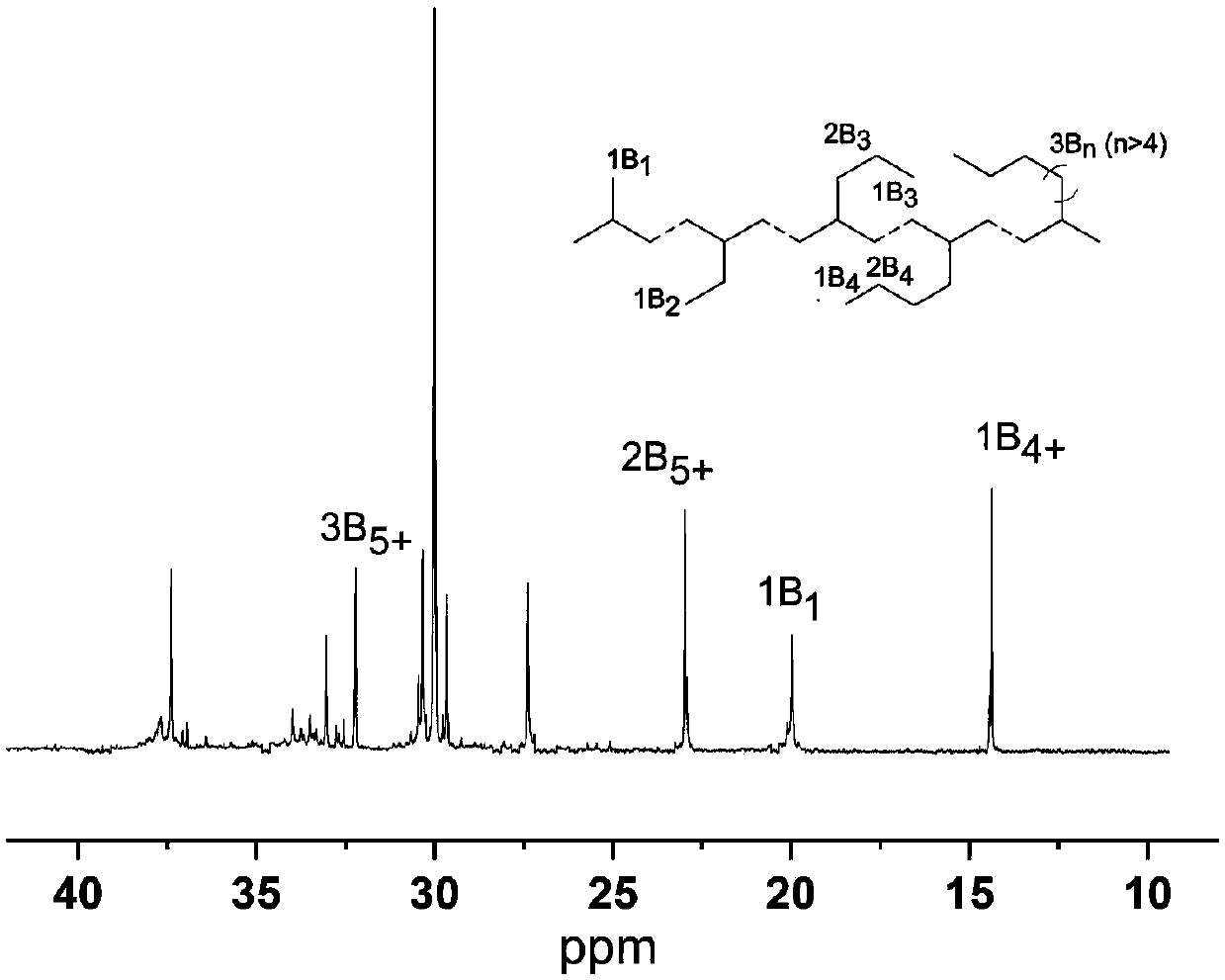

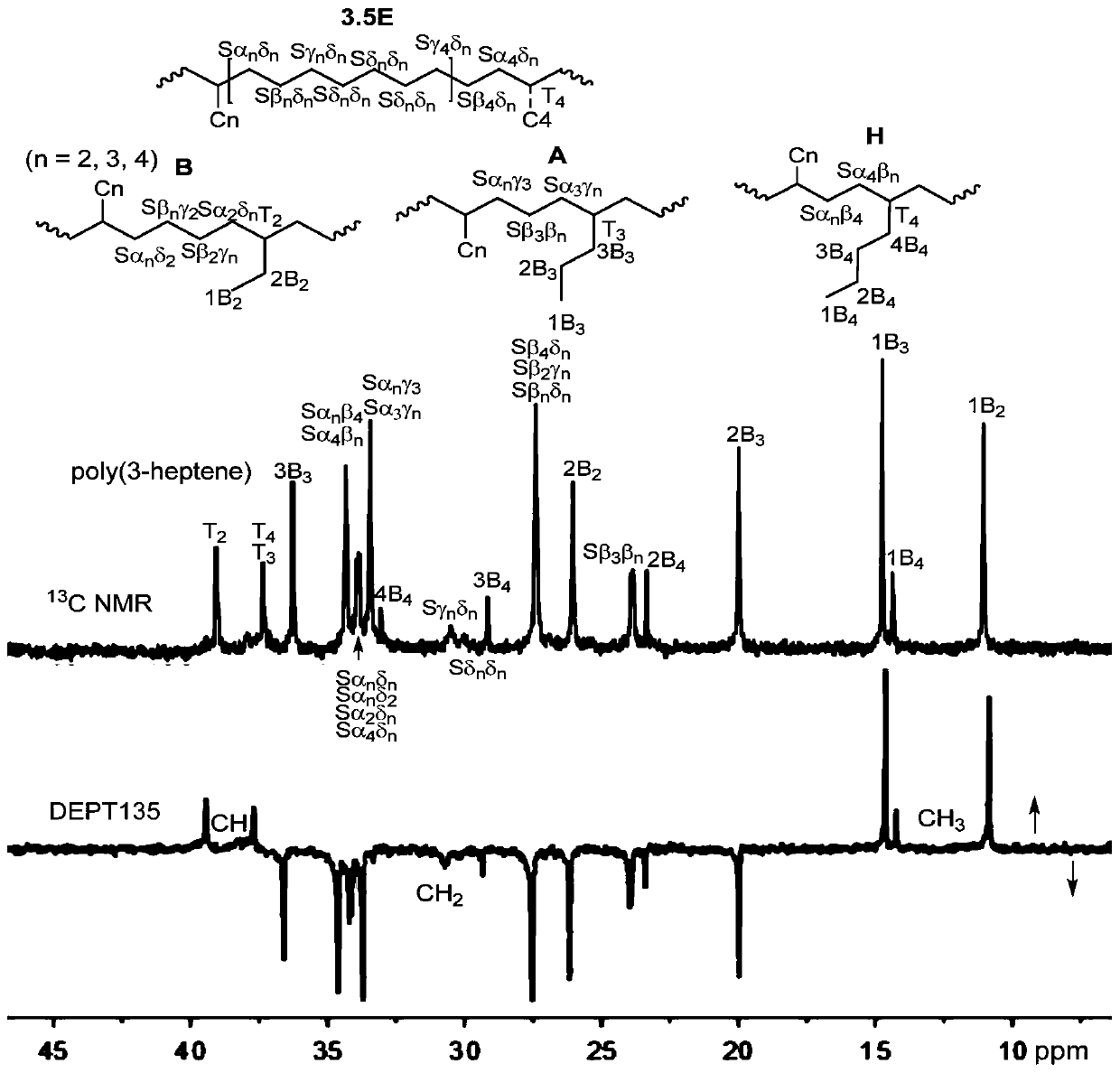

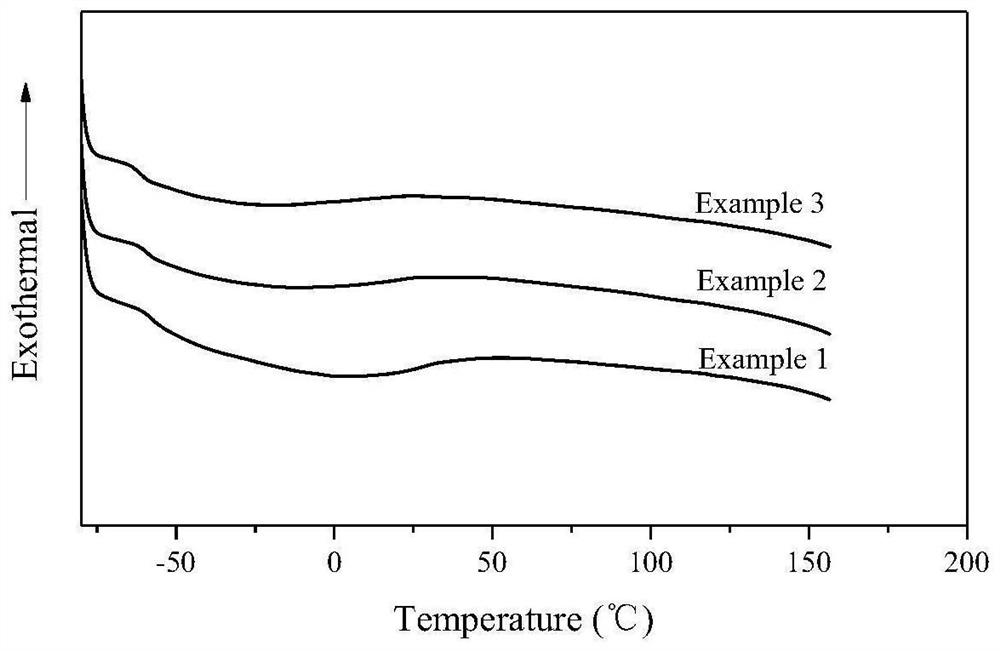

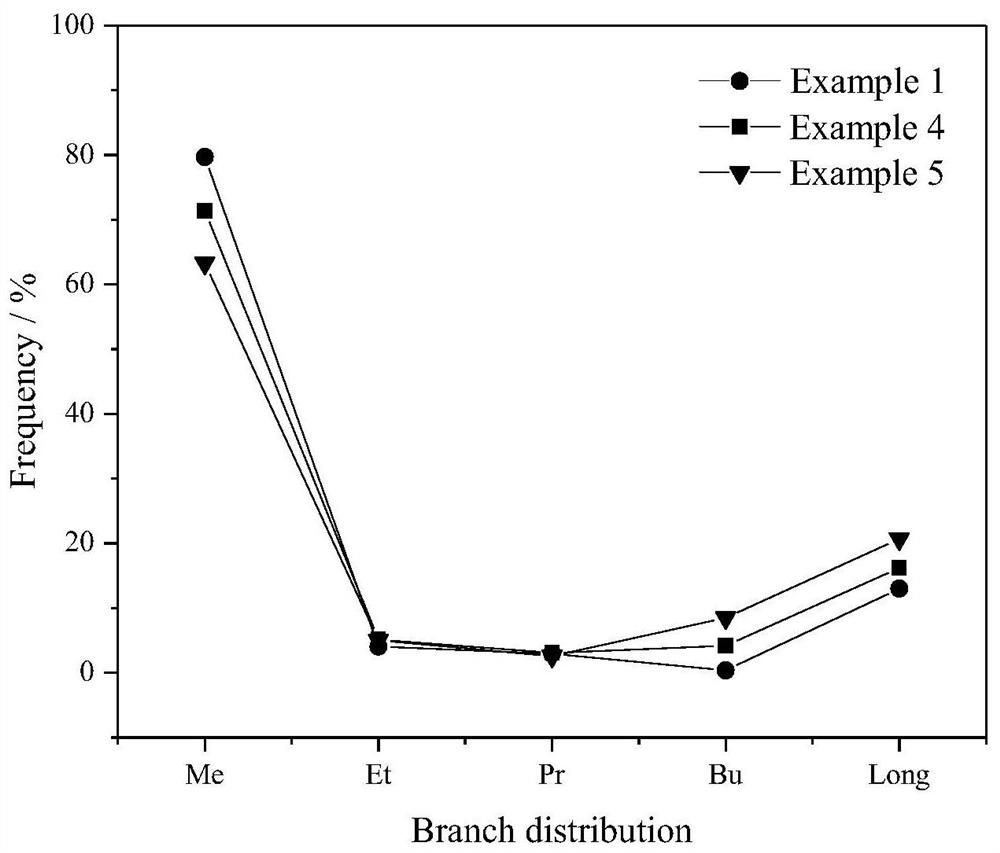

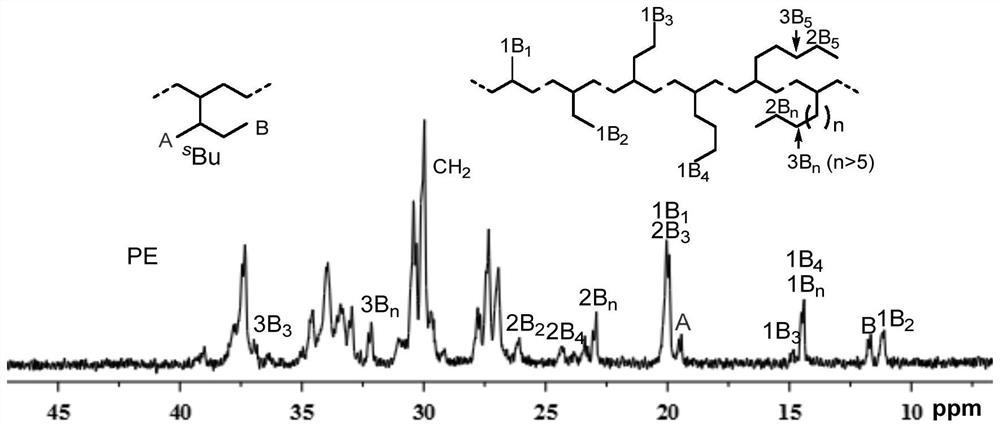

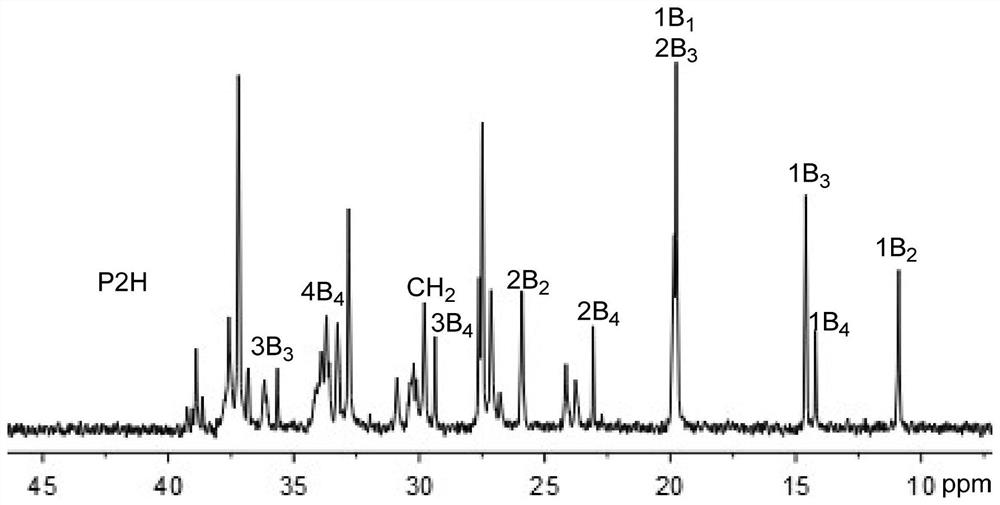

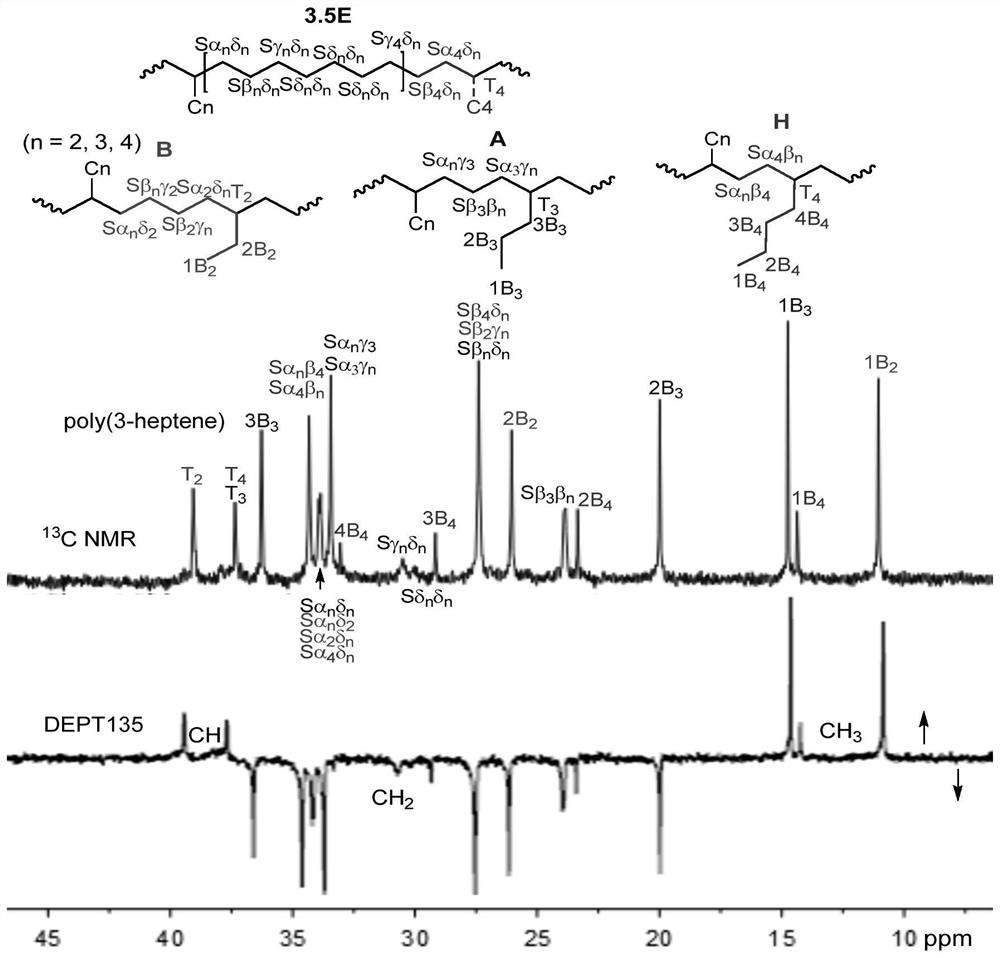

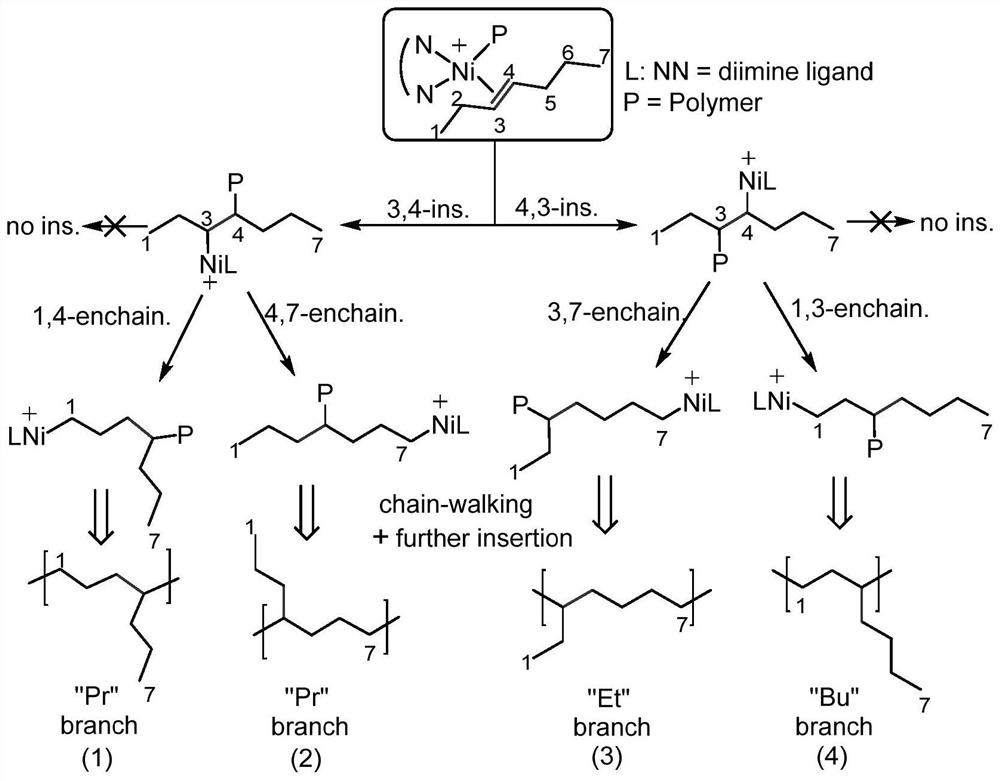

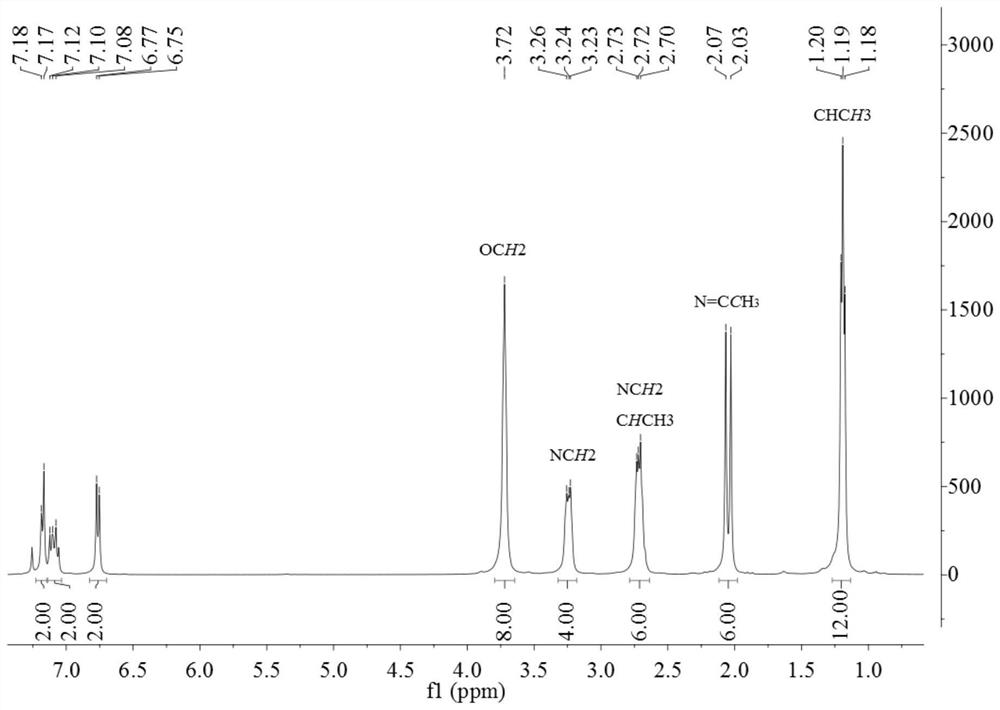

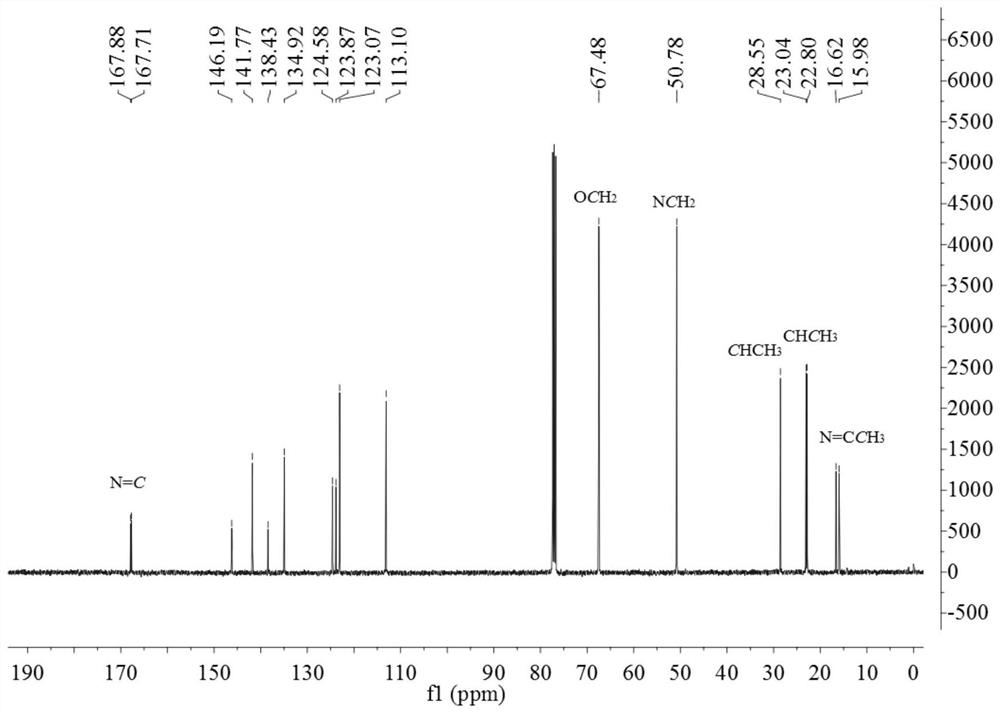

