A kind of preparation method of two-dimensional flake cu3bis3

A flake, dodecanethiol technology, applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve problems such as precise operation control requirements, inability to use flexible batteries, and unfavorable industrial amplification, and achieves low cost and process. The effect of short cycle and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Preparation of bismuth diethyldithiocarbamate

[0043] Add 30mmol sodium diethyldithiocarbamate (Nadedc) into the beaker, add 200mL of deionized water to the beaker, stir at room temperature for 30 minutes to dissolve it completely (the aqueous solution is colorless, clear and transparent) to obtain diethyldithiocarbamate Sodium thiocarbamate aqueous solution; 10mmol bismuth nitrate is added in another beaker, in this beaker, add 50mL deionized water, stir at room temperature and make it dissolve completely (milky white solution) for 15 minutes to obtain bismuth nitrate aqueous solution; Bismuth aqueous solution was added dropwise to sodium diethyldithiocarbamate aqueous solution (the solution began to turn yellow and turbid) at 1 drop / second (with a 5mL plastic pipette), and continued magnetic stirring at room temperature for 3 hours after the dropwise addition Completely react the raw materials; then suction-filter the suspension obtained from the sufficient reaction,...

Embodiment 1

[0045] (1) Place 0.05mmol copper acetylacetonate and 0.05mmol bismuth diethyldithiocarbamate in a round-bottomed flask, then add 4mL dodecanethiol (the molar concentration of copper acetylacetonate in the mixed solution is 12.5mmol at this time) / L), ultrasonic 15min, stirring 20min, obtain precursor solution;

[0046] (2) Preheat the precursor solution obtained in step (1) in a constant temperature oil bath at 230°C for 2 minutes, and then add 1 mL of oleylamine dropwise to the precursor solution at 1 drop / second (with a 5 mL plastic pipette). React for 6h, then cool to room temperature;

[0047] (3) The solution after the reaction is centrifuged, and the precipitate after discarding the supernatant is washed with normal hexane and centrifuged, repeating several times until the supernatant after the centrifugation is colorless and transparent, and the centrifuged precipitate Drying at 60°C is the final product.

