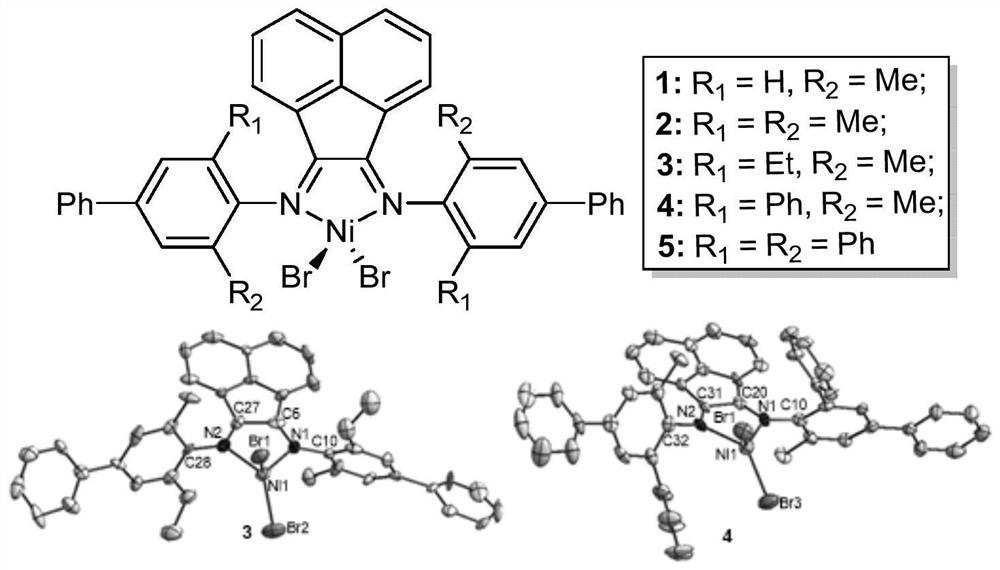

Application of a para-phenyl-containing α-diimine nickel (ii) complex in catalyzing the chain walking polymerization of 3-heptene

A technology of nickel diimide and complex, applied in the field of olefin polymerization, can solve the problem that 3-olefin polymerization monomer has not been successfully reported and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] Preparation of cocatalyst dMMAO:

[0051] Modified methylaluminoxane (MMAO, 20.0 mL, 41.8 mmol) in toluene was vacuum dried at 60°C for 3 hours. The resulting colorless solid was redissolved in 20 mL of toluene. The cycle of drying and redissolution was repeated seven times to yield 3.32 g of a colorless solid. Titration of an aliquot of the resulting solid showed an aluminum content of 11.1 mmol / g (88% aluminum recovered). The prepared MMAO was used as stock solution in toluene (2.0M).

[0052] (3) Application of para-phenyl-containing α-diimine nickel (II) complexes in the chain walking polymerization of 3-heptene.

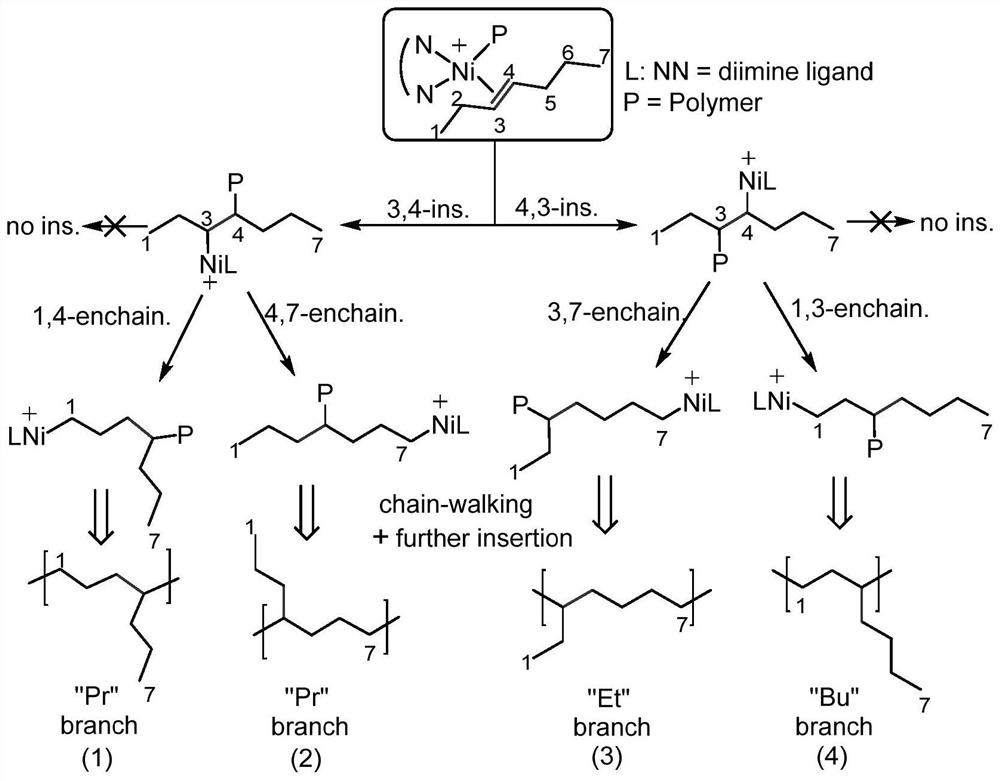

[0053] In the field of olefin polymerization, the preparation of new polyolefins has always been a very interesting challenge. Common olefin monomers that can be polymerized are very limited, generally including ethylene, propylene, long-chain α-olefins, styrene derivatives and different types of polar monomers. Olefins with alkyl substituent groups ...