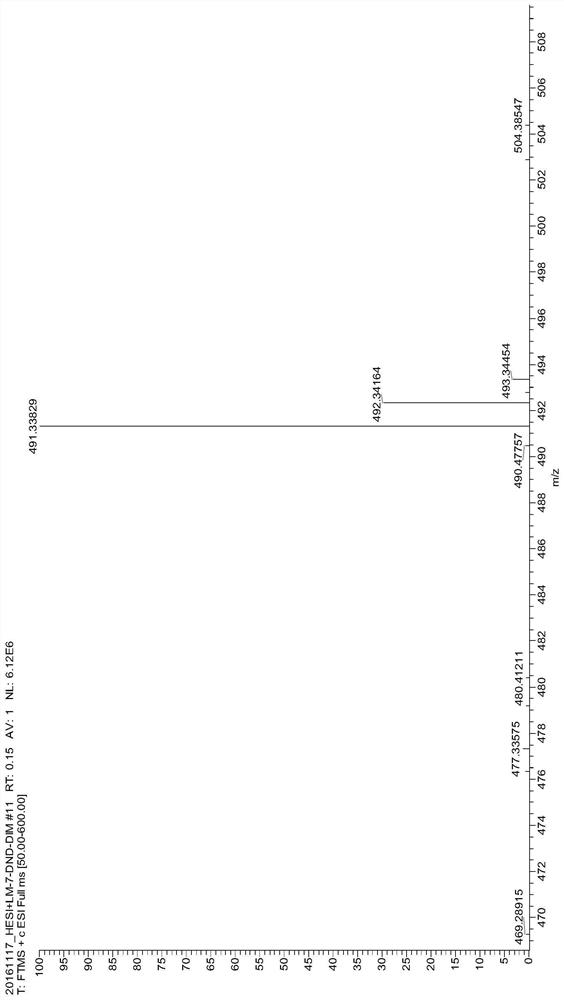

Application of para-position phenyl-containing alpha-nickel diimine (II) complex to catalysis of 3-heptene for chain walking polymerization

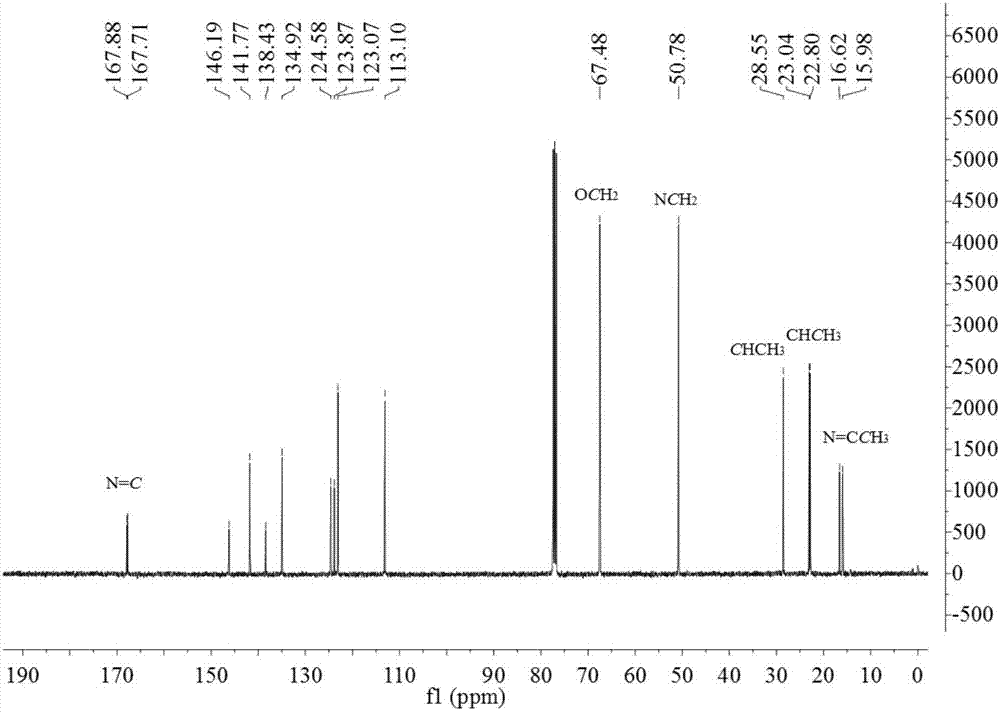

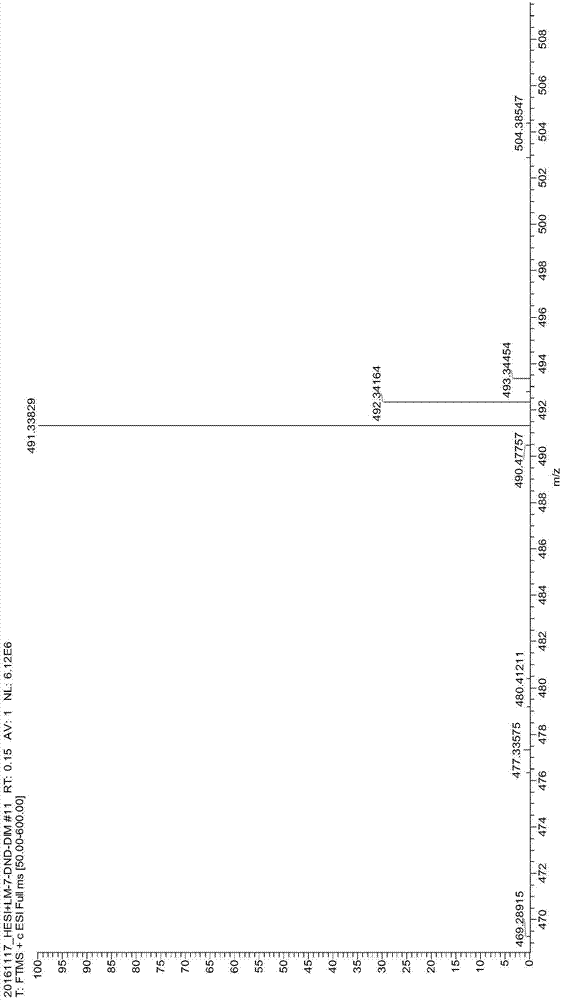

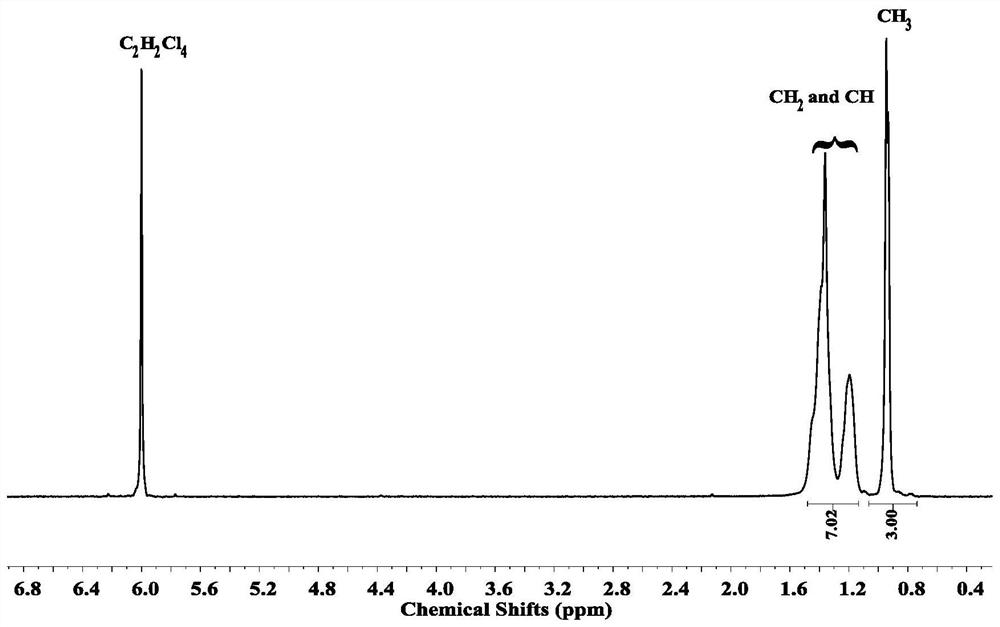

ActiveCN109879992AImprove catalytic performanceAchieving PolymerizationChain walkingNMR - Nuclear magnetic resonance

