A kind of saturated polyolefin lubricating oil base oil and preparation method thereof

A technology of lubricating base oil and polyolefin, applied in the field of lubricants, can solve the problems of high pour point, complex process, poor product stability, etc., and achieve the effects of low pour point, simplified process flow, and excellent viscosity-temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

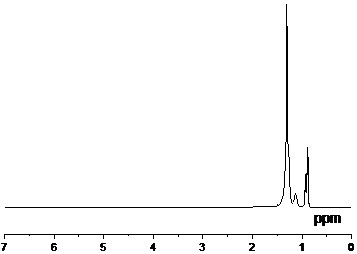

Image

Examples

Embodiment 1

[0055] The preparation of the saturated polyolefin lubricating oil base oil of embodiment 1

[0056] 1. Preparation test of saturated polyolefin lubricating oil base oil

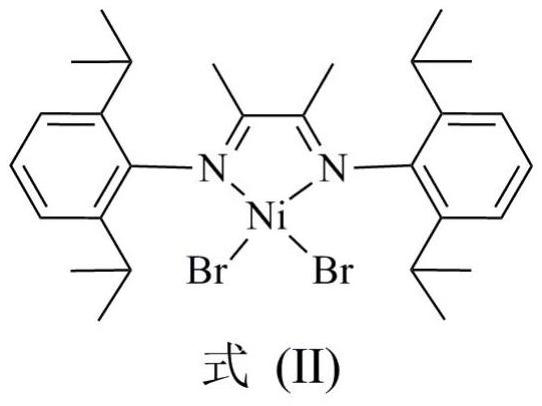

[0057] Under the condition of anhydrous and oxygen-free, add 100mL of dry n-hexane, 5mmol of diethylaluminum chloride, 2mmol of diethylzinc, and 10μmol of catalyst C1 into the reaction kettle, feed 10atm of ethylene at 50°C for ethylene low Polymerization reaction for 5 hours, pour the solution containing polyethylene oil into 5% hydrochloric acid acidified ethanol for washing, separate the liquid, and then spin evaporate to remove the solvent to obtain a saturated polyolefin lubricating oil base oil; wherein, the catalyst C1 is R is benzene α-aminoimine nickel complexes at the base time.

[0058] 2. Results

[0059] The catalytic activity of the catalytic system in this embodiment is 9.2×10 7 g / mol·h, the bromine value of the prepared lubricating base oil is 0.01g / 100g, the number average molecular weigh...

Embodiment 2

[0060] The preparation of the saturated polyolefin lubricating oil base oil of embodiment 2

[0061] 1. Preparation test of saturated polyolefin lubricating oil base oil

[0062] Under anhydrous and oxygen-free conditions, add 100mL of dry toluene, 5mmol of diethylaluminum chloride, 2mmol of trimethylaluminum, and 10μmol of catalyst C1 into the reactor, and then feed 25atm of ethylene to carry out ethylene oligomerization at 50°C After reacting for 12 hours, pour the solution containing polyethylene oil into 5% hydrochloric acid acidified ethanol for washing, separate the liquids, and remove the solvent by rotary evaporation to obtain a saturated polyolefin lubricating oil base oil; wherein, the catalyst C1 is R is phenyl When the α-amino imine nickel complex.

[0063] 2. Results

[0064] The catalytic activity of the catalytic system in this embodiment is 3.2×10 7 g / mol·h, the bromine value of the prepared lubricating base oil is 0.05g / 100g, the number average molecular we...

Embodiment 3

[0065] The preparation of the saturated polyolefin lubricating oil base oil of embodiment 3

[0066] 1. Preparation test of saturated polyolefin lubricating oil base oil

[0067] Under anhydrous and oxygen-free conditions, add 100mL of dry n-hexane, 5mmol of diethylaluminum chloride, 2mmol of trimethylaluminum, and 10μmol of catalyst C2 into the reaction kettle, and then inject 25atm of ethylene at 50°C for ethylene low After 12 hours of polymerization reaction, the solution containing polyethylene oil was poured into 5% hydrochloric acid acidified ethanol by mass fraction to wash, and the solvent was removed by rotary evaporation after liquid separation to obtain a saturated polyolefin lubricating oil base oil; wherein, the catalyst C2 is that R is naphthalene α-aminoimine nickel complexes at the base time.

[0068] 2. Results

[0069] The catalytic activity of the catalytic system in this embodiment is 8.8×10 7 g / mol·h, the bromine value of the prepared lubricating base o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bromine number | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| bromine number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com