Embodiment 1

[0058] (1) 3-heptene polymerization:

[0059] in N 2 Under atmosphere, toluene was used as the polymerization solvent, and the polymerization was carried out in a 10 mL dry glass reaction tube equipped with a magnetic stirrer. First weigh 0.61g of trans and cis 3-heptene mixture (trans / cis=0.82 / 0.18) with a reaction tube, then inject 5mL of toluene and cocatalyst dMMAO (1.0mL, 2.0M, n(Al) / n (Ni)=500) was sequentially added into the reaction tube, kept at the set polymerization temperature, and the mixture was fully stirred for 10 minutes. Then, the toluene solution containing 10 μmol nickel catalyst was added into the reaction tube with a syringe to start polymerization, and the reaction time was recorded. The polymerization was terminated with 50 mL of 3% HCl-MeOH solution. The resulting polymer was thoroughly washed with methanol, and vacuum-dried at 60°C for 3 hours.

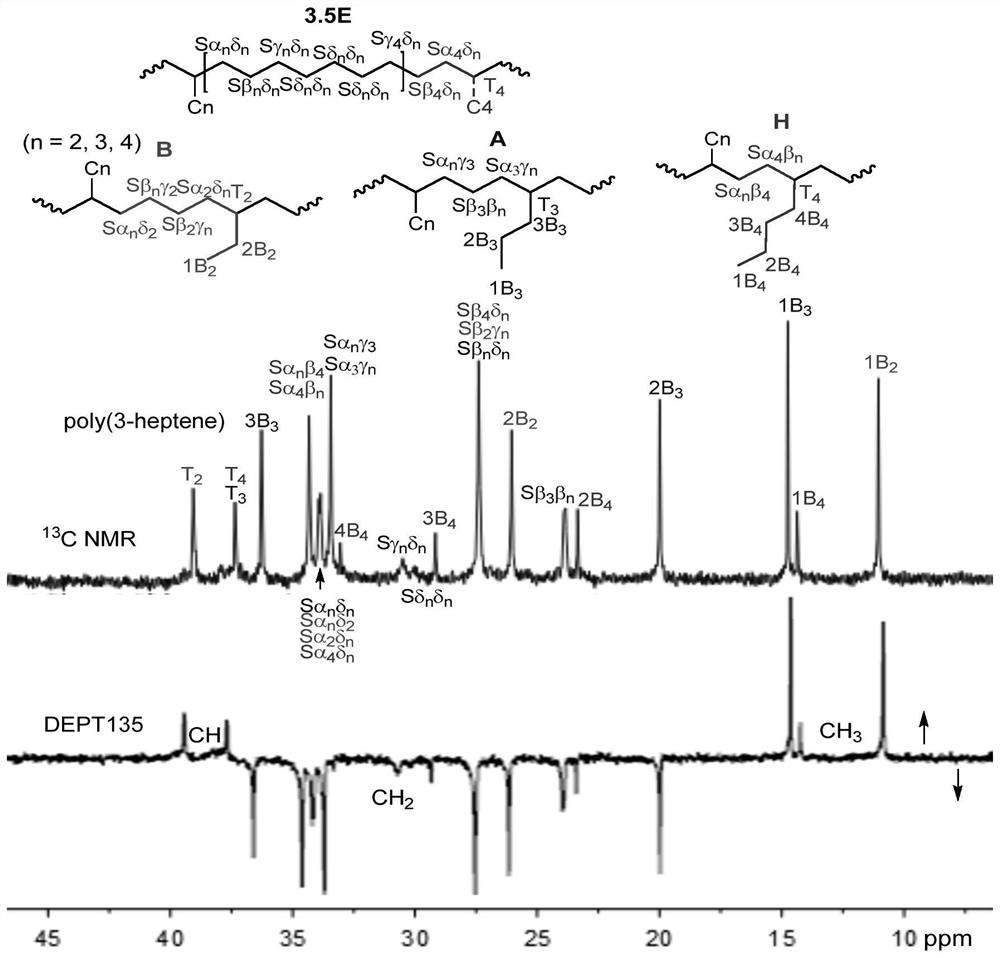

[0060] (2) Evaluation of polymerization performance and analysis of polymer structure: weighing the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com