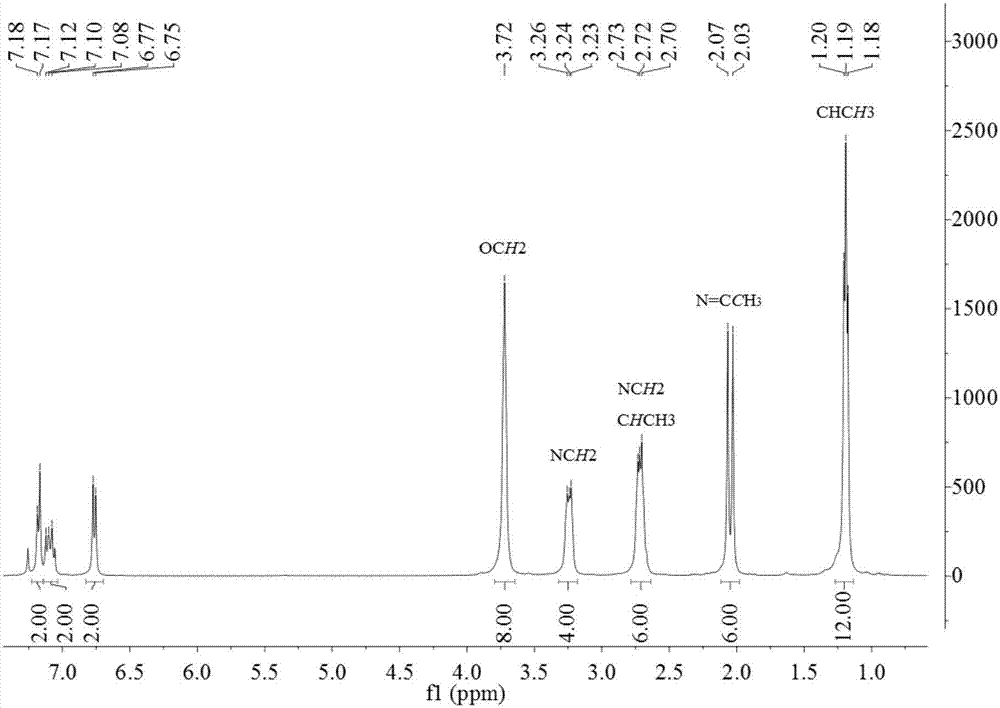

The invention discloses application of a para-position phenyl-containing alpha-nickel diimine (II) complex to catalysis of 3-heptene for chain walking polymerization. The para-position phenyl-containing alpha-nickel diimine (II) complex is used as a chain walking catalyst for catalyzing the monomer 3-heptane for a polymerization reaction; through the conjugate effect of phenyl, the chain walking speed of nonterminal olefin is accelerated; and under the activation of cocatalyst dried and modified methylaluminoxane (dMMAO), the 3-heptene is catalyzed for a chain walking polymerization reaction through the chain walking catalyst, wherein the structural general formula of the para-position phenyl-containing alpha-nickel diimine (II) complex and a relevant polymerization process are shown in the description. A catalysis system involved in the invention realizes the polymerization of the 3-heptane through chain walking behaviors; and an amorphous polymer with a stable branching degree (about139 branch chains / 1000 carbon; and Tg is about minus 68 DEG C) is generated. It is shown, by the NMR (Nuclear magnetic resonance) analysis of the polymer, that obtained poly(3-heptene) has ethyl, propyl and butyl branch chains and a small number of methylene sequences with long chains isomerized by monomers.

Owner:ANHUI UNIVERSITY

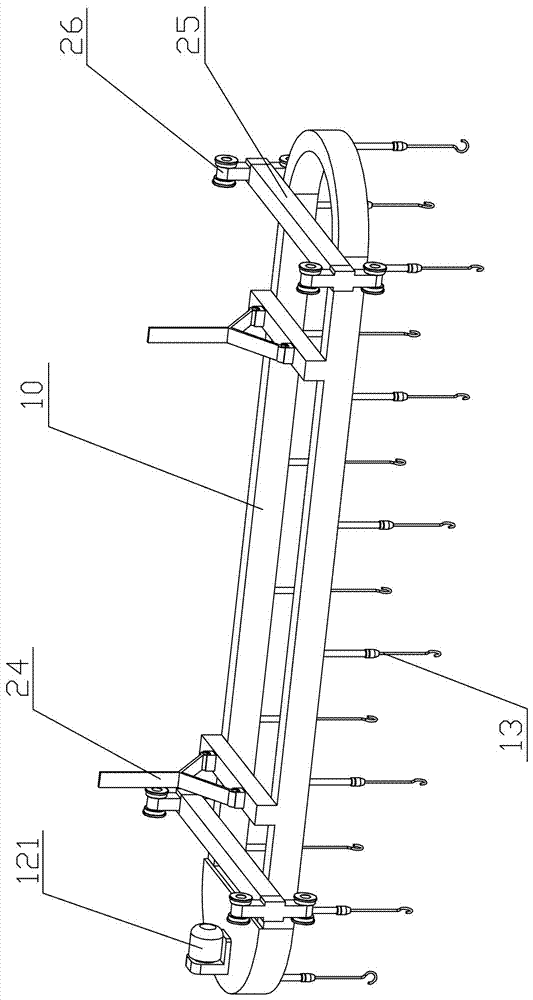

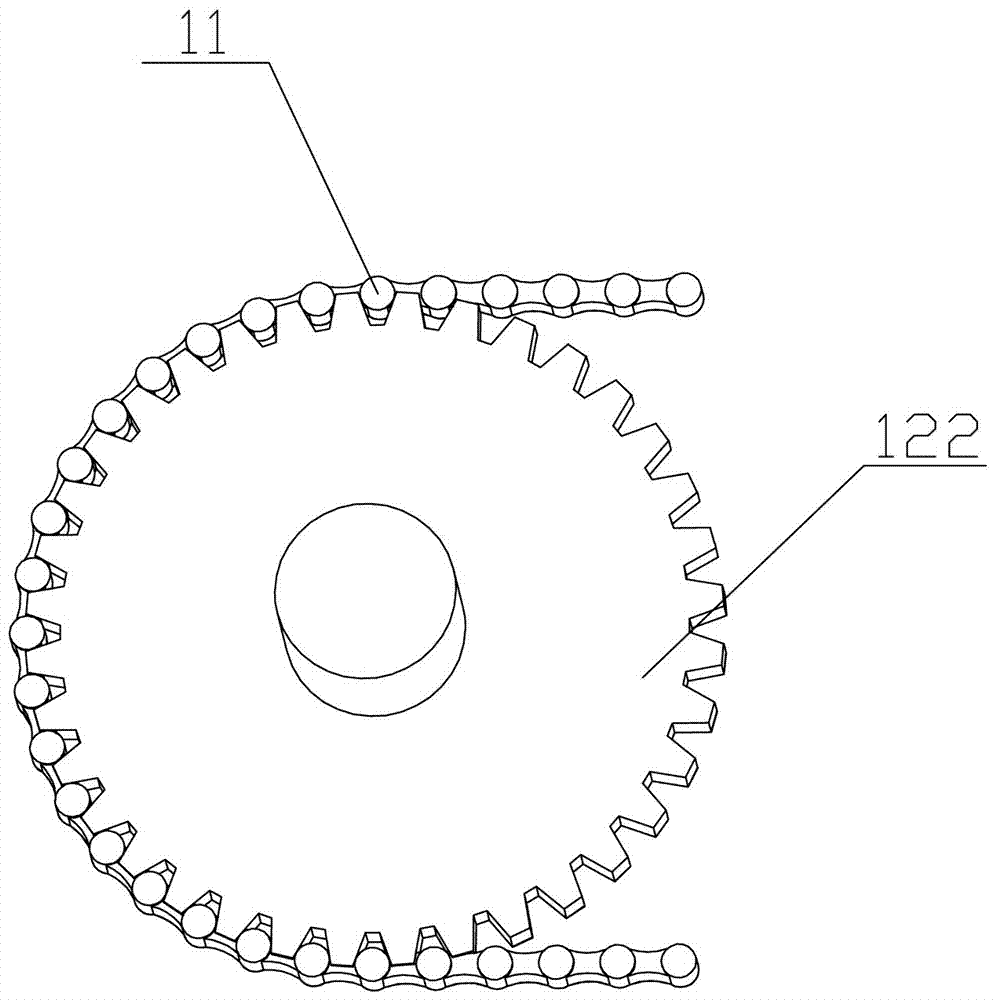

Paint spraying bucket cleaning device and cleaning method thereof

InactiveCN107185932AReduce the number of laborReduce labor intensityHollow article cleaningChain walkingEngineering

A paint spraying bucket cleaning device comprises a support, a closed annular rail is arranged on the upper middle portion of the support, and the annular rail is provided with an annular chain and a chain walking drive mechanism; multiple hooks are hung on the bottom of the annular chain in an annularly spaced manner, an unoccupied station used for upward hanging and taking down a paint spraying bucket is reserved below at least one hook, a cleaning container is correspondingly arranged below each of the remaining hooks, and a lifting drive mechanism for driving the annular rail to vertically move is further arranged on the upper portion of the support. The cleaning method of the paint spraying bucket cleaning device comprises the steps that at the unoccupied station, a paint spraying bucket is hooked upwards through manual work; the lifting drive mechanism acts to enable the paint spraying bucket to be lifted to the position above the cleaning containers; the chain walking drive mechanism is then started to enable the paint spraying bucket to rotate to the position over the cleaning containers; the lifting drive mechanism acts, and the paint spraying bucket falls in the cleaning containers; and the above steps are repeatedly executed. According to the method and device, the paint spraying bucket cleaning efficiency and cleaning effect can be effectively improved, and the service life can be effectively prolonged.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

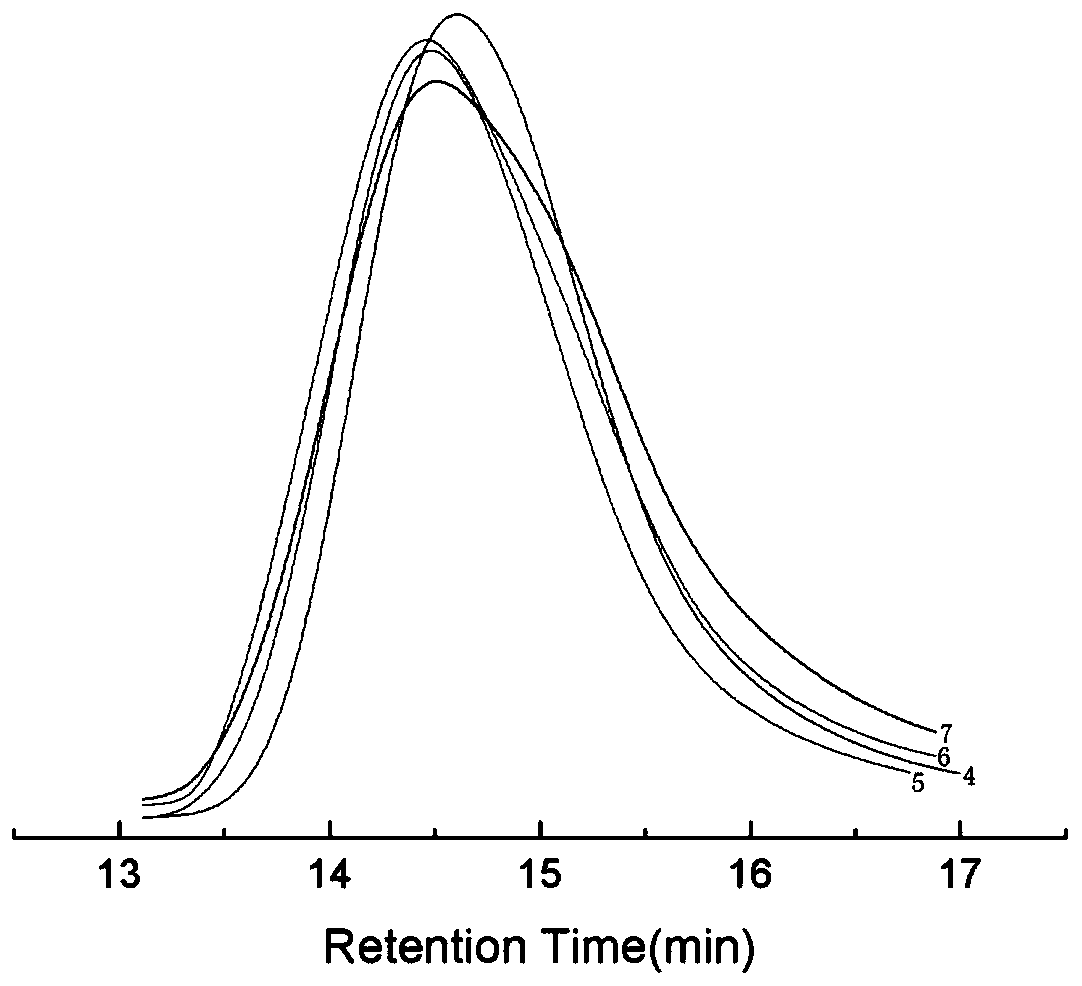

Ethylene and 1-hexene copolymer and preparation method thereof

The invention discloses an ethylene and 1-hexene copolymer and a preparation method thereof. The copolymer poly(ethylene-co-1-hexene) is prepared by taking ethylene and 1hexene as comonomers and usingan alpha-diimine nickel catalyst and a methylaluminoxane MAO cocatalyst through a coordination polymerization method. The process for preparing the ethylene and 1-hexene copolymer is simple, the obtained poly(ethylene-co-1-hexene) has the characteristics of high molecular weight, low melting point, high branching degree and the like, the performance of a polymerization product can be regulated and controlled by controlling reaction conditions; by utilizing a chain walking catalyst, the polyolefin products with different performances are obtained in a coordination polymerization process of thecocatalyst MAO and an olefin monomer in a polymerization reaction system; in addition, the interaction between a nickel metal active center in the alpha-diimine nickel catalyst and MAO is clearer through an EPR map, and the valence state of the nickel metal center is reduced to different extents along with the change of the adding amount of the Lewis acid MAO.

Owner:ZHEJIANG UNIV

Transmission chain protective cover

InactiveCN107701710ASolve lubrication problemsEvenly lubricatedGearingGear lubrication/coolingChain walkingOil and grease

The invention provides a transmission chain protective cover, which includes a cover body, which is composed of a bottom shell and a cover plate that are fastened together. The bottom shell is configured with a transmission chain running groove for the transmission chain to travel, and the transmission chain The two ends of the chain running groove are provided with perforations for the transmission chain to penetrate and pass through. The bottom shell is fixed with a number of oil injection nozzles in a row on the upper side of the transmission chain running groove. and a number of oiling rollers, all of which are arranged in the transmission chain walking groove through the roller shaft. The outer surfaces of the rollers are covered with a flexible surface layer, and the oiled rollers apply oil to the rollers of the transmission chain; a transmission chain protective cover proposed by the present invention can evenly apply lubricating oil when the transmission chain is running, and Collect excess lubricant.

