Hollow silica nanosphere and preparing method thereof

A technology of silica and nanospheres, which is applied in the field of inorganic nanomaterials, can solve the problems of complex configuration of template double emulsions and obstacles to the practical application of hollow silica nanospheres, and achieve a simple and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

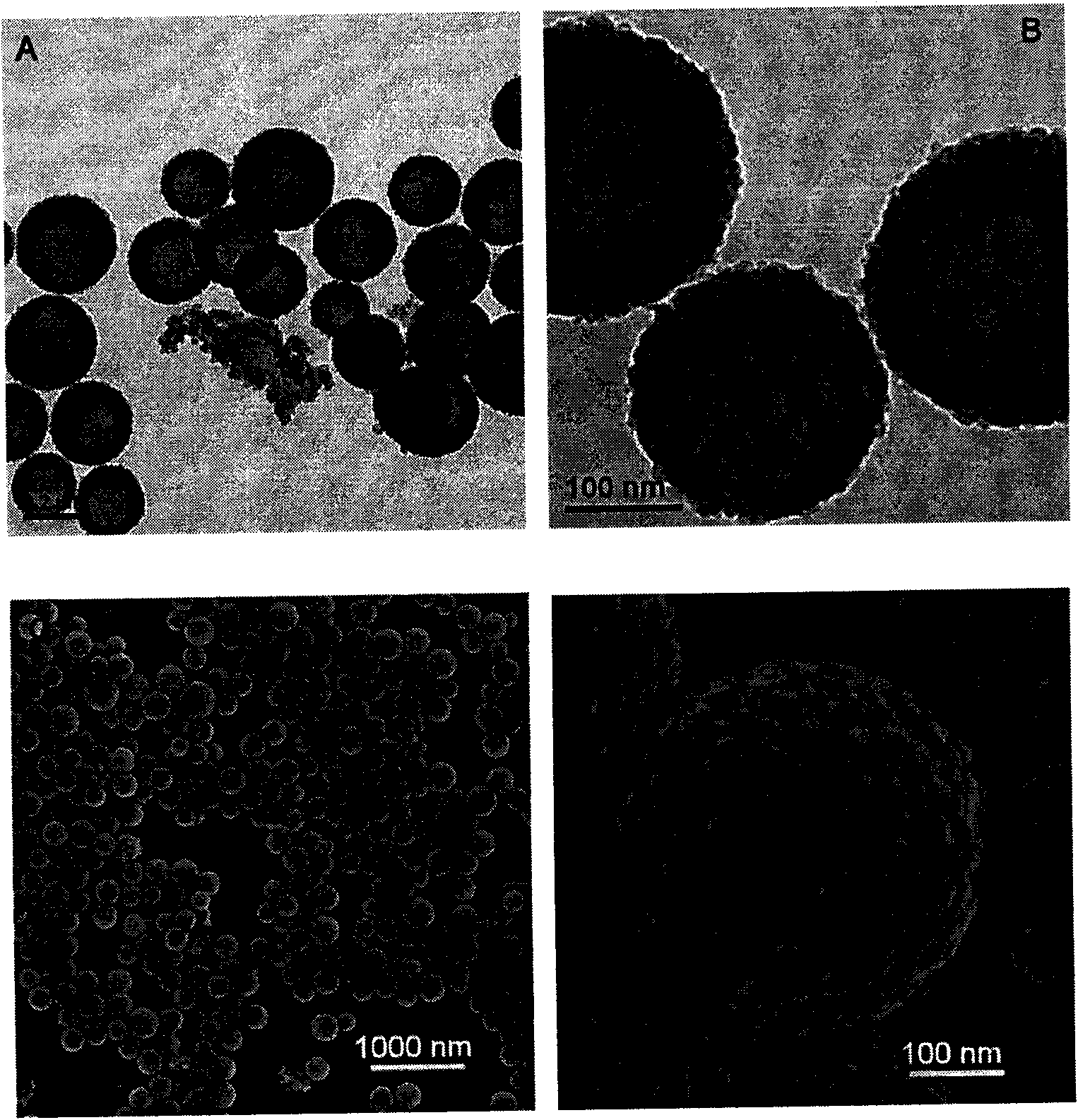

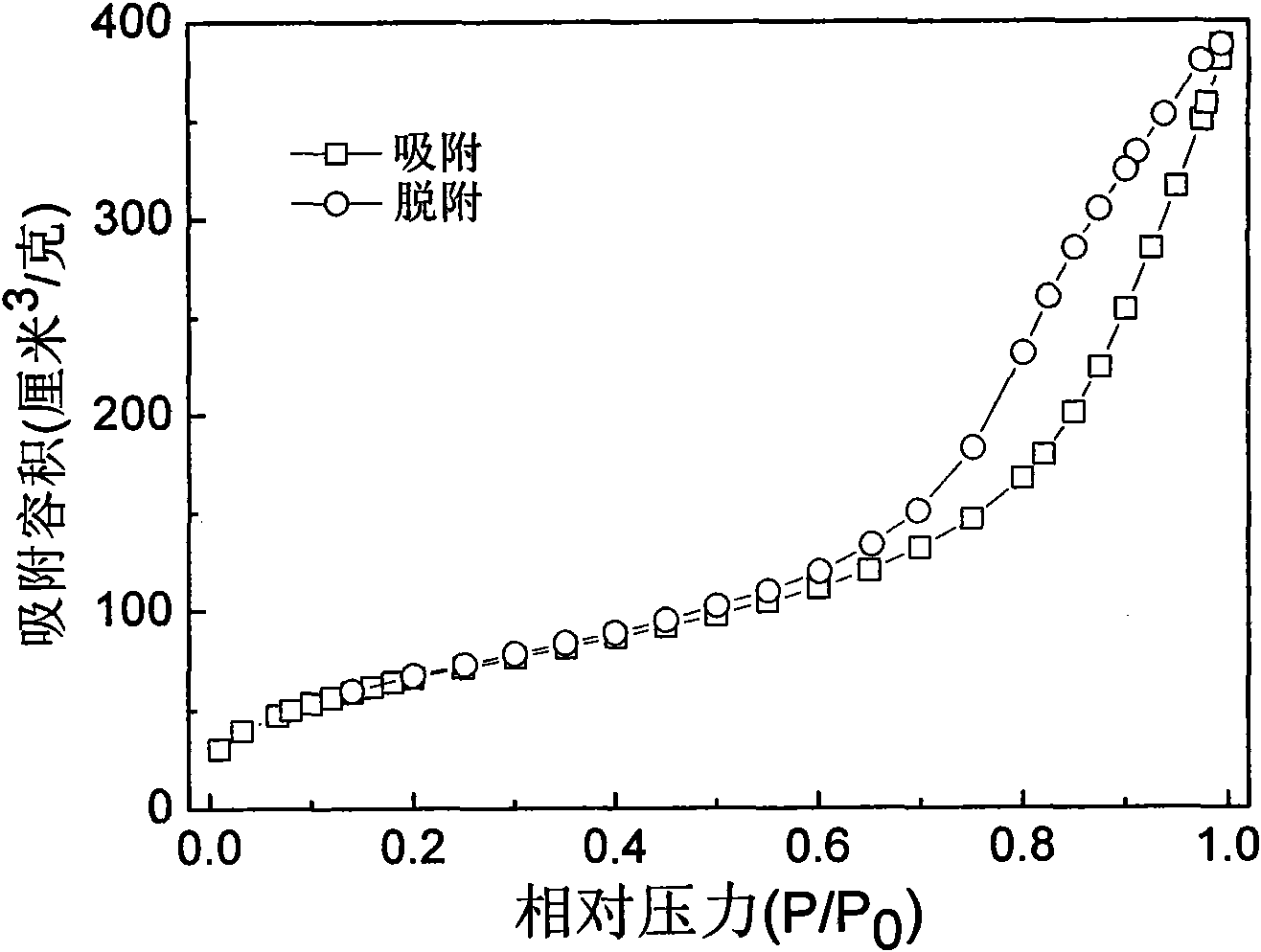

Embodiment 1

[0045] 1.040g temperature-sensitive monomer N-isopropylacrylamide (NIPAm) was dissolved in anhydrous 1,4-dioxane, stirred under nitrogen atmosphere to fully dissolve, then added 5mg azobisisobutyl Nitrile, fully stirred, reacted at 80°C in an oil bath for 24 hours at a constant temperature under a nitrogen atmosphere, then took it out and cooled it to room temperature naturally; precipitated the resulting reactant with ether, centrifuged and vacuum dried to obtain poly-N-isopropyl Acrylamide white powder, tested by GPC, its weight average molecular weight is 3.7×10 4 , with a polydispersity index of 1.43.

[0046] Weigh 250mg of homopolymer poly-N-isopropylacrylamide and completely dissolve it in 50ml of deionized water at 20°C for 1 day to prepare a solution with a mass percentage concentration of 5‰. After heating to 50°C, the solution became turbid, indicating that polymer chains were aggregated, and stirred at constant temperature for 6 hours to obtain solution A. At the...

Embodiment 2

[0048] Weigh 150 mg of the homopolymer poly-N-isopropylacrylamide prepared in Example 1 and completely dissolve it in 50 ml of deionized water at 15°C for 1 day to prepare a solution with a mass percent concentration of 3‰. After heating to 50°C, the solution became turbid, indicating