Transmission chain protective cover

A technology of transmission chain and protective cover, applied in the direction of transmission, transmission parts, belt/chain/gear, etc., can solve the problem that the transmission chain cannot be lubricated, and achieve the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings, but the implementation manner of the present invention is not limited thereto.

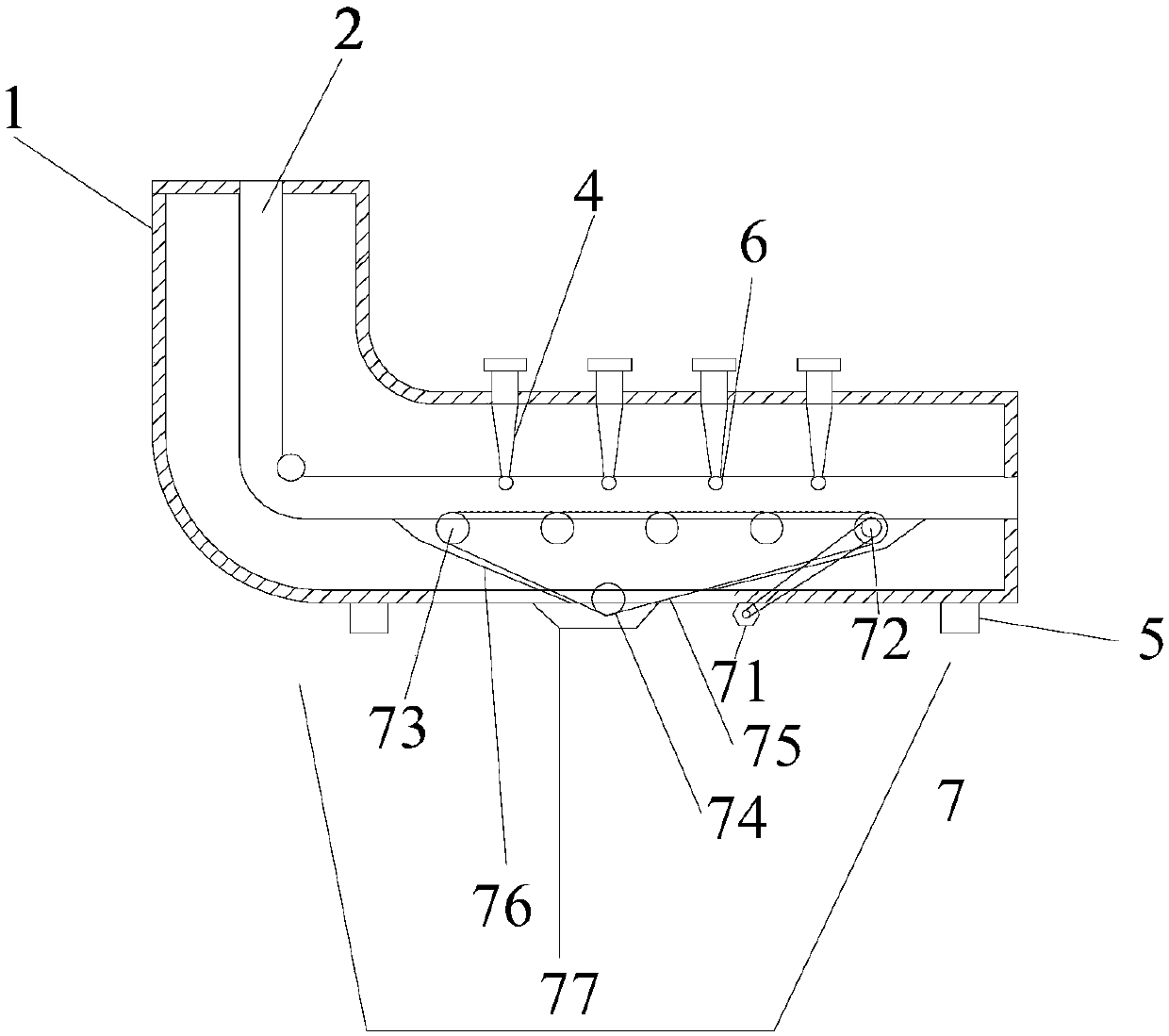

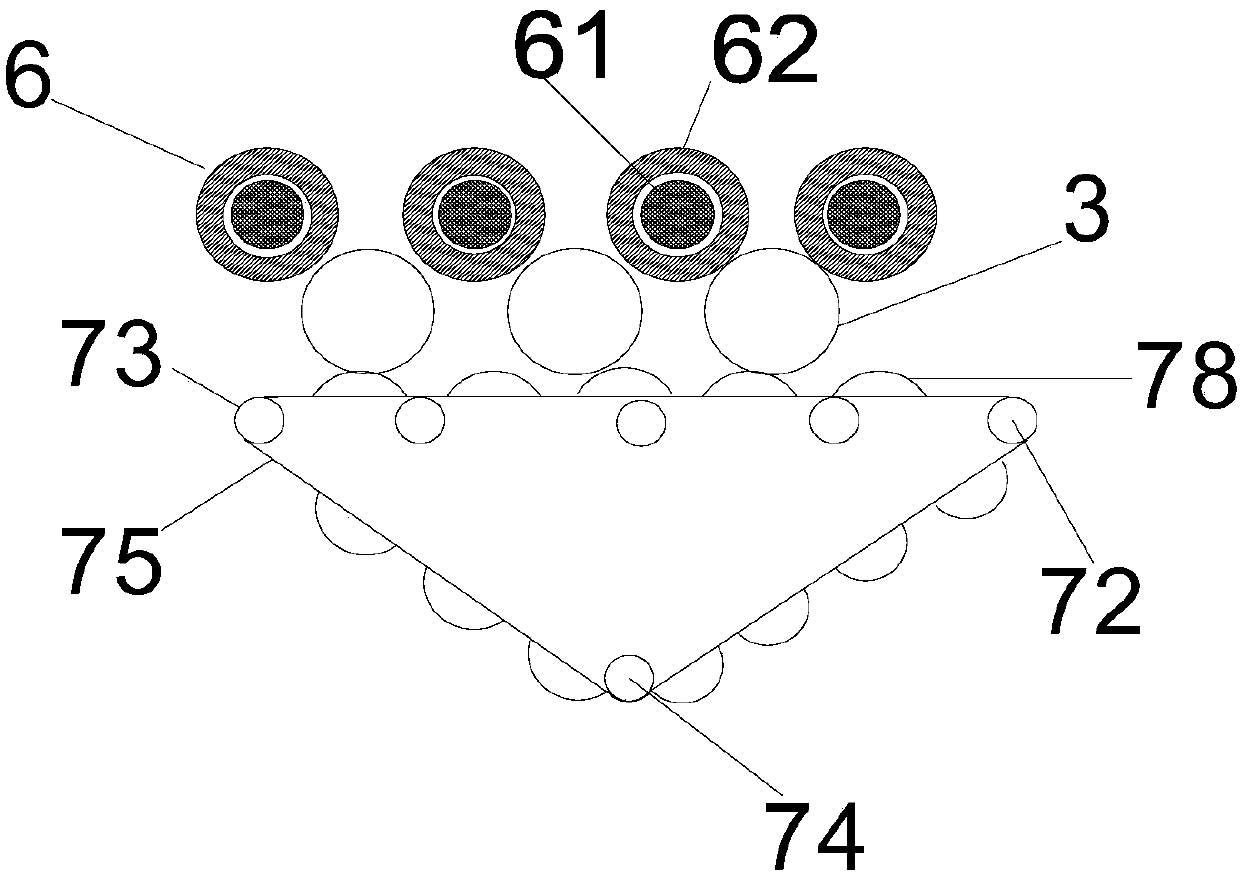

[0014] Such as figure 1 As shown, a transmission chain protective cover provided by the present invention includes a cover body, which is composed of a bottom shell 1 and a cover plate that are fastened together, and a transmission chain walking structure for the transmission chain is configured in the bottom shell 1 . groove 2, and at both ends of the drive chain running groove 2, there are perforations for the transmission chain to penetrate and pass through. The grease nozzles 4 are all facing down and the oil outlets communicate with the drive chain running groove 2; and a number of oiling rollers 6 are all arranged in the driving chain running groove 2 through the roller shaft 61. Corresponding to and respectively located at the oil outlets of each grease...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com