Owner:YICHANG DIYUAN MEDICAL MATERIAL CO LTD

Preparation method and use of crosslinked polyethylene-loaded metal nanoparticles

ActiveCN103263916AEasy to manufactureLow costMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionChain walkingPtru catalyst

The invention discloses a preparation method and a use of crosslinked polyethylene-loaded metal nanoparticles. The preparation method comprises that ethylene and a crosslinking monomer undergo a chain walking copolymerization reaction in the presence of a palladium-diimine catalyst to produce a crosslinked polyethylene carrier for loading metal nanoparticles; through a one-step loading or two-step loading technology, a metal compound is fixedly loaded on the crosslinked polyethylene carrier; and the metal compound loaded by the crosslinked polyethylene carrier undergoes a reduction reaction and is transformed into metal nanoparticles so that the crosslinked polyethylene-loaded metal nanoparticle catalyst is obtained. The crosslinked polyethylene-loaded metal nanoparticles are used for catalysis of a carbon-carbon cross-coupling reaction, has high catalytic activity and good stability, and can be recovered and recycled easily.

Owner:ZHEJIANG UNIV

Nickel(ii) complexes containing p-diphenylmethyl-substituted α-diimine for catalyzing the polymerization of ethylene and 2-hexene

ActiveCN107698699BSpeed up the walking processHigh activityNickel organic compoundsChain walkingPolymer science

Novel late-transition-metal alpha-diimine nickel (II) complexes containing p-benzhydryl substitutes are disclosed. According to the complexes, two bulky groups which are benzhydryl are introduced to the para positions of imine nitrogen atoms on aromatic rings, and therefore ethylene insertion is accelerated, catalyst activity is improved, the transferring rate of active chains to a monomer is reduced, and a polymer having a high molecular weight is prepared. Under activation by a cocatalyst that is diethylaluminium chloride, a catalytic system catalyzing ethylene polymerization has high catalytic activity (can be 10<6> g PE / (mol Ni h)), and prepared polyethylene having a high molecular weight has a high degree of branching (can be 131 branches per 1000 C). Because of ortho-position small-steric-hindrance substitution and immobilization by para-position bulky benzhydryl, 2-hexene can be easily inserted to a metal center, and therefore chain shuttling polymerization of the 2-hexene has ahigh conversion ratio (88%), and a branch polymer having a high molecular weight and a low degree of dispersion is obtained. Accordingly, the catalyst has good potential application value in industrial polyolefin production.

