Lifting chain single-ring bending force testing machine

A technology of bending force and testing machine, which is applied in the testing of mechanical components, testing of machine/structural components, testing of machine gears/transmission mechanisms, etc. It can solve problems such as strength testing, failure to know potential safety hazards, chain links, etc., and improve stability Sexuality, reduction of labor intensity, and efficient effect of trial pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

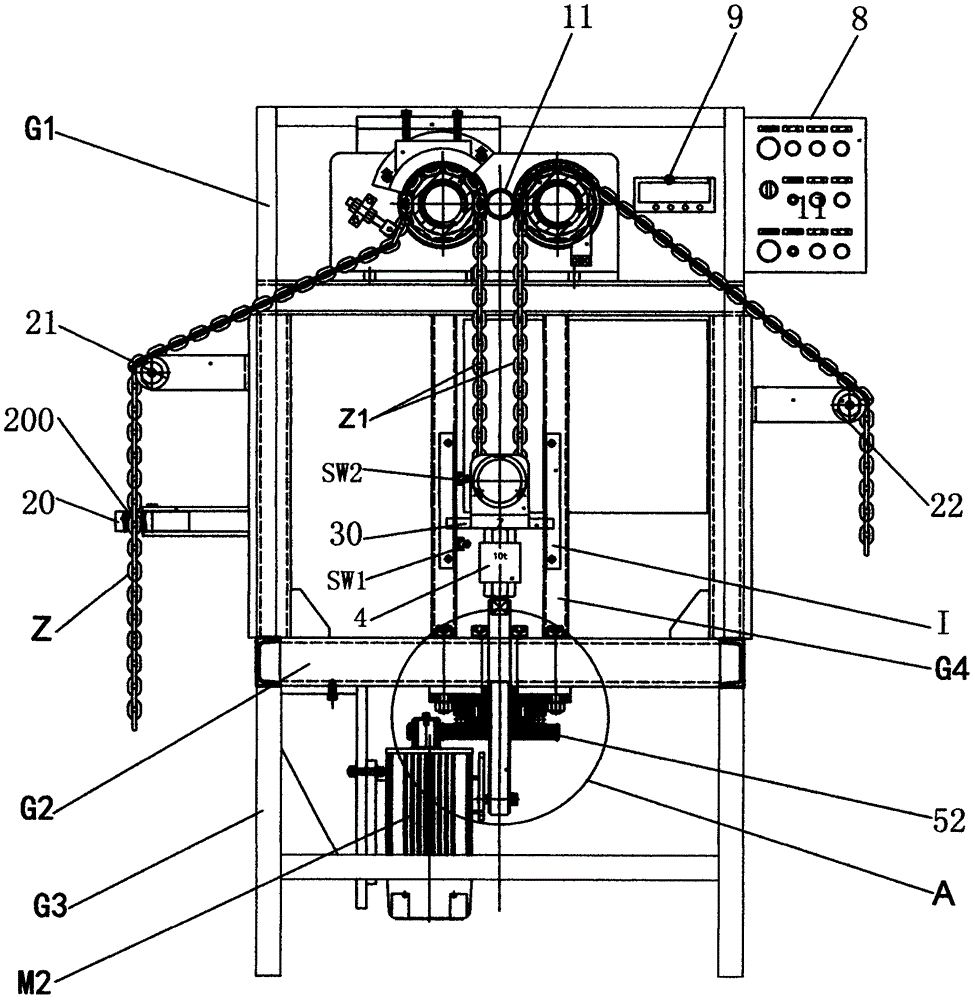

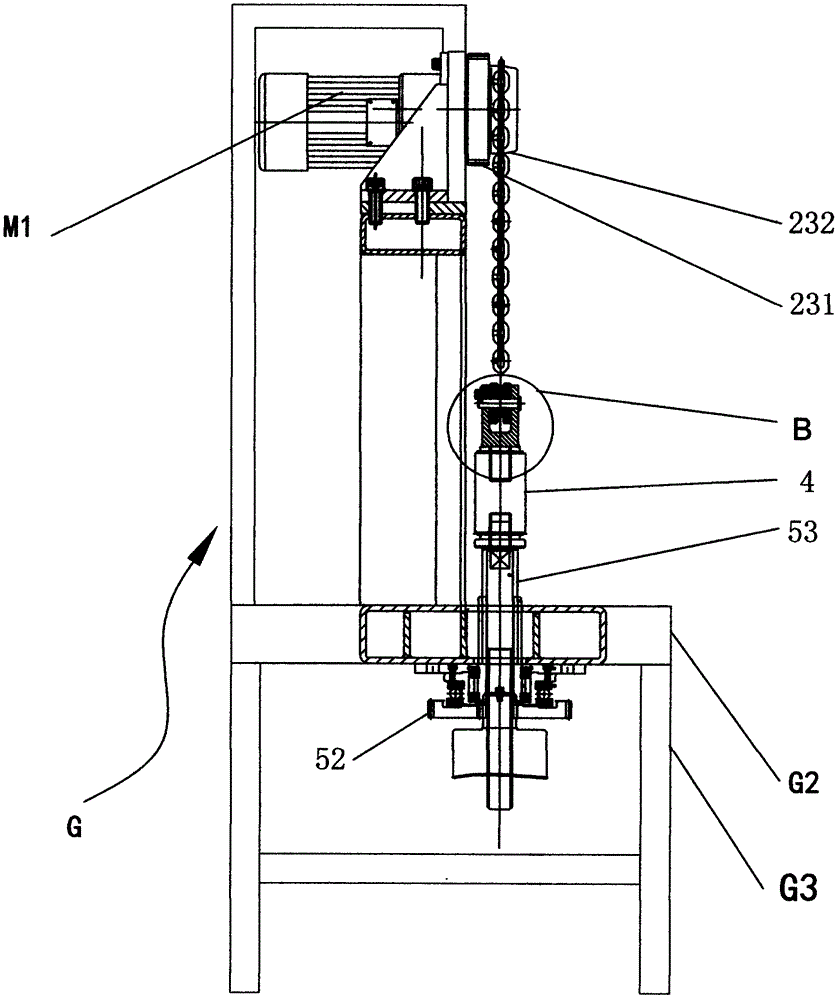

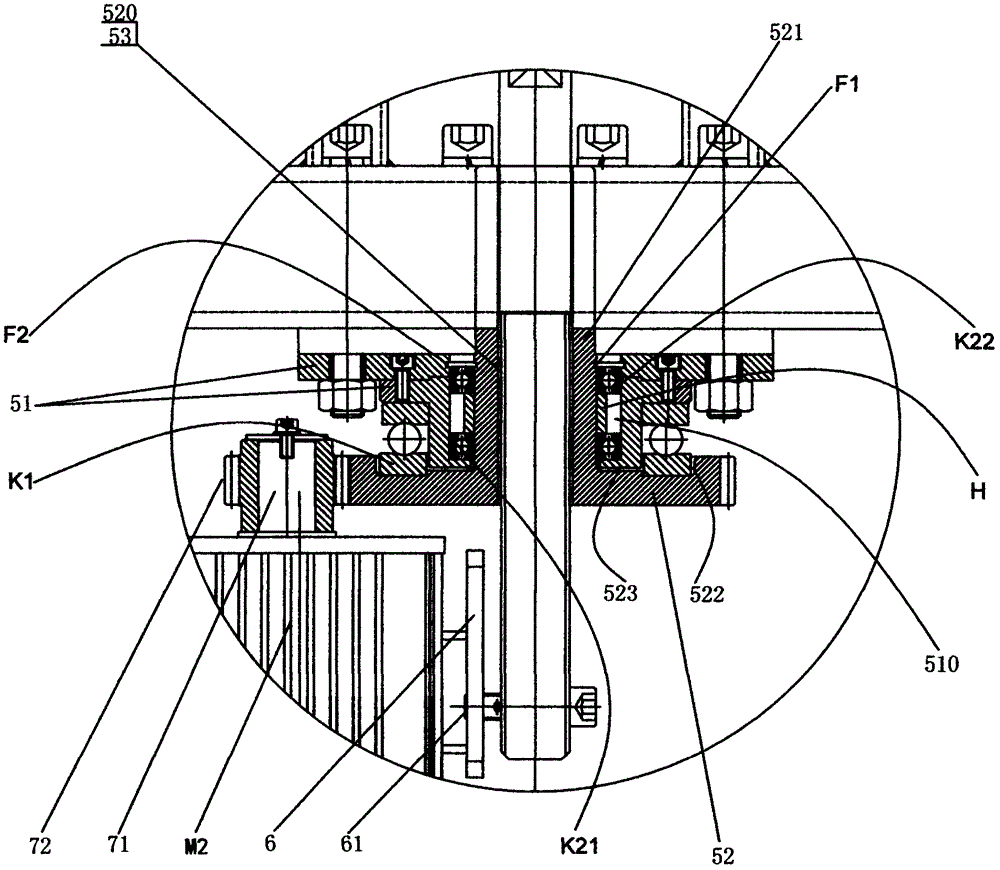

[0026] see figure 1 , 2 , 3, 4, 5, 6, and 7 show preferred embodiments of the present invention.

[0027] The lifting chain single-ring bending force testing machine includes the fuselage G, the chain transmission mechanism and the driving device of the chain transmission mechanism. A chain drive motor M1 with a central pinion 11 on the upper part of the body G1, the chain drive mechanism includes a chain-in guide wheel 21 located on one side of the fuselage G, and a chain-out guide wheel 21 located on the other side of the fuselage G. The guide wheel 22 and the input chain shaft wheel assembly 23 and the output chain shaft wheel assembly 24 respectively arranged on the upper part G1 of the fuselage, the middle pinion 11 meshes with the input chain shaft wheel assembly 23 and the output chain shaft wheel assembly 24 respectively, and is rotated on the cruise ship The cruise ship 31 on the seat 3 meshes with the double-row chain Z1, and the cruise ship 31 suspended by the dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com