Chain walking catalysts, preparation method thereof, and application of catalysts in ethylene polymerization

A technology for catalyzing ethylene and catalysts, which is applied in the fields of catalyst synthesis and polymer synthesis. It can solve the problems of inability to form branched sequences and low branching numbers, and achieve high temperature resistance and high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a preparation method of a chain walking catalyst, comprising:

[0040] A class of novel benzobarrelene pentadecene ligands described in general formula (II) and (DME)NiBr 2 (DME=ethylene glycol dimethyl ether) is dissolved in a solvent, the solvent is preferably dichloromethane or chloroform, and the resulting mixture is stirred at 20-50°C for 3-30 days, preferably 3-10 days, more preferably For 3-5 days, the solvent is preferably evaporated by rotary evaporation, recrystallized with n-hexane or ether and dichloromethane or chloroform, and the solid is separated by filtration, washed three times with hexane or ether and dried under vacuum to obtain a structural formula such as general formula (I) a class of transition metal catalysts. A class of novel benzobarrelene pentadecene ligands described in the general formula (II) and (DME) NiBr 2 The molar ratio is 1:1.

[0041]

[0042] According to the present invention, the general ...

Embodiment 1

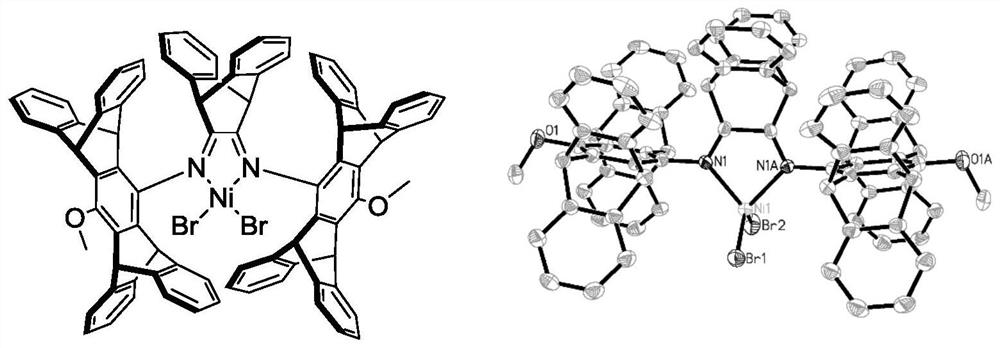

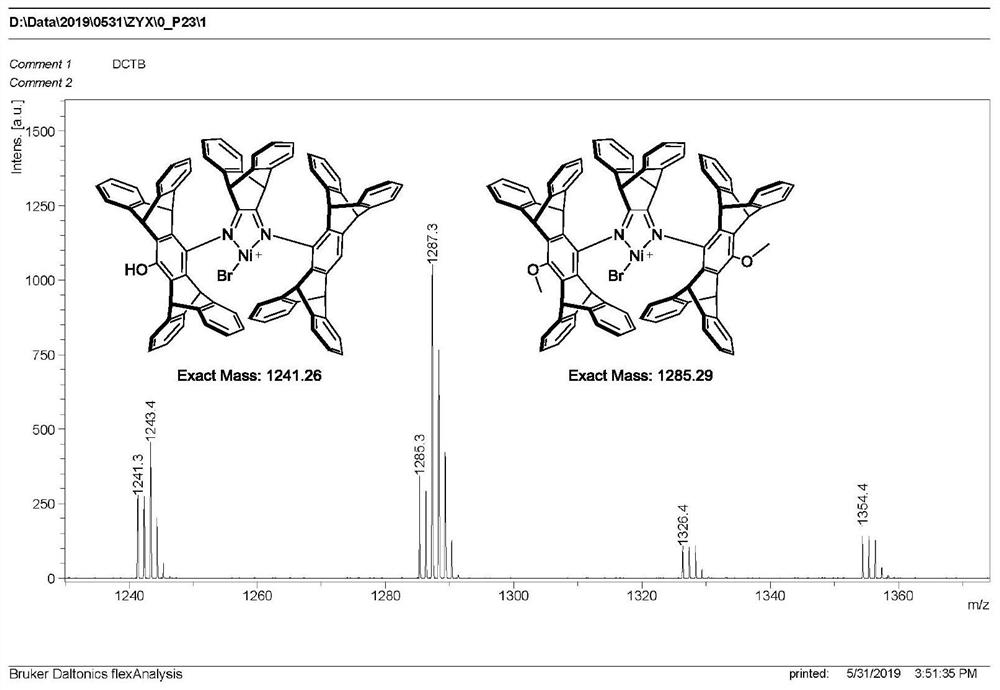

[0047] Preparation of Example 1 Benzobarrelene Pentadecyl Nickel Dibromide (corresponding to 14 in Table 1)

[0048] The benzobarrelene pentadecene ligand (2.00g, 1.74mmol) and (DME)NiBr 2 (462 mg, 1.74 mmol) (DME = ethylene glycol dimethyl ether) mixture was stirred in 20 mL of dichloromethane at 25° C. for 72 hours. After the reaction was completed, the solvent was evaporated under reduced pressure to give a reddish-brown solid, which was then filtered and recrystallized from dichloromethane / hexane to give the pure compound as a reddish-brown solid (2.00 g, 82.10% yield). The single crystal diffraction pattern of the product prepared in Example 1 is as follows figure 1 shown. MALDI-TOF-MS spectrum such as figure 2 shown. Concrete reaction process is as follows:

[0049]

[0050] The catalyst synthesis methods used in Tables 1-5 are the same as those in Example 1 above, except that the ligand structures and yields are different, and the rest of the steps are the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com