Metal curtain box connected with I-beam structure and integrated with curtain wall fireproof sealing

A fire blocking and steel structure technology, applied in the field of curtain boxes, can solve the problems of poor fire resistance, unfavorable use and maintenance, and unstable connection of curtain boxes, and achieve the effects of preventing fire expansion, easy installation and construction, and reliable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

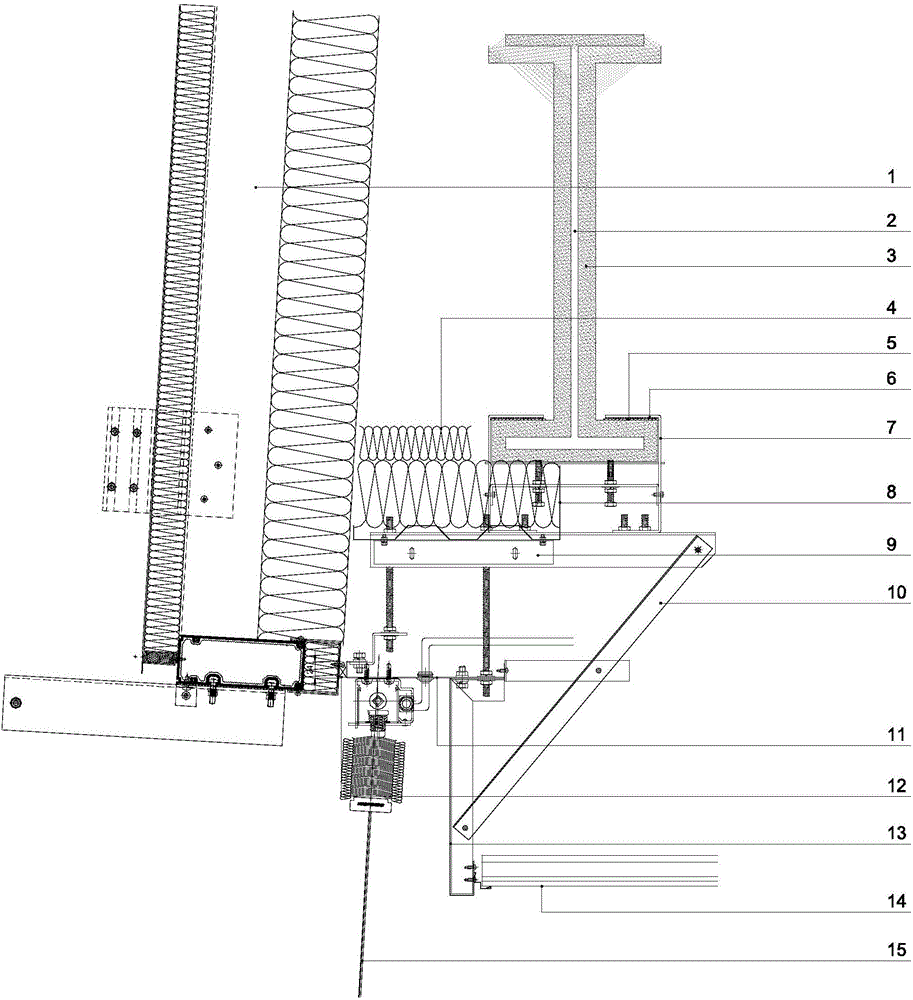

[0023] Embodiment: a metal curtain box connected with an I-shaped steel structure and integrated with a curtain wall for fireproof sealing. The curtain wall is a curtain wall for a high-rise building, including a hanging bar assembly located on the inner side of the curtain wall 1 and suspended on the I-shaped beam structure 2 7, and the box body installed on the bottom of the hanger assembly 7. The box body is used as the trimming of the indoor ceiling 14 .

[0024] The hanging bar assembly 7 includes a hanging block whose shape matches the shape of the bottom of the I-beam structure 2 , a supporting pallet 9 fixed on the bottom of the hanging block, and a suspension rod installed on the bottom of the supporting pallet 9 . The contact position between the hanging block and the I-beam structure 2 is lined with a steel plate 5 and a shock-absorbing pad 6 , and the outer side of the I-beam structure 2 is wrapped with a layer of fireproof paint 3 . The upper surface of the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com