that polymer chains were aggregated, and stirred at constant temperature for 6 hours to obtain solution A. At the same time, measure 2.5ml of tetraethyl orthosilicate in 20ml of deionized water, and pre-hydrolyze at a constant temperature of 50°C for 3 hours to prepare solution B. Quickly transfer solution A to solution B, and react with magnetic sub-stirring at a constant temperature of 50°C for 160 hours. After the reaction is completed, the solution is translucent and slightly milky white. Add ethanol to the reaction solution for cleaning, first ultrasonically shake for 10 minutes, then centrifuge at a speed of 2000 rpm for 10 minutes, repeat this three times, and finally redisperse the obtai...

Embodiment 3

[0050] Weigh 150 mg of the homopolymer poly-N-isopropylacrylamide prepared in Example 1 and completely dissolve it in 50 ml of deionized water at 15° C. for 1 day to prepare a solution with a mass percent concentration of 3‰. After heating to 60°C, the solution became turbid, indicating that polymer chains were aggregated, and stirred at constant temperature for 6 hours to obtain solution A. At the same time, measure 2.5ml of tetraethyl orthosilicate in 20ml of deionized water, and pre-hydrolyze at a constant temperature of 60°C for 3 hours to prepare solution B. Quickly transfer solution A to solution B, and react with magnetic sub-stirring at a constant temperature of 60°C for 160 hours. After the reaction is completed, the solution is translucent and slightly milky white. Add ethanol to the reaction solution for cleaning, first ultrasonically shake for 10 minutes, then centrifuge at a speed of 2000 rpm for 10 minutes, repeat this three times, and finally redisperse the obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com