Ethylene and 1-hexene copolymer and preparation method thereof

A kind of hexene copolymer, ethylene technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

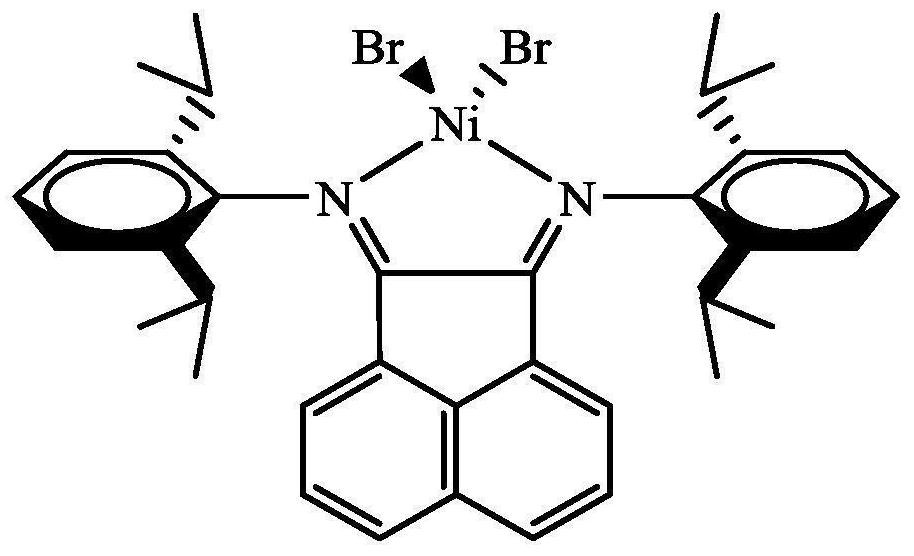

Image

Examples

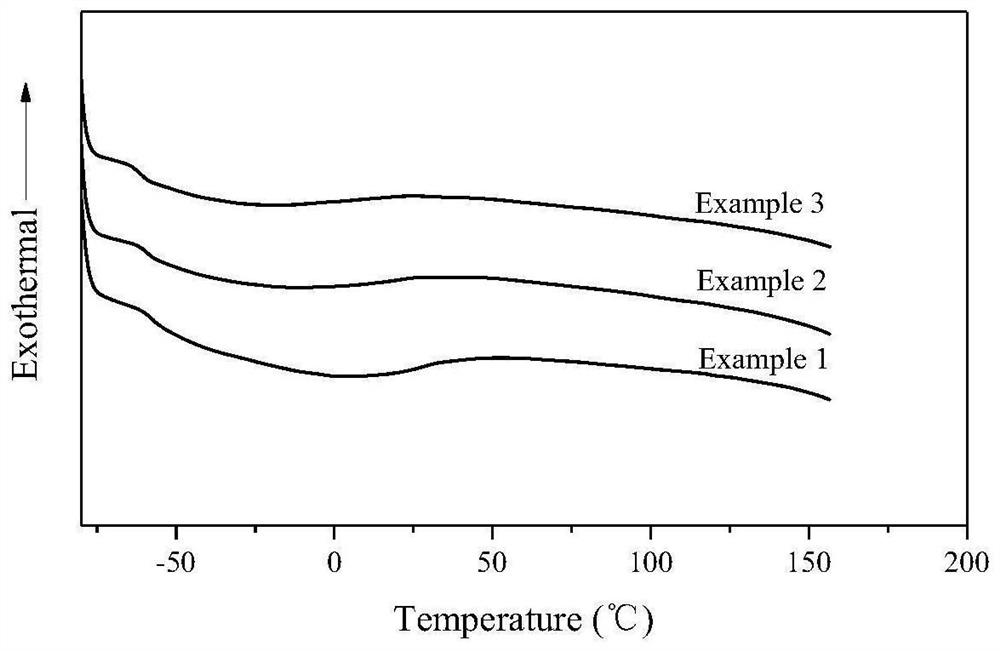

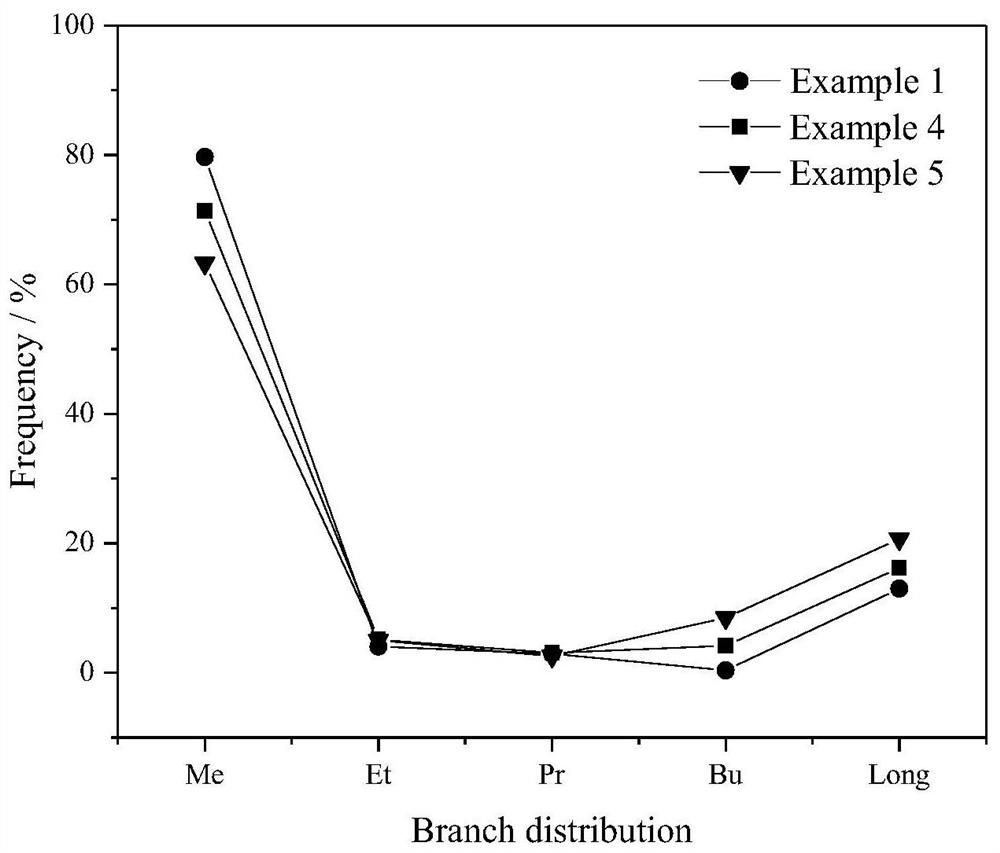

Embodiment 1

[0030] After the polymerization reaction device has been anhydrous and oxygen-free, add 45.55mL toluene, 0.95Ml 1-hexene and 1mL MAO toluene solution with a concentration of 1.5mol / L to the polymerization reaction under the conditions of normal pressure ethylene atmosphere and 25°C water bath In the device, fully mix at a speed of 600r / min to fully dissolve ethylene in the toluene solvent, add 2.5mL of methylaluminoxane MAO cocatalyst toluene solution with a concentration of 0.001mol / L into the polymerization reaction device, and initiate the reaction And timing, when the reaction time reaches 30min, take 3mL of hydrochloric acid acidified ethanol solution (5wt%) to quench the polymerization reaction, and the polyethylene product is precipitated after the reaction is completed. The precipitated polyethylene product was washed with 95% ethanol for several times, put into a 40°C normal-pressure oven and a negative-pressure oven, and dried to a constant weight to obtain the final ...

Embodiment 2

[0032]After the polymerization reaction device has been anhydrous and oxygen-free, add 44.55mL of toluene, 0.95mL of 1-hexene and 2mL of MAO toluene solution with a concentration of 1.5mol / L to the polymerization reaction device under the conditions of normal pressure ethylene