Owner:CHANGZHOU UNIV

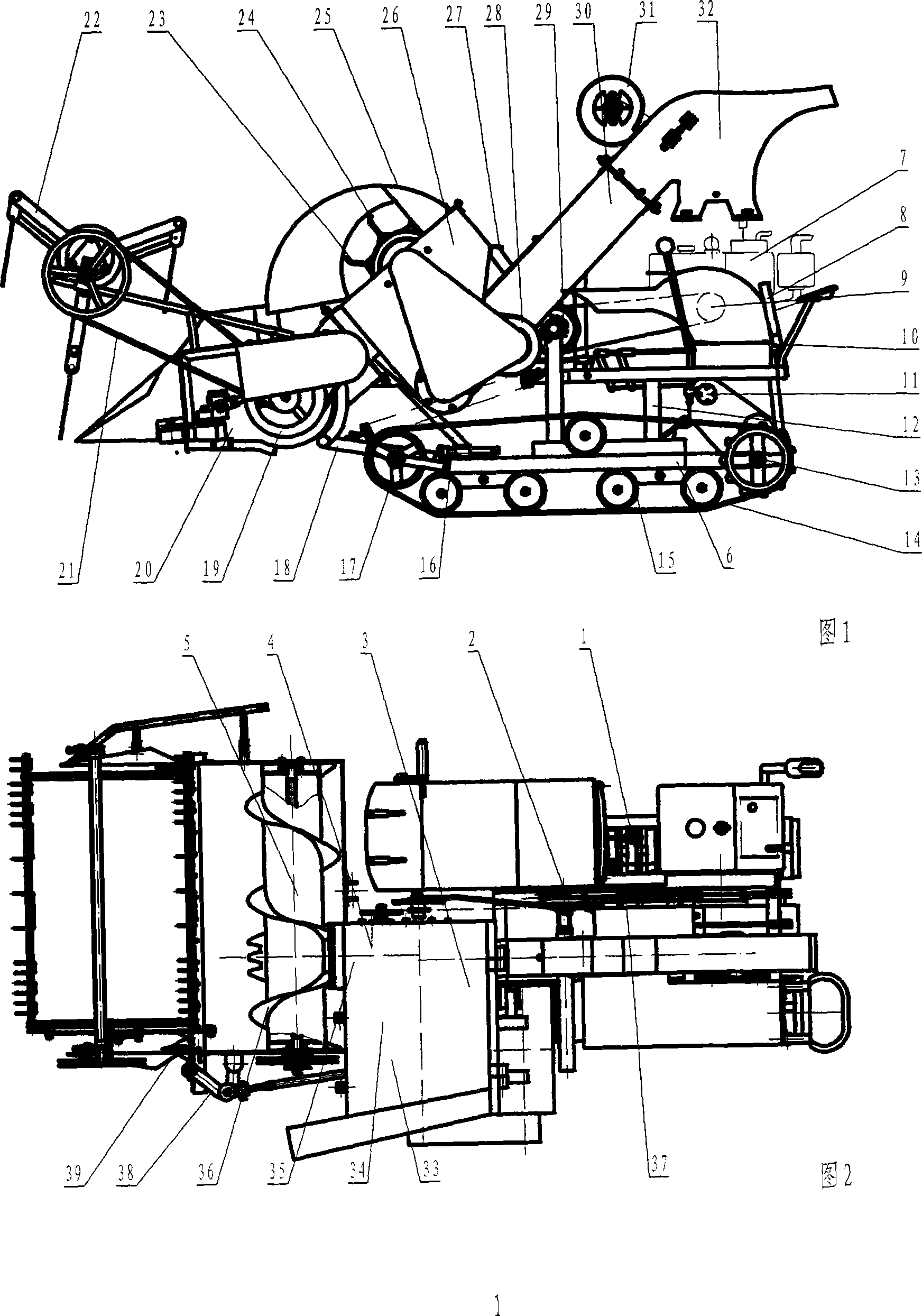

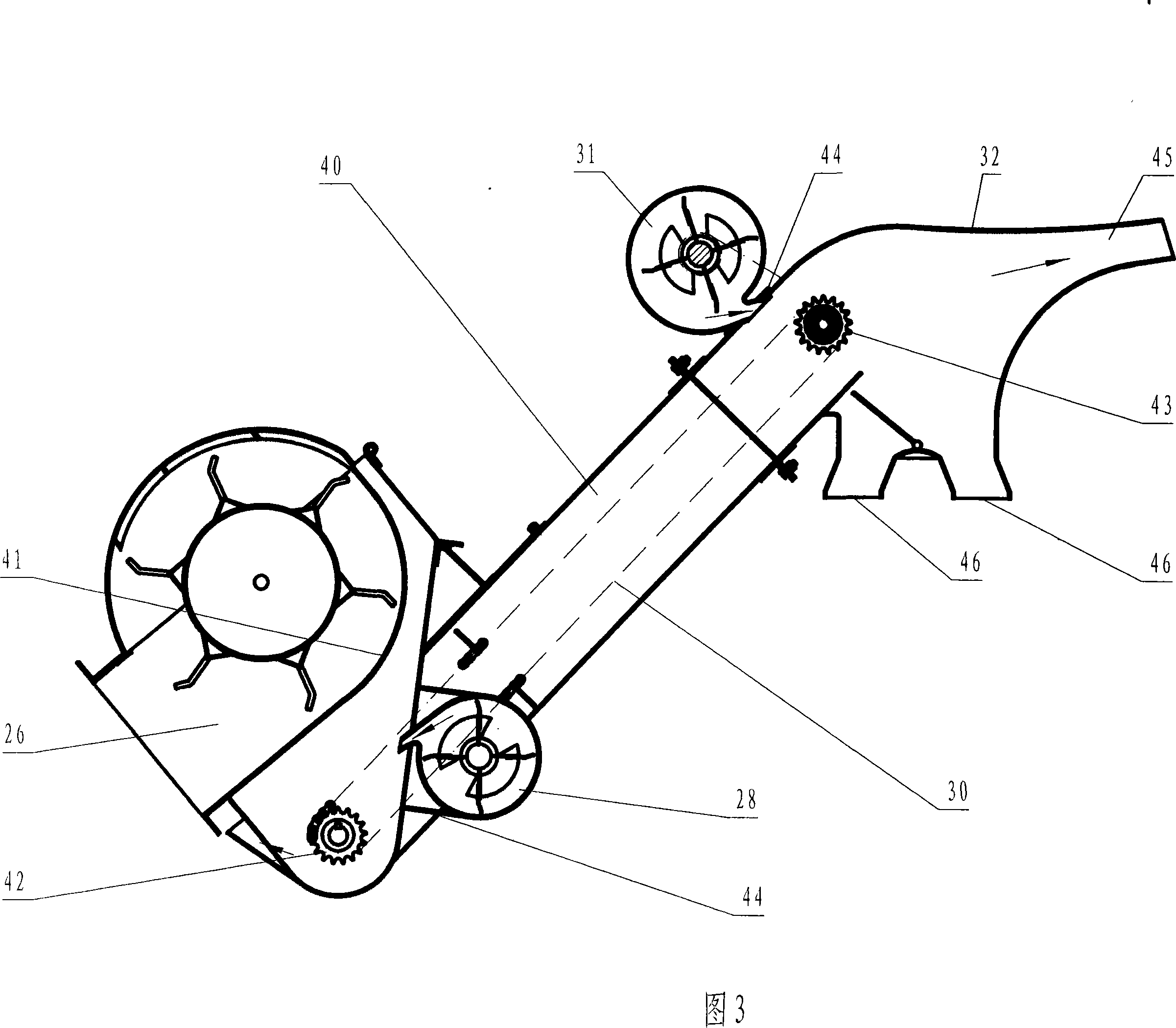

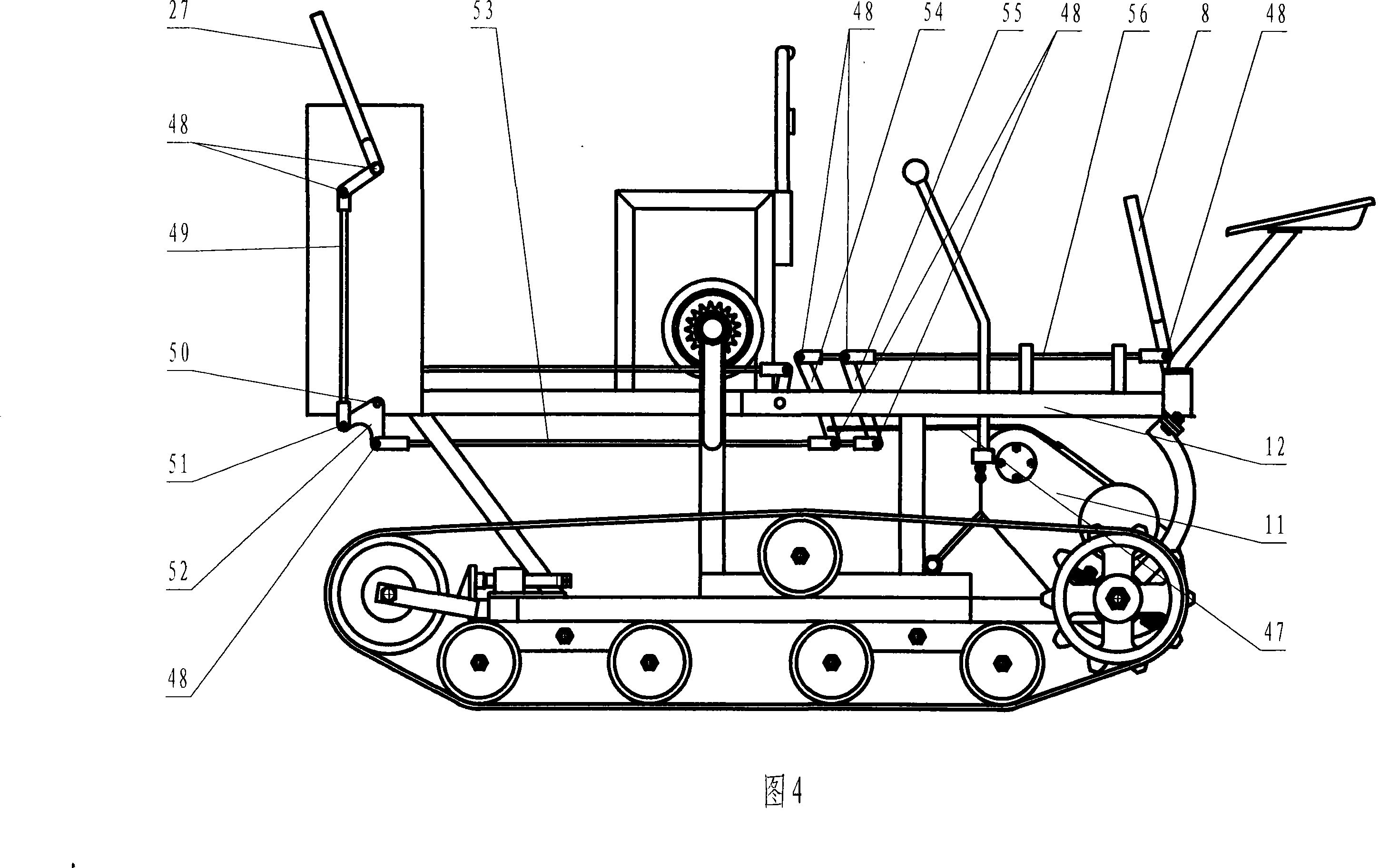

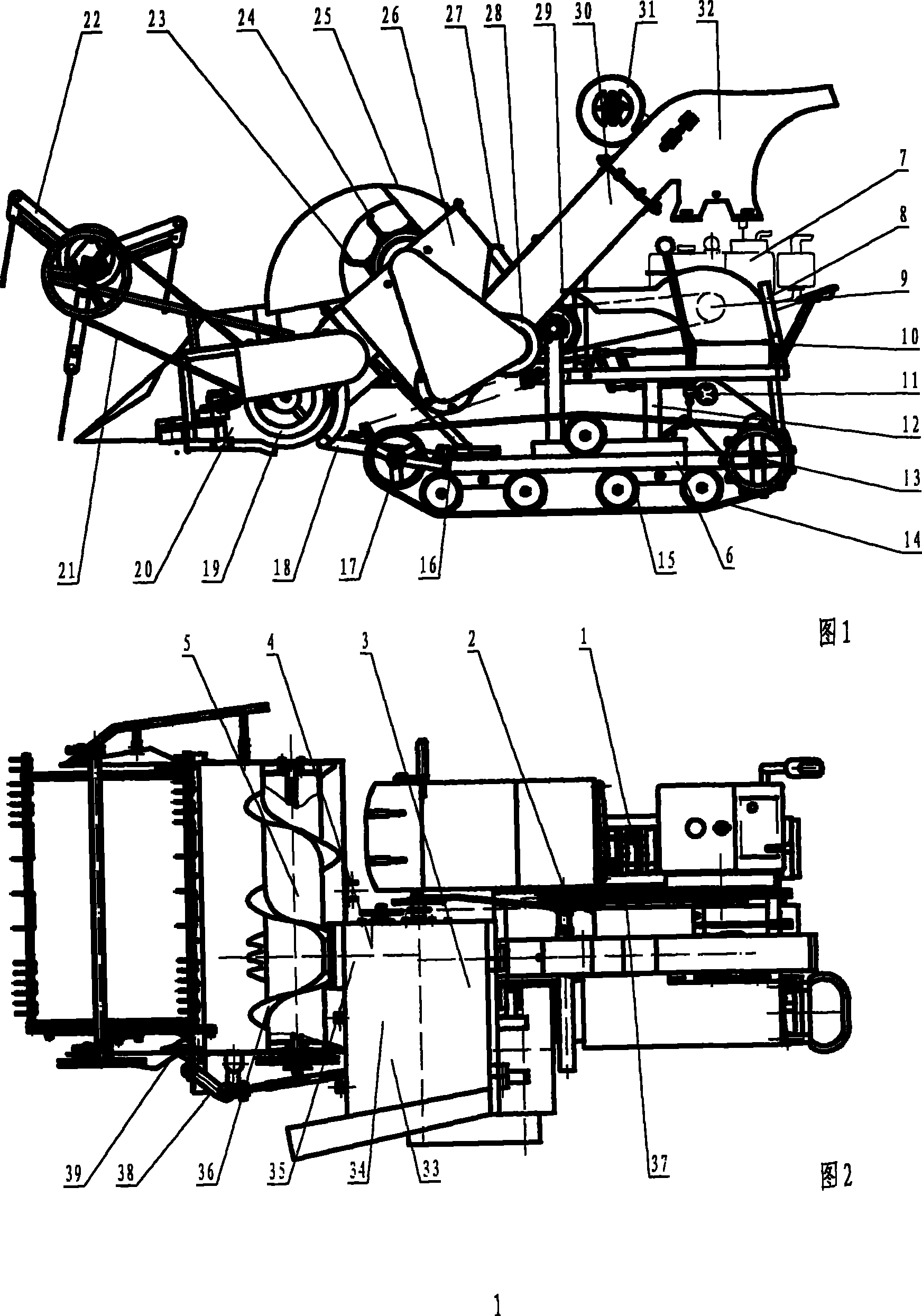

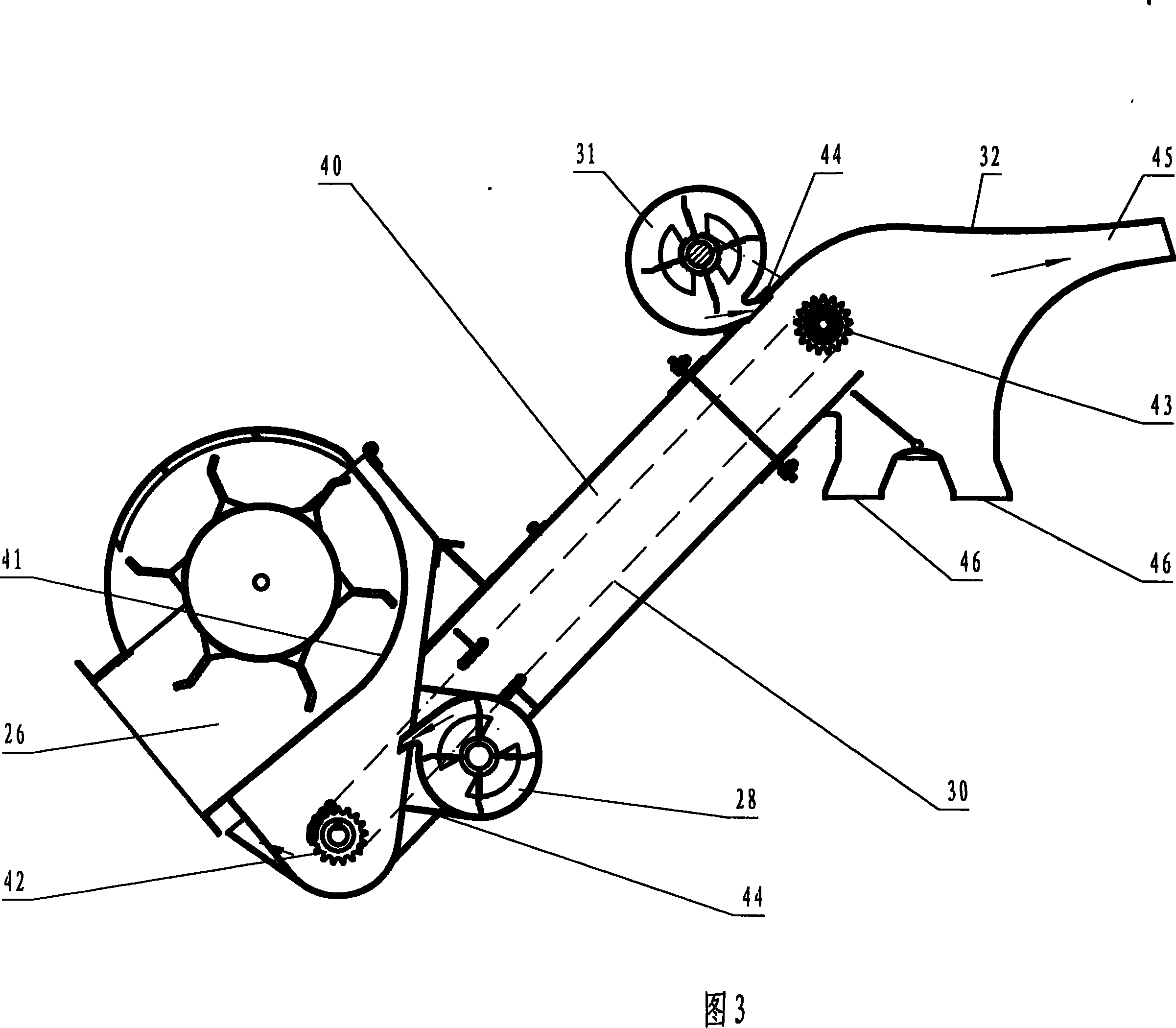

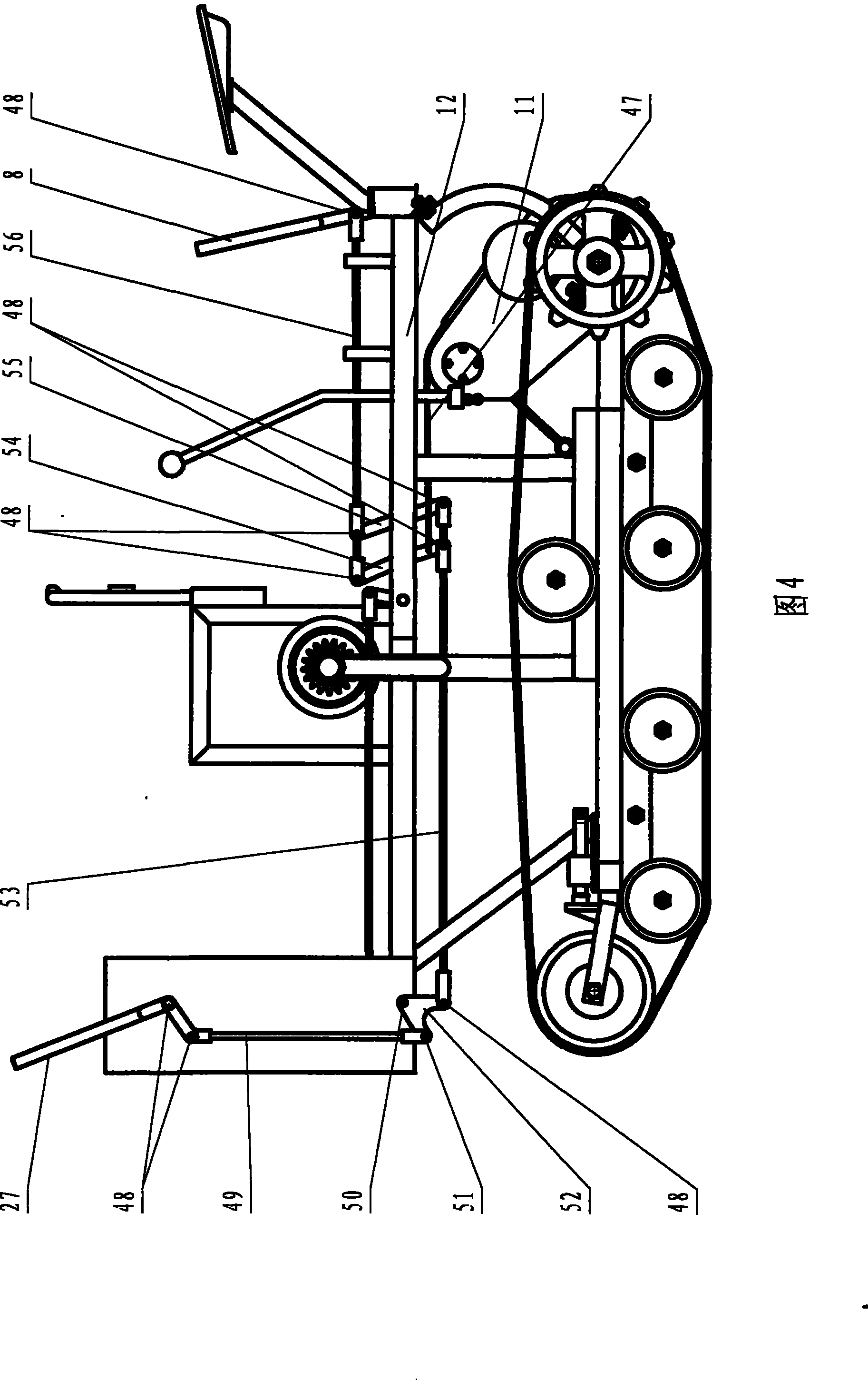

Track walking type minitype rice combine harvester

InactiveCN101213902ANot easy to damageEasy to disassemble and replaceMowersThreshersChain walkingAgricultural engineering

A caterpillar-chain walking-type micro rice combined harvester comprises a chassis, a walking device, a transmission mechanism, a conveying device, a reaping apparatus and a threshing mechanism, wherein, a dual-fan soot blower is arranged inside the threshing mechanism, the walking device is provided with a four-bar linkage control mechanism consisting of four transmission bars and a linkage so as to realize the consistent method for controlling the harvester both with the front operation bar and the rear operation bar and to realize the same operation controlling function; the walking caterpillar chain is an iron pouring composite that is composed of an upper dental plate and a lower dental plate which are arranged on a bridge chain in clamping way through bolts, wherein, the upper dental plate is provided with steel teeth, the lower dental plate is provided with rubber teeth with a lower-tooth steel bracket, and the bridge chain is a stratiform composite chain that is formed by a rubber layer and a nylon-wire layer. The present invention has the advantages of compact structure, small volume, light weight, flexible operation, low energy consumption and convenient maintenance, which is applicable to the small fields in the mountainous area and the hilly area.

Owner:王辉

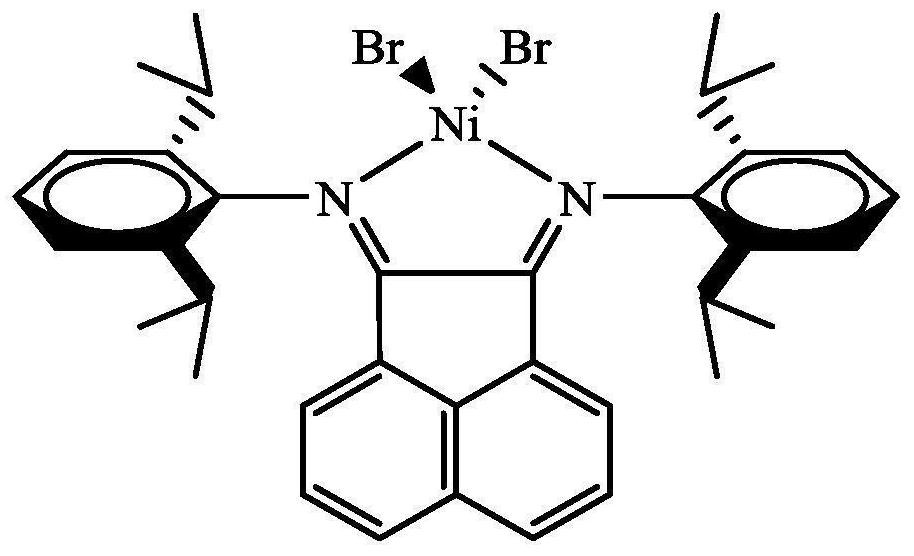

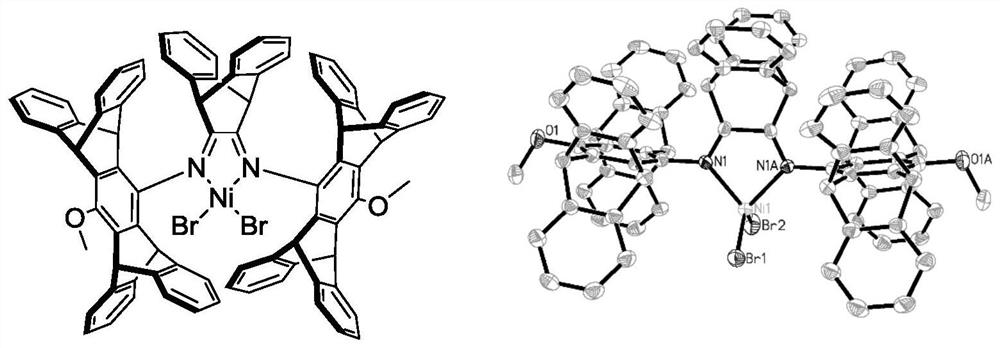

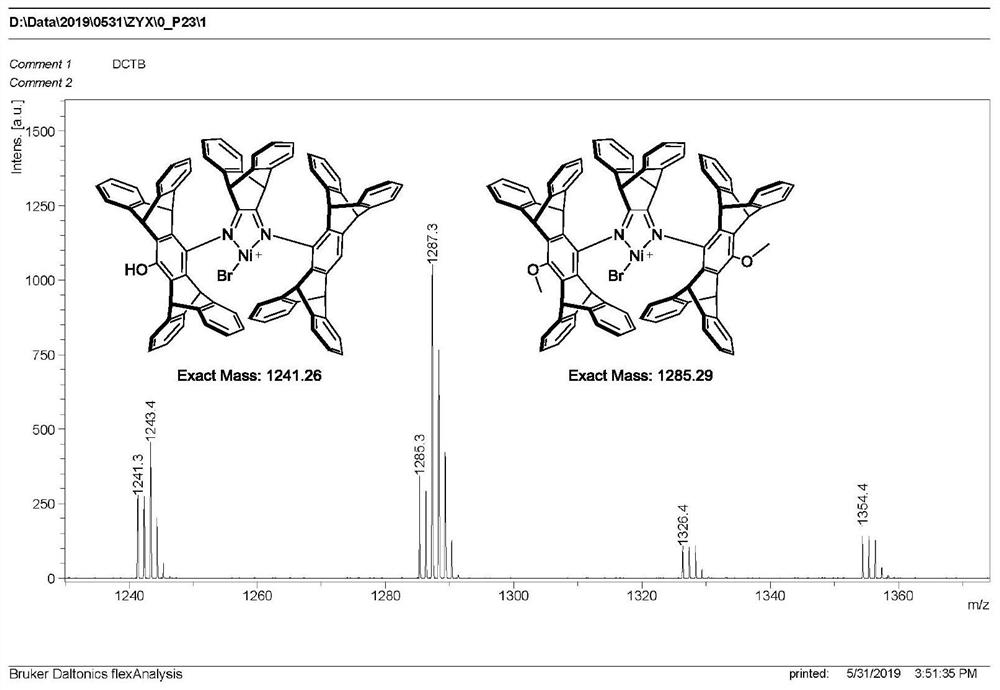

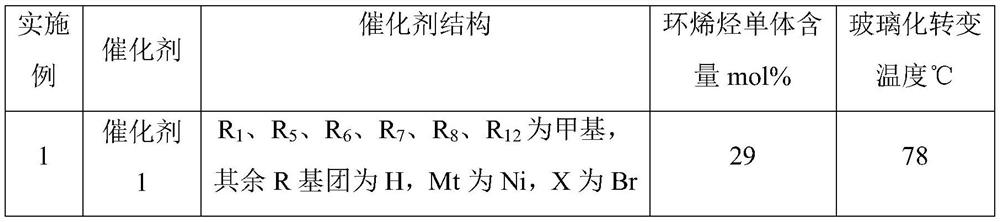

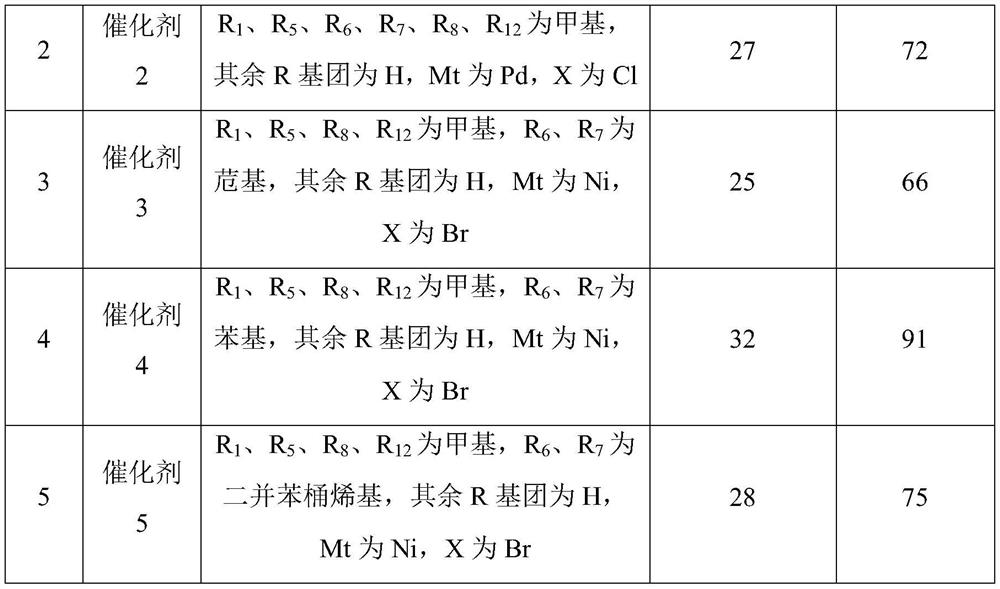

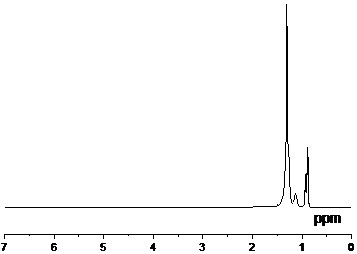

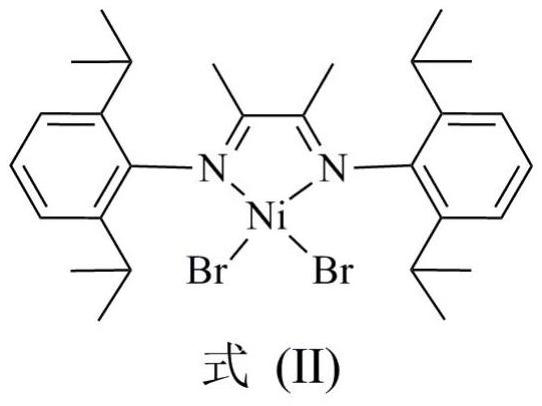

Chain walking catalysts, preparation method thereof, and application of catalysts in ethylene polymerization

