Alpha-diamino palladium catalyst as well as preparation method and application thereof

A palladium catalyst and diamine-based technology, which is applied in the field of α-diamine-based palladium catalyst and its preparation, can solve the problems of reduced catalyst activity, poor low-temperature fluidity, and reduced branching degree of products, and achieve excellent low-temperature fluidity and stability performance, good low temperature fluidity, and strong chain walking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

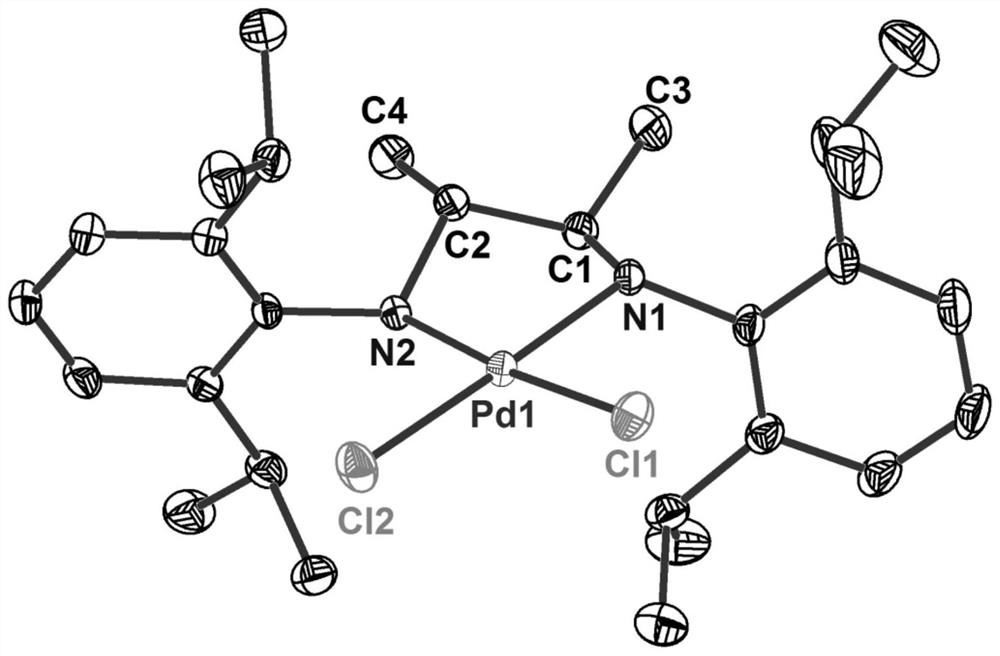

[0080] Present embodiment 1 provides a kind of palladium dichloride complex 1, and its structural formula is as follows:

[0081]

[0082] Present embodiment 1 also provides the preparation method of this palladium dichloride complex 1, comprises the steps:

[0083] Weigh 1 mmol of PdCl into a 100 mL branched flask with a stirring bar 2 , add 20mL of acetonitrile, heat to 82°C and reflux to obtain orange-yellow clear (MeCN) 2 PdCl 2 solution; add 1 mmol of α-diamine ligand [2,6-Me 2 C 6 h 3 -NH-CH(Me)-CH(Me)-NH-2,6-Me 2 C 6 h 3 ], keep reflux at 82°C and stir overnight; the system is lowered to room temperature, filtered to obtain an orange-yellow precipitate, washed with 2×20mL n-hexane, and vacuum-dried to obtain an orange-yellow powder solid, which is palladium dichloride complex 1, with a yield of 89% .

[0084] The NMR spectrum of the palladium dichloride complex 1 that present embodiment 1 makes is as follows:

[0085] 1 H NMR (400MHz, DMSO, ppm): 7.15-6.96...

Embodiment 2

[0088]This embodiment 2 provides a kind of palladium dichloride complex 1, its structural formula and preparation method are the same as in embodiment 1, the only difference is that the amount of α-diamine-based ligand is 2.5 mmol, that is, α-diamine Ligand and PdCl 2 The molar ratio is 2.5:1;

[0089] The yield of palladium dichloride complex 1 prepared in Example 2 was 89%.

Embodiment 3

[0091] This embodiment 3 provides a kind of palladium dichloride complex 1, its structural formula and preparation method are the same as in embodiment 1, the only difference is that the amount of α-diamine ligand is 5 mmol, that is, α-diamine Ligand and PdCl 2 The molar ratio is 5:1;

[0092] The yield of palladium dichloride complex 1 prepared in Example 3 was 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Catalytic activity | aaaaa | aaaaa |

| Bromine value | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com