Hydraulic lifting chain stamping machine and printing method thereof

An embossing machine, hydraulic technology, applied in the field of embossing machines, can solve the problems of low efficiency, high labor consumption, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

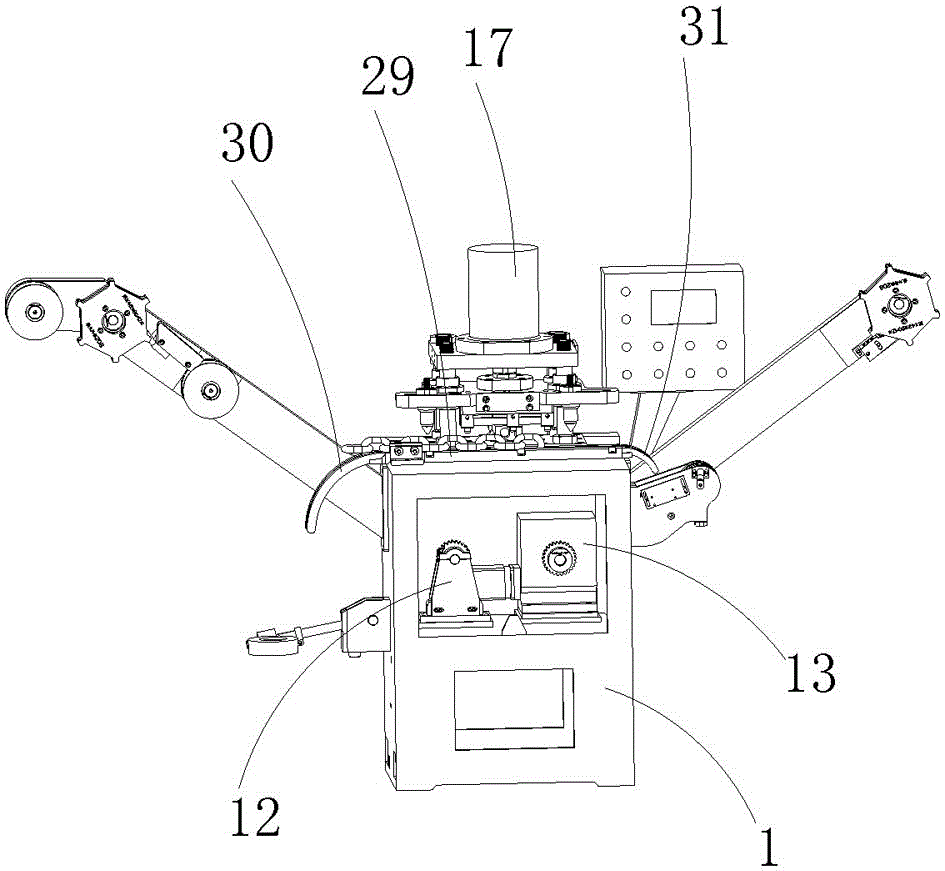

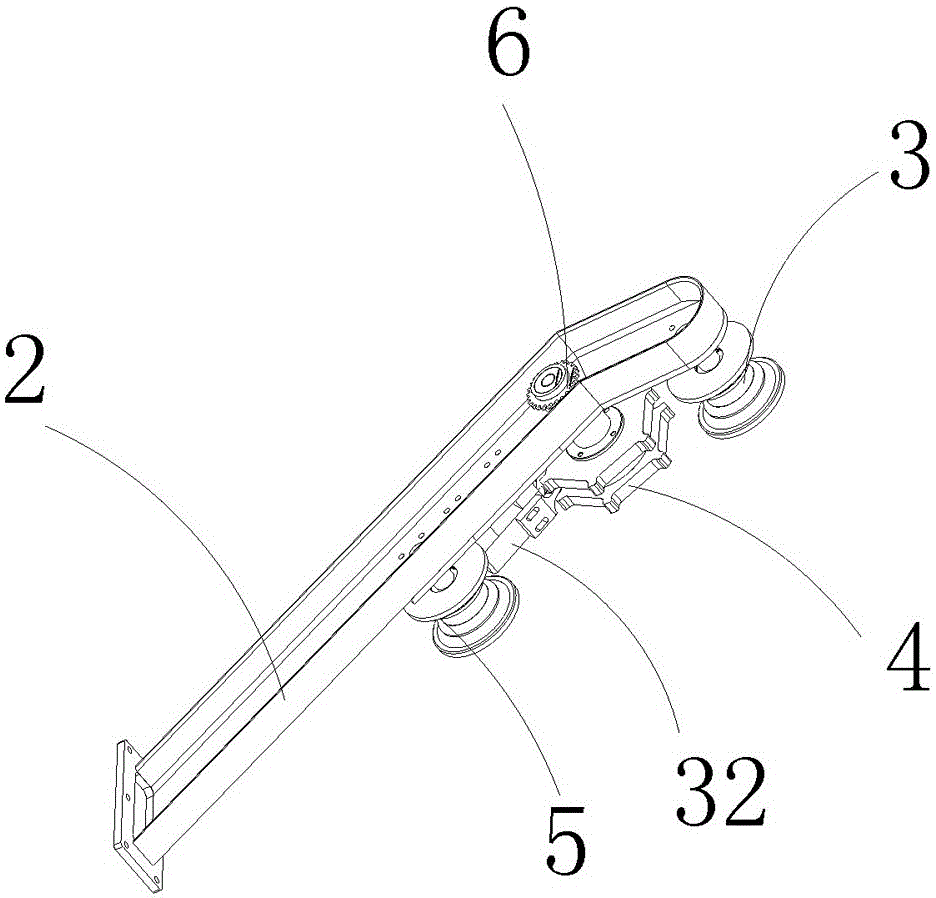

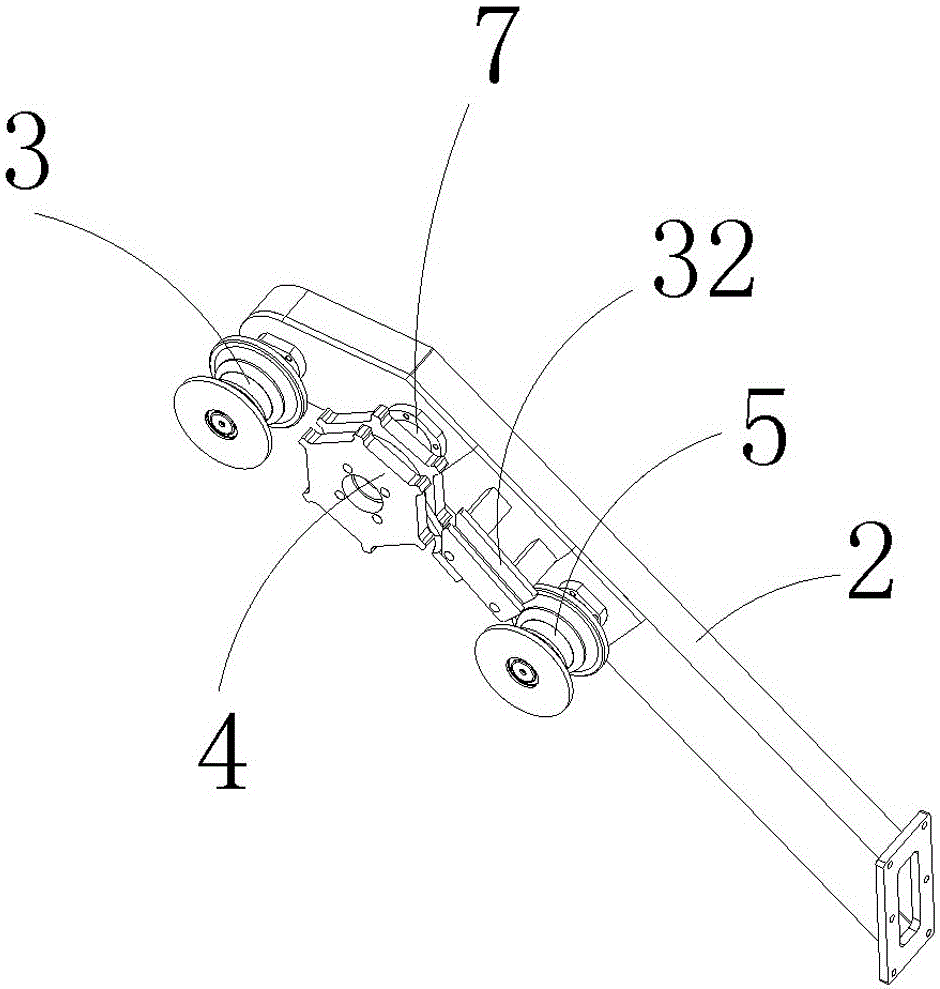

[0050] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 12 with Figure 13As shown, a hydraulic lifting chain embossing machine includes an operating frame 1, the left end of the operating frame 1 is provided with a pre-feeding mechanism, and the right end of the operating frame 1 is provided with a pre-feeding mechanism. The feeding mechanism corresponds to the chain discharging mechanism, the operation frame 1 is provided with a drag chain transmission mechanism and a printing action mechanism, and the drag chain transmission mechanism and the printing action mechanism are in a corresponding distribution;

[0051] Described pre-feeding mechanism comprises feed channel steel 2, and the afterbody of described feed channel steel 2 is fixed with operating frame 1, and the upper end of described feed channel steel 2 is provided with upper guide sproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com