PendingCN111732678ARegulating branching typeHigh activityNickel organic compoundsChemical recyclingChain walkingPolymer science

The invention provides chain walking catalysts, a preparation method thereof, and application of the catalysts in ethylene polymerization, and belongs to the technical field of catalyst synthesis andpolymer synthesis. The structural formula of the catalysts is shown as a general formula (I). The invention also provides the preparation method of the chain walking catalysts. The preparation methodcomprises the following steps: dissolving novel benzobucene pentaptycene ligands shown in the general formula (II) and (DME)NiBr2 in a solvent, and stirring the obtained mixture at 20-50 DEG C for 3-30 days to obtain the chain walking catalysts with the structural formula shown in the general formula (I). The invention also provides the application of the chain walking catalysts in ethylene polymerization. The catalysts can adjust the branching type, the branching sequence and the branching number of the polymer to a certain extent.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Reverse limiting device for chain

PendingCN112238321ARealize the reverse limitLimit swingWelding/cutting auxillary devicesAuxillary welding devicesChain walkingControl engineering

The invention provides a reverse limiting device for a chain. The reverse limiting device comprises a base, wherein the base is provided with a chain locking part which is provided with a clamped endused for being clamped into a chain link gap; the clamped end is provided with a passing station which rotates to allow the chain to pass through when the chain moves forwards, and is further providedwith a locking station which is clamped into the chain link gap to lock the chain when the chain moves reversely; the base is further provided with a deviation preventing part, and the deviation preventing part comprises a stop surface opposite to the clamped end; and a chain walking space for the chain to pass through is formed between the stop surface and the clamped end, and a loading openingwhich communicates with the chain walking space and is used for loading the chain into the chain walking space is formed in one side of the stop surface and the clamped end. The reverse limiting device has the beneficial effects that reverse limiting of the chain is achieved; the structure is simplified through the one-to-one limiting mode of the clamped end and the stop surface; the chain does not need to overcome the counter-acting force of too many chain locking parts during moving, smooth moving of the chain is facilitated, chain wear is reduced; and meanwhile, the chain can be loaded intothe chain walking space from the loading opening in the side direction, so that installation is very convenient.

Owner:HENAN SENYUAN HEAVY IND

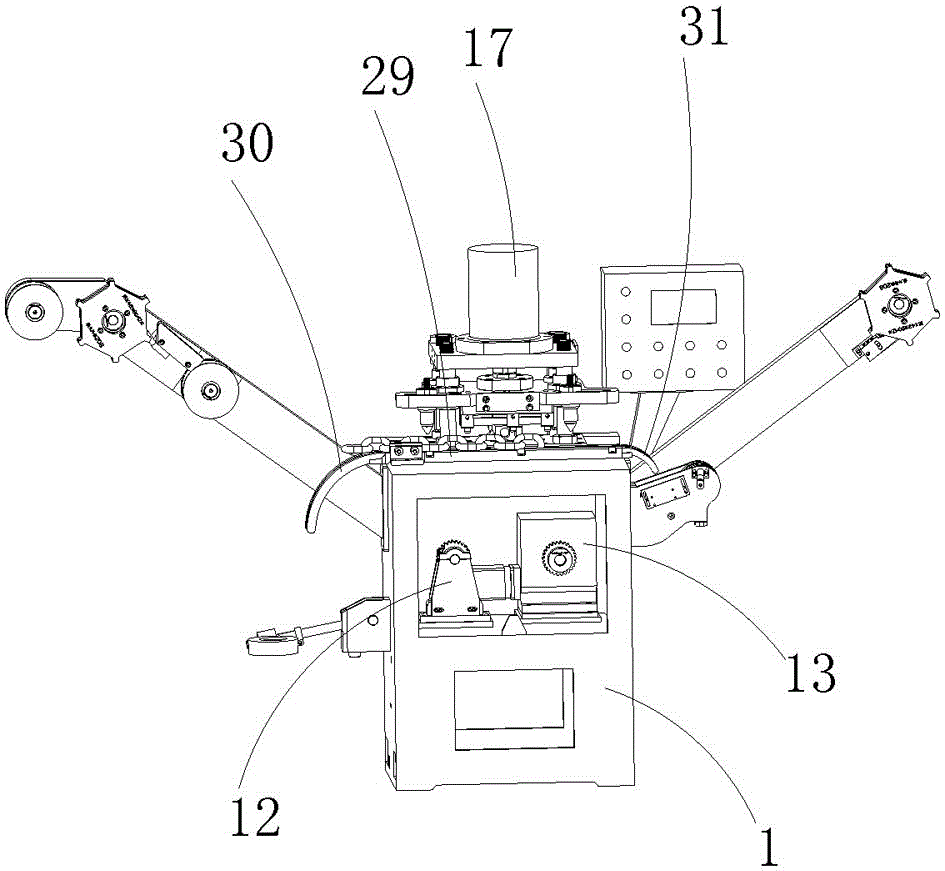

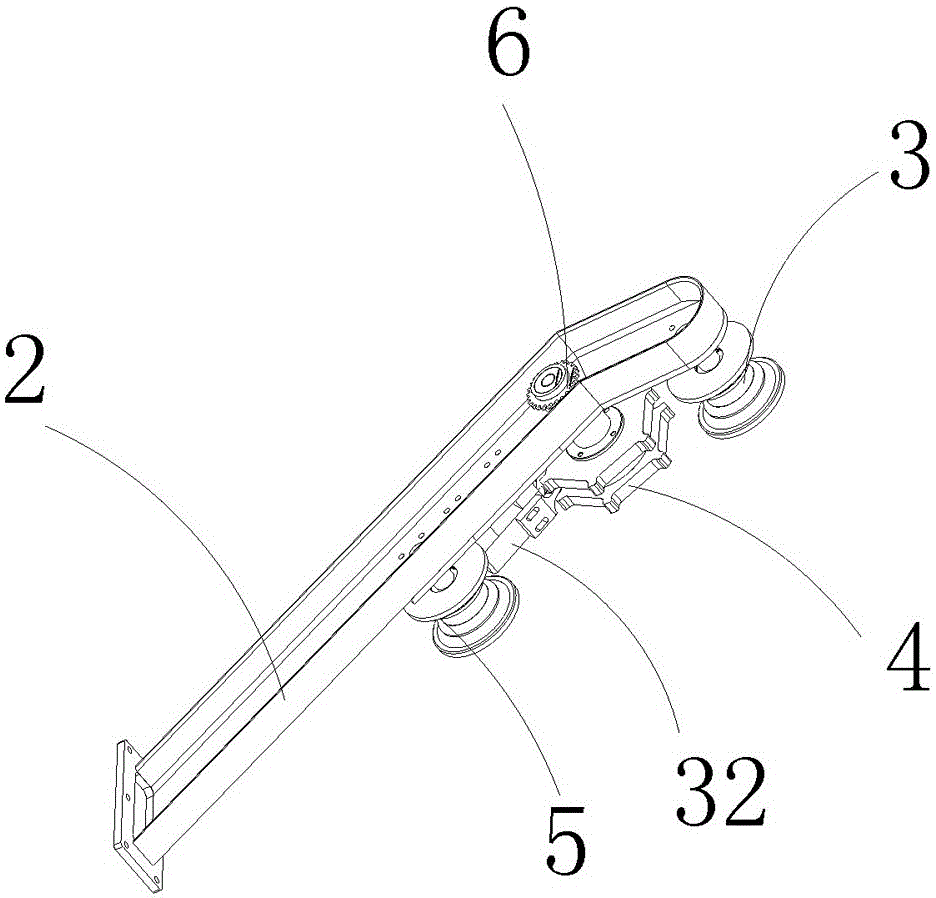

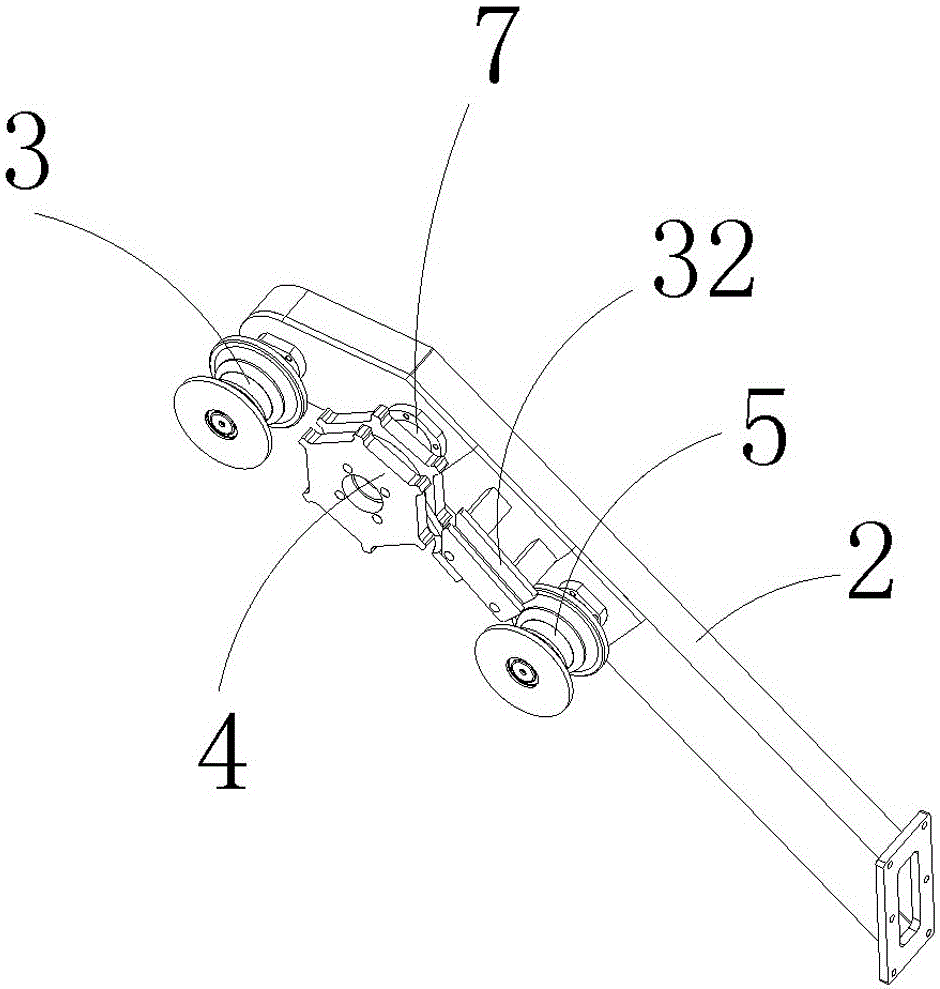

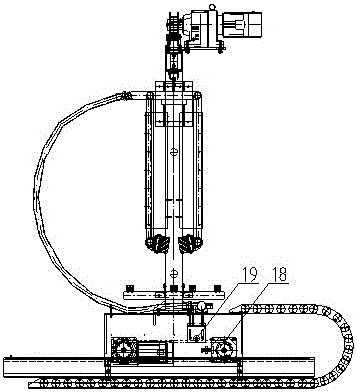

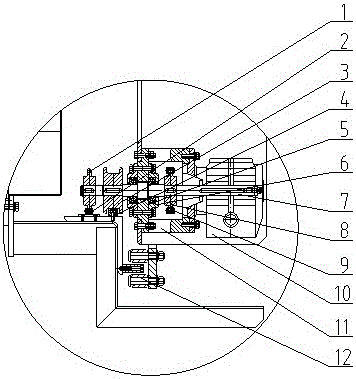

Hydraulic lifting chain stamping machine and printing method thereof

ActiveCN105128546AReduce labor intensitySimple structureOther printing apparatusStampingChain walkingEngineering

The invention relates to a stamping machine, in particular to a hydraulic lifting chain stamping machine and a printing method thereof. The stamping machine comprises an operation frame, wherein a prefeeding mechanism is arranged at the left side end of the operation frame; a walking chain discharge mechanism corresponding to the prefeeding mechanism is arranged at the right side end of the operation frame; a drag chain transmission mechanism and a printing action mechanism are arranged in the operation frame; and the drag chain transmission mechanism and the printing action mechanism are correspondingly distributed. The printing method is performed by the steps of: chain walking-positioning-steel mark depth adjustment-chain discharge-quality inspection. The hydraulic lifting chain stamping machine and the printing method thereof are simple in structure, realize automatic loading, automatic steel sealing and automatic unloading, improve the working efficiency, and reduce the labor intensity of workers.

Owner:HANGZHOU ZHEZHONG CHAIN

Application of a para-phenyl-containing α-diimine nickel (ii) complex in catalyzing the chain walking polymerization of 3-heptene

The invention discloses the application of a para-phenyl-containing α-diimine nickel (II) complex in catalyzing the chain walking polymerization of 3-heptene, which is used as a chain walking catalyst to catalyze the synthesis of monomer 3-heptene Polymerization reaction, and the chain walking speed of internal olefins is accelerated due to the conjugation of phenyl groups; under the activation of cocatalyst dry modified methylalumoxane (dMMAO), the chain walking of 3-heptene is catalyzed by the chain walking catalyst Polymerization reaction, wherein the general structural formula and related polymerization process of the p-position containing phenyl α-diimine nickel (II) complex are as follows: the catalytic system of the present invention realizes the polymerization of 3-heptene through chain walking behavior, and produces stable branches degree of amorphous polymer (≈139 branches / 1000 carbons; T g ≈–68°C). NMR analysis of the polymer revealed that the resulting poly(3‑heptene) had ethyl, propyl, and butyl branches and a small amount of long-chain methylene sequences through monomer isomerization.

Owner:ANHUI UNIVERSITY

A hydraulic lifting chain embossing machine and its printing method

ActiveCN105128546BReduce labor intensitySimple structureOther printing apparatusStampingChain walkingIndustrial engineering

Owner:HANGZHOU ZHEZHONG CHAIN

Cycloolefin copolymer and preparation method thereof

The invention relates to the field of olefin polymerization, in particular to a cycloolefin copolymer and a preparation method thereof, and the cycloolefin copolymer is composed of structural units. A post-transition metal catalyst with a specific structure and a chain walking characteristic is adopted, generation of crystalline ethylene chain segments is avoided, the transparency of the obtained copolymer is improved, a branched structure is introduced into a polymer chain, under the same norbornene content, the polymer has a higher glass transition temperature than a metallocene ethylene / norbornene copolymer, and the thermal stability of the polymer is improved. Meanwhile, the catalytic system has good tolerance to water, oxygen and polar groups, can be used for preparing cycloolefin copolymers with polar groups, and has a wider application prospect.