atmosphere and 25°C water bath 2.5 mL of methylalumoxane MAO cocatalyst toluene solution with a concentration of 0.001 mol / L was added to the polymerization reaction device to initiate the reaction and Timing, when the reaction time reaches 30min, take 3mL hydrochloric acid acidified ethanol solution (5wt%) to quench the polymerization reaction, and the polyethylene product is precipitated after the reaction is completed. The precipitated polyethylene product was washed with 95% ethanol for several times, put into a 40°C normal-pressure oven and a negative-pressure oven, and dried to a constant weight to obtain the final product.

Embodiment 3

[0034] After the polymerization reaction device has been anhydrous and oxygen-free, add 43.55 mL of toluene, 0.95 mL of 1-hexene and 3 mL of MAO toluene solution with a concentration of 1.5 mol / L to the polymerization reaction device under the conditions of normal pressure ethylene atmosphere and 25 °C water bath 2.5 mL of methylalumoxane MAO cocatalyst toluene solution with a concentration of 0.001 mol / L was added to the polymerization reaction device to initiate the reaction and Timing, when the reaction time reaches 30min, take 3mL hydrochloric acid acidified ethanol solution (5wt%) to quench the polymerization reaction, and the polyethylene product is precipitated after the reaction is completed. The precipitated polyethylene product was washed with 95% ethanol for several times, put into a 40°C normal-pressure oven and a negative-pressure oven, and dried to a constant weight to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com