Newly-built truck production line

A production line and freight car technology, applied in the field of railway freight car production, can solve problems such as low operating efficiency, scattered workstations, and unsafety, and achieve the effects of avoiding process backflow, improving production efficiency, and reducing product reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. It should be noted that, in the drawings or description, similar or identical elements all use the same reference signs.

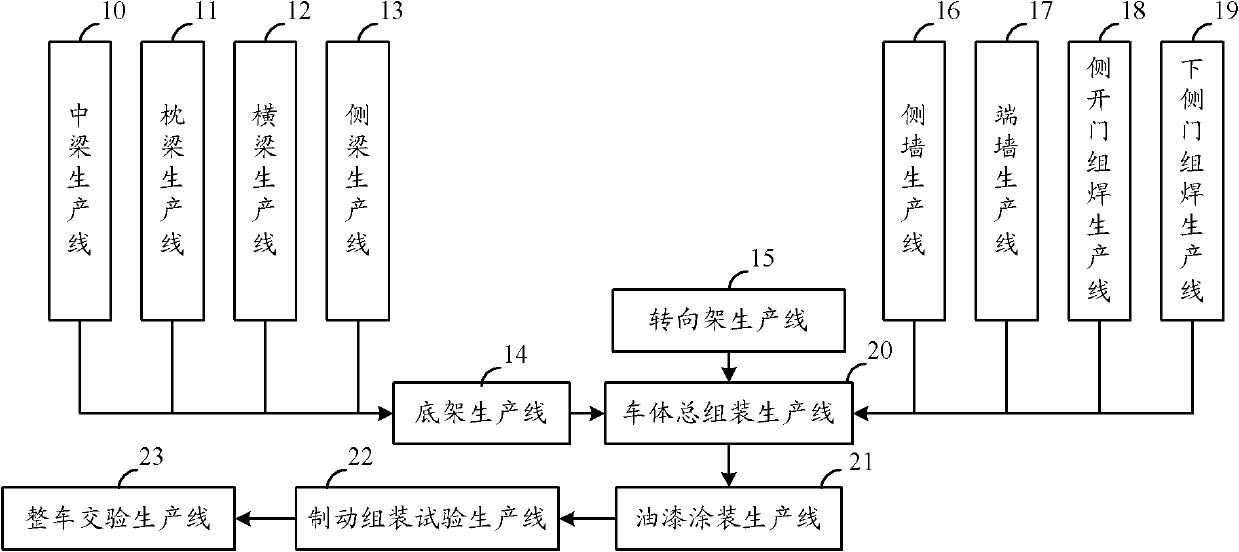

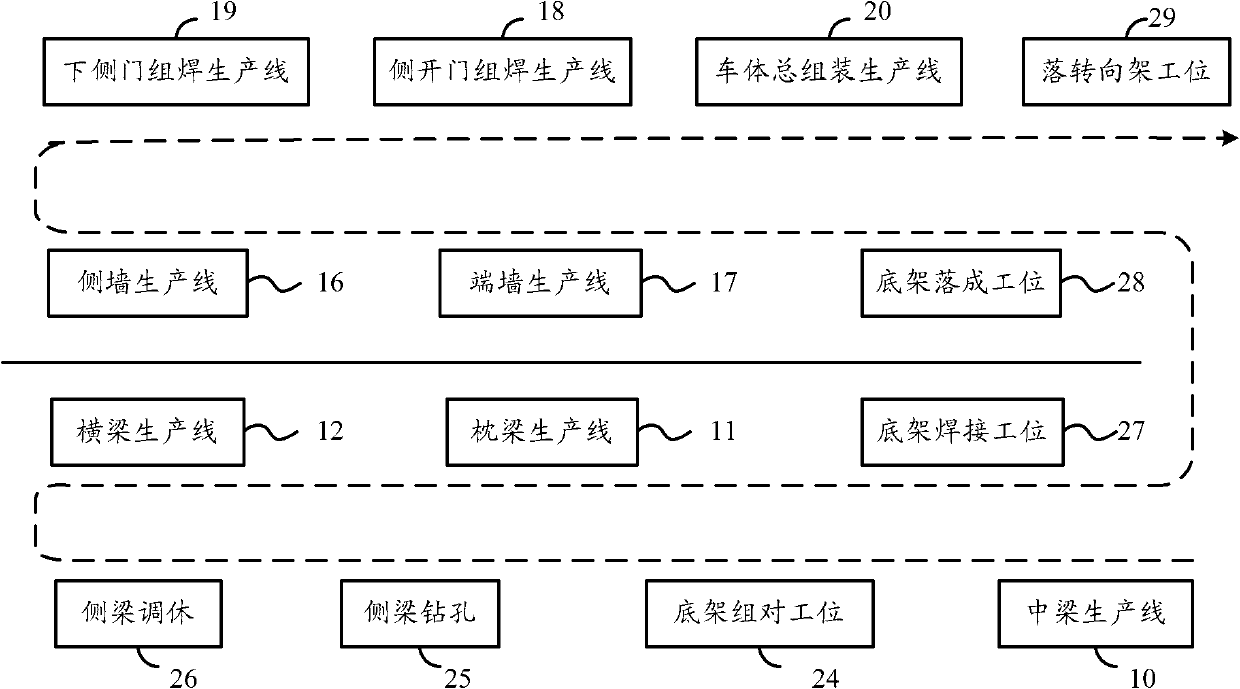

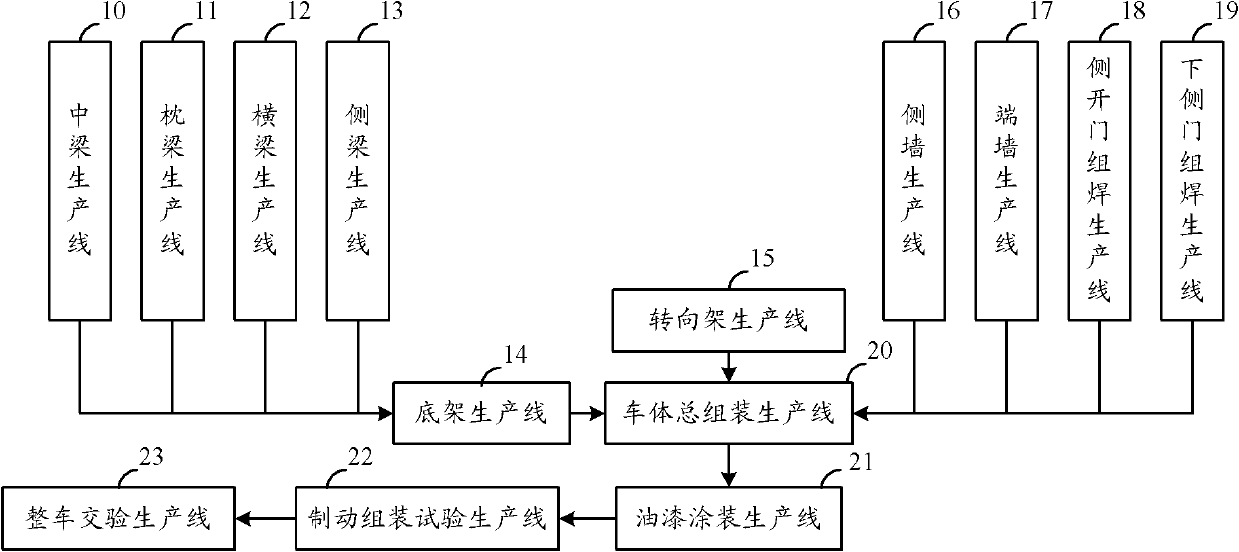

[0046] figure 1 The structural schematic diagram of the new truck production line that the embodiment of the present invention provides, such as figure 1 As shown, the new truck production line includes a center beam production line 10, a bolster production line 11, a beam production line 12, a side beam production line 13, an underframe production line 14, a bogie production line 15, a side wall production line 16, an end wall production line 17, and a side door group Welding production line 18, lower side door assembly welding production line 19, car body g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com