Owner:广东华锦达新材科技有限公司

Box type filter press side beam filter cloth washing car chain traveling mechanism and traveling mode

The invention relates to a chain travelling mechanism and a chain travelling way of a side beam type filter cloth washing vehicle for a box type filer press. The chain travelling mechanism comprises a driving side helical worm gear reduction motor, a driving chain wheel, a driven chain wheel, a transmission shaft, a short-pitch roller chain, a chain wheel mounting seat, a supporting seat of a water washing vehicle, a bearing, a bearing seat, a travelling limit wheel and a supporting track thereof, anti-slip chain wheels, chains and a supporting track thereof, anti-overturning limit holding wheels of the water washing vehicle, a chain tensioning adjusting device, a driven side travelling supporting wheel and a track. The chain travelling mechanism and the chain travelling way have the advantages that firstly, the demands of horizontal non-slip travelling and positioning guidance of the side beam type filter cloth washing vehicle can be met; secondly, the driven wheel is changed into a power wheel in a chain transmission manner, thereby changing the traditional way that the single travelling wheel drives the water washing vehicle to move; and thirdly, the chain travelling mechanism is simple in structure, convenient to manufacture and low in cost.

Owner:杭州兴源环保设备有限公司

Catalyst for preparing saturated lubricant base oil

InactiveCN111269271AIncrease the degree of branchingImprove thermal stabilityPalladium organic compoundsBase-materialsChain walkingPolyolefin

The invention discloses a catalyst for preparing saturated lubricant base oil. The saturated lubricating base oil is obtained by catalyzing an ethylene oligomerization reaction with a pyridine-imine palladium complex as a main catalyst. The method for producing the saturated lubricating base oil comprises the following steps: 1, catalyzing ethylene oligomerization by using a pyridine-imine palladium complex, and obtaining a highly branched product by using a chain walking process; and 2, hydrogenating polyolefin to obtain the lubricating base oil. Various additives are added into the base oilto prepare high-performance fully-synthetic lubricating oil, the obtained lubricating base oil has the characteristics of good antioxidant stability, excellent flowing property and low pour point, excellent viscosity-temperature property and the like due to high branching.

Owner:卢静

Polyolefins having reduced crystallinity

Owner:CORNELL UNIV CORNELL CENT FOR TECH ENTERPRISE & COMMLIZATION CCTEC +1

New truck production line

The invention provides a production line for new trucks, including a center beam production line, a pillow beam production line, a beam production line, a side beam production line, an underframe production line, a bogie production line, a side wall production line, an end wall production line, a side door assembly welding production line, and a lower side door assembly. Welding production line, car body general assembly production line, paint coating production line, brake assembly test production line and vehicle inspection production line, center beam production line, bolster production line, cross beam production line and side beam production line are respectively connected with the chassis production line, the chassis production line , bogie production line, side wall production line, end wall production line, side opening door assembly welding production line and lower side door assembly welding production line are respectively connected with the car body assembly line, car body assembly line, paint coating line, brake assembly test line and The whole vehicle inspection production line is connected sequentially. Each production line is connected by a hydraulic lifting mechanism and a power chain traveling mechanism, which improves the production efficiency of new trucks.

Owner:CRRC SHENYANG CO LTD

Capsochrome leaching device

InactiveCN101869777ASimple structureReduce manufacturing costNatural dyesSolid solvent extractionChain walkingNatural product

The invention relates to a capsochrome leaching device, which belongs to the technical field of natural product extraction. Chain transmission wheels with the symmetrical structure are fixedly arranged at both ends of an inner cavity of a tank body in a rectangular box type structure, material boxes in square structures are ranged and placed at the upper side of a transmission chain walking around the chain transmission wheels, materials in the material boxes can be turned and buckled out of the material boxes to fall into a leaching chamber arranged in the inner cavity of the tank body, the outer sides of both ends of the chain transmission wheels are respectively provided with arc-shaped baffle plates, an upper group and a lower group of ranging structures in the middle of the chain transmission wheels in the tank body are provided with oil spray nozzles, each oil spray nozzle corresponds to a feed pump, an oil collection tank, the oil spray nozzles and the feed pumps are communicated through solvent pipes for forming a circulating system of leaching solvents, the bottom side of the tank body and the same end of a material inlet are provided with slag outlets, and cayenne pepper materials are conveyed into the inner cavity of the tank body through material inlets via the rotation of a spiral conveyer. The invention has the advantages of simple body structure, good leaching effect, high efficiency and good product quality.

Owner:青岛青大物产股份有限公司

Preparation method and application of cross-linked polyethylene supported metal nanoparticles

ActiveCN103263916BImprove stabilityLow costMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionChain walkingTwo step

The invention discloses a preparation method and a use of crosslinked polyethylene-loaded metal nanoparticles. The preparation method comprises that ethylene and a crosslinking monomer undergo a chain walking copolymerization reaction in the presence of a palladium-diimine catalyst to produce a crosslinked polyethylene carrier for loading metal nanoparticles; through a one-step loading or two-step loading technology, a metal compound is fixedly loaded on the crosslinked polyethylene carrier; and the metal compound loaded by the crosslinked polyethylene carrier undergoes a reduction reaction and is transformed into metal nanoparticles so that the crosslinked polyethylene-loaded metal nanoparticle catalyst is obtained. The crosslinked polyethylene-loaded metal nanoparticles are used for catalysis of a carbon-carbon cross-coupling reaction, has high catalytic activity and good stability, and can be recovered and recycled easily.

Owner:ZHEJIANG UNIV

A closed-chain walking leg mechanism

The invention discloses a closed-chain type walking leg mechanism, and belongs to the technical field of robot vehicle walking. The walking leg mechanism comprises a first closed-chain mechanism (thighs part) and a second closed-chain mechanism (shanks part), each thigh adopts a crank-swing block mechanism and comprises an installing bracket, a connecting rod, a crank, a sliding block, a motor, a sliding bearing, a rotating shaft, a guide rail, a crank shaft and a connecting rod shaft; each shank adopts a crank-rocker mechanism and comprises a sliding block, a motor, a guide rail, a leg rod, a sliding bearing, a crank shaft, a crank and a connecting rod; and each crank-swing block mechanism of the corresponding thigh is used for controlling up-and-down moving and back-and-forth swinging of the leg rod of the walking leg mechanism, and each crank-rocker mechanism of the corresponding shank is used for controlling extend-retract of the leg rod of the walking leg mechanism. According to the closed-chain type walking leg mechanism, the walking function on a complex roadway can be achieved through synergistic driving of the motors of the thigh parts and the motors of the shank parts; and the closed-chain type walking mechanism can be applied to a walking system of an obstacle-climbing vehicle or a robot.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