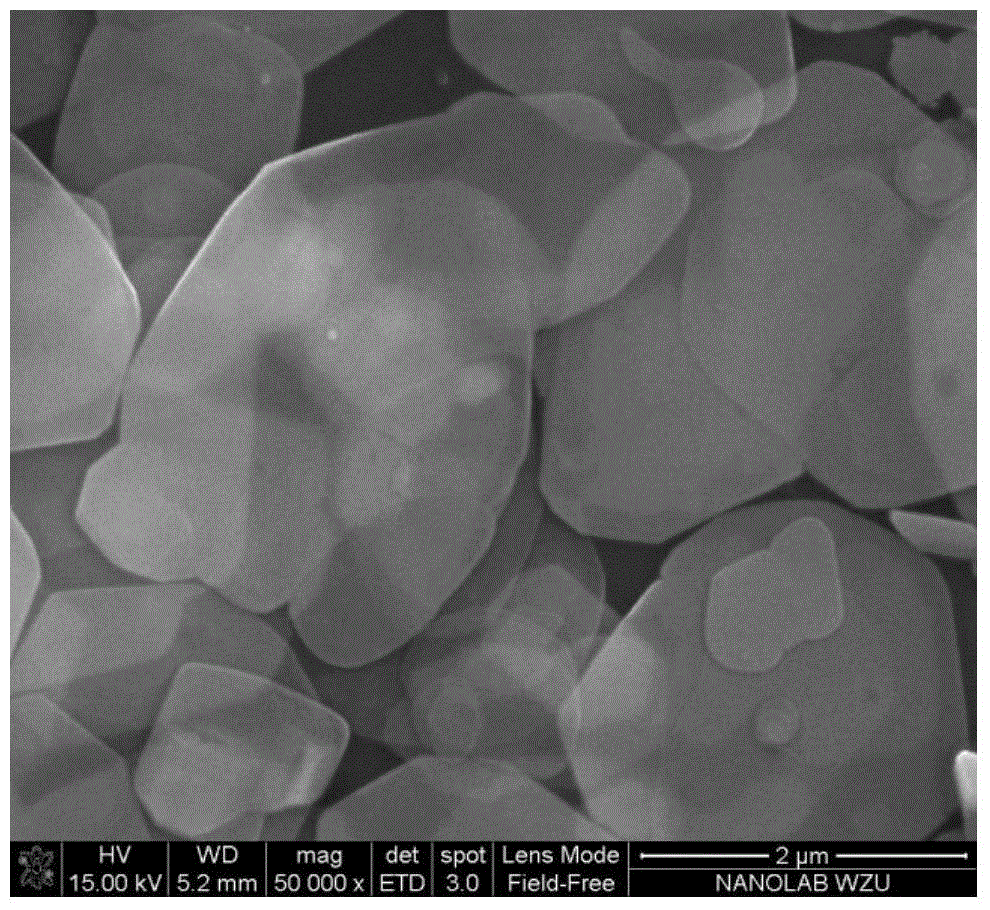

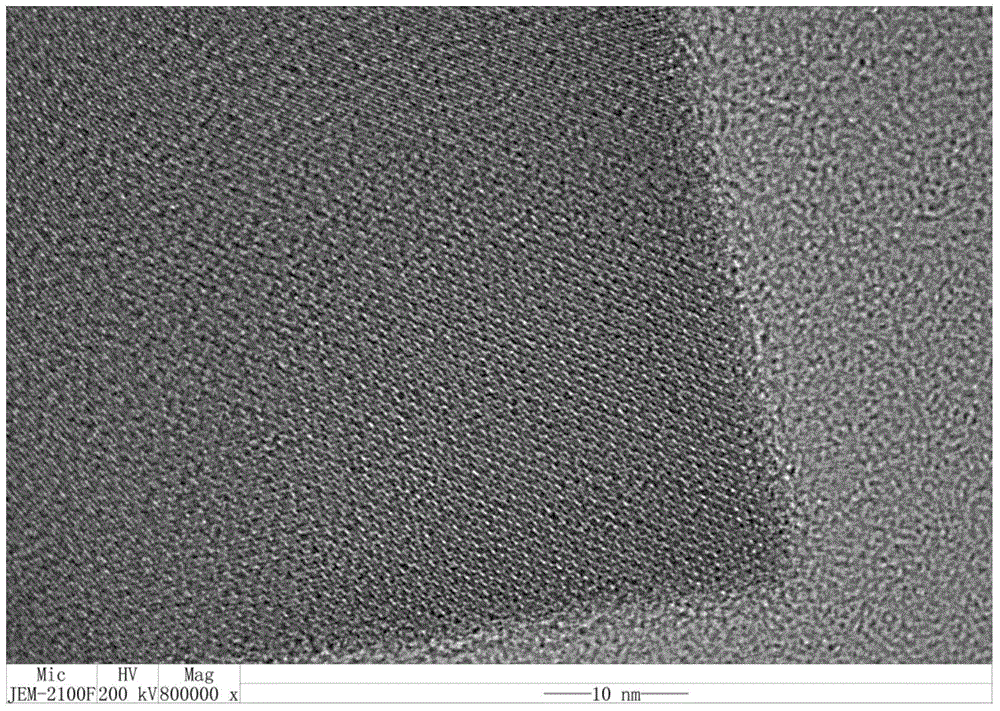

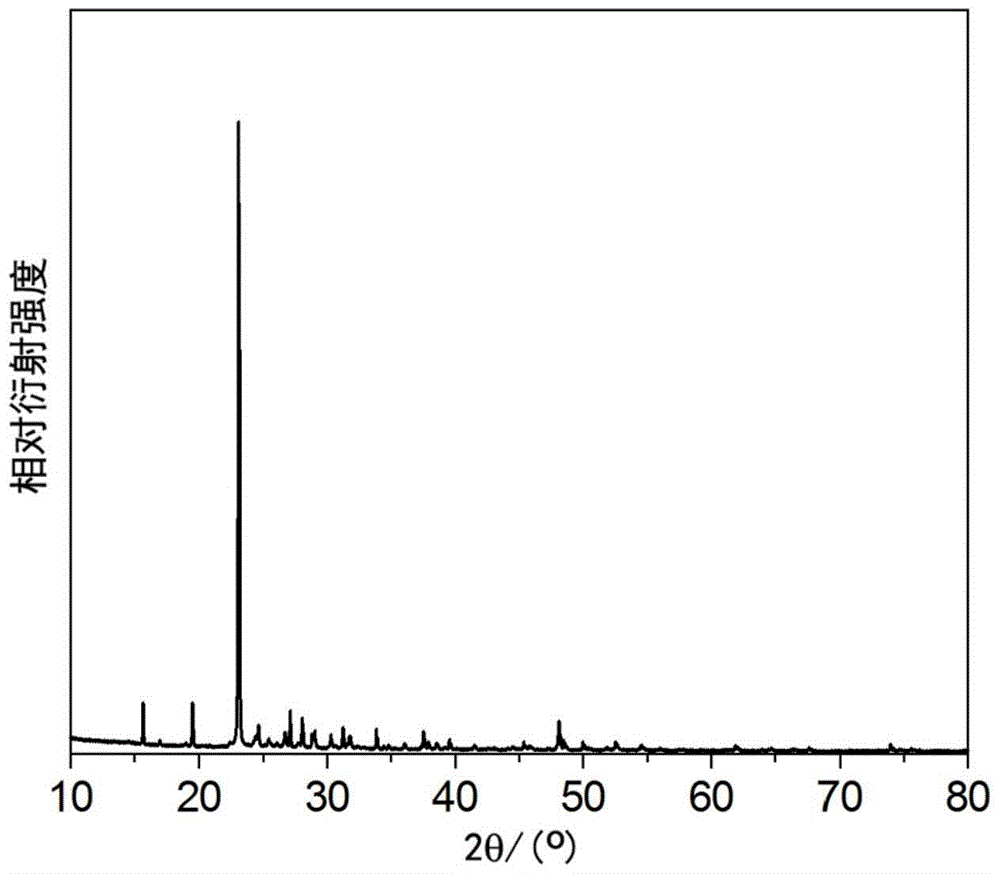

[0048] Product composition, structure and morphology characte...

Embodiment 2

[0065] The difference from Example 1 is that the temperature of the constant temperature oil bath is 200° C., and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com