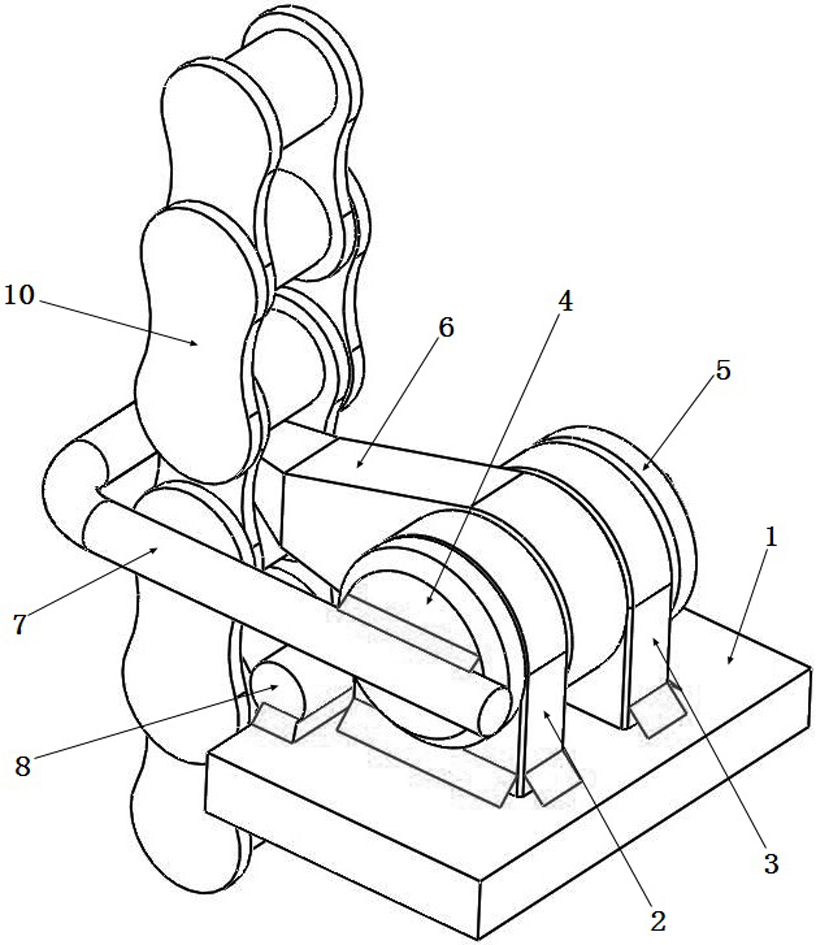

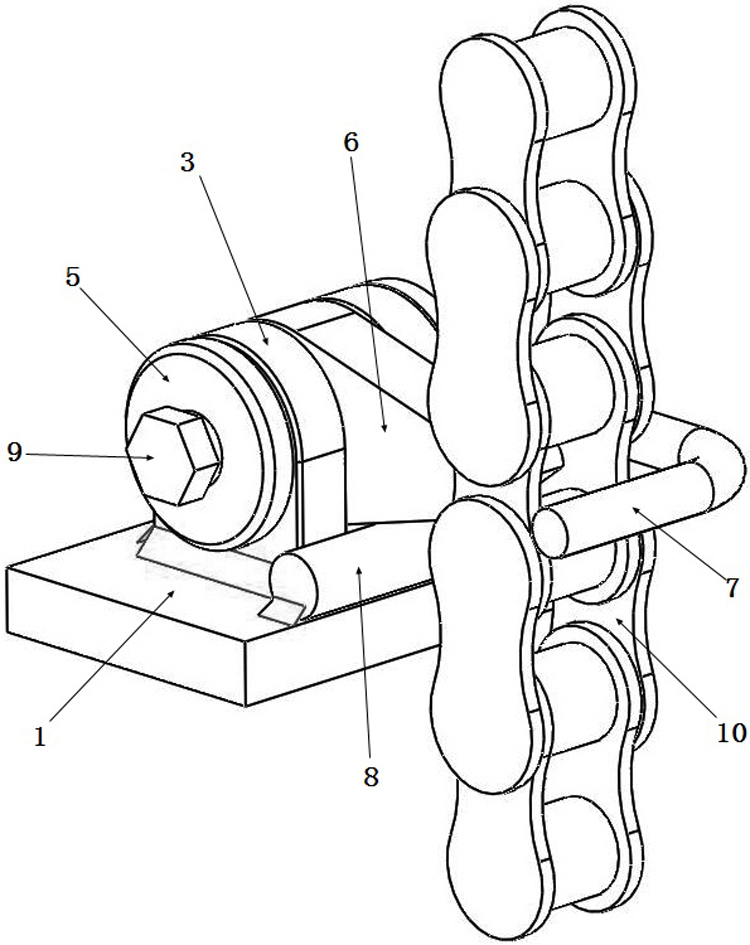

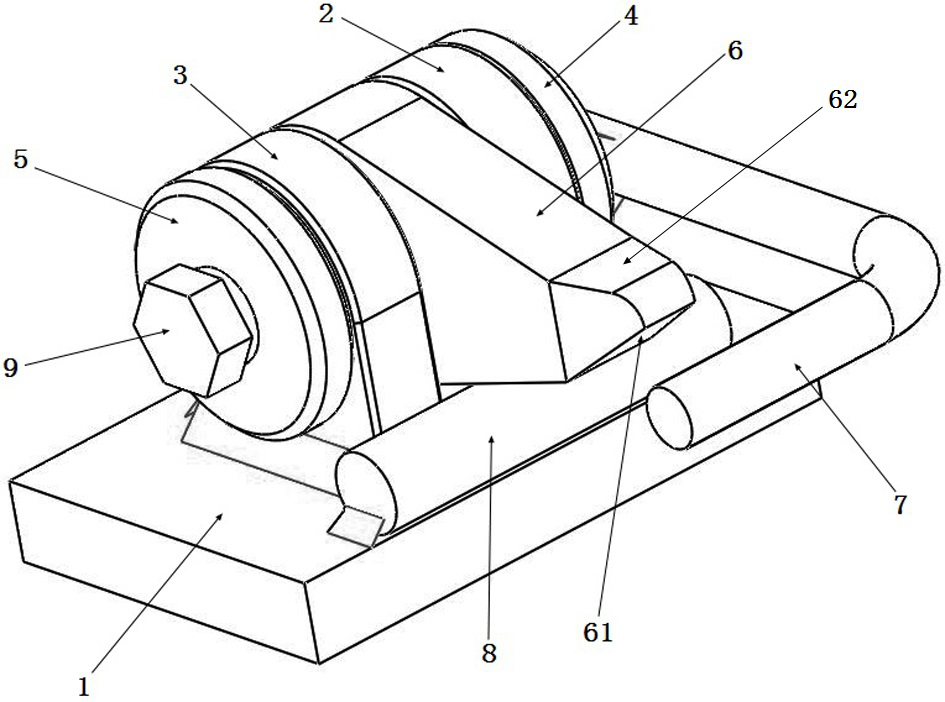

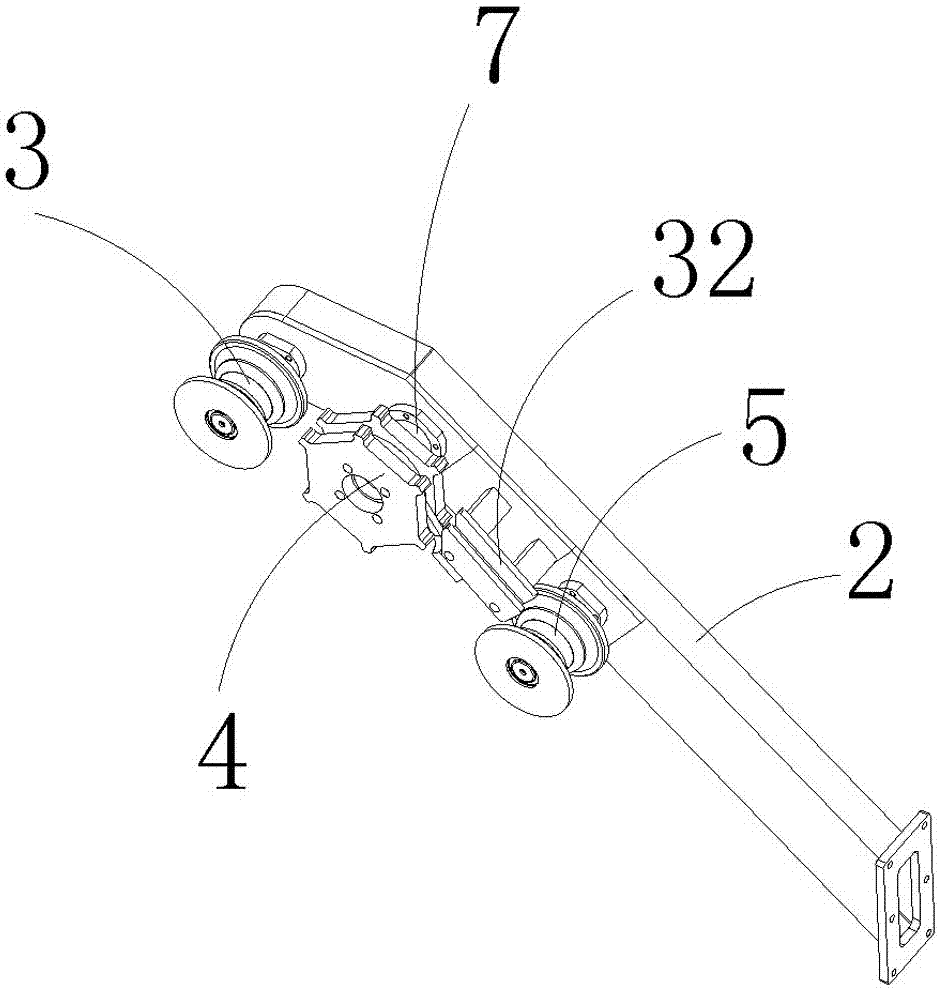

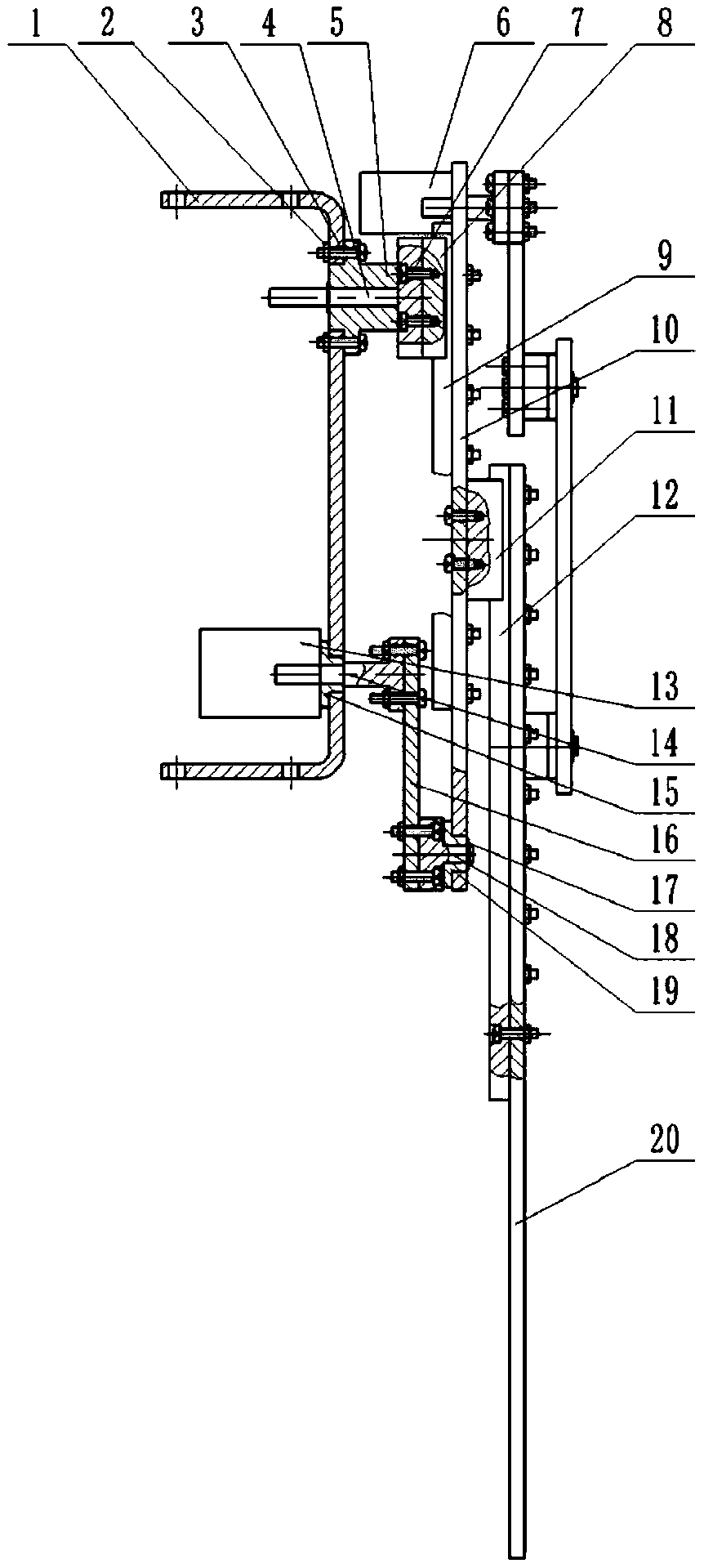

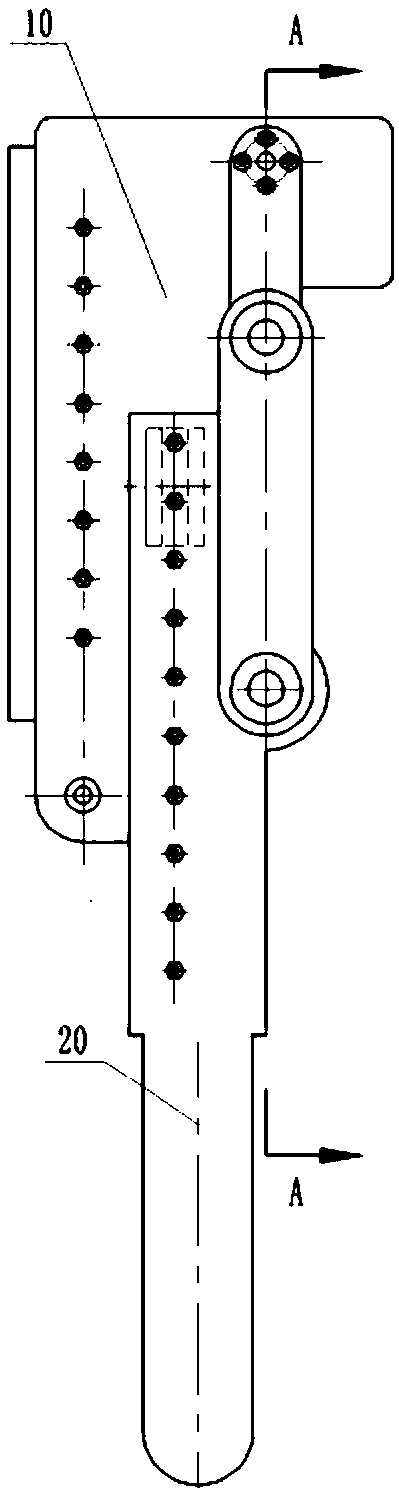

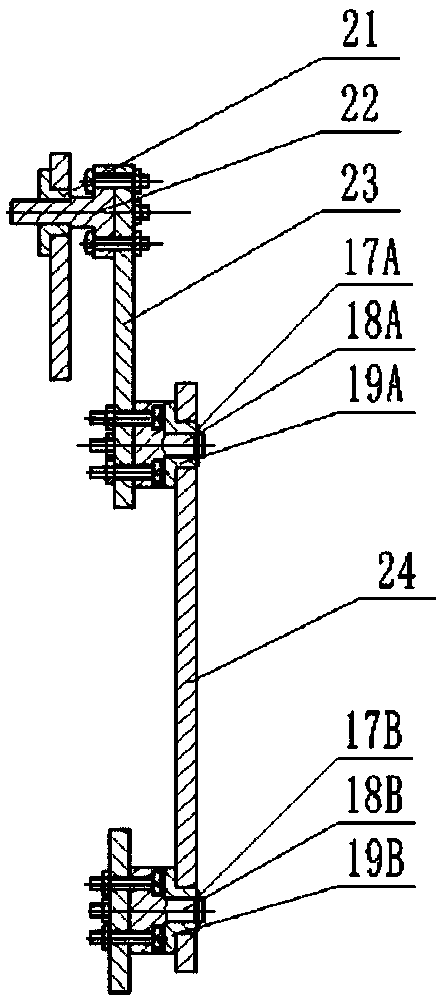

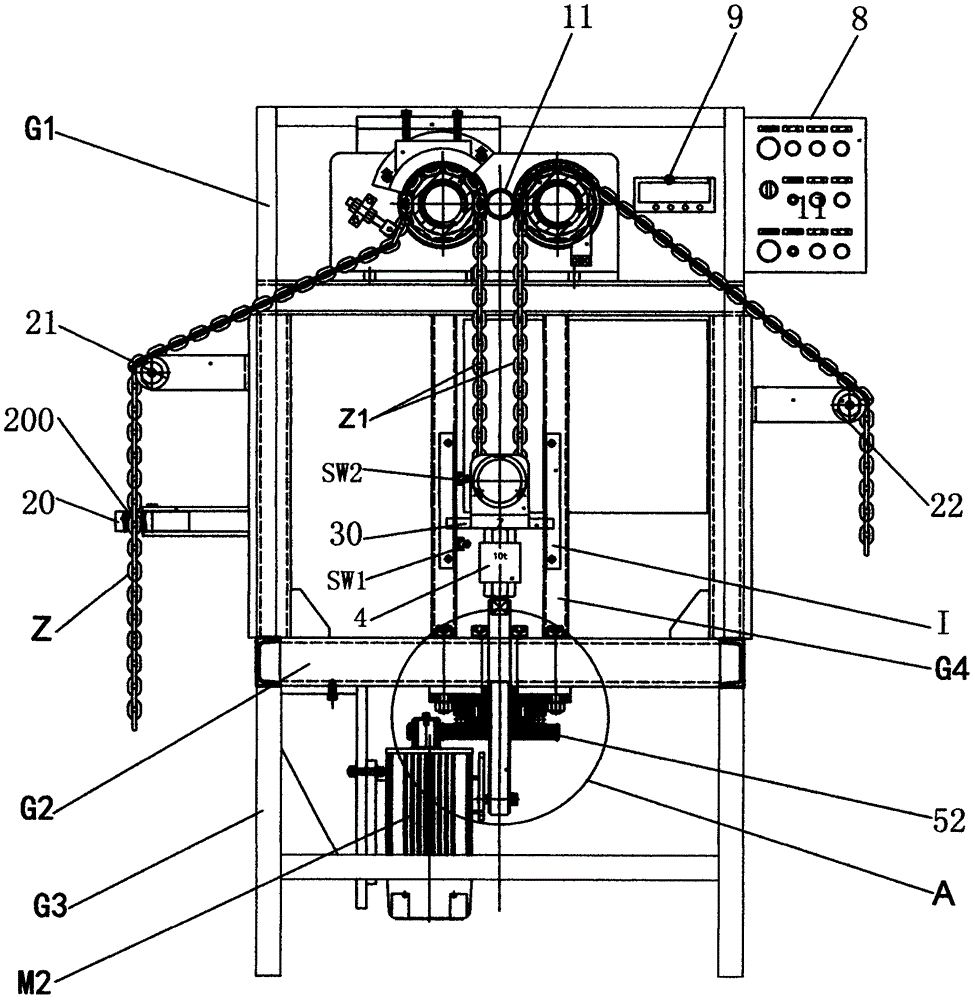

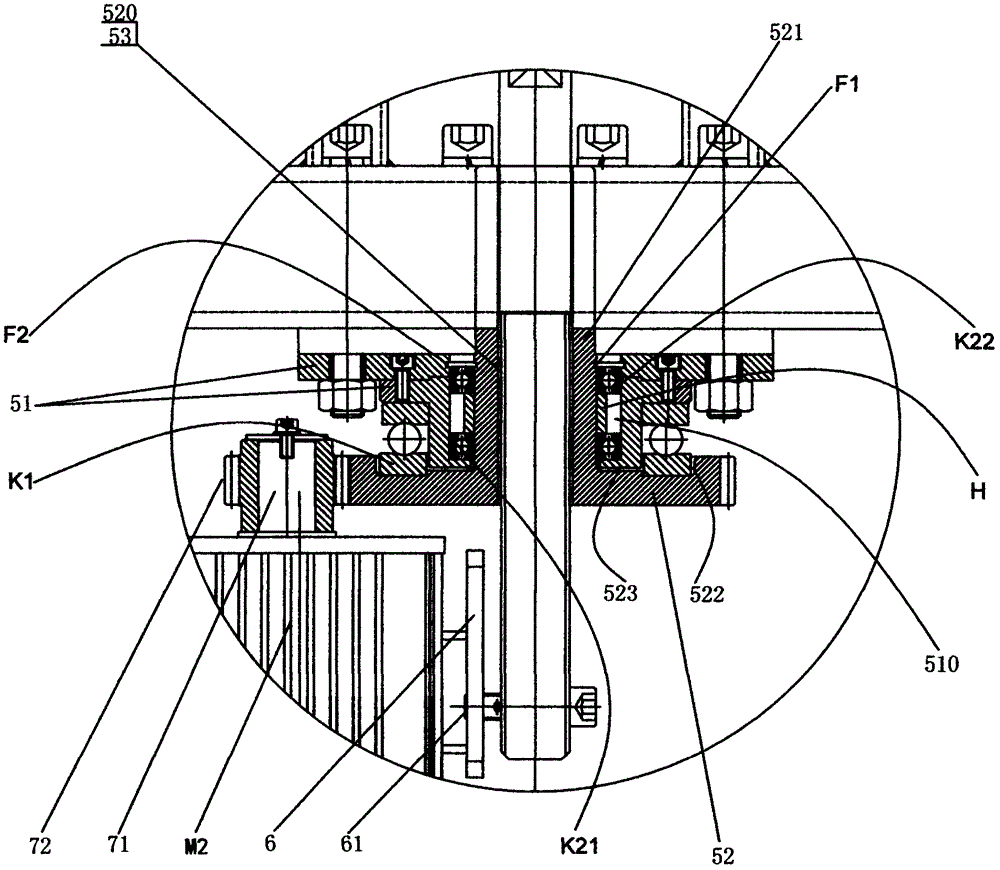

Lifting chain single-ring bending force testing machine

ActiveCN106546428AImprove stabilityPrevent twistingMachine gearing/transmission testingNuclear energy generationChain walkingStub axle

The invention discloses a lifting chain single-ring bending force testing machine. The lifting chain single-ring bending force testing machine comprises a chain walking transmission mechanism and a lifting and speed reduction mechanism; the chain walking transmission mechanism includes a chain incoming guide wheel and a chain outgoing guide wheel which are located at two sides of a machine body in a split manner as well as a chain incoming axle wheel assembly and a chain outgoing axle wheel assembly which are arranged on the machine body in a split manner; the chain incoming axle wheel assembly and the chain outgoing axle wheel assembly are both engaged with a centrally-installed pinion in a chain walking driving motor installed at the upper portion of the machine body; a loose pulley is suspended by a double-row chain; a torque sensor is fixed to the lower end of a loose pulley holder; the lifting and speed reduction mechanism includes a chassis, a transmission large gear and a screw rod; the chassis is fixed at the bottom of the platen of the machine body; a stepped hole is formed in the chassis; a central screw hole formed in the large gear is in transmission engagement with the screw rod; a necking section at the upper end of the central screw hole, which extends axially, is limited in the stepped hole; the top end of the screw rod extends out from the necking section and fixes the torque sensor; a guide short shaft fixedly arranged at the bottom end of the screw rod is arranged in the guide hole of a guide fixed plate in a sliding manner; and the transmission large gear is engaged with the output pinion of the output shaft of a lifting motor. The lifting chain single-ring bending force testing machine can test the strength of the double-row chain through bending, pulling and tensioning.

Owner:ZHEJIANG SHUANGNIAO MACHINERY

Complex catalyst, catalyst composition and preparation method of a kind of olefin polymer

The invention provides a compound as shown in formula (I) and a complex catalyst. The compound is based on the ligand effect of second layer space among molecules, and ensures that the second layer coordination space strategy is applied to olefin body polymerization and the copolymerization of olefin and polar monomers, so as to obtain a good technical effect. The complex catalyst belongs to palladium, nickel and iron catalysts containing alpha-diimine ligands with second layer coordination space effect, in the system, beta-H and beta-X elimination is restrained through the second layer coordination space effect, but normal coordination of ethylene is not prevented, therefore, the occurrence of chain walking is restrained, the polyethylene branching coefficient is reduced, and the copolymerization of ethylene and more polar monomers is realized.

Owner:合肥中科科乐新材料有限责任公司

Track walking type minitype rice combine harvester

InactiveCN101213902BNot easy to damageEasy to disassemble and replaceMowersThreshersChain walkingAgricultural engineering

A caterpillar-chain walking-type micro rice combined harvester comprises a chassis, a walking device, a transmission mechanism, a conveying device, a reaping apparatus and a threshing mechanism, wherein, a dual-fan soot blower is arranged inside the threshing mechanism, the walking device is provided with a four-bar linkage control mechanism consisting of four transmission bars and a linkage so as to realize the consistent method for controlling the harvester both with the front operation bar and the rear operation bar and to realize the same operation controlling function; the walking caterpillar chain is an iron pouring composite that is composed of an upper dental plate and a lower dental plate which are arranged on a bridge chain in clamping way through bolts, wherein, the upper dental plate is provided with steel teeth, the lower dental plate is provided with rubber teeth with a lower-tooth steel bracket, and the bridge chain is a stratiform composite chain that is formed by a rubber layer and a nylon-wire layer. The present invention has the advantages of compact structure, small volume, light weight, flexible operation, low energy consumption and convenient maintenance, which is applicable to the small fields in the mountainous area and the hilly area.

Owner:王辉

A kind of saturated polyolefin lubricating oil base oil and preparation method thereof

ActiveCN109569724BHigh content of long chain branchesGood fluidity at low temperatureOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsChain walkingPolyolefin

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com